I have a quetion about Steve Ogilvie's method of joint building.

Posted 13 April 2016 - 06:02 PM

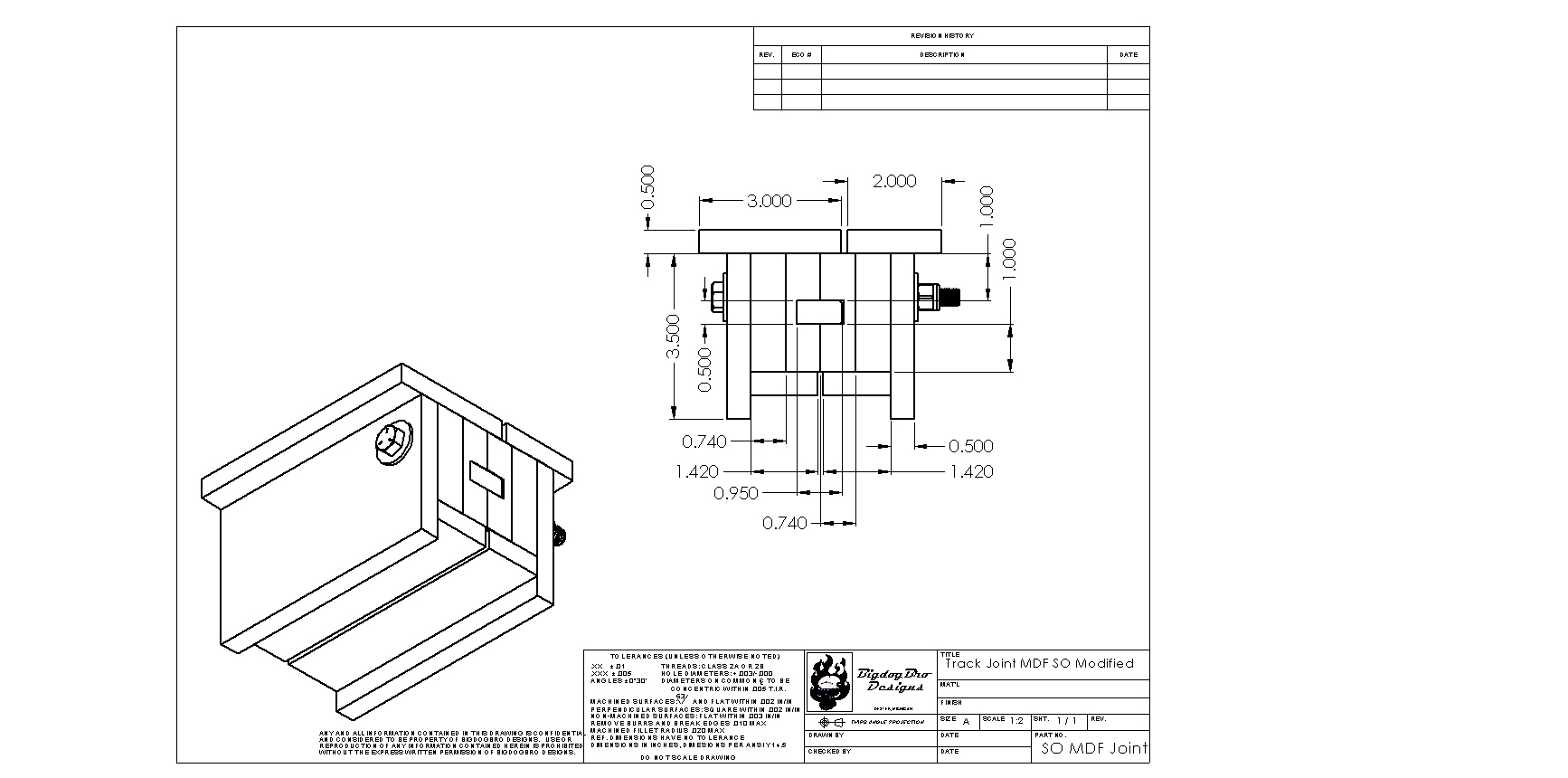

To build these joints , you need a table saw , dado blade for 1/2" slots , a motorised thickness plainer and some clamps .

Start with a straight 2X4 and cut it to the width of your track plus 1/4" .

Cut the height down to 3" .Use a table saw with a long fence and cut a little off the top and bottom to make it as straight as possible .

Put your dado blade in the saw , set at 1/2 " thickness . You can't use the guard when you are dadoing .This is dangerous especially for someone not used to table saws .As a safer alternative , a router table with a 1/2" two flute carbide bit can be used .

