I have not been involved in the hobby for a while. When my wife passed away in 1999 I became a single parent of three kids and the income from building tracks could not support us and pay for college, let alone save for my retirement. So I went back to where I started working in 1973 after graduating high school - the Bruce nuclear power development. I hold an electricians license so I went in as a temp worker for an outage in 2002 and never left. I switched to a staff field operator job in 2003 and have worked at Bruce "B" ever since.

But I do miss my track building days and that especially hit home when my long time business partner and friend, Brian Crosby passed away recently. I do not intend to resume my career as a track builder, Don Bryans builds all our tracks now, but I would like to contribute to the hobby.

I have always thought that the best way to keep slot racing going was with home tracks. I am sure there are books on how to build tracks out there, but they usually involve overly complicated construction methods. So here are a few tips to make your home track building experience much more enjoyable...

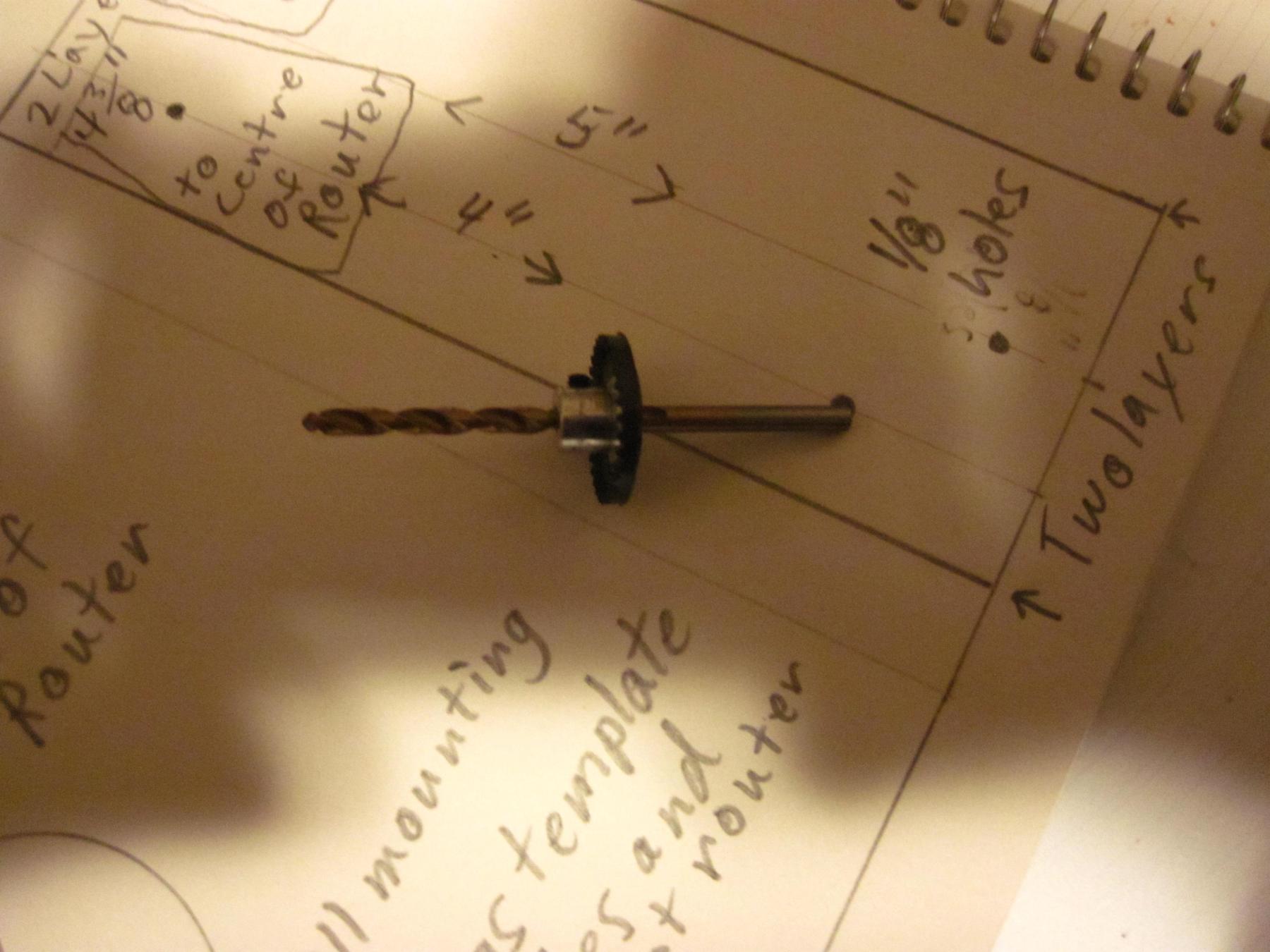

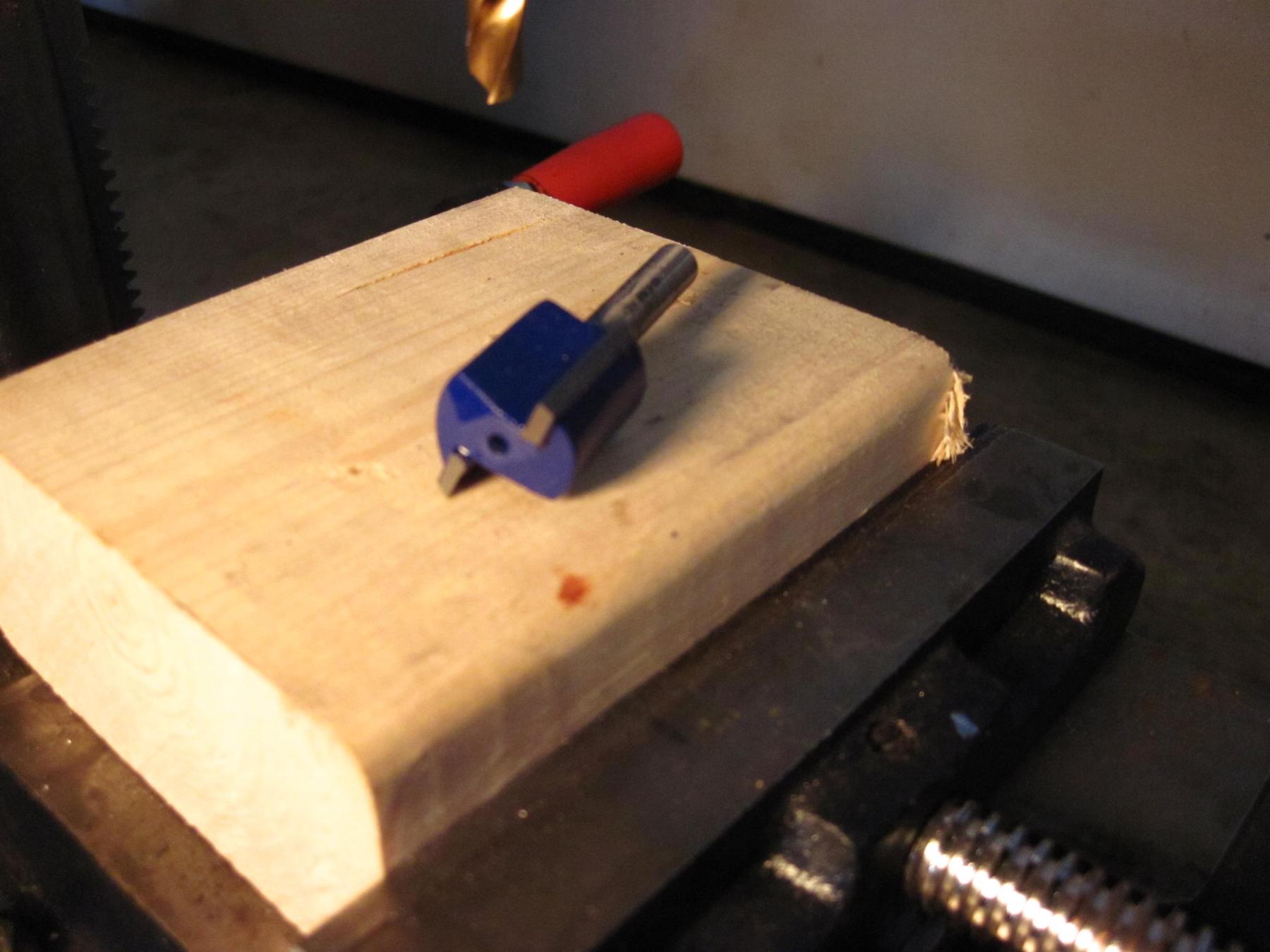

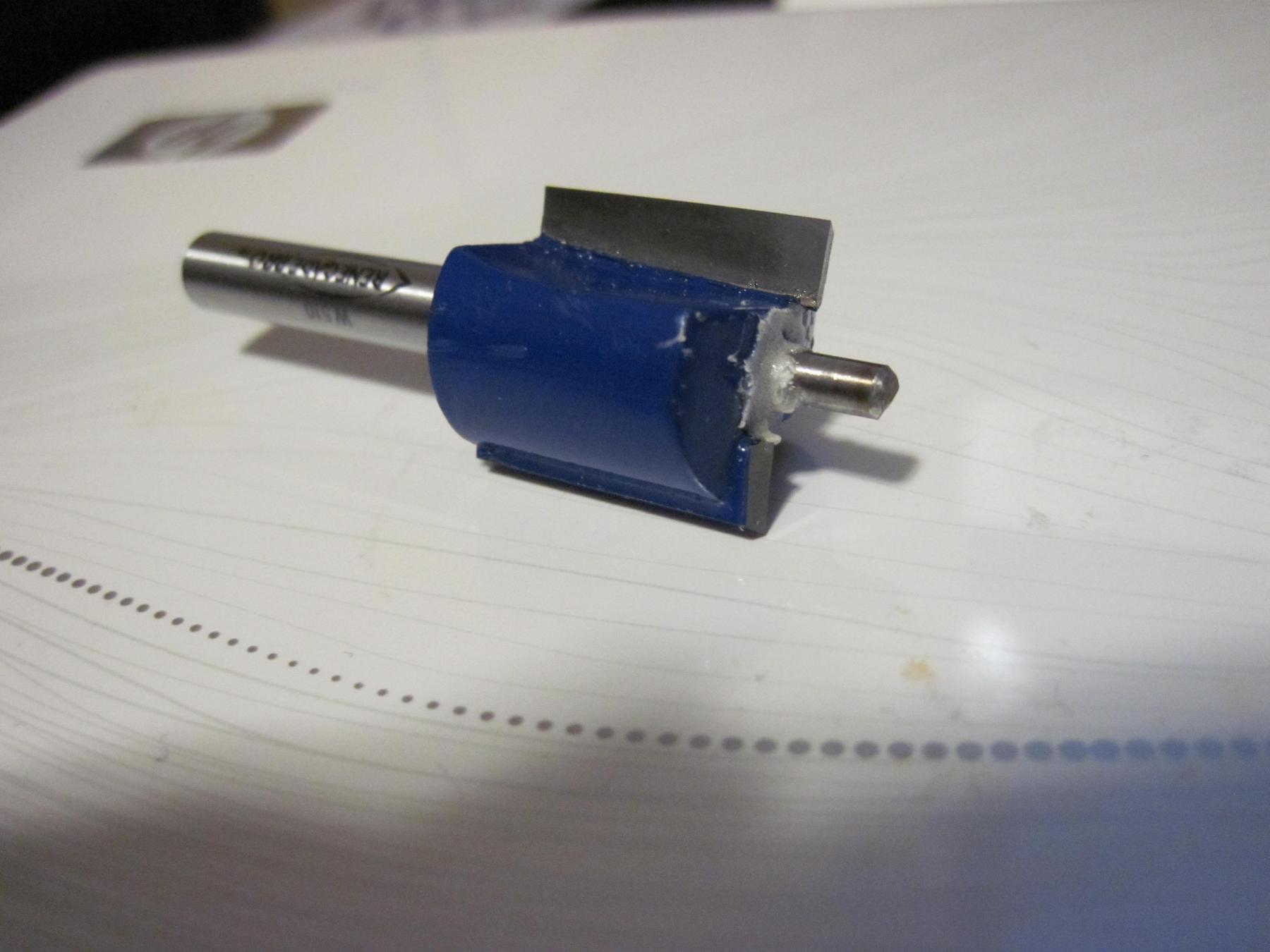

