Rick

Some good questions you have there. As for what I like about an indirect main rail system (“Z-Rail” as commonly called here…) is that it creates a greater amount of inherent flex to a chassis that can be lessened through the use of other controlling structures as desired. (The opposite, a direct main rail system does not allow greater flex to be added.) And as for what I have learned about the successive designs, not much for my part, as all the designs/builds I have made have used the same design and materials (all of mine are 0.047” wire framed chassis) as I incorporated other design elements onto this type of main rails. Others might better be able to chime in here with their observations on various layouts and wires used. The one thing I have found is there is no difference between medial-to-lateral versus lateral-to-medial layout of the rails (other than which fits the desired design better).

As for what will “…hold the main rail's from spreading apart…”, I use one or both of two design elements. One, I always incorporate a front “spreader” wire that holds the front wing assemblies together (due to the fact all the designs have had separate center-guide assemblies). The second, on some designs the use of spanning front axle uprights on the laterally adjacent rails (ie, your side pans as you said) accomplish the same result.

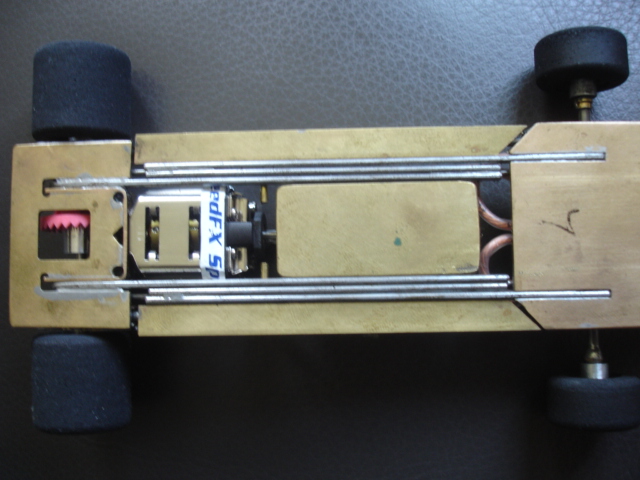

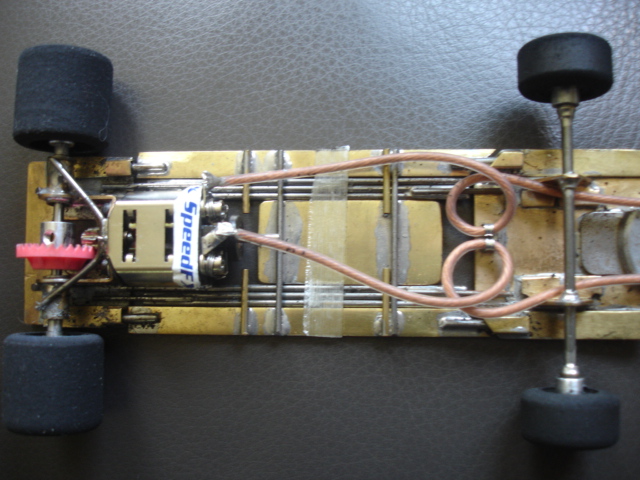

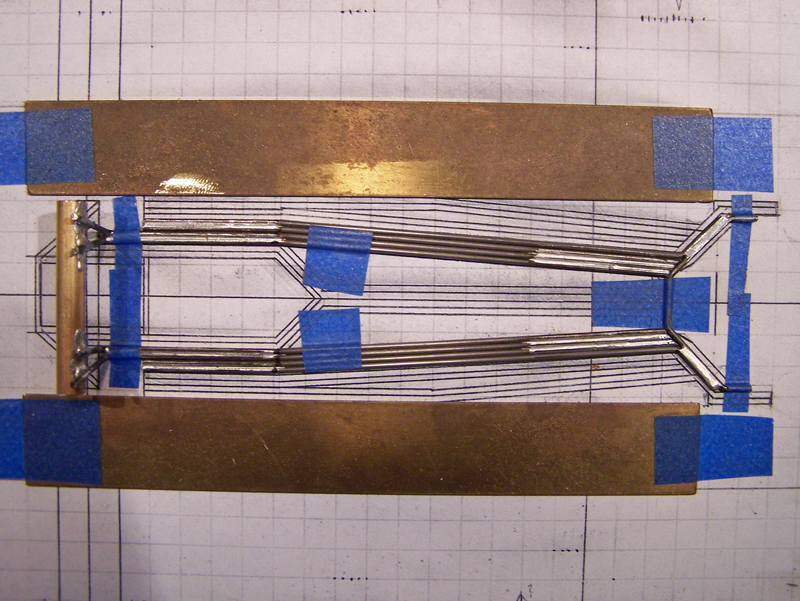

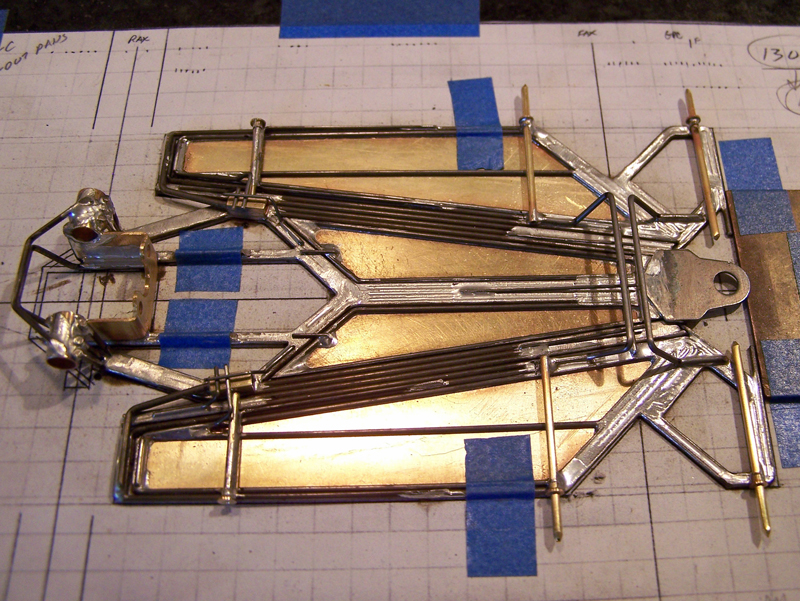

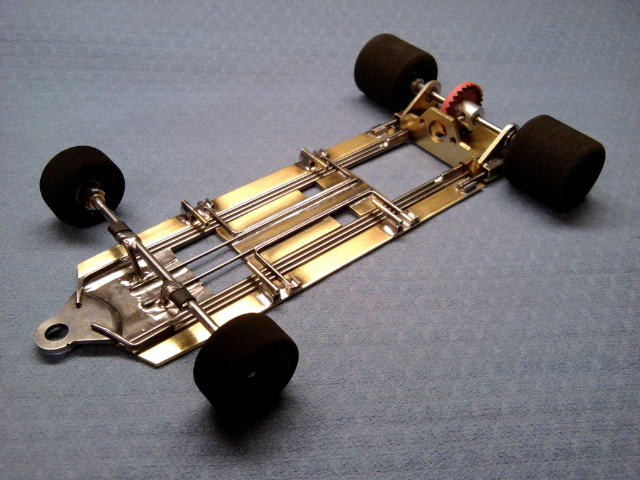

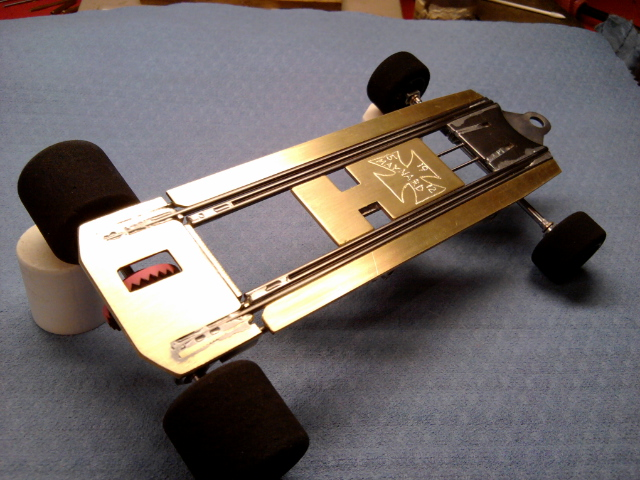

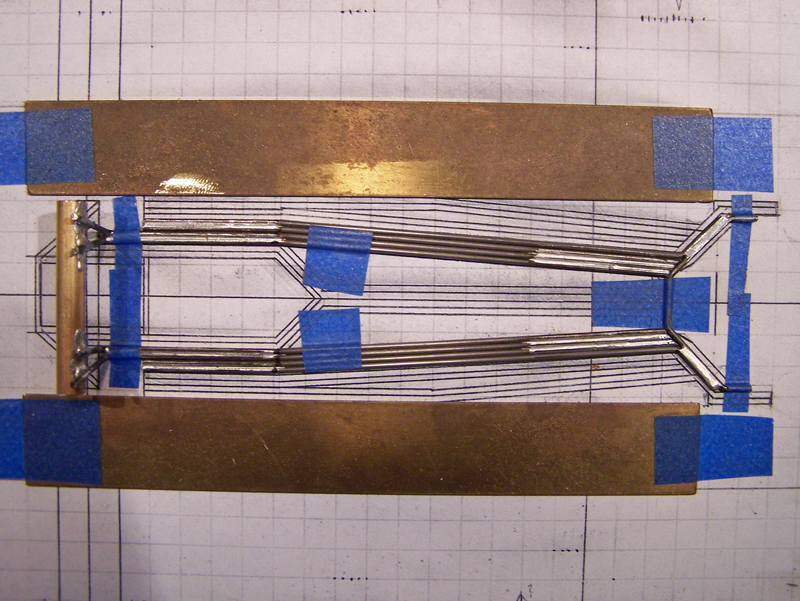

Here are two pics, a CanAm and F1, showing the main rails (with the front spreader):

