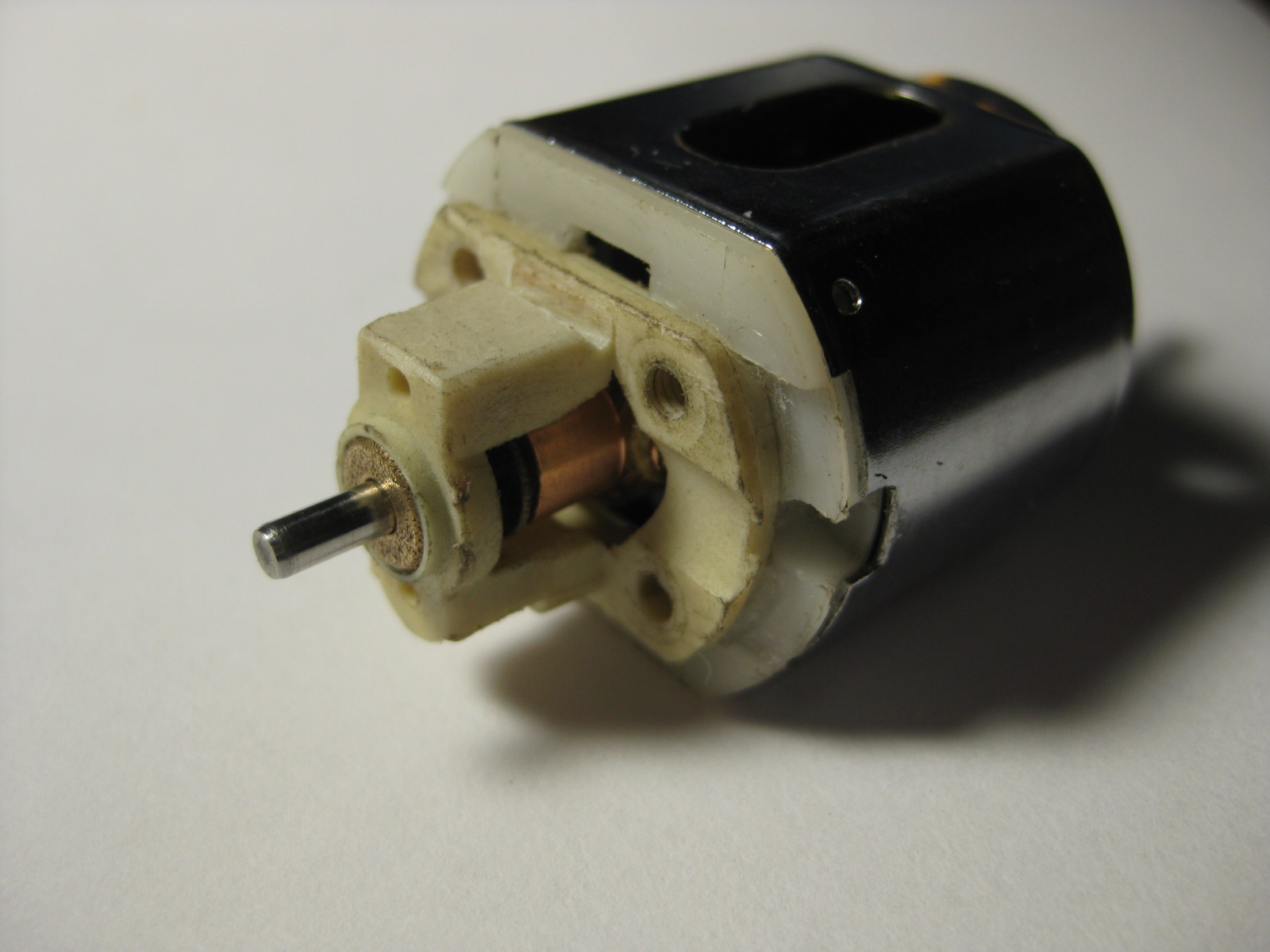

