Controllers... what was used with all these great cars?

#26

M. Steube

M. Steube

Posted 03 April 2006 - 11:43 PM

#27

Posted 03 April 2006 - 11:55 PM

Philippe de Lespinay

#28

Posted 04 April 2006 - 12:04 PM

From '59 to '62, I drove with a rotary rheostat! Then I bought the MRRC after coming back to the US, then an early Cox, then the first blue Russkit at 15 ohm. I used this in parallel with the MRC Varipower. The MRC was easy to modify to take serious power by bypassing the breaker and rewiring it. I used the Varipower to dial-in where the controller needed to be with a new motor, then build up a Russkit to suit!

Still have that old blue Russkit with a 15 or 10 ohm. Not the SAME resistor, though.

Fate

- Ramcatlarry likes this

3/6/48-1/1/12

Requiescat in Pace

#29

Posted 07 July 2019 - 11:19 AM

With all this great background I thought it appropriate to revive this post.

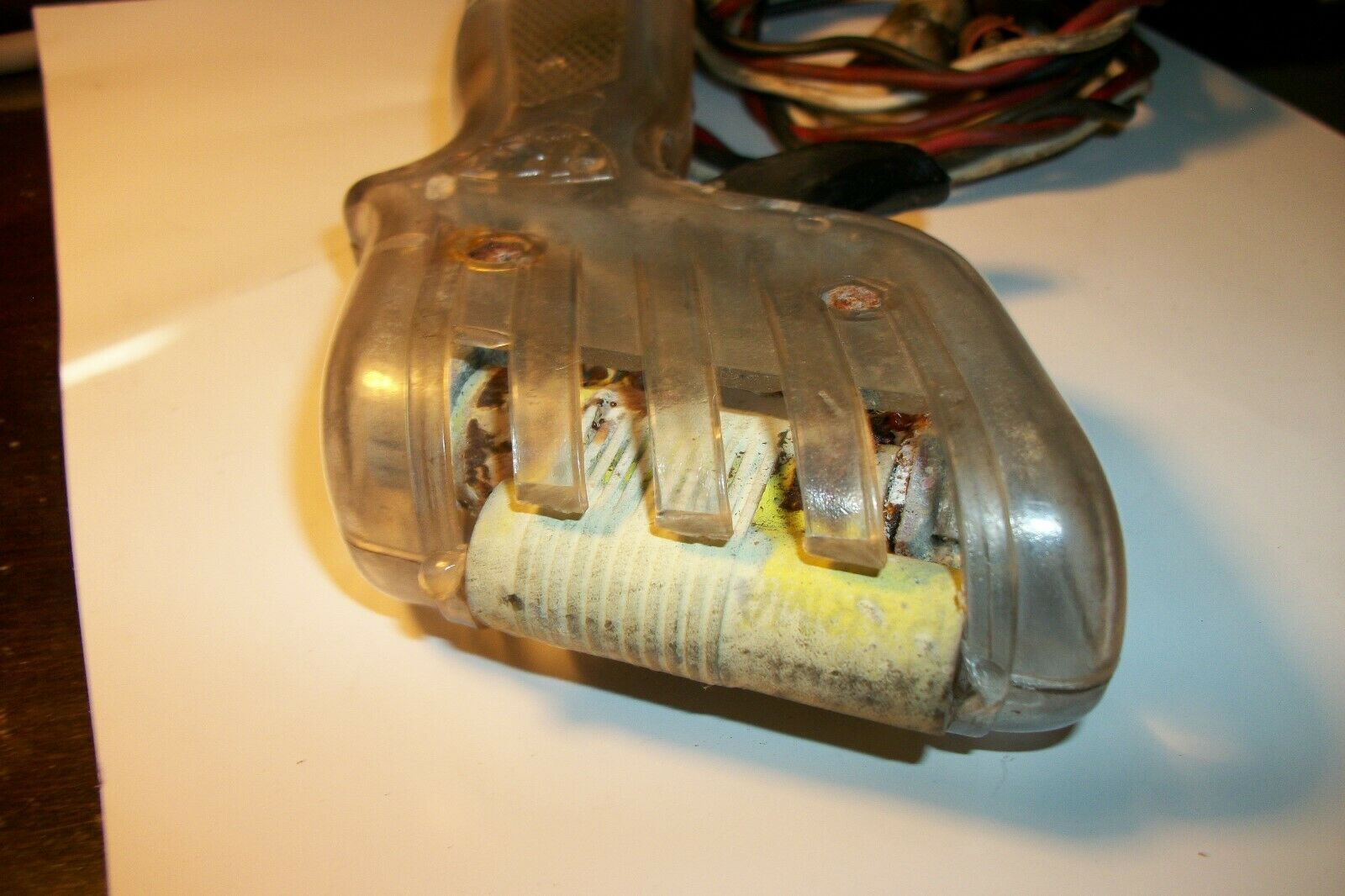

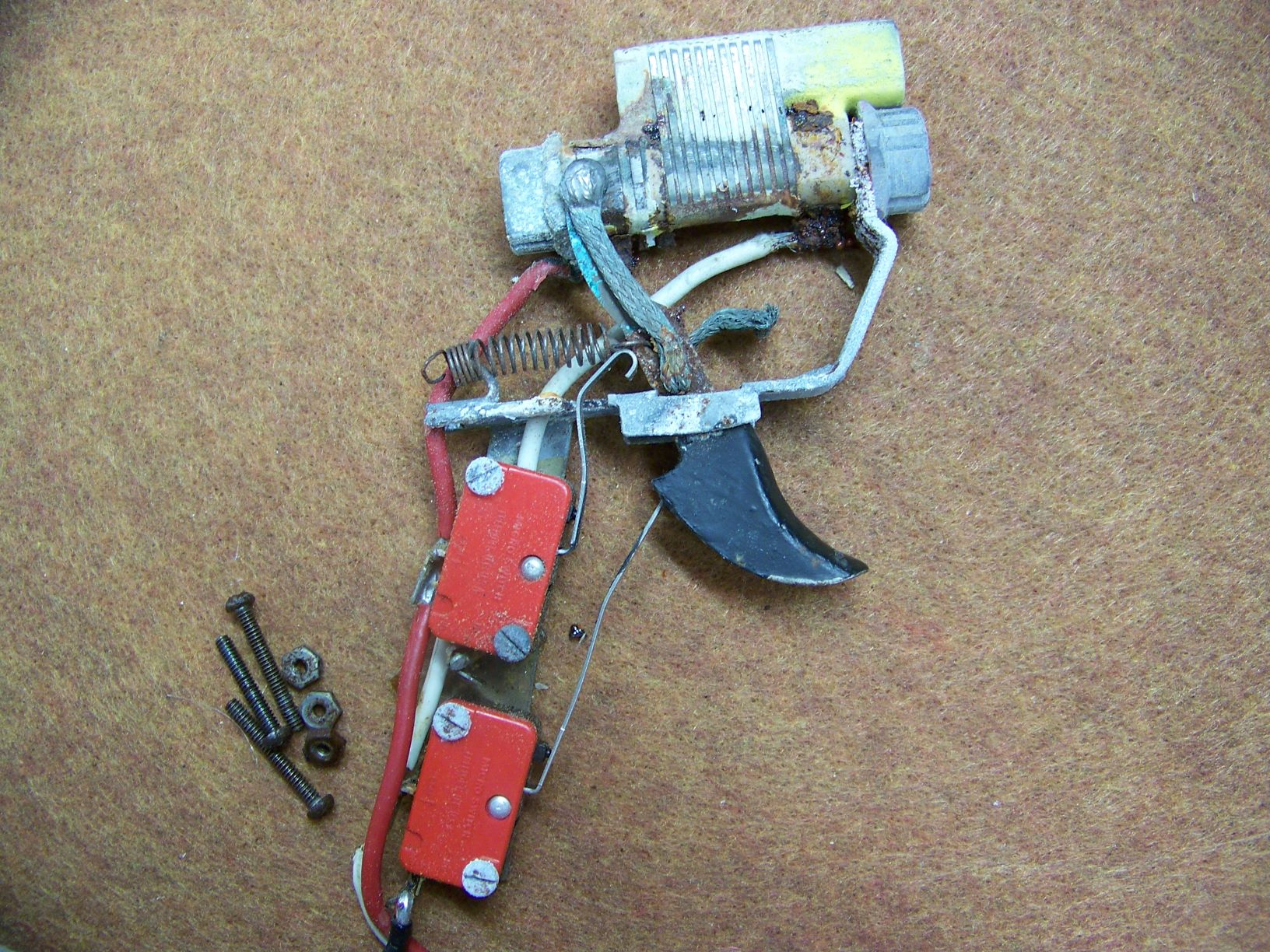

I was looking for a clear Russkit handle when I found this controller. It has a double micro switch and a cool looking heat sink.

