We used the Mura endbell with the champion can. The Mura had better hardware and the material was more bullet proof. The Cobra endbells listed in any of the east coast reports were Muras.

Motor How-To Articles for the 1969 MCS/USRA Series

#26

Posted 06 August 2014 - 06:57 AM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#27

Posted 06 August 2014 - 10:14 AM

Hi Tony,

We used the Mura endbell with the champion can.

The Mura endbell fits loosely in the Champion can. I've seen Champion cans with two punch marks on the top and bottom to take up the gap. I always thought this a bit ugly and wondered why not use shims as was done when fitting a narrowed Mura B endbell to a Mura C-can?

Cobra endbells listed in any of the east coast reports were Muras.

That's good to know Tony, thanks! I knew Cobra repackaged things like Cox quick change guides.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#28

Posted 10 August 2014 - 02:39 PM

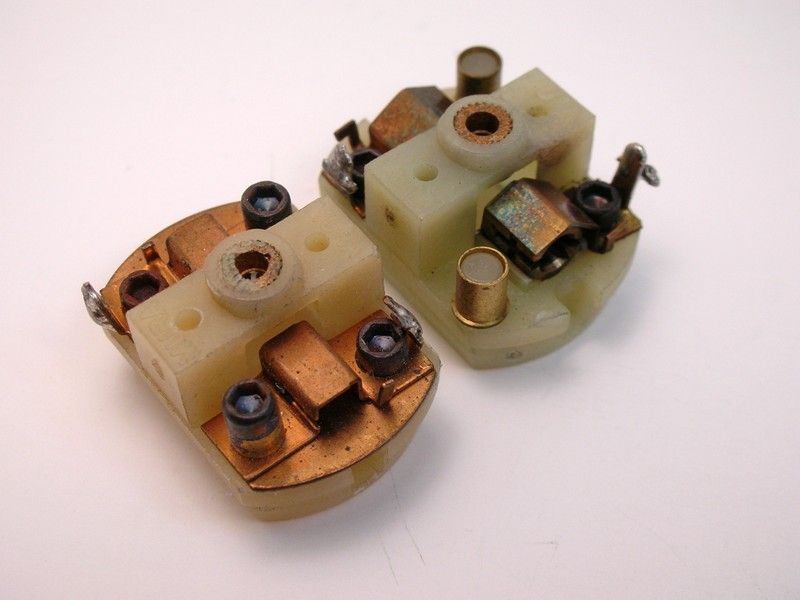

Here's a bit of clarification on the Mura A-Can (16D) endbells. The Korrect endbell for this series is the early "plastic spring post" style shown on the top-right below. It's very much like a Mabuchi FT16D endbell but with pent roof brush hoods and made from a high temperature plastic:

The later style on the bottom was redesigned after the introduction of the B-Motor to take the great B-motor brush hardware. The plastic spring post of the early version is replaced with a screw and brass sleeve. This style of endbell served Mura well into the 90's on their C-can motors.

I'll be editing post number 1 with this info.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#29

Posted 10 August 2014 - 06:15 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#30

Posted 10 August 2014 - 07:06 PM

Shims sound good to me Tony, thanks!

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#31

Posted 31 August 2014 - 05:30 PM

I always wondered what pintabs were originally used for.

I don't know if it's the original use, but "drive rivets" are still used in the aircraft industry on tubing weld assemblies. Many of the tubes in these weld assemblies are sealed, with no provision for corrosion proofing the interior. So a small hole is drilled in an unobtrusive area, linseed oil is injected into the tube, the pin tab installed, and the weld assembly rotated around so as to coat the entire inside with oil. With the outsides painted, these assemblies last for multiple decades with no significant corrosion. One case where pin tabs do some good.

5/26/??-9/12/17

Requiescat in Pace

#32

Posted 31 August 2014 - 09:19 PM

When I wanted to remove these tabs without marking up the can I would grind a slot in the head and unscrew it. Then replace them with screws.

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush