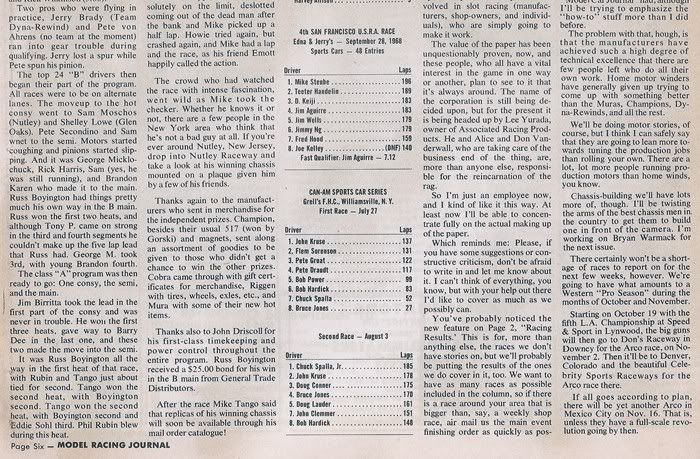

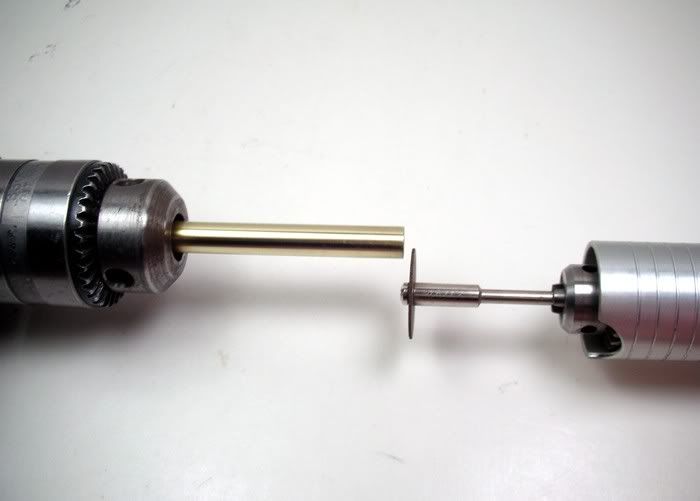

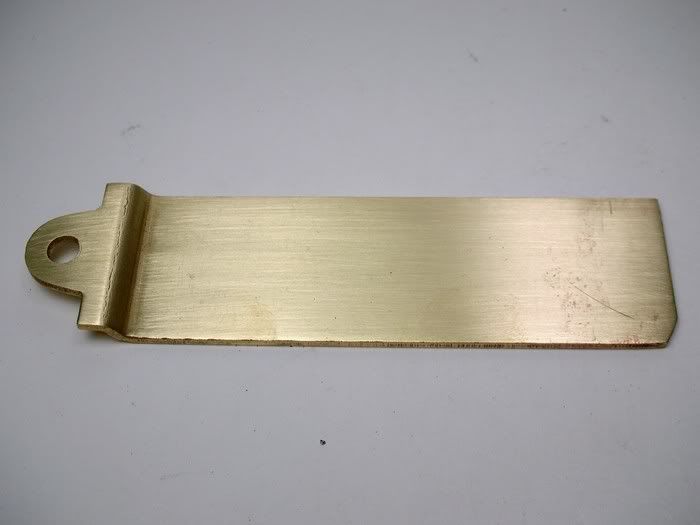

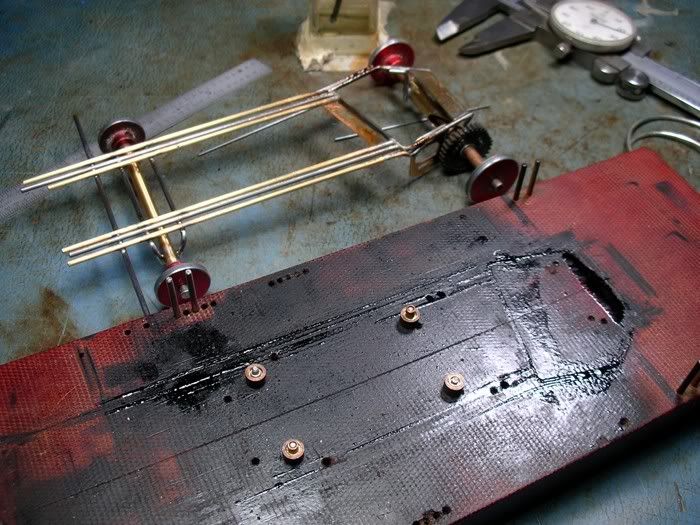

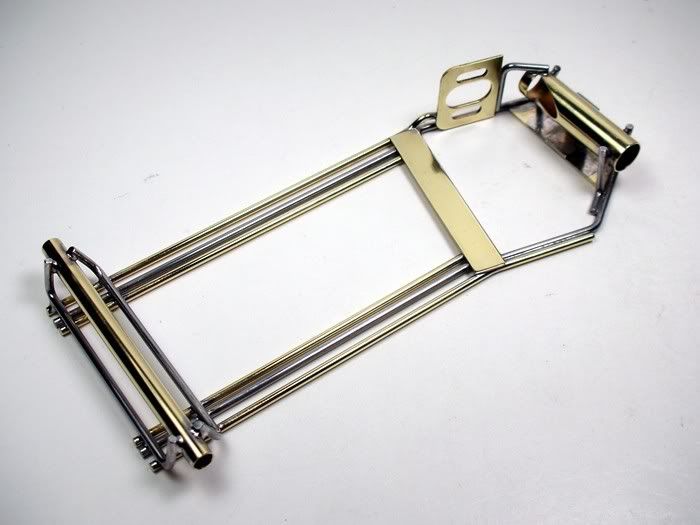

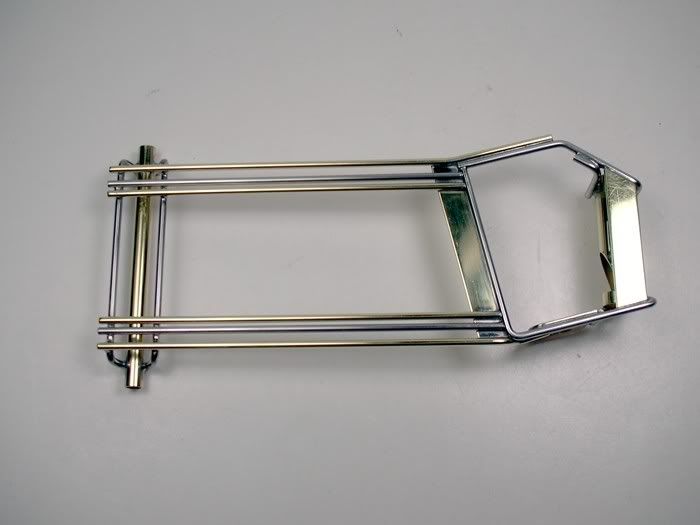

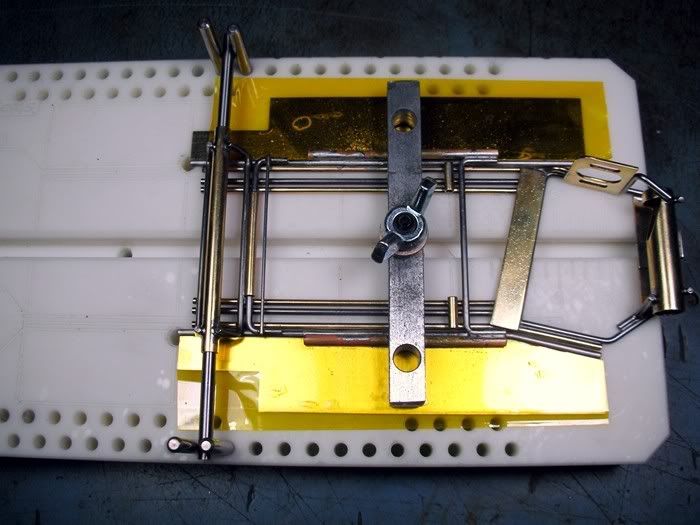

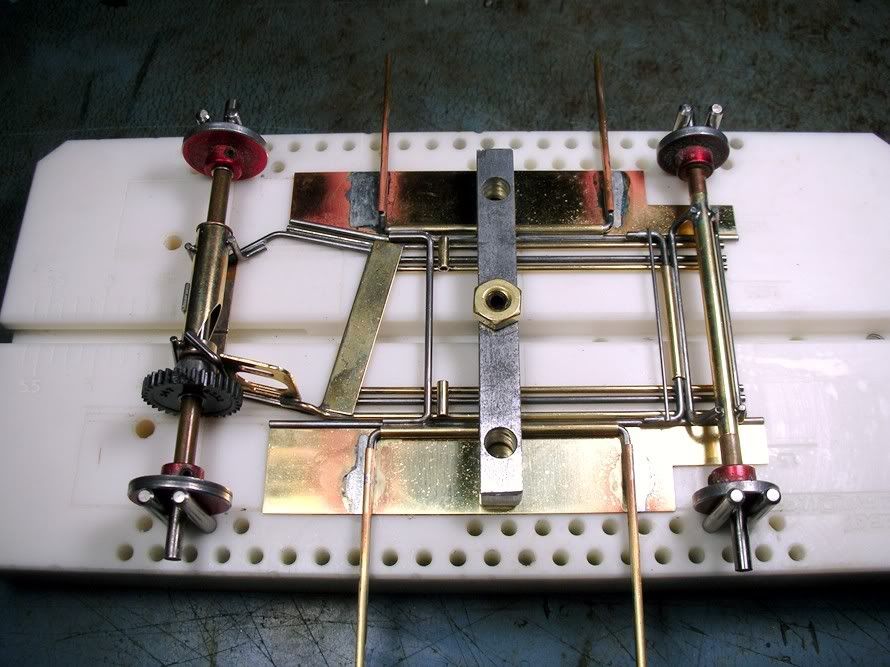

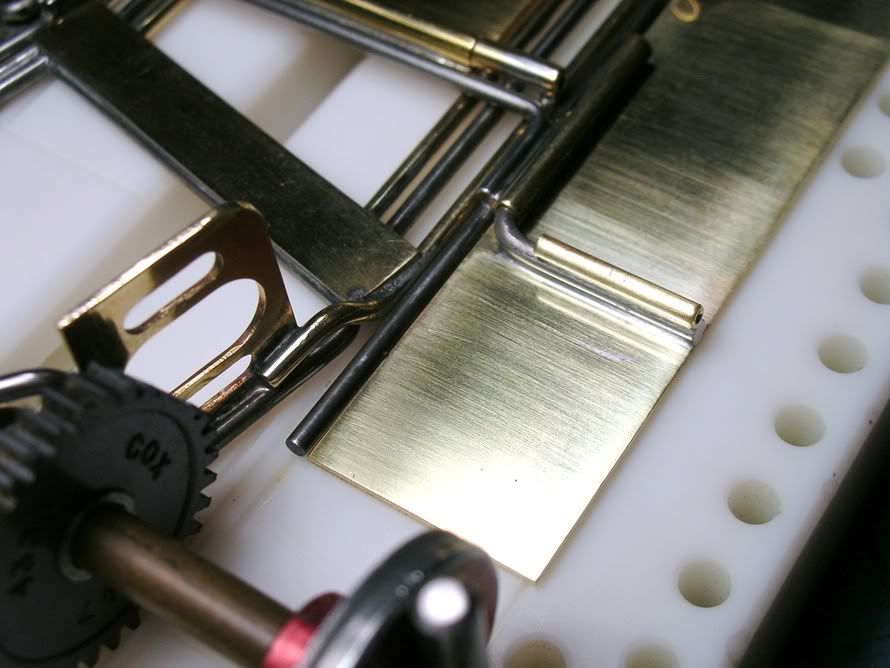

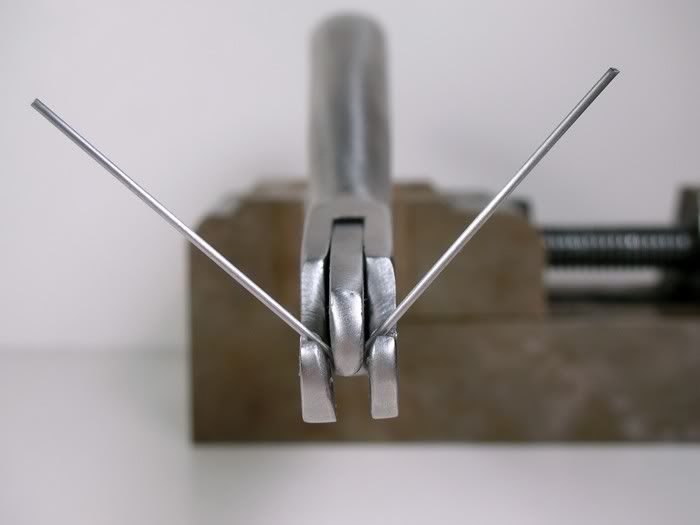

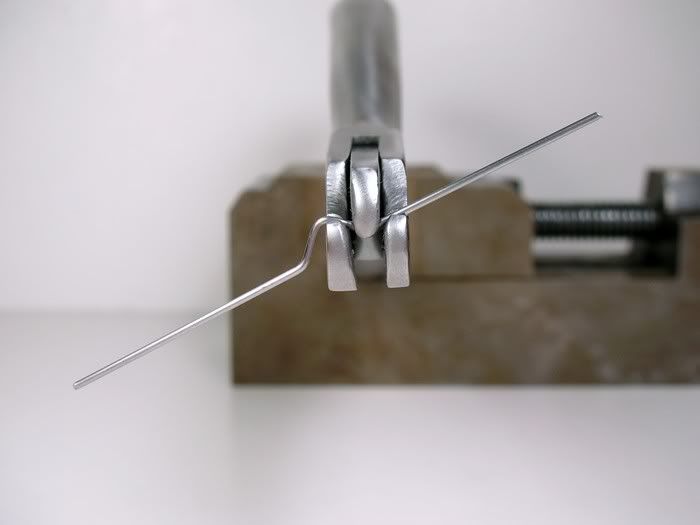

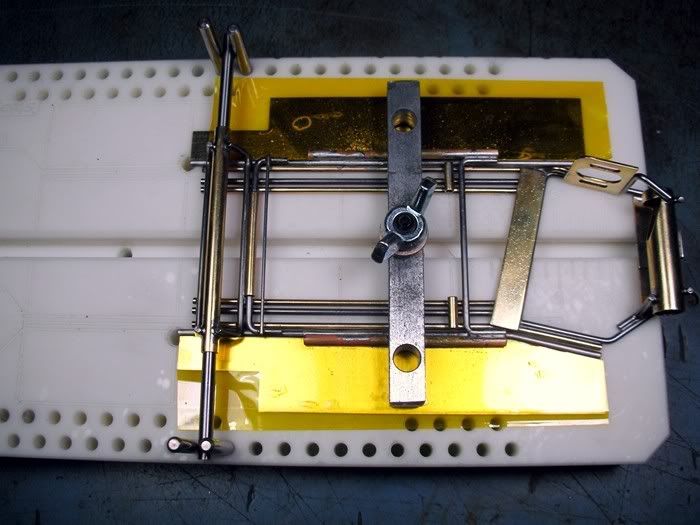

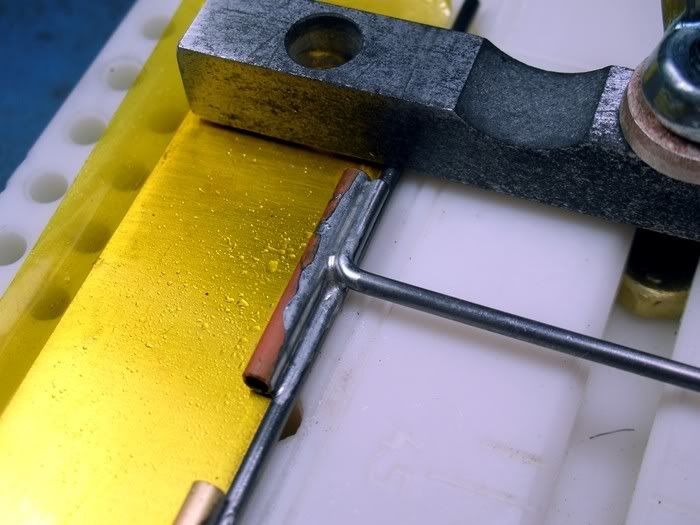

I'm trying out my new Rick's chassis jig. I need to clamp the chassis center section