Here's the latest in the Duffy Diaries--stuff I place up on the 'Blog not because it's in any way authoritative or With It or even Hip, but because I am this Inquisitive Guy who's trying to puzzle out the mystery of slot car physics; and I figure there may be a couple other guys presently on just the same developmental spot on that same road, that may like sharing in these stumbling learning moments. May come in handy, someday, for someone. And also I like to write.

Since I'm basically clueless in the wild wisdom of chassis dynamics, and incapable of just plunging in and going "I'll just build like HE does..." I am trying to come up with a roller that's as "Baseline" as I can get and as durable as I can drive--so I can try to watch and learn its behavior, and to then use as a jumping-off-point for developing and adding-on, hopefully learning how each change affects the Baseline, isolating the results for what I do. That's the plan.

Now, in all these threads, I'm tossing up everything in my learning curve for discussion. Where I can (where I remember the reason!), I'll tell my logic for a decision, and you lot can go at me with whatever you know or think or just say. I do this for me first, that I might maybe jog some relevant thought from your complacent veteran mind & thus learn something myself; and like I say, also for any poor soul as clueless as I, that he may learn too and maybe become A Real Racer one day.

So.

OXCART began as an attempt to further isolate chassis pan movement from what the plumber-actuated HOODOO chasses do. You see that moment of offshoot in the Duffy "HOODOO" thread--basically, I did a quick "beater" frame with bent-wire connections up front instead of the HooDoo-style plumber (mostly because I'm lazy, the typical Duffy-Fussy integral plumber hinge is a perfect bitskitty to blacksmith-up!)--and the immediate result was a slicker, snakier ride on my neighborhood King. As time and my budget permit, I will develop a couple more OXCART Can-Am rollers and see what this trend teaches me--

--But, more to the point right now, this thread opens with the first OXCART 4.5"Stocker.

I forget who came up with the "One Wire, One Bend" paradigm (was itTonyP?), but that's just like waving a red cape in front of this bullstuff factory. One thing I know about wire, it "springs" differently in its free, unattached state than it will when soldered to anything else: that solder joint is gonna make a change in the dynamic, it's gonna (prob'ly) [/size][size="2"]"soften" the springiness of whatever's coming before it or after.Since I was just setting a "baseline" build, the thing I'll compare all my mods to, I opted for the "Fewer Wires, More Bends (Less Filler, TastesGrit)" route here. I want to see what that springy steel does on the track, and then I'll start the series of change-ups.

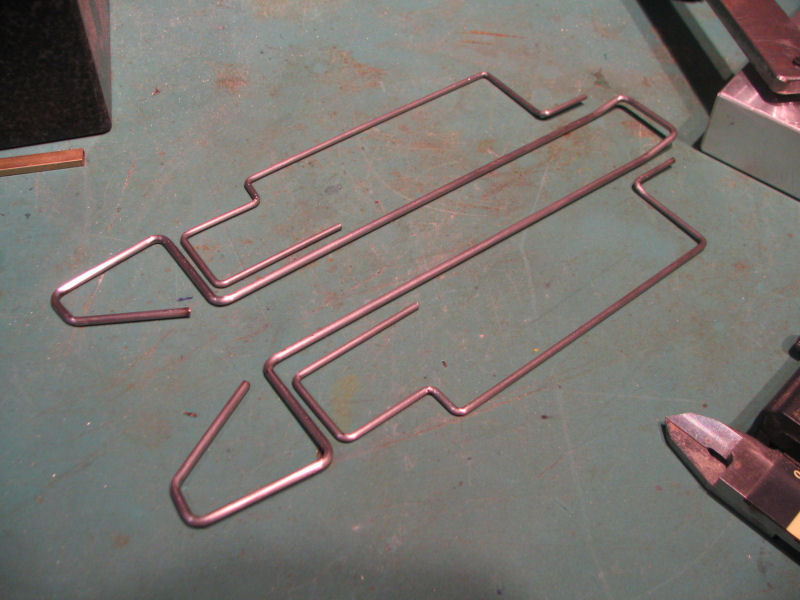

.078" mains, .062" perimeter and axle uprights--with a .055" filler, so the uprights get a "valley" to drop in for more solder area. Duffy.062" bracket and tongue. I went to the Super-Duper Wire Bender to do the.078" stuff, but all the lesser stock was bent with my good ol' GFCparallel-jaw pliers and my Proto 8" needlenose.

I wish I'd hipped to the following trick a long time ago, I'd have saved me a lot of scrap: make small marks on the plier with a Sharpie to show the spot along the nose taper where you want that next bend to go. The 45's you see here were tried, corrected, and then done by marking that spot and letting the bend-to-bend distance be set by the plier. If you need a pic of this, ask.

Cropper& Dunn look on as I ply my soldering skills.