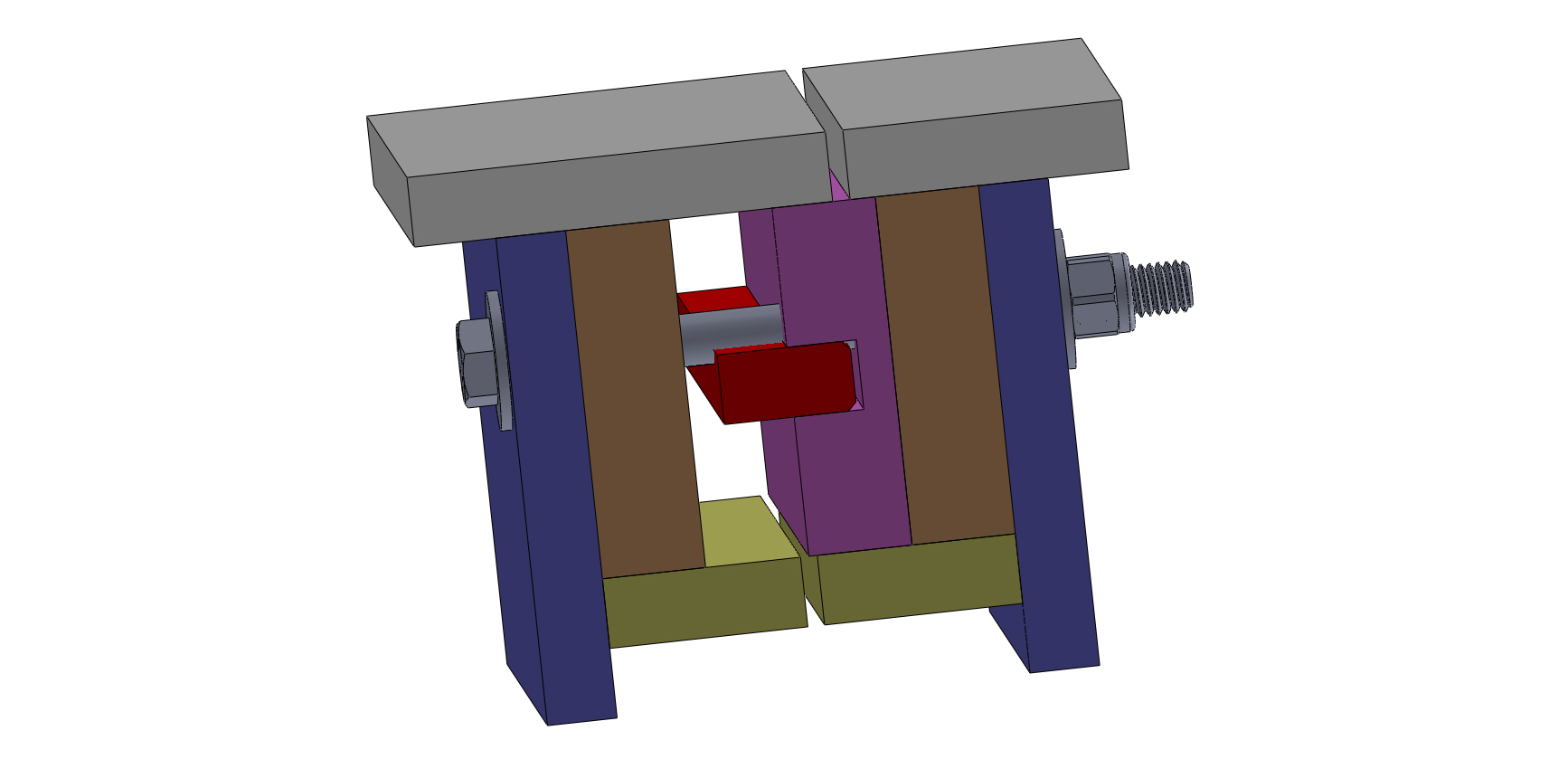

Practice cutting a slot on some scrap until you are happy with the fit of the tongue .Cut a 1/2" deep slot down the middle of the 3" side of each 2X3 .Cut with the straightest side against the fence of the saw or router table .

Check your cuts with a piece of 1/2 " MDF from the sheets you are going to use for your track .Usually you use track off cuts for this .

The tongue is going to be 1/2 " by 7/8" .With the 1/2" slot lightly beveled the tongue should fit very snug but not to the point that is spreading the wood .

If you need to , run the 2 x 3 's through the cutter again .

Run some glue in the bottom of one of the slots and push the tongue in .Tap it with a block and hammer to get it all the way in .

