Jail Door: Duffy's "Slithery Jungle Tails"

#26

Posted 05 September 2011 - 10:24 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#27

Posted 06 September 2011 - 06:54 AM

I have one that is from 1966.

Only thing I want t use a 16D motor.

Nice work on the car, work of art.

#28

Posted 06 September 2011 - 01:35 PM

Fine with me, let's get some guys to the track--how 'bout Sunday?Hey Duffy how about that ,lets just race what we build, Kenny would not care.

- Mark C. likes this

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#29

Posted 06 September 2011 - 04:43 PM

- Mark C. likes this

#30

Posted 06 September 2011 - 04:50 PM

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#31

Posted 12 September 2011 - 09:24 PM

O--kay: so, I promised, More twist, more bends, more Snaky Goodness in every box of Jaildoor Golden Crisp...and gennulmenns, I do b' lieve I've hereby d' livered.

See, like the preceding conversation should point out pretty abundantly, it don't matter how Cool you are, it's how the Prevailing Wisdom (read: RULES Pirate) sees what you've done. (This should be no surprise, really: not to anyone who's attended High School in the US, if not elsewhere--you step too far outside the Dominant Paradigm, you get Sanded after school. It's Just The Way.)

So, after having a ball making the last <illegal> JD chassis, I set out to have a ball making one that fit the Rule. And even more so.

I should clarify: there's not much really new we can discuss with J/d frames-and that was the whole idea! But the fairly-standardized format of the type still allows for some creative wiggle room--and that's how I'm approaching these more and more. After a hard week of building Can-Am, how nice to settle in to a JD, and create. sorta.

Anyway, that's what I'm about here.

A JD Sports Car first:

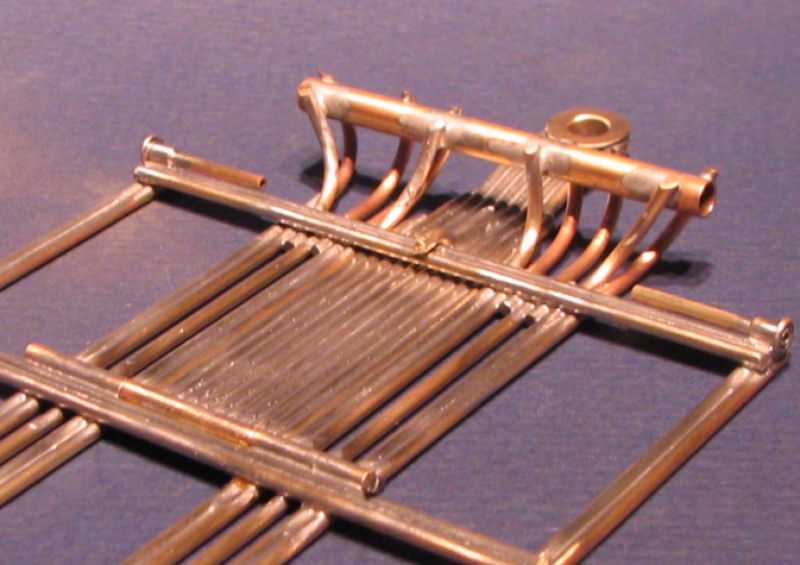

So, all rails but the outermost (in JDSC) must be parallel--"no tapering or bending...except for the bend up to bracket or axle tube"--okay, so I took that to heart. Now, I've got a lot of chassis out there now with this, so nothing's new except where I am trying to learn from the mistakes in this thread--and I played that literally. Look closely inside the upsweep bend and see the plier mark for the .062" sidewise bend on the innermost run of rails.

I get two runs of rails inside the Duffy .875" JD Bracket--I'm experimenting with inboard mass distribution and durability in this series--and then the next one-and-pair outboard get fitted after. As many rails as I can affix to the bracket cheeks, I do; then the outer one splits off its sister and heads up to the carrier at the outermost spot.

