Very nice Geary! A lot of folks mention wanting to get into this, but very few actually do! Just some things to consider (I know I'm probably repeating myself)

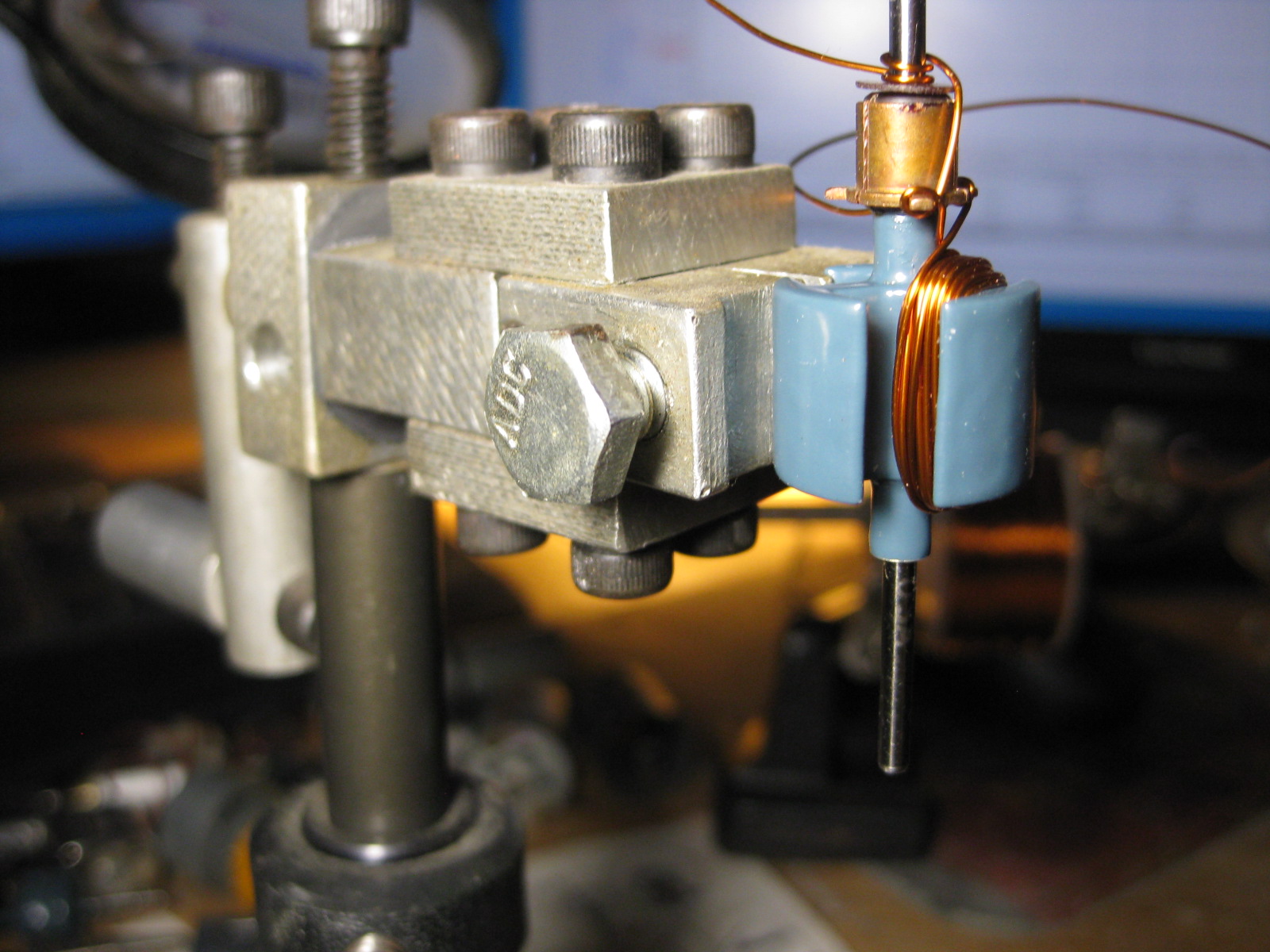

1)The first, and to a lesser degree the second, layers will greatly determine how the whole coil comes out. Use a good amount of tension on the wire as you make each turn...more on the bottom layers and a little less as you get near the top to avoid the coil collapsing. Tension is as important as anything.

2)Don't be afraid to waste wire. Getting a handle on how to wind up with the number of turns you want...how to "pattern" the wind is important. Once you figure out a pattern, write notes and try to duplicate that on the two subsequent poles. In other words, "10 turns/first layer, one turn behind" would mean, when you come back on top of the first layer towards the shaft/com, go one turn PAST where you started. BTW, that one turn past the starting turn is how you can help strengthen the first layer's turns and help to keep them from spreading apart because of pressure from the layers above.

3)Try to be aware of how far "out" from the poles (how "fat") your coils are. With some laminations like the Mabuchis, and even more so the old Mura .007 lams, you can get through the first two poles and have a devil of a time fitting your coil on the third/last pole.

4)In general, "stacking" the coil layers so the winds on top sit "between" the winds below will give you consistent, sturdy and neat poles. While you CAN go past the ends of the winds below back at the shaft end of each layer, try and avoid doing that out by the crown end.

5)Try and work your coil patterns so the number of turns you're going after leaves you back at...or near the shaft/com and not out at the crown.

6)Consistency is actually more important than "beauty". Even if the coils don't "look" gorgeous, having electrically and physically consistent coils will generally produce a better armature than one that looks great, but where there are significant differences between the poles. Some awfully "ugly" armatures run surprisingly well, and some "beauties" run like doody. Good-looking coils MIGHT be a measure of consistency because it can be easier to duplicate a nice coil on the other poles. Good looking coils MIGHT also be more stable physically but, tensioning and how you handle the ends of the coil layers (at the shaft end and the crown end) will make for more solid coils than don't tend to fall apart. Epoxy isn't always enough to prevent the coils from shifting around if you don't go for physically stable coils.

7)The Kirkwood/Champion com you're using is a good one for the big Mabuchis. They're old at this point though, so make sure the com tabs are clean before welding or soldering. Any old corrosion on there may change the conductivity of the tabs and each pole.

***You're doing great!