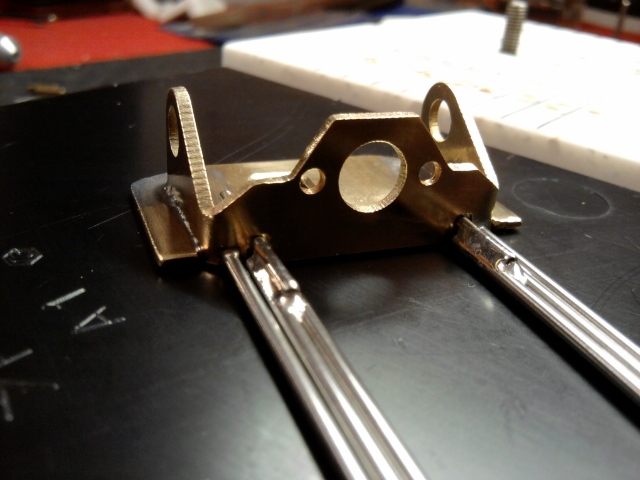

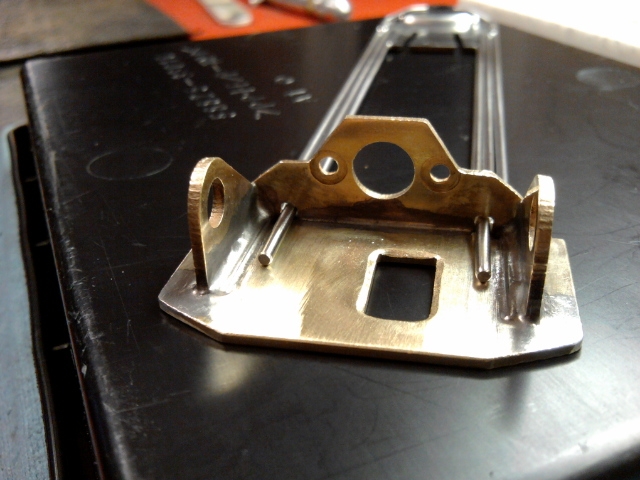

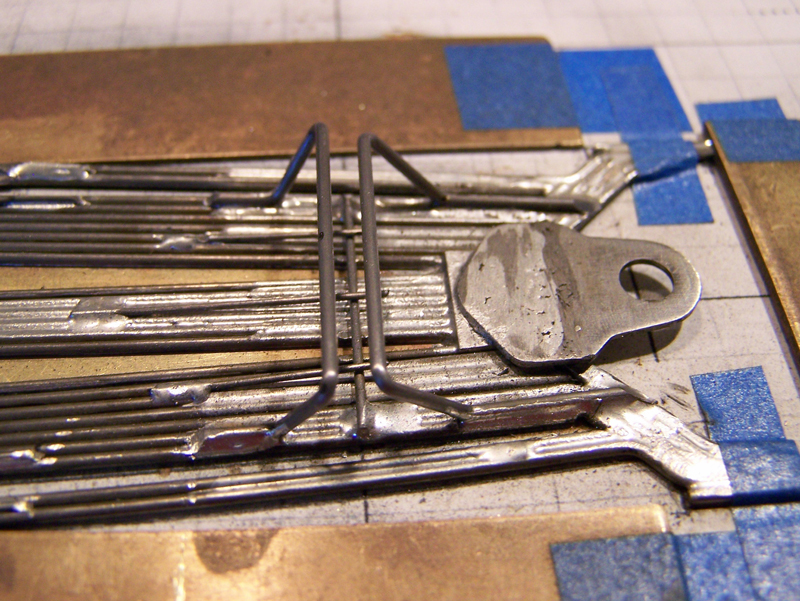

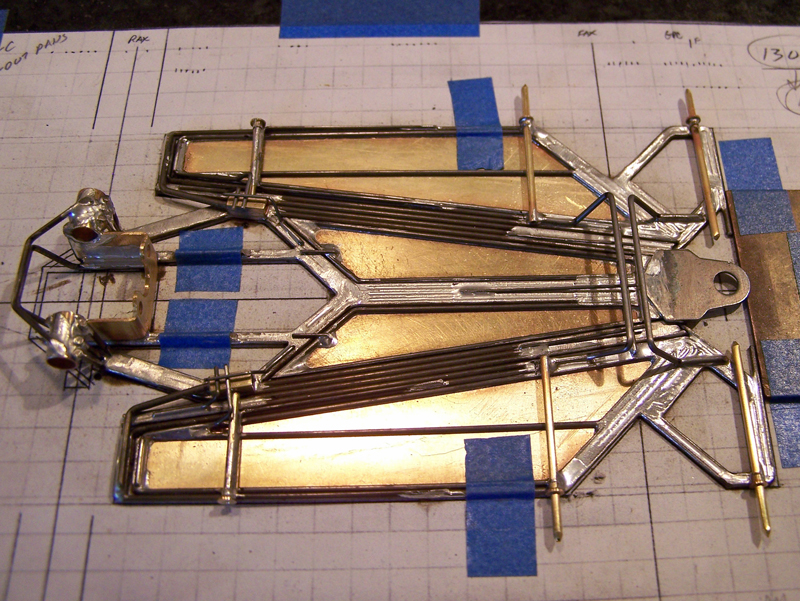