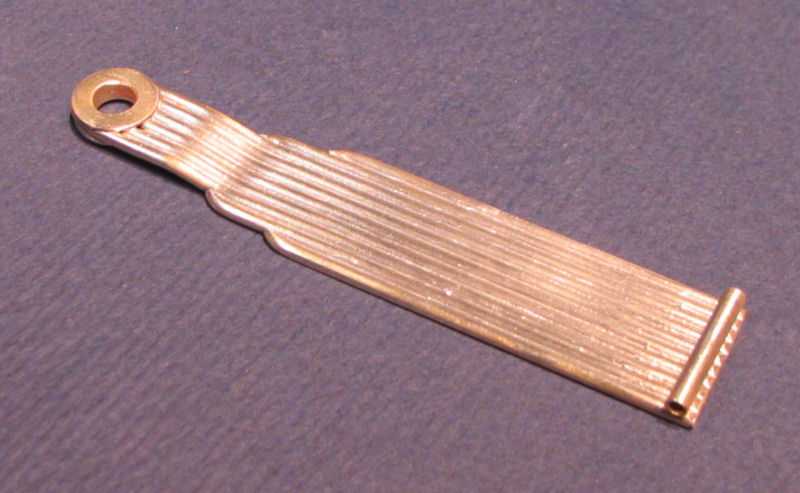

A while back I ran out of Duffy Flag Grommets, so I made some new. These are .38" diameter and undercut to .250" dia. for a bale of 1/16" rod. I like the depth of this groove, as it allows me to completely bury the ends of my fill rods inside the grommet.

It's at this point that I start to measure carefully, making sure my rod stackup is staying inside my allowed space; to save me some major filing & fitting later.

Now, this is just pure arrogance: the extra stackup of my 5/8" wide main rails mean I get 10 spaced rods in the "drop" arm, tops. Okay, but as I chopped off and set alongside, I suddenly got all esthetic on my 'oss! and bent&flattened the dipping-end of each run of rod outboard--well I like it, it looks like a reeely good Parker 51 cap!! And this is the point of all this ramble: If you can't have FUN building, do you want to be here? So, any cutoffs on the side courses got a Bend & Clip job, resulting in something Sigourney Weaver oughta be shooting at. I kinda like that.

and--

More a plug for the R-geo chassis jig; the original, stonger and more versatile, and the more you build the more you need more pin holes...

AND more in a couple days.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#32

Posted 12 September 2011 - 09:32 PM

Paul Wolcott

#33

Posted 12 September 2011 - 10:04 PM

1/24/48-2/18/16

Requiescat in Pace

#34

Posted 13 September 2011 - 04:48 AM

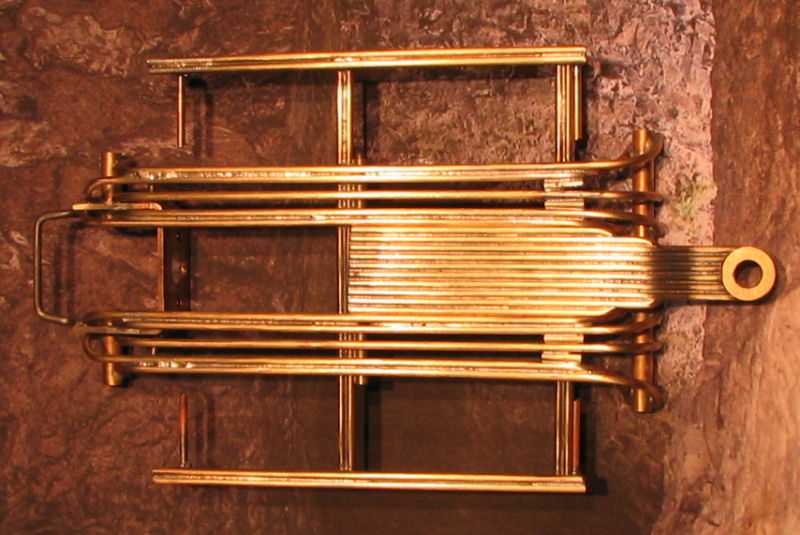

There's a reason for More Snaky Goodness, the way my fevered little mind works: I think the use of square and parallel joints allows flexure in a parallelogram sort of way, like a garden gate without diagonal bracing. So a few odd angles should cantilever things and give a little stiffness.