and plumber rails down flat against the block. Then slide the pans against the plumber rails and set the pan hinge tubes ON TOP of the pans. I'm using Rick's guide tongue stud and wing nut and a 5/16" wide clamp I made. The clamp also sets the space between the tubes (notice the funny transparent amber colored tape on the pans

more on that later ):

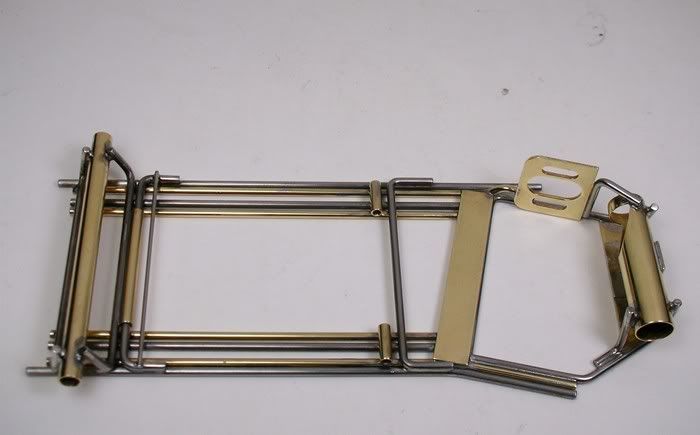

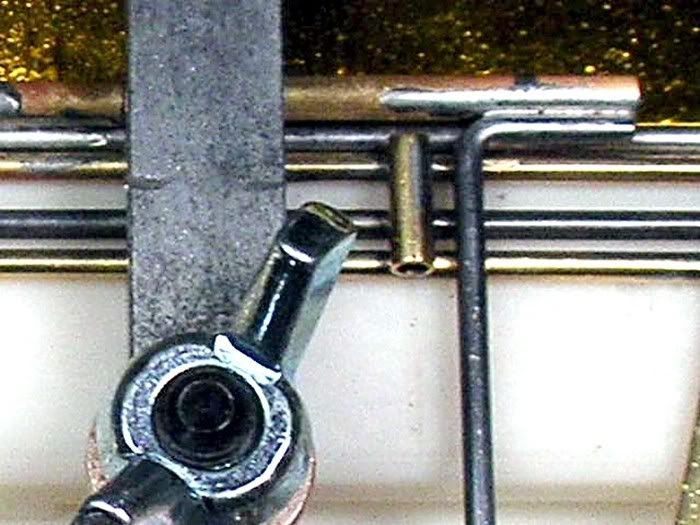

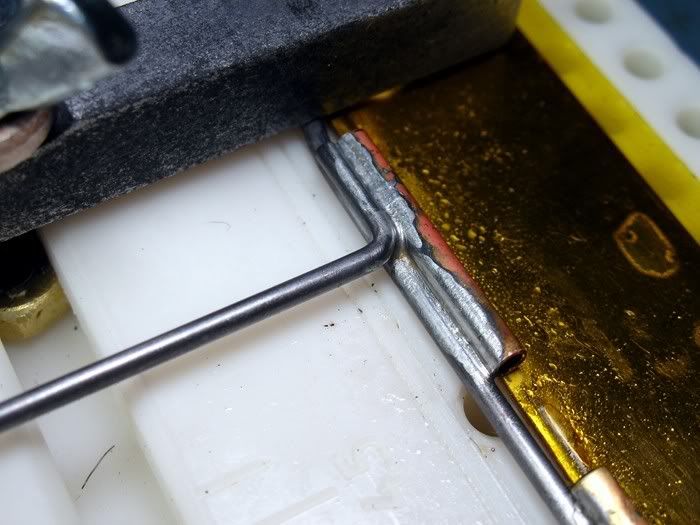

I couldn't get the tip of the iron between the clamp and drop arm pivot tubes so I just soldered the pan tubes to the plumber cross piece for now:

