Scratchbuilt chassis gallery

#1226

Posted 17 December 2012 - 08:56 PM

another great looking F1 build and re-do of Dennis'F1,

i have a Hanada-F1 that Dennis built,that rocks,with his

style of shakers pans,& middle shaker too,,,

8/16/49-9/18/13

Requiescat in Pace

#1227

Posted 30 December 2012 - 02:28 PM

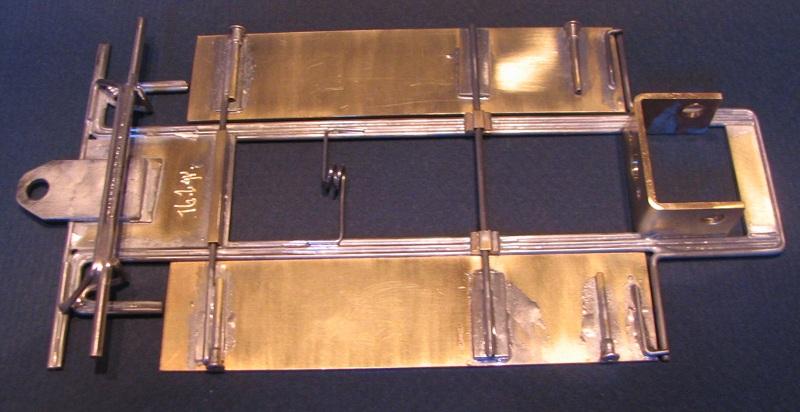

The prototype "Livery" stock car chassis, Duffy #66 "Iggy Katona."

All Duffy components; .050" bracket w/ .520" hypoid lead, all other brass .040" sheet. .055" rails, akas & axle hanger, .062" rear bale. Shaker pan gives .009" fore-aft, .014" sidey-side. Porky little 76 gr. slider, targeting ~124 grams with carefully-chosen bod, & plenty of surface for painting more lead onto.

First use of the new Duffy .050" Hones2GodSpringSteel guide tongue, too. Tweak this, rock crusher!

Let's see what this baby'll do.

Duf

- S.O. Watt likes this

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#1228

Posted 30 December 2012 - 04:08 PM

Love the wire-bending, Duffy! Cute little lead wire retainer, too!

- Joe Mig likes this

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#1229

Posted 30 December 2012 - 09:40 PM

dragon slayer 3

8 rails of .047

4 rails of .032

- Rick and Hipsticker like this

Team R-Geo

#1230

Posted 30 December 2012 - 09:45 PM

Nice job Preston.

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

#1231

Posted 30 December 2012 - 09:49 PM

nice work... so many rails, so little time, lol

Cry like a baby, drive like a girl, walk like a man.

Give me enough rope and I'll build a fast car... or hang myself?

#1232

Posted 30 December 2012 - 09:51 PM

Nice job Preston.

thanks John

- Chris Barnes likes this

Team R-Geo

#1233

Posted 31 December 2012 - 02:49 AM

nice work... so many rails, so little time, lol

12 ain't that many. Thinking of trying a 30 rail tomorrow. :0

Team R-Geo

#1234

Posted 31 December 2012 - 02:34 PM

My first Stock Car

2 rails .055

4.5 wb

1inch Guide lead

Duffy motor Bracket

Team R-Geo

#1235

Posted 31 December 2012 - 03:58 PM

I got a couple of these in development right now, & we were nervous about whether 2 - .055" rails would be too flexy for a stocker: I chickened out (like the one above). If I am lucky, I'll be over one of these Wednesdays & we can compare.

Duf

- Joe Mig likes this

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#1236

Posted 31 December 2012 - 04:27 PM

Team R-Geo

#1237

Posted 31 December 2012 - 09:47 PM

Love the look on that stocker

Paul

#1238

Posted 01 January 2013 - 12:24 AM

not too much. I'll have it set up next week for testing.How much movement are in those pans?

