Yes, you are reducing the heat transfer between the brushes and hoods, to the aluminum endbell.

OK, that at least makes sense. At least at this stage, it seems to prove that the issue here is the point of attachment...the screws.

You can not count on anodizing in the threaded holes to act as an insulator.

Yep, I saw where you had posted that before Mike, so even though I was concerned, I blasted ahead anyway...and failed!

At Koford, the drilling and tapping was done after hard coating.

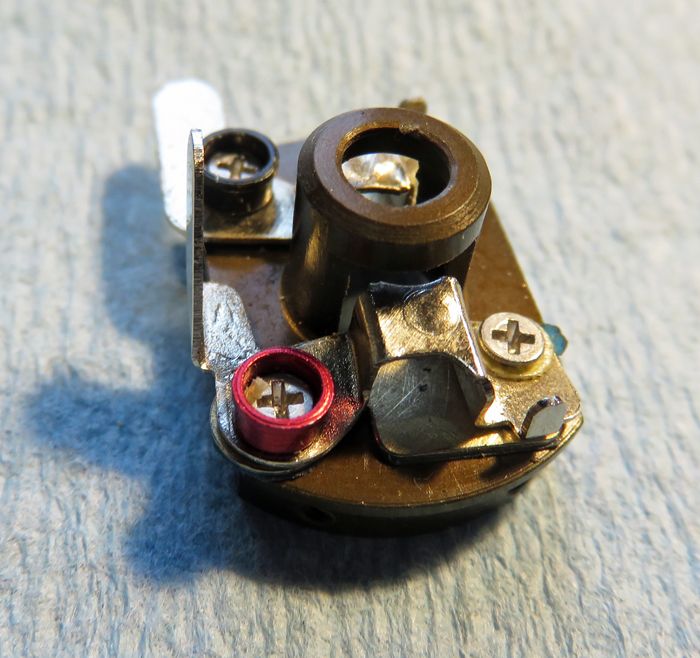

More proof that the tapped screw holes losing their anodizing (these seemed to have been anodized after drilling and tapping, as the red color was in the screw holes) shouldn't be a problem.

Maybe it's time to post some good pictures.

That would be nice, as well as a step-by-step guide to assembling this hardware. I mean... it's not like I haven't tried to do the same thing here... hundreds of times. ![]()