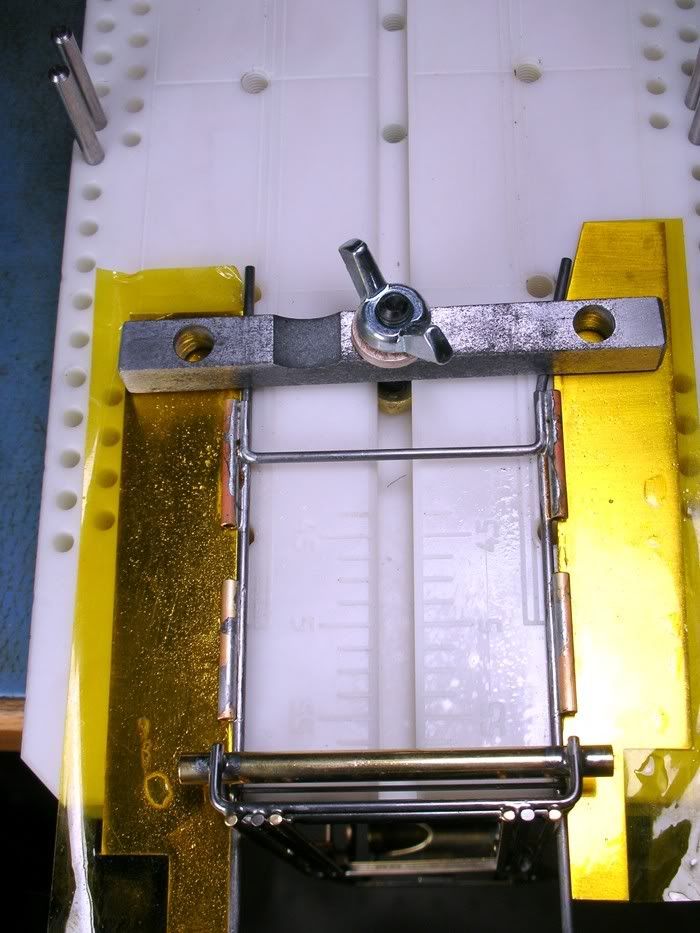

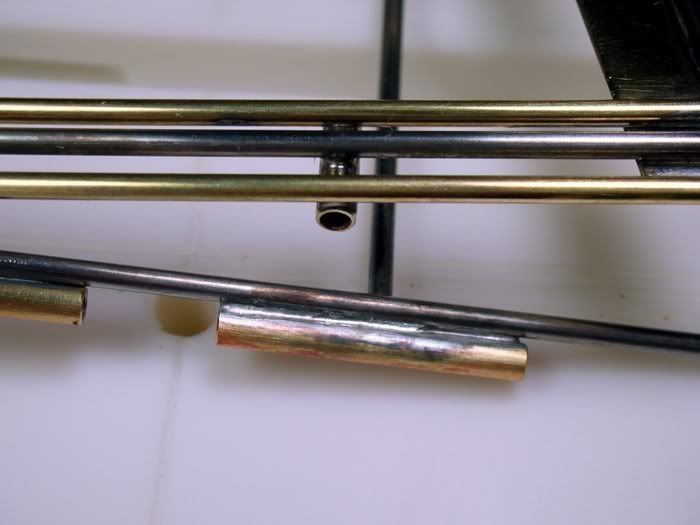

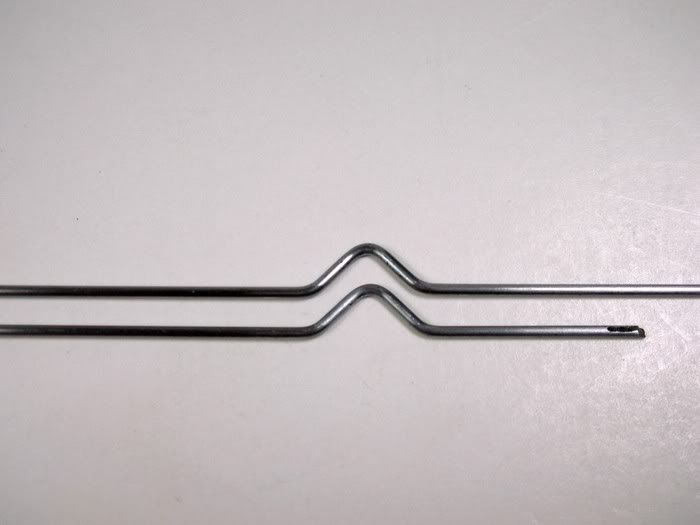

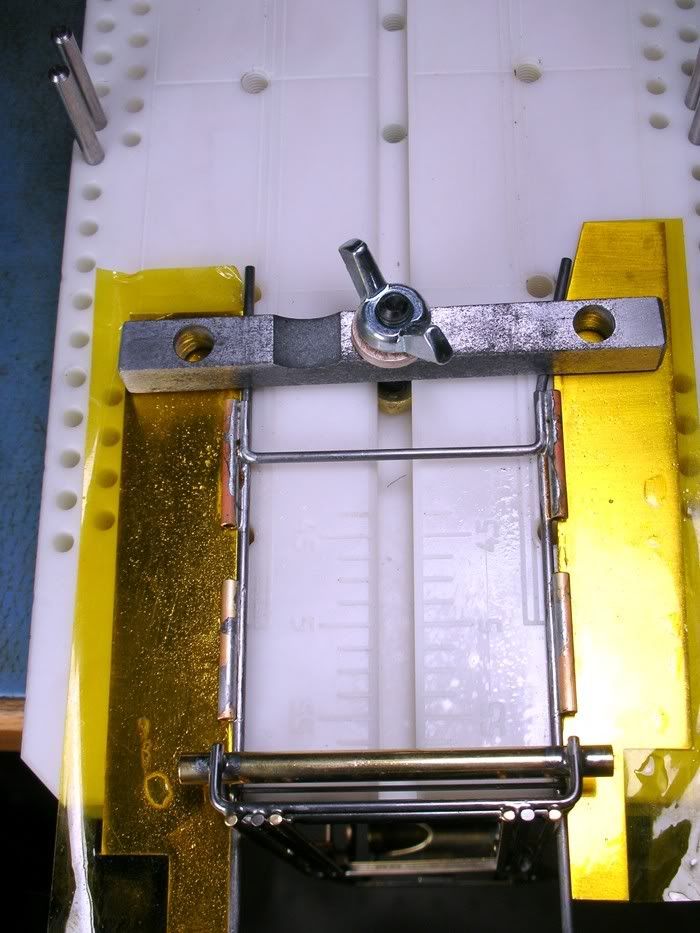

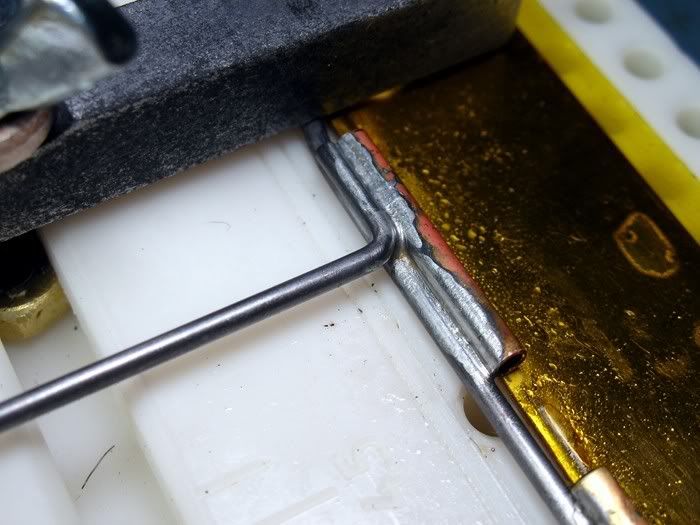

To solder the rest of the pan tube I clamped the plumber rails only and let center section hang down off the end of the bench (This new jig is coming in handy

).

I used Mike Steube's technique of soldering the tube in halves, watching the color of the solder so that it didn't melt the full length of the joint. It worked great. THANKS MIKE!

( You do have Mike's chassis building video right?)

