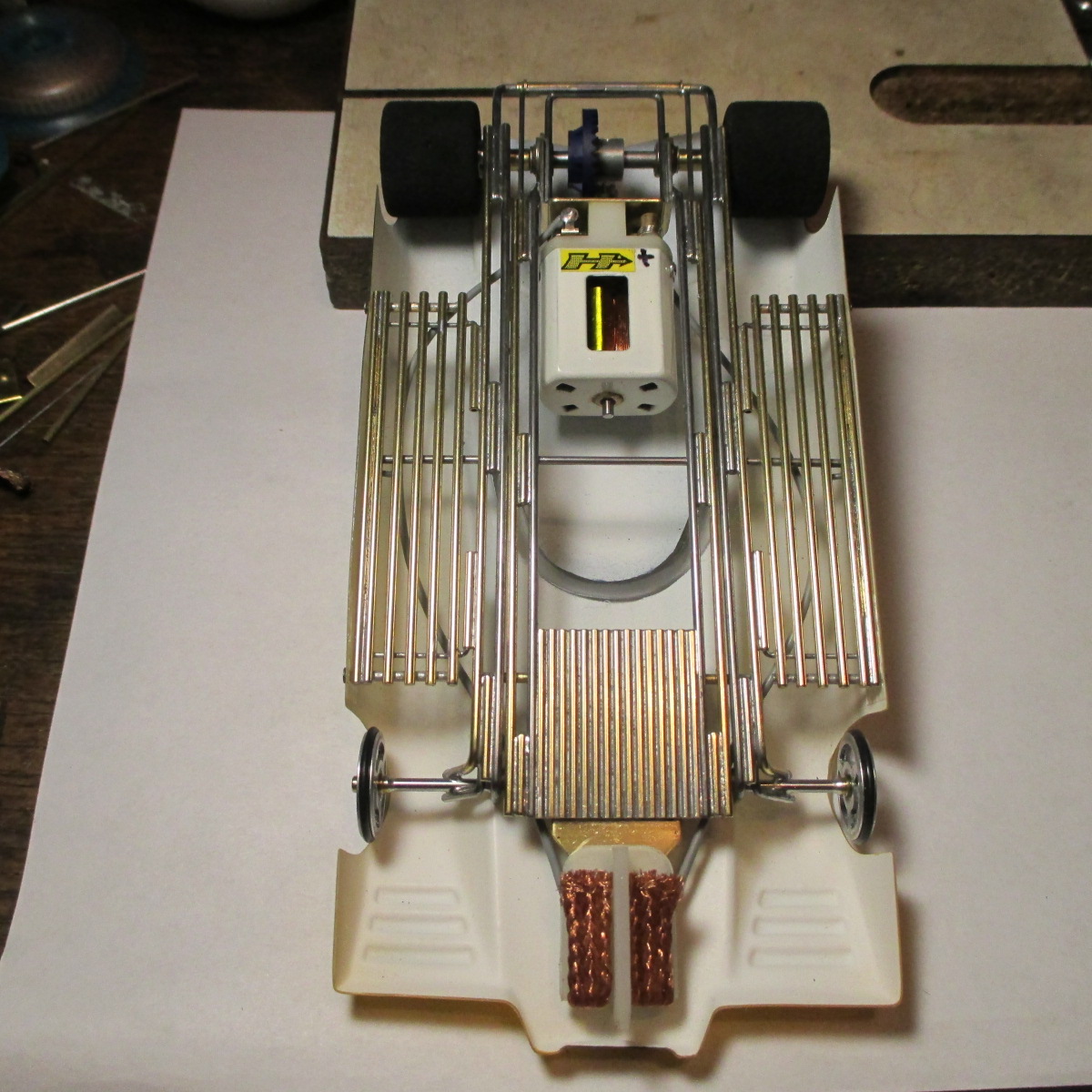

John, not if you have a lathe.

Thin pieces stacked to make a rotating mass introduces harmonic vibrations.

If a lathe is available, it would be easier to open up some undersized tubing to a "proud" .078" ID. The "stacked pieces thing" is more of a *potential* issue with an armature than a "geared-down" axle spinning far slower, and even less so with a vintage car where the axle isn't spinning all that fast. Then too...it's far less likely even still to be any kind of issue with fronts! Pablo's solution (*arm spacers) is the best practical one!