--Oh hey, looka that, the guide grommet's a little crooked! Fix it.

In back, tying the uprights to the bracket takes advantage of the shear property of the bracket's motor face.

Also in this pic, you see the steel bale obediently soldered in inside the bracket cheeks--it helps to go re-read the rules now and then, & find all the thinking you forgot you didn't want to know.

Here's another angle on the angles: everything tied together in swoops and corners, and there's significantly less flex and bounce. --Too much less? I'm gonna find that out. Once I have a "baseline" on the stiffness of this chassis (and some guys will chortle when I use the terms "stiffness" and "JailDoor" in the same thread), I can start working back from that, beginning by selectively soldering along the joined rails to allow some more twist in areas where I can control it.

That's the plan, anyway. I really don't know, but it's fun to play at finding out; and the weird thing is, this work with bronze & pliers has become kinda second-nature to me with some practice, so I'm more casual about just whipping some experiment up for recreation.

So, Vanity Shots of Duffy #50 "Blarney Castle Dungeon"--I'll hang the gear on this over the week and get some shakedown time this weekend.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#35

Posted 13 September 2011 - 06:44 AM

Paul Wolcott

#36

Posted 13 September 2011 - 06:53 AM

#37

Posted 13 September 2011 - 10:09 AM

Jairus H. Watson

3/12/59-5/19/25

Requiescat in Pace

#38

Posted 13 September 2011 - 05:43 PM

I have nice friends. One PM'd me to ask if my droparm was trimmed off crooked in back--

--and he nobly asked me privately first. Wasn't that sweet? --No, Marty, it's actually only a

little bit not-square but then I just took a blithe swipe with the file to debur--and that's what

you see.

What he didn't see (or ask about, anyway) was the 'orribly sloppy spacer over on the right!

Ohhh, that's gonna hurt for a while.

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#39

Posted 13 September 2011 - 06:12 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#40

Posted 13 September 2011 - 06:16 PM

Duff, shoddy work my man,. For punishment 3 drops of acid flux on your tongue. Lol.

Tony,

No acid for Duffy!

Nor for you!

1/24/48-2/18/16

Requiescat in Pace

#41

Posted 13 September 2011 - 06:35 PM

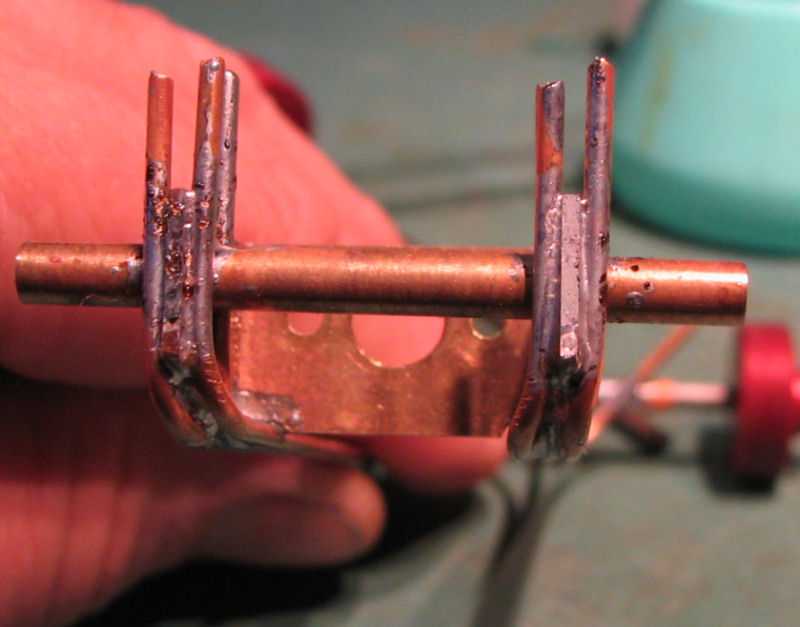

I'm fussy sometimes and mostly not the right times, but here's a really laughable

bit I made up just because I can't bear to keep a rusty old motor around for builds...

