In the old days, before the Mabuchi brothers invaded the United States with their cheap can motors, commercial raceways used a variety of motors in which the Pittman, especially the model 196B, eventually dominated.

In 1963, Mabuchi descends on the scene with their first slot racing specific motor, the FT16. it is immediately embraced by Revell, then Monogram and Russkit, then by a whole generation of enthusiasts. The new motor will be the basis for the motors we still have today in the form of what is called, the "16D", now manufactured by several companies.

FT16 (1963)

The very first motors are all endbell-side drive and are painted in dark gray (Revell, IMC, AMT, many Japanese kits) or red (Monogram). Their armature stack is uncoated and easily rusts. They came as a three-pole or six-pole, but the six-pole was never that popular or successful.

Commutator and endbell are molded of white Delrin plastic. The motor brushes ride directly on the endbell's plastic, a nasty recipe for disaster when the motor gets too hot and the Delrin melts. The molded and very weak ceramic magnets are notched on top and bottom, to lock on the indentations stamped on the top of the can. A single U-shaped spring retains them at the bottom of the can. Small can bearing is blind. The endbell is quite a loose fit in the can, quality is mediocre, and manufacturing precision nowhere. It is called "FT16" by the Mabuchi factory.

Can size (outer dimensions):

Length: 0.965"

Width: 0.928" (average, tapered drawn can)

Depth: 0.640"

Thickness: 0.015"

Armature diameter: 0.508"

Magnet clearance: 0.548"

Armature clearance: 0.020"

Magnet thickness: 0.162"

Magnet length: 0.604"

Magnet height: 0.568"

FT16 (1964)

The motor is upgraded in 1964 with a better armature, now coated with a gray protective oxide, and with a better quality commutator with segments molded in. The new commutator has a higher temperature plastic in gray or green. Magnets remain the same for most versions but the Cox (TTX100) and Russkit (22) versions have thicker magnets of the same design, at 0.175", reducing armature clearance. No change in can and endbell,

Comparison between the two types of magnets:

No changes in the can and endbell. Can colors are as before plus gold (Russkit 22), nickel-plated (Revell), chrome-plated with black endbell (Cox).

The first aftermarket magnets were produced for the French Motor Co (see picture below) and were of excellent molding quality. Soon after, the first generation of so-called "broken" magnets was available. These were made from magnets from an unknown origin, and retooled to somewhat fit inside the FT16 cans. The radiuses are not correct and the fitment is at best, fair, but they were a definite improvement over the very weak Japanese Mabuchi and the French magnets. Here is a set of rare survivors, that show how crude they really were:

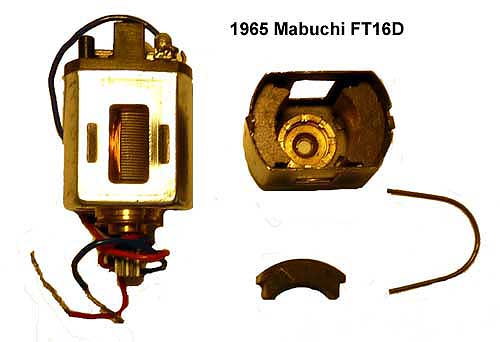

FT16D (1965-1966)

in 1965 appears an updated version, called by the factory, the FT16D (this is where the "16D" name came from). The "D" was defining a "can-side drive" motor, but in this case and while most were indeed, can-side driven, it also was available as with the Russkit 23, in endbell-side drive form.

The can is thicker and slightly longer, and there are two versions, one with the small blind bushing (Russkit "23", K&B...) and another with a large brass housing holding a Gimbal style self-aligning brass bearing. Magnets remain the same.The endbell is all new (but still a rather loose fit in the can) and with its brush arrangement reversed from the FT16, unfortunately still made of Delrin.

Brushes and springs are also different and not compatible with those of the earlier FT16. The brushes now ride in hexagonal sintered metal brush holders. The armature is the same as the second issue of the FT16, but got more radical windings. There are plenty of colors for the manufacturers' own versions: red (Monogram), silver (Revell), purple (AMT & Dynamic), yellow (K&B ), mustard with black endbell (Marx), white (MDC), chrome with black endbell (Cox)...

Can size (outer dimensions):

Length: 0.978"

Width: 0.928" (average, tapered drawn can)

Depth: 0.645"

Thickness: 0.022"

Armature diameter: 0.513"

Magnet clearance: 0.566"

Armature clearance: 0.0265"

Magnet thickness: 0.162"

Magnet length: 0.604"

Magnet height: 0.568"

FT16D-BB (1967)

By the end of 1966, Mabuchi lauches its FT26, a motor taller than the FT16 but lower than its big FT36. This "medium" Mabuchi, quickly called "26D" by the enthusiasts (despite that the FT26D is strictly the little used can-side drive version) is followed in 1967 by a new FT16D, called "BB" for "ball bearing".

