Continuing with this discussion, trying to puzzle-out some of the "why" of a chassis for those crazies to whom such things are important (yah, I took my clarinet apart, too, to understand how to play the thing. It's jus' how I roll.)

We're gonna bring in a couple of other voices here (one of 'em dead...woooo...) to add to the mix. Gettin' interesting now, at least to me. Hope it entertains.

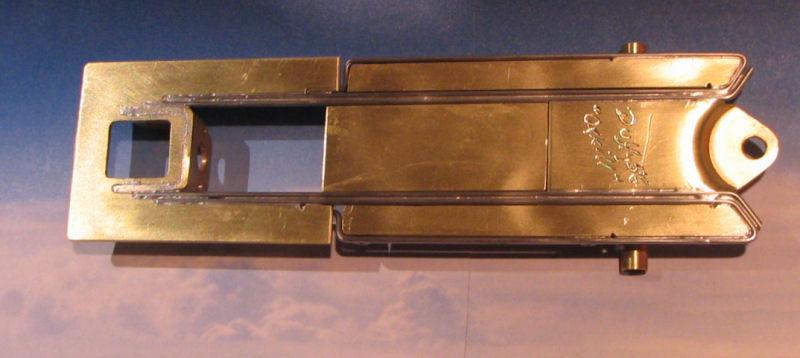

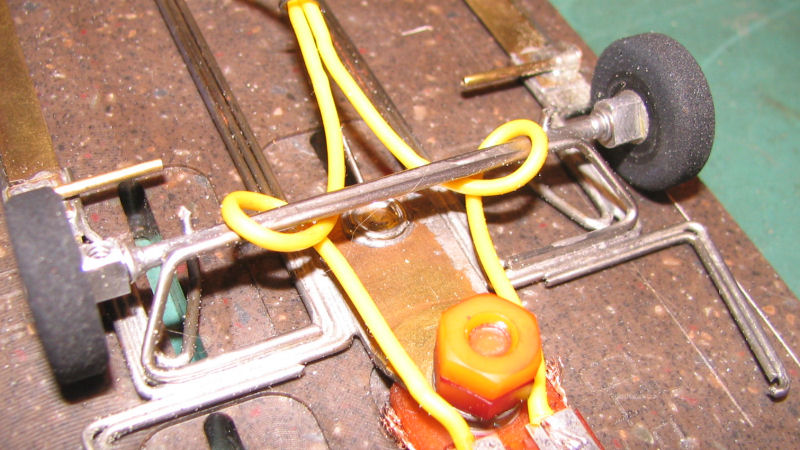

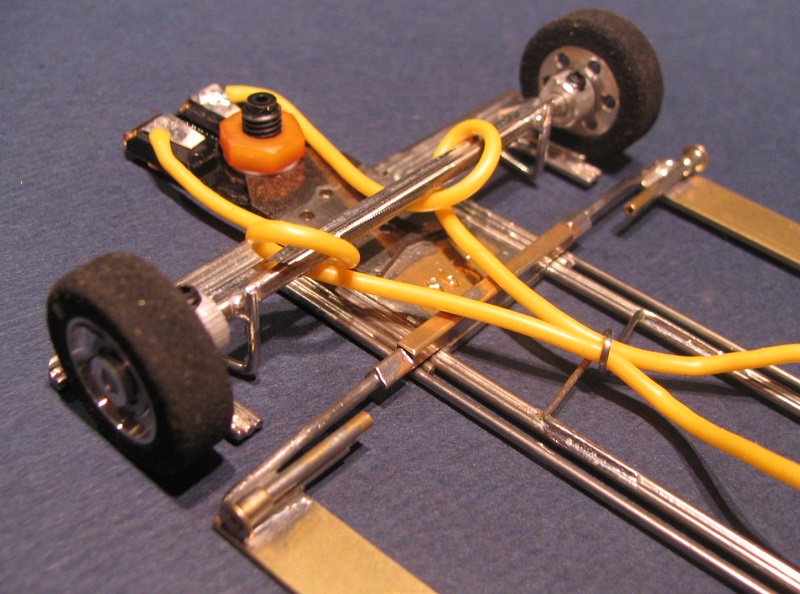

The idea here is to date the vertical flex from a point just for'd of the motor, & use multiple rails to limit horizontal flexure and twist. Reasoning that two rails are twice as multiple than what I've been using, I dug into the .055" tube and went crazy. Other pertinent numbers are: bracket, rear plate & guide tongue .050" stock, pans .040" & center pan .031".

Funny how few 1/16" single-rail chassis we see anymore--smaller, multi-rail is the current fashion. This one splits the difference, really for no good reason. I want to see what happens here, and then think about what to do next.

Got some time out on the track this weekend with this car, and it's pretty positive so far.

I didn't have tyres soft enough for the track on this day, and my testing was done with HVR Wonder mags straight from the bottle and terribly conical; even at that, the car was behaving quite predictably. One other guy got his hands on it and started out tentative, bringing it up, a little more--& finally spun in the donut after 25 laps. "That's the flattest thing I've ever driven." Okay so far.

Like I say, we haven't got the tires right yet, but the transfer of weight rearward is just getting better all the time, and the stiffening-up of the rear hasn't hurt anything I've seen yet.

tonyp suggested this forward-flex spot as a further development of the Twistamon concept, without the "rear steer" gobblygook of that roller; and it took into consideration that most all the venues I'd be campaigning the car in were markedly swoopy and decidedly not-flat.