Pulled down a hunk of STN and made me a more-permanent template to jig chasses up with.

It's hollowed out a good bit so as to make it somewhat less of a heat sink. You see a step in the diameter,

which reflects the difference between the PD and FK cans; and likewise the flats on two sides, as there's

a difference in heights as well. The big step across this top flat represents the PD length.

These different steps & surfaces denote the minimum tolerances for any structure I may want alongside

the future motor, particularly if I use a non-hypoid setup and want the front edge to lie as close as possible

to the ground plane.

Two hours' work, just to avoid some rust. NOT a right time to be:

Fussy Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#42

Posted 13 September 2011 - 06:38 PM

One PM'd me to ask if my droparm was trimmed off crooked in back

If anything looks off, it is usually just the camera angle.

Nice jig motor, Duffmaster

Paul Wolcott

#43

Posted 13 September 2011 - 06:50 PM

Very cool. For that your punishment is reduced to 2 drops of acid flux.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#44

Posted 13 September 2011 - 06:58 PM

Products--hm. This is a tough one. it's expensive, for my one-off tooling. Toss-away cans are cheaper by at least a zero.

Not for me to do, I think.

Who do we know with a STAR CNC and a stock of machinable ceramic rod?

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#45

Posted 13 September 2011 - 07:04 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#46

Posted 23 October 2011 - 10:53 AM

This'll probably be the capper for this thread: how many ways can you build a JD roller anyway, and who's interested in building 'em? This ain't exactly a pressing issue. But, since I didn't justify my waste of protoplasm this week by writing the Manifesto for Occupy Wall Street / inventing Broadcast Power / Finding The Lost Chord (I think it's in my sock drawer), I figure there're a couple of things to follow-up on and then we'll let it go.

If you've been following the show up to now, the idea I was working with was to pack mass and rigidity into the confines of the JDGP chassis, both dimension- and rule-wise. So, stuffing things as narrow as possible, I got two rails inside the cheeks of my standard JD bracket and two outside. --That's where I ran into trouble, up above: the snaky bends to get around the bracket aren't legal.

Okay, so I address that puzzle here, by running the third course directly under the cheeks, and then moving the upright portion over to the outside once the rod breaks the jig plane. This required filing off the bottom of the bracket to conform to the radius of the rod, and then bending the rod to move the upright over .040" (the thickness of the bracket material). I don't have real good photos of this, I hope the description helps--but here's the

rear view showing the inner course on one side of the cheek, bent over to pass the next-out course with its upright joined forward of the bushing; and the first outer course more subtly bent to nuzzle up against the cheek as well. That makes this one mightily-nuzzled cheek. Romantic.

The happy advantage of this was, I was able for the first time to get continuous joining between the bracket and the rails. A real scientific grab&twist test between this frame and one of my earlier tries tells me that there's a huge improvement in stiffness gained by the triangulated upright segments and close-as-possible linking of any rod elements where they separate from each other.

I think it's worth considering that flexy-ness in JD is not an advantage that we can control to our gain. The construction depends on soldered rails joining front and rear, and no room for incorporating motion in there. If that's true, I opt for the stiffest, crashproofest frame I can make; and this is heading a good way in that direction.

I had this and the "illegal" car out last week on Slots-A-Lot's Hillclimb, and this car was showing lovely promise; a totally plotz motor kept me from racing it, but the couple of Real Drivers who tried it were lovin' it in the corners. I think I'm close to doing this right.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#47

Posted 23 October 2011 - 11:24 AM

Jairus H. Watson

3/12/59-5/19/25

Requiescat in Pace

#48

Posted 23 October 2011 - 11:35 AM

Oh yah: capper to the capper--

Here's the body Noose did for this Slithery series. Look close at the logo.

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#49

Posted 23 October 2011 - 03:18 PM

Paul Wolcott

#50

Posted 23 October 2011 - 08:05 PM

Matt Sheldon

Owner - Duffy's SlotCar Raceway (Evans, CO)