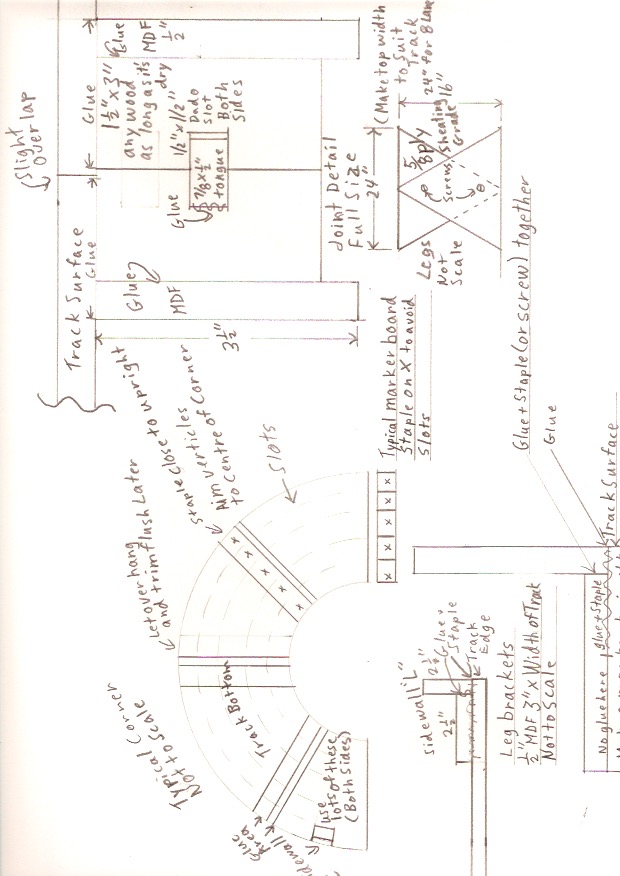

Cutting your corners: Corners are cut with a router riding on radius rods using a 1/4" single flute carbide tipped router bit. Use a medium-sized router that has holes for your radius rods to go in. Use long threaded rods connected to a piece of wood the same width as the router base. You can connect with L-brackets or drilled holes; use your imagination but make your jig keeping in mind how big you need for the size of the corners you are planning on. Drill a 1/2" hole for your pivot point in the piece of wood. Use a couple of sawhorses and mount the sheet of 1/2" MDF or whatever you want to make your track out of on the saw horses.

The formula for a corner is simple. Say you want to make a four-lane corner with an outside diameter of 60". Use the formula for the circumferance of a circle - pi X diameter = 60 X pi = 188.5 " rounded off. Divide that by 360 and you have the inches per degee of corner = .52359, etc. Never calculate by hand, always use a calculator and minimize the error factor. So if you want a 190 degree corner you multiply this number by 190 = 99.48" circumferance. Your tape measure is obviously not that precise but we can get to that later .