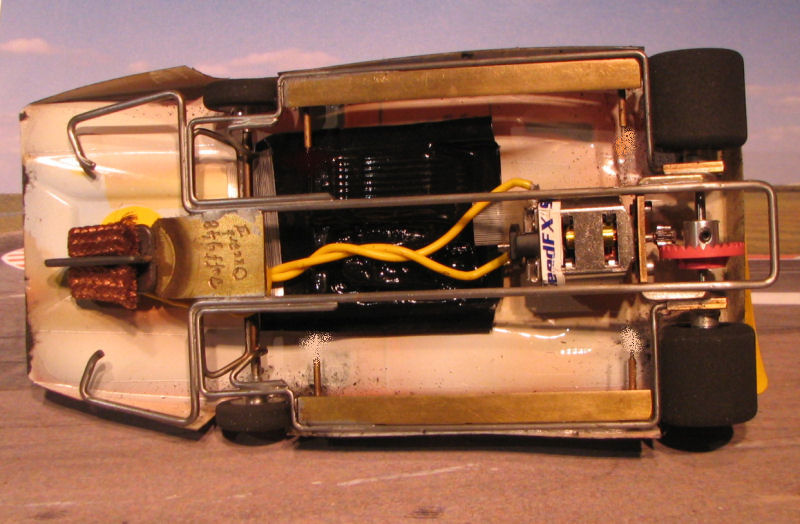

The little bright hatchmark near the rear of the .040" x .31" brass infill shows the spot those pans are soldered up to, allowing some torsion in the perimeter wire aft of that point. This will be a major bit of experimenting with this chassis ( and two more like it, if I am true to my dreams--three to run, one to try out ideas on and two more to compare & swap in successful ideas)--what happens with more movement or less, based on where and how I fix the pans to the perimeter.

One guy I showed this to said, "Yah, I'd solder no further than one-third back and let that pan flop aft of that"--and I wil try that, when I overcome my fear of the pan coming off and flying across the Deadman in a terminal smash! "OhDearOhDear it's a slotcar it'll break..."

The original OXCART Can-Am proto had just the fussiest ball-and-socket rear fix you ever saw. It was elegant, it was crafty, it was never never to be repeated--it was just too much fiddly work! But it was fun. The simple wire-in-tube hinge here does everything the Rotator Cuff did, and took five minutes to make. See the fussy little kink bend that keeps the perimeter wire flat until the last moment.

Moving forward to the front axle uprights. I've canted the wires as far outboard as I can go here, and I'll copy that angle with the front uprights too.

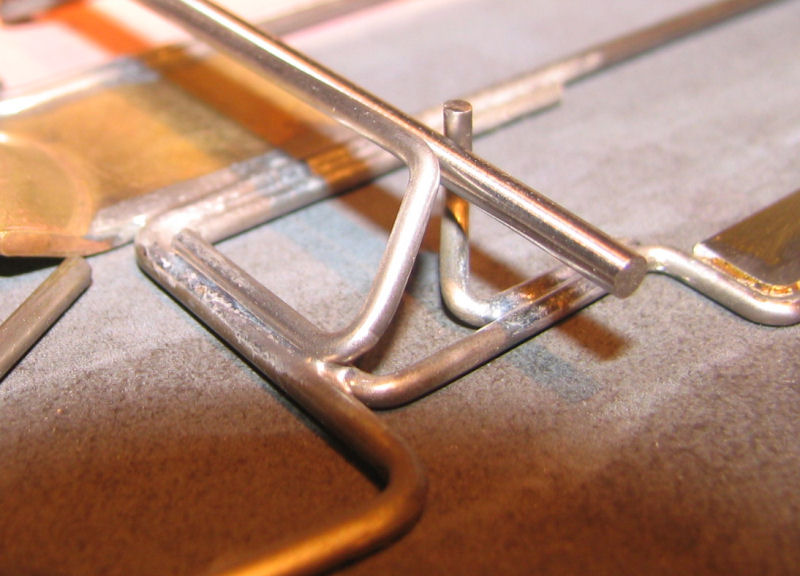

Remember the "valley" I intended? It didn't work out so well with the.055" wire, did it? Lesson learned, I'l draw a blow-up of my diameters next time and plot it out proper!

Another Useless Building Tip (imagine Bullwinkle with a soldering iron, going "Greetings, Culture Lovers..."): how d'you hold on to that itty-bitty kink of a front upright? ans: leave it on a long bit of wire, and as an extra convenience take your Dremel and grind halfway thru on the bottom to get half your job done! (This helps to "seat" the Duffy-style complex bends in this joint, too, giving some clearance where the axle upright curls around in the "valley.")

So now you have something to hold onto as you solder the little wire in. Because the pre-cut I put into the wire also reduces the cross-sectional area of the wire at that cut, I got less heat transfer up the wire and could hold it with my wimpy musician's fingers even as I soaked the joint with heat.

--And here they are, all cut off. I'll assemble the BB front axle and tyres and solder it in at final set-up, Pablo-style.

So, the vanity shots, Duffy #47 OXCART (Gravy)*--63.4 grams dripping wet, easy to make the 120 gram minimum in the IRRA™ Stocker class, but I hear they tend to run ~130 grams around these parts. I'll know more in two days, after the HVR event. Stay tuned.

Duffy

*--well, it's a stock car, & sponsored by "Duffy's Roadkill BBQ" at that; the nickname only makes sense, right?

EDIT:Didn't make it to that race, I had a medical/parenting emergency! Initial reports must wait until I get out of Brooklyn the next time, --again, stay tuned!--Df.