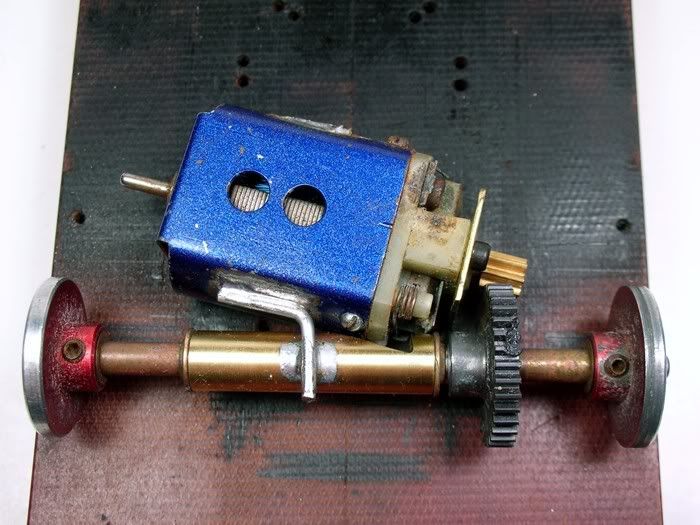

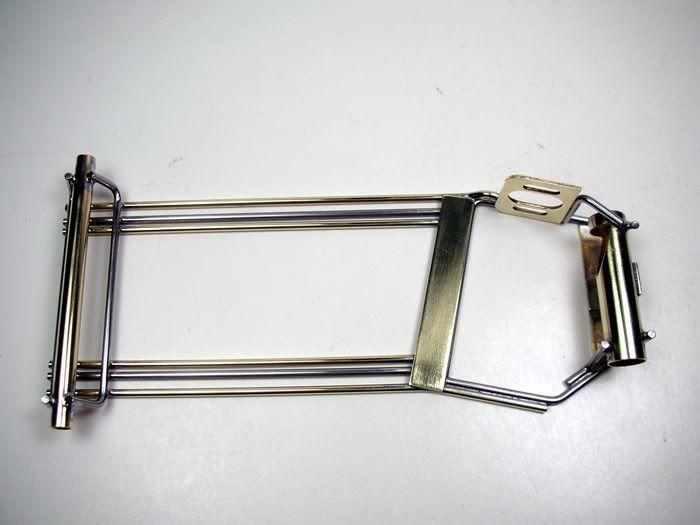

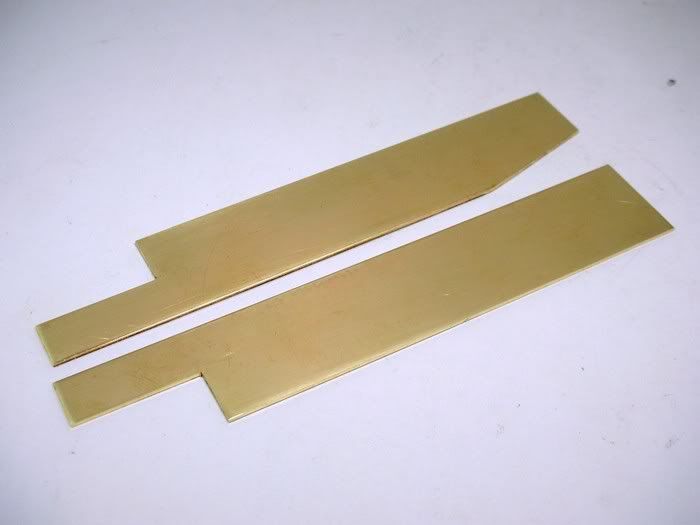

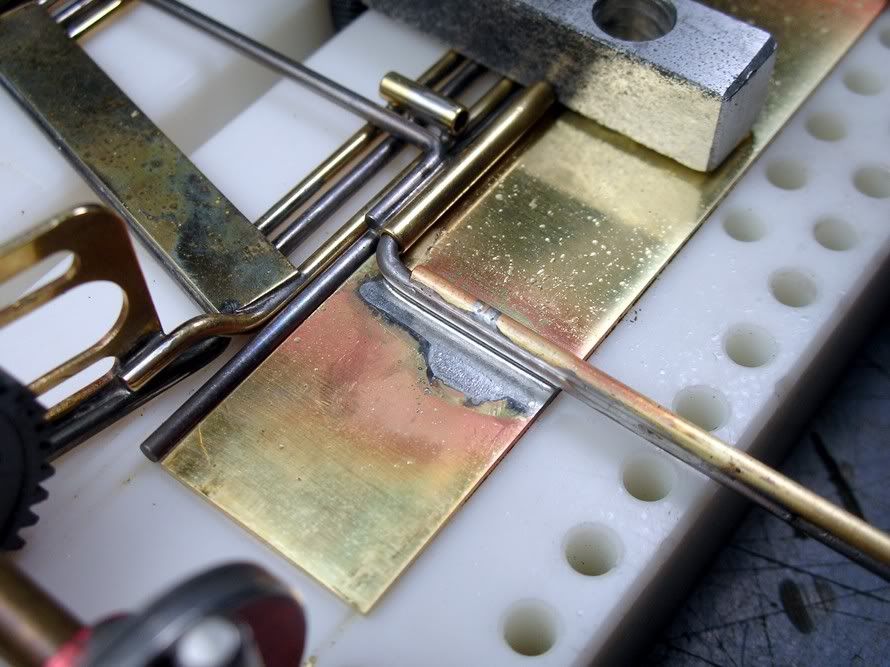

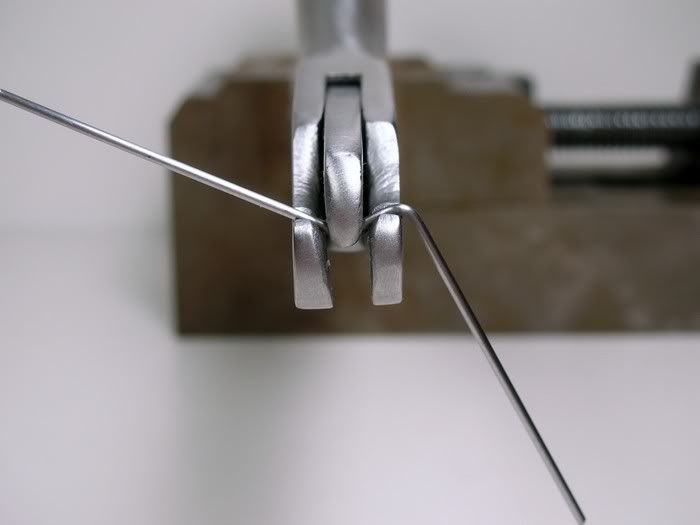

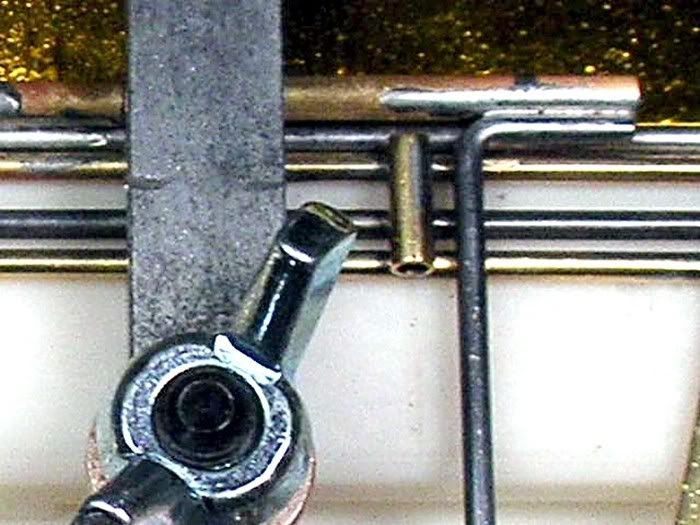

The pans do not have a cut out for the hinge tubes, they sit on top of the pans. The first time I soldered the pan tubes onto the plumber rails some solder wicked down and also soldered the tubes onto the pans