These are the pics from the e-bay. It was hard to tell if the handle had the ® but for $30 I took a chance.

I will open her up take some more pics then clean and see if it still works.

Any info on dates or do's and don'ts will be appreciated.

#30

Posted 07 July 2019 - 12:12 PM

The most fragile part of your 'find' is the yellow resistor coating. It will likely just flake off. I do not know what the coating is and I would just clean it as best you can, superglue the coil wires down to the ceramic tubes and replace the coating with an epoxy coating to make it a 'wet wound' resistor. Paint it yellow if you care and it should work fine after cleaning the other corrosion from the rest of the controller.

You could replace the resistor, but they only have made hot pink ones lately, but a different ohm value might work better.

Larry D. Kelley, MA

retired raceway owner... Raceworld/Ramcat Raceways

racing around Chicago-land

Diode/Omni repair specialist

USRA 2023 member # 2322

IRRA,/Sano/R4 veteran, Flat track racer/MFTS

Host 2006 Formula 2000 & ISRA/USA Nats

Great Lakes Slot Car Club (1/32) member

65+ year pin Racing rail/slot cars in America

#31

Posted 07 July 2019 - 02:37 PM

Thanks Larry for the advice. I am about to open her up and see what I have.

Any idea when double micro switches became popular?

This is some good reading too from the late and the great. http://slotblog.net/...by-sandy-gross/

#32

Posted 07 July 2019 - 03:19 PM

Early 70´s - I did invent the shunted micro as they tended to blow at least when connected wrong. Micro switches (rude) were already used late 60's in some thumb controllers.

#33

Posted 07 July 2019 - 03:20 PM

Parma sold double micro kits in the early '70s. These used the old "half" frames. I bought two of these kits for wing racing. One got built up, its backup still awaits assembly. ![]() I had new clear Russkit handles for the second one, but I swapped them to a Canadian friend about 20 yrs. ago.. I used the same heatsink shown in the above photos, except I used two of them with a 2 ohm double barrel resistor. The controller I built up still works 45 yrs. later, but it's not competitive with today's electronics.

I had new clear Russkit handles for the second one, but I swapped them to a Canadian friend about 20 yrs. ago.. I used the same heatsink shown in the above photos, except I used two of them with a 2 ohm double barrel resistor. The controller I built up still works 45 yrs. later, but it's not competitive with today's electronics.

I intend to live forever! So far, so good.

#34

Posted 07 July 2019 - 03:35 PM

The trick to keeping the brass micro switch plate attached to the frame was using a piano wire "L" brace across the frame & down the outside of the switch plate. Silver solder also helped too.

- Rotorranch likes this

I intend to live forever! So far, so good.

#35

Posted 07 July 2019 - 03:59 PM

The first "Pro" Russkit controller I remember seeing had been hand built by Russ Boyington. It had the blue Russkit handles, an MRC 5 ohm resistor (which made a short stroke trigger pull), and a spring made from a safety pin.

#36

Posted 07 July 2019 - 04:24 PM

Lots of of great input, do you think this is home or professorially made? Starting to clean up wires and handles.

Just wondering if I should soda blast hard to get to places?

Sorry have no control over rotation of first pic.

- brnursebmt likes this

#38

Posted 07 July 2019 - 06:39 PM

Lots of of great input, do you think this is home or professorially made?

Parma "Tiger Double Micro" with "Green" bolt.

Bob Green had these finned threaded ends made for Gorski and Parma micro controllers.

- tonyp likes this

Philippe de Lespinay

#39

Posted 07 July 2019 - 07:37 PM

Thanks Philippe. I felt it was worth saving. It is cleaning up nice. Do you agree it is early 70s?