Wipe off all excess glue . Let the glue dry overnight .

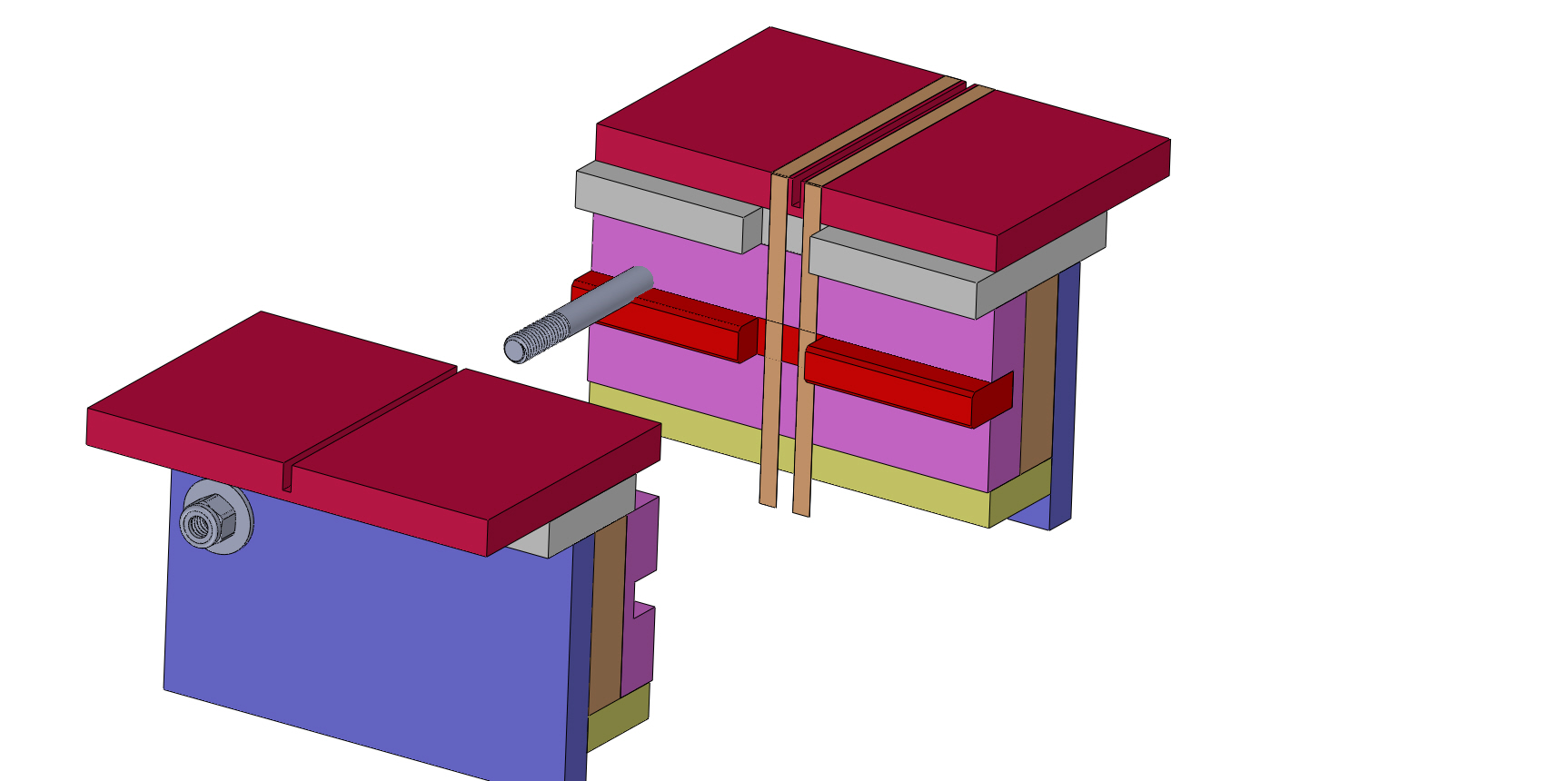

Cut lengths of 3 1/2" MDF to the same length as your joints .