Love the look on that stocker

Paul

Team R-Geo

#1239

Posted 01 January 2013 - 04:54 PM

Im crazy I know...

Flex Frames #20

.078 main rals

torsion style movement

I know torsion is a little out dated.. but i never built one, and it only took me 45 minutes.. so why not.

I ran out of pin tubing, so that will be added once i get more.

Team R-Geo

#1240

Posted 01 January 2013 - 05:57 PM

Is that motor bracket upside-down?

- Joe Mig likes this

#1241

Posted 01 January 2013 - 07:07 PM

![]() Looks like it to me too!!! Preston did you build that with a motor in it? I spend 45 minutes blueprinting the bracket!!

Looks like it to me too!!! Preston did you build that with a motor in it? I spend 45 minutes blueprinting the bracket!!

Mike Katz

Scratchbuilts forever!!

#1242

Posted 01 January 2013 - 07:21 PM

Must be a "speed trick" that we dont know about. LOL

Is that motor bracket designed to run rails through?

J. P. Milcherska

Keep it in the slot!!!

#1243

Posted 01 January 2013 - 07:33 PM

I know torsion is a little out dated..

Hmm. I can think of a half-dozen guys you oughta break that news to!

Part of the problem is, what we do here isn't really "Torsion" per se. It's one way of allowing movement in the overall mass of our sled, while limiting the extent of that movement. "Torsion" is a tool in the box, with its limits as well as potentials.

-And similarly you could claim everything since Newton "outdated" - or not, by definition.

I spend 45 minutes blueprinting the bracket!!

I wanna get you to critique a couple of mine, next chance we get.

Duf

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#1244

Posted 01 January 2013 - 07:38 PM

![]() You're on Mr. Duff!!!

You're on Mr. Duff!!!

Mike Katz

Scratchbuilts forever!!

#1245

Posted 01 January 2013 - 09:44 PM

Team R-Geo

#1246

Posted 01 January 2013 - 09:48 PM

This is an update of a chassis I posted in #138, Oct '09. REH bracket, Slick 7 guide holder. Center section still has 2 .062 hollow brass tube rails with a .055 piano wire center rail & spacers, but had to rebuild the pans since the original build was 3.125 wide & I was informed at its first race by Chris Barnes, in late 2010, that it had to be 3" even. Front axle tube has a piece of .047 piano wire soldered to the bottom to strengthen the tube. However I think it instead it warped it, 'cause there is some binding in the tube; may have to change this...

After much contemplation & lots of laps, I finally removed the original plumber assembly & went to a solid plumber with floppys with floating body mounts. Pans are .062 x .25 solid inner & .1 x .2 hollow for less sprung weight; also about .08 fore & aft movement. First running revealed the pans had a tendency to pop out of the pan up stop. So I added a piece of ultra skinny wire to stop this but still allow a little flop action. Consequently flop is all but eliminated but there is some slider action... the pans still have some capacity for independent movement. I haven't been able to track test this but it will be interesting. Also the floating body mounts make the body very loosey goosey: possible modification to eliminate much of the side slop in them. This is a work in progress that will be race tested soon. I don't build real purdy like most of you all do, I just want something that slides thru the corners well, & this one always has.

8/3/53-4/11/21

Requiescat in Pace

#1247

Posted 02 January 2013 - 12:52 AM

If have learned one thing, it is that once a car works well don't touch it. Build another one with the ideas floating around In your head. This way your program will evolve and come race day you have a few options to use. One car may like the track better on a certain day, the other a different day. Plus, the more you build the more you learn, and the cleaner your builds become.

Regarding the pan movement you have described... I have been experimenting with pans that have virtually no movement... The concept works extremely well on smooth tracks.

- Jocke P likes this

Team R-Geo

#1248

Posted 02 January 2013 - 05:36 AM

"It's like how we get a freight train moving, but in reverse. A locomotive can't move all that tonnage at once, but it gets the first car going a little, which yanks the third, then the mass of those already in motion will help pull the next, and so on.