The new motor has a new can with no more notches for magnet retention, a pair of oval cooling holes, new magnets now retained by a formed one-piece sheet-steel keeper, and an uncaged ball bearing replacing the gimbal. The bearing housing is the same but now is made of aluminum. Armature and endbell remain the same as before, but winding specs are updated. Incredibly the endbell fitment in the can is still rather loose. Most of these motors have a nickel-plated can and a white endbell, and are marketed by Mabuchi directly as well as found in late issues of Monogram and even Cox kits. The only painted version I know of is a series of samples made for Classic, in orange.

Here is an actual factory sample, with its magnets and retainer:

Can size (outer dimensions):

Length: 0.978"

Width: 0.928" (average, tapered drawn can)

Depth: 0.635"

Thickness: 0.015"

Armature diameter: 0.513"

Magnet clearance: 0.555"

Armature clearance: 0.021"

Magnet thickness: 0.162"

Magnet length: 0.604"

Magnet height: 0.568"

FT16D-74

Mabuchi issued an ultimate version of the FT16D in 1974, to suit the needs of the few manufacturers left in the business, especially Nichimo, Twinn-K, Parma, Cobra, and Champion. This was an all-new motor reverting to previous features such as the brass bearing housing and notches for magnet location. The can was always plated with gold zinc, the endbell, a new design of, at last, better plastic and at last, tighter fitment and with a larger bearing, molded in black. This never made it to what was left of the slot car enthusiasts who had long ago left Mabuchi for either Mura or Champion.

Can size (outer dimensions):

Length: 0.958"

Width: 0.965" (average, tapered drawn can)

Depth: 0.668"

AFTERMARKET

Many rewinders used the FT16, FT16D, and FT16D-BB motors as the basis to their own versions. Champion, Mura, and Dyna-Rewind are the best known but there were literally dozens of small companies making special versions of the Mabuchi FT16 motors. With little doubt, the Champion and Mura were the most successful.

Because of the evolution in technology, we will mostly address here, the Mura and Champion versions that led to the modern "16D".

MURA M-244 "Magnum 880"

Specifically addressed here is the Mura version of the FT16D-BB, the M-244 "Magnum 880" with its "semi can" housing a pair of magnets called "Magnum 88". This was available in the second quarter of 1967:

The full-contour shim holds the magnets without the need for a spring. The magnets are only 1/2" tall, meaning that they "float" inside the shim, contacting it mostly at their back. The shim, also marketed by Dynamic with their own magnets, was sold separately:

Shim thickness; 0.015"

Armature diameter: 0.508" (uses Igarashi "Hemi" blanks)

Magnet clearance: 0.520"

Armature clearance: 0.011"

Magnet height: 0.500"

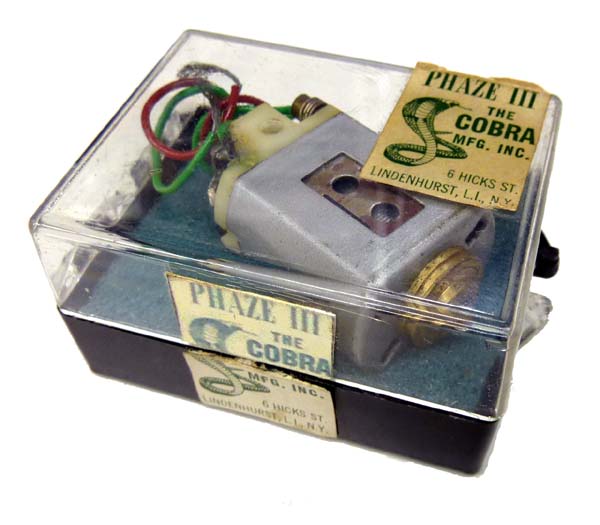

However, other manufacturers also depending on Mura for parts, had issued their own versions using the OLD Mabuchi can and the Semi Can, such as this Cobra-Phaze III motor:

Hence, not everything is written in stone yet...

CHAMPION "517"

Before Mura came up with their own American-made motor, Champion had already issued their own American-made can, the 517, using the old U-shaped shim from the 507R motor. But while the Mura shim did properly center the magnets, the Champion shim did not, relying on the pressure of the single retaining spring to somehow push the magnets down.

Can size (outer dimensions):

Length: 0.965"

Width: 0.955" (average, tapered drawn can)

Depth: 0.659"

Thickness: 0.025"

Armature diameter: 0.521" to 0.523"

Magnet clearance: 0.550"

Armature clearance: 0.0135"

Magnet thickness: 0.152"

Magnet length: 0.645"

Magnet height: 0.557"

The Arco magnets are all of the same size, regardless of whether they're "33". "DZ", "Blue Dot", or "White Dot" type.

This centering problem was later resolved when Champion issued a new two-piece shim that at last resolved that issue. Below are pictures showing, from the top:

- A set of aftermarket French Motor Co. slotted magnets and single retaining spring, the thick 0.170" magnet reducing the gap to standard armatures to about 0.015". Magnet length is 0.586", providing a 0.555" armature clearance when fitted inside an FT16 can.