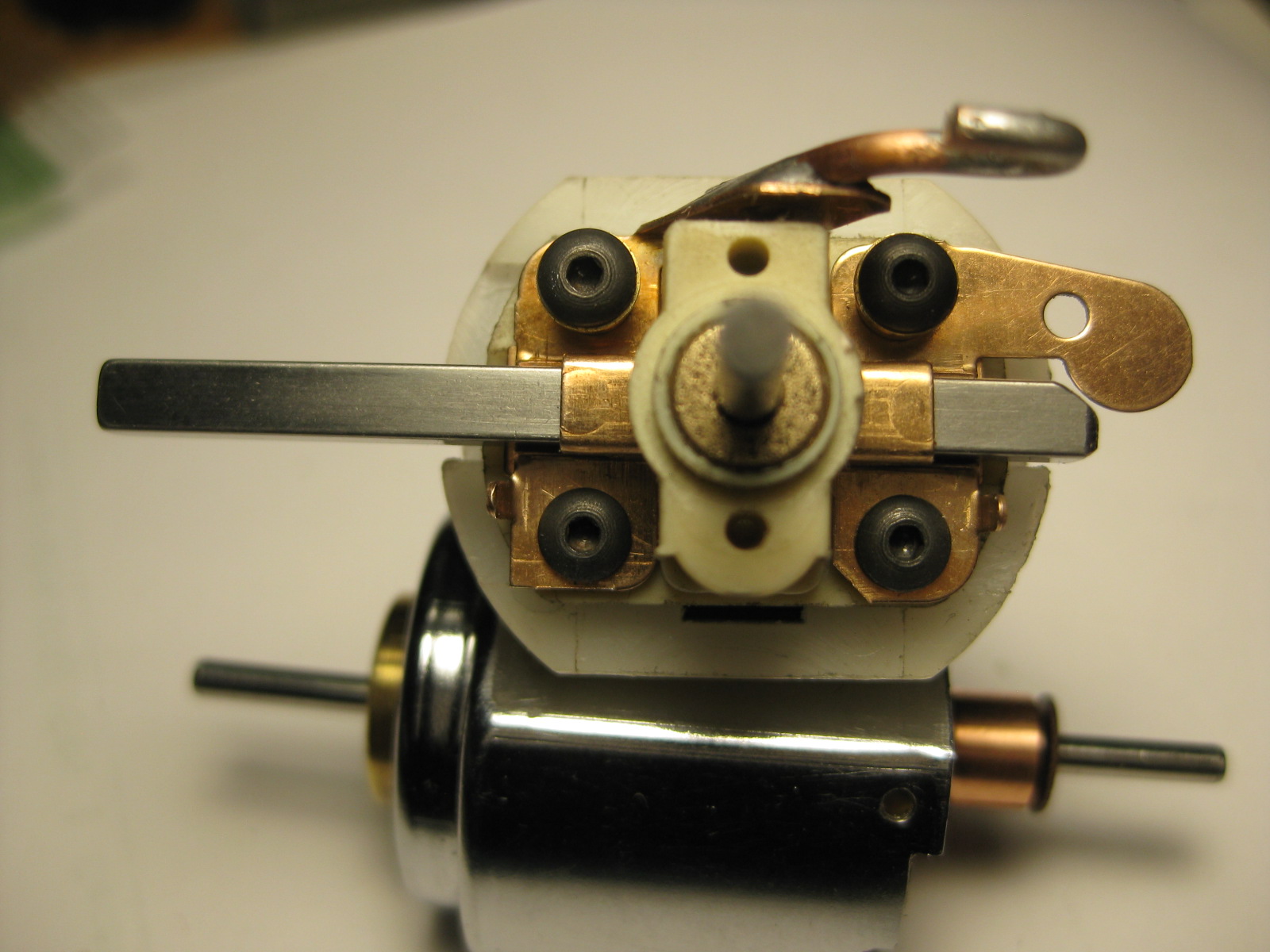