"It happens backward in our car, when it hits a side load like a corner: try to make the whole thing move at once and the guide will pop out - but get the center section moving a little and let that pull the pans...it's delaying the side load and spreading it out, stretching the time the chassis gets to react to the change.

"Now, the trick is, that motion has to be finished by the time the car no longer needs it, like when you're punching out of the corner - or even still in there, once the car's settled into its dynamics; otherwise the moving mass is gonna start pulling back against the whole, just when you want things to settle down. That's the limit of too much movement, and that's also why you need less on smoother tracks; but it's never really all gone, even in a locked-down flat plate, it's just less."

Try applying that to what you see in your chassis.

Duf

- glueside and Jocke P like this

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#1249

Posted 06 January 2013 - 01:03 PM

Just a footnote, after taking a lot of the slop in the floating body mounts, I raced this chassis last nite & took 3rd place in our 7 second breakout class. I have never finished that high in that class using a parma 501& turboflex due to excessive sub 7 second laps. My first podium finish at this track (Slot-car Cave's Dadds 220 Engleman) & with 11 entrants I was happy. The chassis was MUCH improved after the rebuild with minimal pan movement; no de-slots till the third heat with great cornering & speed ![]()

![]() . BTW body was O/S '68 Charger.

. BTW body was O/S '68 Charger.

- Jocke P likes this

8/3/53-4/11/21

Requiescat in Pace

#1250

Posted 07 January 2013 - 03:10 PM

Duf,

That was the best explanation of effective pan motion that I have ever read!

You said things that I thought I understood really well when I used to build plumbered hinged bat pan HO scratchbuilts when I was a teenager (the "glory" days of can motor HOPRA "gravity" racing in the early 70's) but was never able to express.

Now that I am a trained and experienced mechanical engineer with a specializing in Multi-Body Dynamics, my description sounds too technical for anyone but another engineer to understand - and he/she wouldn't understand why one would want to race slot cars in the first place!

The motion of the train starting to move is an inflection - an instantaneous change in motion or direction and even Newton knew that just can't happen! It requires a series of impacts that must happen in a series of events in order to get even a small mass moving. If the train cars were "taut" (like on a hill with tension or compression in all the cars), then it would be immensely tougher for the locomotive to get the whole thing moving at once - well, the physics will tell you it's impossible, that you still need some kind of sequential "slop" to make it happen!

The inflections are the instantaneous change in curvature from a straight to a radius - these don't occur in nature because nothing can go from infinite to finite curvature in an instant! Slot car tracks force us to deal with this because of the way they are made.

You are right in that you must get the timing of these motions right - we knew that in HO (back in the day) and the motions had to be profound in the days of clickety-clack tracks - it made a huge difference! Now, with the very smooth "routed" HO tracks, more subtle motions work better - but you still need some!

I think 1/24 Retro racing appeals to me because, if you get that design right (for that track), it is only a matter of tuning the tires for the conditions of the day.

I've noted that the cars that run the best are chassis that make the whole lap a "fluid" motion, not a series of straights and turns. It's the cars that can change directions quickly and not upset the chassis (while entering or exiting the turn) to the point where it lifts, rolls or the tail pulls the car out. It's an intangible thing but you know it when you see it and when you drive it!

It's like a railroad train starting to move - brilliant! - genius! That's exactly it! Well stated!

Keep it in the slot,

AJ

- ejgehrken and Jocke P like this

Sorry about the nerf. "Sorry? Sorry? There's no apologizing in slot car racing!"

Besides, where would I even begin? I should probably start with my wife ...

"I don't often get very many "fast laps" but I very often get many laps quickly." ™

The only thing I know about slot cars is if I had a good time when I leave the building! I can count the times I didn't on one two three hands!

Former Home Track - Slot Car Speedway and Hobbies, Longmont, CO (now at Duffy's Raceway), Noteworthy for the 155' Hillclimb track featuring the THUNDER-DONUT - "Two men enter; one man leaves!"