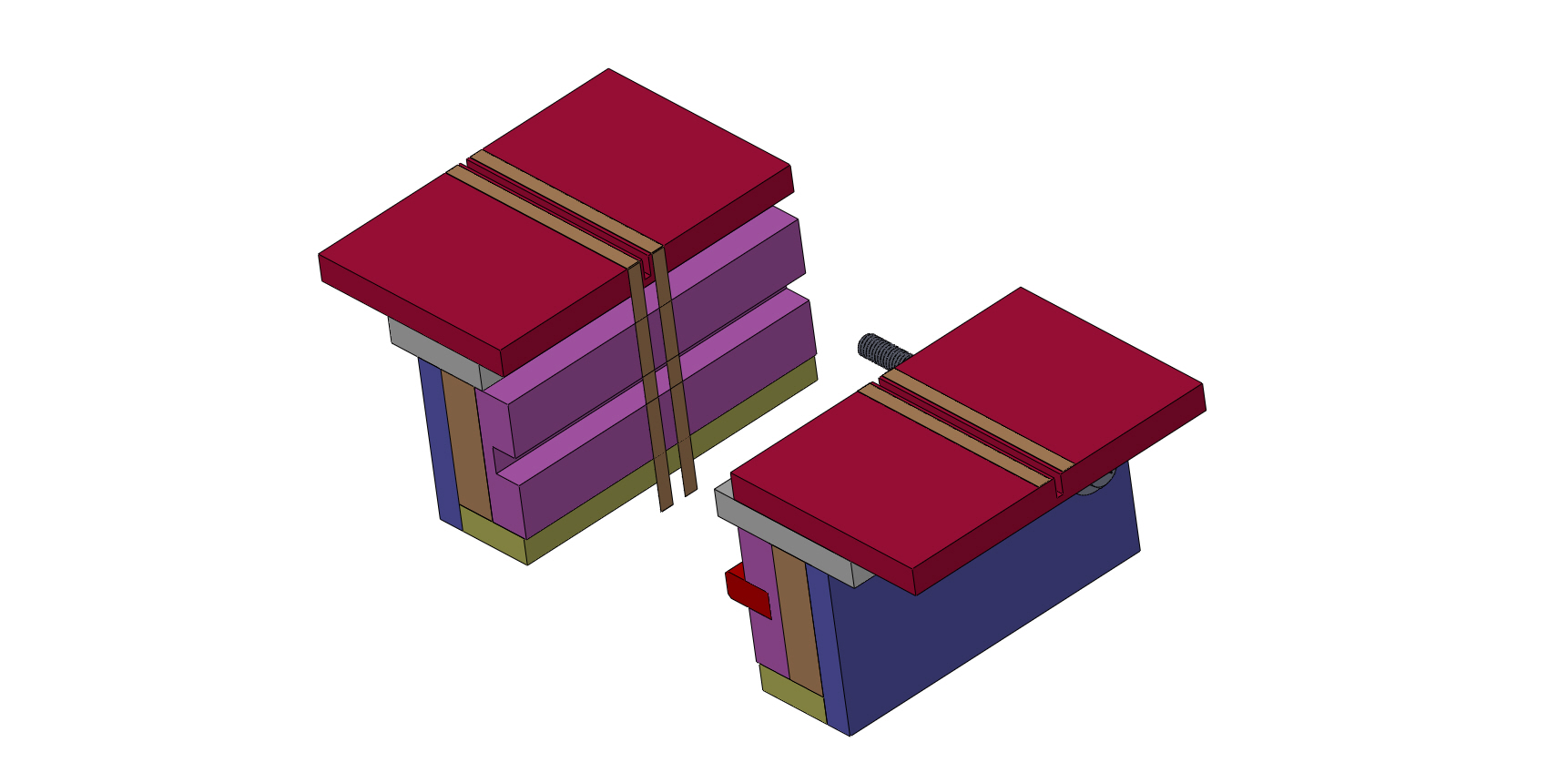

Push your 2X3's together and put the smoothest top down on a flat surface .

Glue the MDF sides on flush with the flat surface .

Clamp them all together .A Workmate style clamping bench works well for this .

Drill three 3/8" holes for the 5 1/2" long blots that are going to hold this together One at each end and one in the middle .Use your slot marker to avoid putting a bolt directly under a slot .Tighten the bolt to around 30 ft lbs .Not critical , you just don't want to crush the MDF .

Let dry for an hour . Run it through the thicknes plainer with the overhanging MDF on the bottom rollers of the plainer to have a perfect surface to glue your track pieces to.

Would the planer cutter not hit the staples or brads. Not sure which surface Steve is actually planing. Is it the top joint overlap that gets glued to the underside of the track MDF. Any help here would be appreciated. Thanks.

Update: I think Steve is planing the top of the side plates and the top of the inner T&G block before adding (stapling) on the top 1/2" MDF plates for the underside track glue. Is he using staples or brad nails and what size?

The overhanging MDF I think what Steve speaks of are the side outer MDF plates that extend down past the T&G block.