Which brings in the "other voices"--

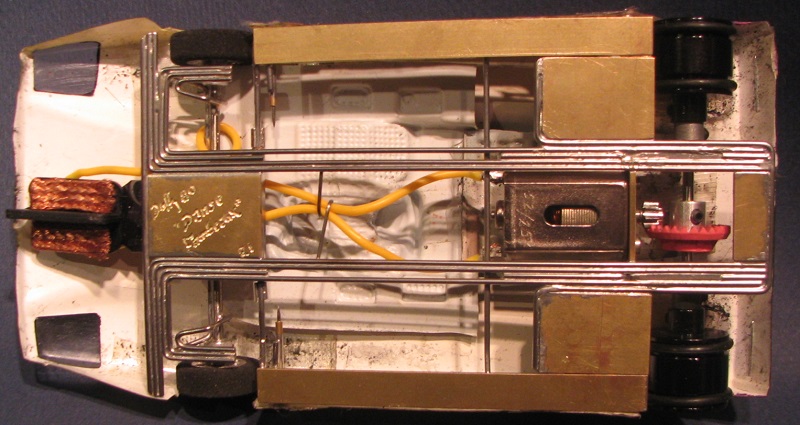

Mike Kettleson showed us this chassis a few weeks back. It was actually just yesterday that I flashed to the obvious similarity in our rear ends (no quips from you, JJ) and wrote him about it. Here're his pertinent comments:

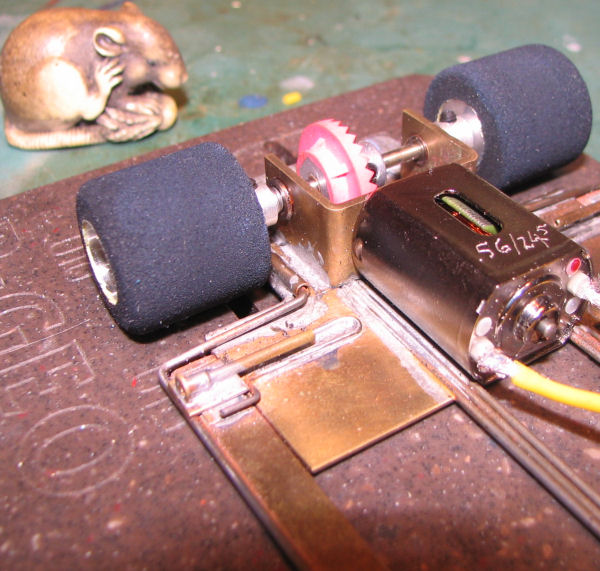

I believe its basically the rear end that's similar, I use a wide bracket, helps rear end grip and stability, a axle when fitted with a 29 tooth gear just clears the bearing of the motor very little in front or behind the axles,These are tricks I used in 1/32 F1 in the 80's before my last retirement. I solder a plate between the main rails and put a raised bar along the C/L of the chassis which greatly increases the rigidity vertically, with it on push down on the motor and the tires squish down, with it off the chassis bends and decks. My pans are completely floating, almost independent of the rest of the chassis and allow the body to float. Incidentally I have abandoned the tube front axle, in a knock the axle bends in the tube and locks the wheels , I use 3/32 piano wire because it's easy to straighten in a heat.Interesting for the differences, and I wondered how much those differences were influenced by the different venues the cars are built for.

Mike says this series of cars has been dominant on the

RACEWAY 81 track, check it out--nice and flat, with some wicked Esses in the short chute.

Now, when I started messing around with rising-rate resistance "Torsion" stuff, Prof. Fate talked a lot about the application of movement and where the whole idea came from. I channel him here--fingertips on the table, everybody--

A second reason we used floppy parts in chassis was to help deal with the bumps and irregularities in the old tracks; and the proof of that is, on our smoother modern tracks a plain solid pan isn't that much slower than a really loose car, when properly set up. That's the simple version.--But there's a catch, and that's the Flat Track! See, even the best flat track isn't really flat. A couple of thousandths lump in the wrong spot will launch you just as sure as a big one; so you have to deal with that. Banked tracks, you can count on G-force to keep you nailed down--even a tilted corner section will do it, if the car hits something it's almost instantly landing "uphill" on that tilt and doesn't have time to react to the bump. So, we've learned we can get our movements down smaller and actually get an advantage, because larger movements take longer to STOP

reacting, sometimes too long--and that's a bad thing. You want the car to settle down by the time it's straightening out.Flat tracks, you lose all that advantage. There, it's back to building in your motion to time-out when you need it gone.--But YOU

don't need to worry about that!Sooooo...the much-oversimplified shakedown to all this...

Mike's got a stiff center section with full-floating pans, body floating with the pans.

Lotsa guys in my neighborhood are running multi thin wires for some vertical-NOT-horizontal flex, and varying degrees of twist too.

What do you think, how much of these two paradigms relate directly to the track?

The body mount thing is worth noting. A coupla Florida guys talked me into the notion that a firmer mount in front and a floating mount in the back is a good thing--Rick Moore, especially, typically uses a third pintube forward of the front tyres. I've gone away from fancy floating pintubes, for simplicity, but I count on the flop of my inner pans at the rear to approximate what Rick's suggesting.

How I do run on. Off to some painkillers, then try to get to the track again tonight for more thrash.

Duffy