Cool controller with the adjustments Jeff.

#40

Posted 07 July 2019 - 10:04 PM

It has Russkit handles. It's worth cleaning up to look like new. It appears to me to be factory built rather than user built. You can recoat the trigger using some "liquid electrical tape." Someone use to sell a similar material for tool dipping but I haven't seen it advertised for several years.

I intend to live forever! So far, so good.

#41

Posted 08 July 2019 - 07:00 AM

It's a little newer than my first one. Mine had those purple Cherry micros that were really fragile and orange wire wound double barrel resistor. Don't know if that heat sink bolt is a later upgrade, I bought mine separate. Originally I had a golden heat sink.

#42

Posted 08 July 2019 - 12:12 PM

Parma used to sell the yellow resistor coating in about a two or three ounce bottle that came with a brush attached to the cap. I remember buying some but my results were not too good. It was way too thin.

Here's a question. I bought a new Gorski controller in about '79 and I remember the paperwork that came with it saying that it had a reworked resistor face. I stared at that thing for hours trying to figure out how it was reworked! It looked just like any other Parma resistor to me!

Any thoughts on this?

Bobby Robinson RN, BMTCN

"Nobody rides for free." - Jackson Browne, 1980

"Positivity and optimism can overcome a lot of things." - Tom Brady, 2019

"Trying is the first step towards failure." - Homer Simpson

#43

Posted 08 July 2019 - 02:20 PM

Bobby:

I've got several Parma Turbo controllers that I use as "loaner controllers" for my home track. I believe reworking the face of resistor is talking about smoothing out the often rough and uneven windings of the resistor as it comes from the factory.

- Rotorranch likes this

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#44

Posted 08 July 2019 - 08:36 PM

Jay is correct.

I remember a while back I worked over a few old resistors with double barrels, flat winds and chipped insulation.

I would coat them in JB Weld and then after the epoxy set up, went about wet sanding the wiping surface till it was smooth as a newborn baby's bottom.

The action was sooooo smooth. But it took so long....

A lot of work for a controller so obsolete.

Jairus H. Watson

3/12/59-5/19/25

Requiescat in Pace

#45

Posted 08 July 2019 - 10:46 PM

Also remember to check that the end of the resistor is square to the face of the windings. This will help ensure the wiper button maintains an even pressure across the wires.

#46

Posted 09 July 2019 - 09:52 PM

Martin,

the Parma "Tiger Double Micro" was a copy of the Gorski. It was issued in 1971. The clear handles were produced after Parma bought the tooling from Jim Russell. First in Styrene, then in Lexan.

You should use a brand new small steel wire brush to clean the mess and the oxidation. To clean the braided shunt on the wiper arm, stiff toothbrush with scrubbing powder, then wash, rinse and dry. The wiring to the alligator clips is best washed with solvent such as mineral spirits and a cotton rag.

Lubricate the trigger's hinge, wash the handles and you are done.

Philippe de Lespinay

#47

Posted 09 July 2019 - 11:09 PM

Well, I always thought it was common practice with a new resistor to use a belt sander to get a smooth flat surface for good wiper button contact and smooth trigger action.

Glenn Evans

Life is only as fair as you make it.

#48

Posted 10 July 2019 - 07:25 AM

A belt sander might be too aggressive. A fine grit sheet of wet-n-dry paper placed on a known flat surface would be more helpful. I have a friend who used to belt sand his wire chassis flat.

I intend to live forever! So far, so good.

#49

Posted 10 July 2019 - 08:43 AM

At 14 or 15, it was a challenge, to install.

The power micro was easy.

Parma supplied a large diameter, precut brass tube, to solder into the recess of the trigger.

Getting the brake micro set up, to work reliably, was tricky (for me, anyway).

I finally decided a little more braking action was overrated, and took out the brake micro.

I used that same controller, when I raced HO, in the early, to mid 70's, and when I got back into 1/24, in late '81, of course, changing resistors, back and forth.

- TSR likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#50

Posted 10 July 2019 - 08:44 AM

A belt sander is very aggressive and you have to be very careful but it only takes a minute or less to get rid of any high or low spots.

Glenn Evans

Life is only as fair as you make it.