. I hate it when that happens

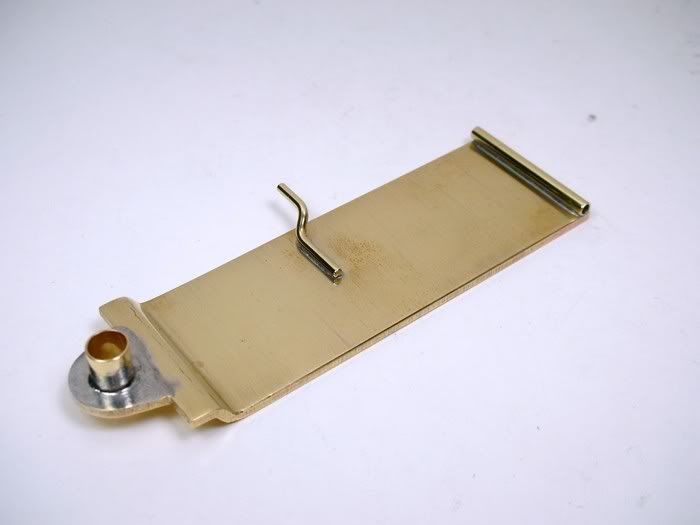

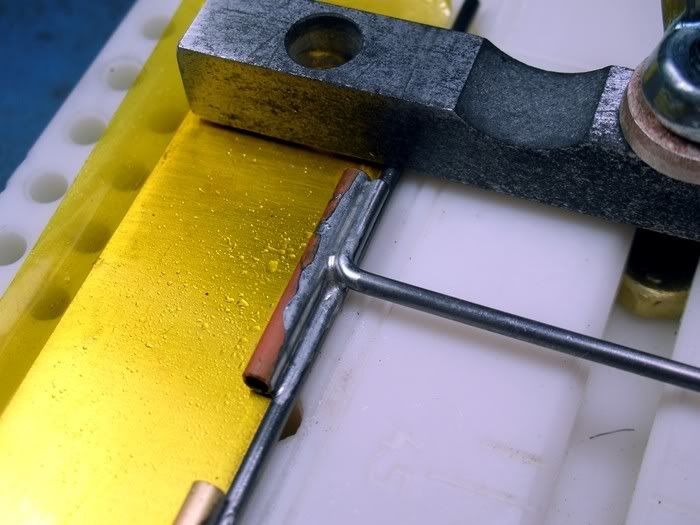

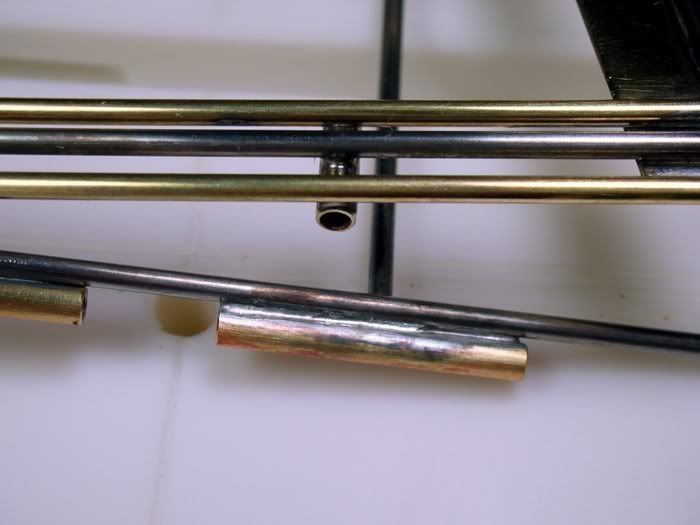

. Now for the funny colored tape. It goes by a trade name of Kapton and is very high temperature and very thin. You can Google Kapton and find out were to get it cheapest. It is somewhat expensive but I think the one roll I bought should last the rest of my life. Here is a link to one source:

Kapton TapeHere is the bottom of the pan hinge tube. See where the solder wicked down? It would have soldered the tube to the pan again for sure. The Kapton tape didn't even have any marks in it from the heat of soldering

:

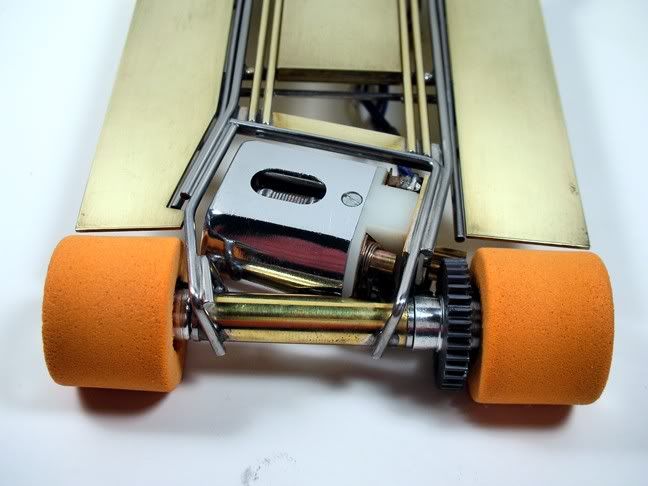

Time to spiff up the collateral damage with some sanding and polishing