- The two-piece shim and magnets used by the Dyna-Rewind company on their motors (note that the Chong rewinds from Oregon also use the same shim, likely produced for Dyna by Tradeship, as there was a tight relation between the two businesses).

- The second generation Champion shim and Arco magnets.

- The first generation Champion shim and Arco magnets.

Mura added their own American-built can by taking over the tooling of a Tradeship can in late 1968. The hole pattern and bearing size were changed but the basic die remained the same size as the Tradeship can, that was used by Cobra and Dyna-Rewind.

MURA M-444 "MAGNUM 1000"

The new motor had an endbell that was an exact copy of the Mabuchi, including hardware now made of copper, but molded in a high-temp black plastic. The can was painted in black or an olive color and the motor was available in four different combinations of windings. Please note that the can color MAY be indicative of the wire used on the motor, but I have not verified this yet, and the motor was available in four different specification. By 1969, these colors had changed as the endbell also changed specification and was molded in a white phenolic plastic, while the influence of ex-Team Champion John Cukras introduced the much improved pent-roof brush holders to the endbell.

The motor used the same "semi can" full-contour shim and magnets as in the previous, Mabuchi based model.

Can size (outer dimensions):

Length: 1.045"

Width: 0.955" (average, tapered drawn can)

Depth: 0.670"

Thickness: 0.030"

Available in winds of AWG 25, 26. 27. 28-28. each for $14.95.

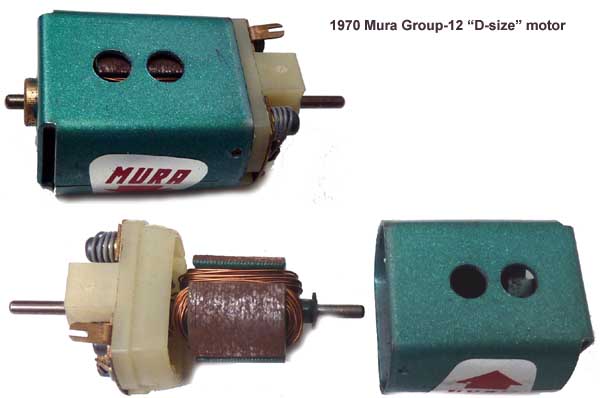

In 1970, as the "D" sized can was soon to be rendered obsolete by the new, smaller "C" can, Mura produced a line of "Group-12" motors using the M-400 series can, now fitted with a white endbell made of better material and featuring what would become to this day, the standard for brush holder design. The brushes were now larger, of the same size as that of the big Mabuchi FT36D. These motors used a much larger diameter armature, that measured 0.595", almost as large as the FT26 arms! To clear the magnets, Mura had new, taller, and thinner magnets made, that needed no shim to fit tightly inside the can. They were only 0.143" thick and provided a 0.610" armature clearance.

There are two types, the one shown here is the first:

The second type uses this can, clearly marked with the NCC label:

The magnets are rather weak, but OK for the FT26-size armatures in these motors:

If one compares the Mabuchi FT16 and FT16D motors to the Champion and Mura "American-made" motors, it appears that the American jobs are quite larger, and taller, too. So was that progress? In reliability, yes. But it also explains why great motor builders such as Bob Kean, used the Cox and Mabuchi cans well after the new motors were issued, as the older cans were lower, smaller, and made the cars handle better...

We will talk more about this soon.

We have discussed all the above motors, that were both "D-size", as in "16D".

But in the meantime, Mura went awry and engineered a new, lower motor, called the Mura B. This was a disaster and eventually after many attempts to get it to work, was discarded. This motor came in multiple versions that are even today hard to figure out as there were so many. Here is a typical example from mid-1969:

MURA "B" MOTOR (1969)

Can size (outer dimensions):

Length: 1"

Width: 0.992" (average, tapered drawn can)

Depth: 0.617"

Thickness: 0.030"

Armature diameter: 0.521" to 0.523"

Magnet clearance: 0.550"

Armature clearance: 0.0135"

Magnet thickness:

Magnet length: 0.725"

Magnet height: 0.507"

At first Mura used some terrible magnets that "bound" the motor, but eventually they purchased the Versitec ceramic magnets that were oriented and resolved some of the issues, but by that time the motor was no longer used by the ones that counted, the pro racers. Here is a set of the famous magnets, as used in the Globe SS101:

By 1970, Bob Green and others had been working on smaller motors using the Champion magnets without shims, and eventually this became the "C" can. This deserves a long story of its own, as it was quite an adventure in itself.

MURA C-CAN (1970)

Can size (outer dimensions):

Length: 0.968"

Width: 0.903" (average, tapered drawn can)

Depth: 0.620"

Thickness: 0.030"

Armature diameter: 0.521" to 0.523"

Magnet clearance: 0.550"

Armature clearance: 0.0135"

In another new post, we will study the Tradeship can and its evolution into the Mura D-size can and the numerous models of motors that ensued, and the "C" can by both Mura and Champion.

All copyrighted pictures courtesy www.lascm.com.