Now you need to know your corner radius. I had no problem figuring the math for the circumferance but for the first 10 tracks I built paper models that I bent to replicate banking. Very not accurate but worked nonetheless. Too much trimming to fit though. Then I built Ernie Mosseti's first track, a hillclimb, and he provided me with exact drawings with circumference and radius dimensions. That was so much better, but Ernie did not reveal his formulas so off to the library I went. (Mind you, I probably never asked him either, assuming it was some closely guarded secret.) This was 1988 so no quick Google for me. I remembered from my construction days watching tinwackers make all kinds of cones and shapes by hand out of sheet metal and I spent a day reseaching and I figured out the math behind the physical methods they use.

If you want a flat turn, no math involved your radius is half your diameter. If you want banking multiply the finished radius by the cosine of the degree of banking. The circumference stays the same whether you are building flat or banked.

So now you have your 4'x8' sheet of whatever on your sawhorses and you want to cut a corner. So you take your calculated radius measurement and measure down from the centre of the sheet and drill a 1/2 inch hole. Put your circle jig on the sheet and drop your centre bolt in and you are ready to cut. Except you want to cut in the proper direction. You want to cut against the rotation of your router, so that it does not pop you out at the end of the cut. I always made the cut twice, to get rid of rough edges.

With the outer cut made, take a straight edge and draw a line from the centre of the radius hole to the start of the outer circle. Tape the end of your tape measure to this mark and pull it around the circle and make a mark at your circumference demension. Draw a line from there to the centre of your radius hole. Now you want to change your circle cutter to the inner part of your corner. Just change it to the outer radius dimension - track width and make another cut. (You can do this by sliding it on your radius rods and then locking back in, but it is easier to make you radius block with inner and outer holes.) But this time you want to start your cuts on the lines you just drew, to make everyting more stable as you cut. After the inner circle is cut, rough cut the ends of the corner with a circular saw (stay at least 1/4" away from your finished edge) and finish trim with a straight edge and router.

Tomorrow night I will get in to offset routing jigs and methodology.

Feel free to ask questions.

Steve