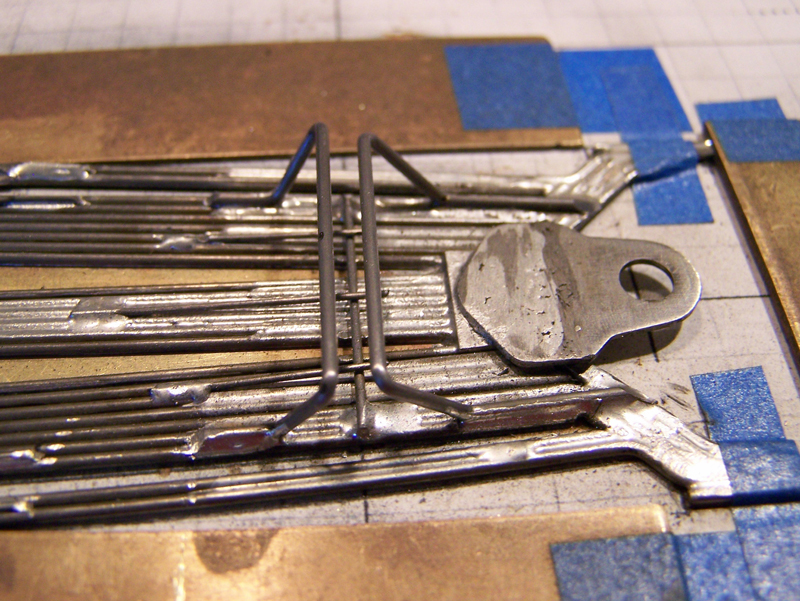

And the same chassis with the spanning front axle uprights:

Hope this gives you some food for thought.

CMF3 (Rick)