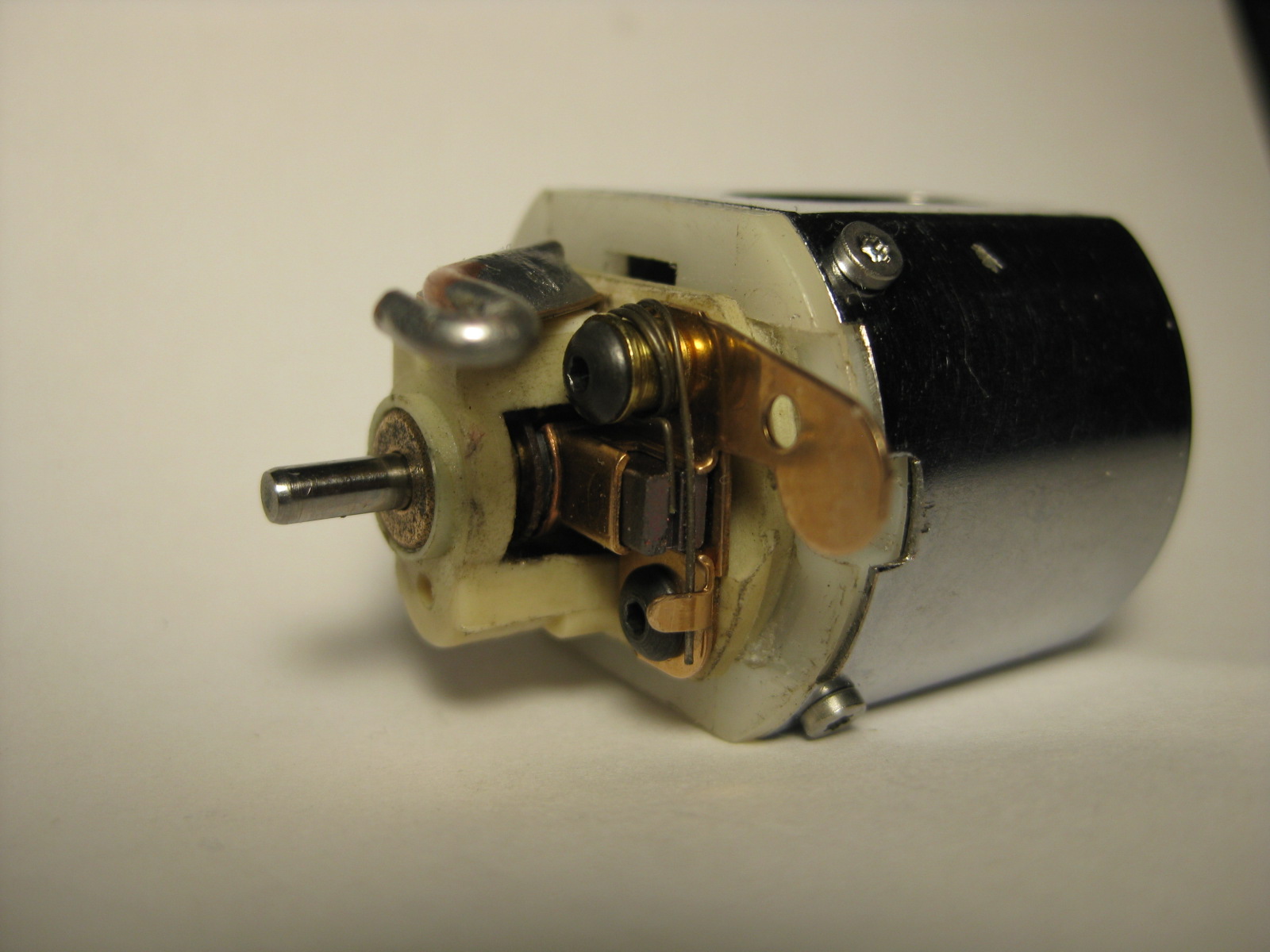

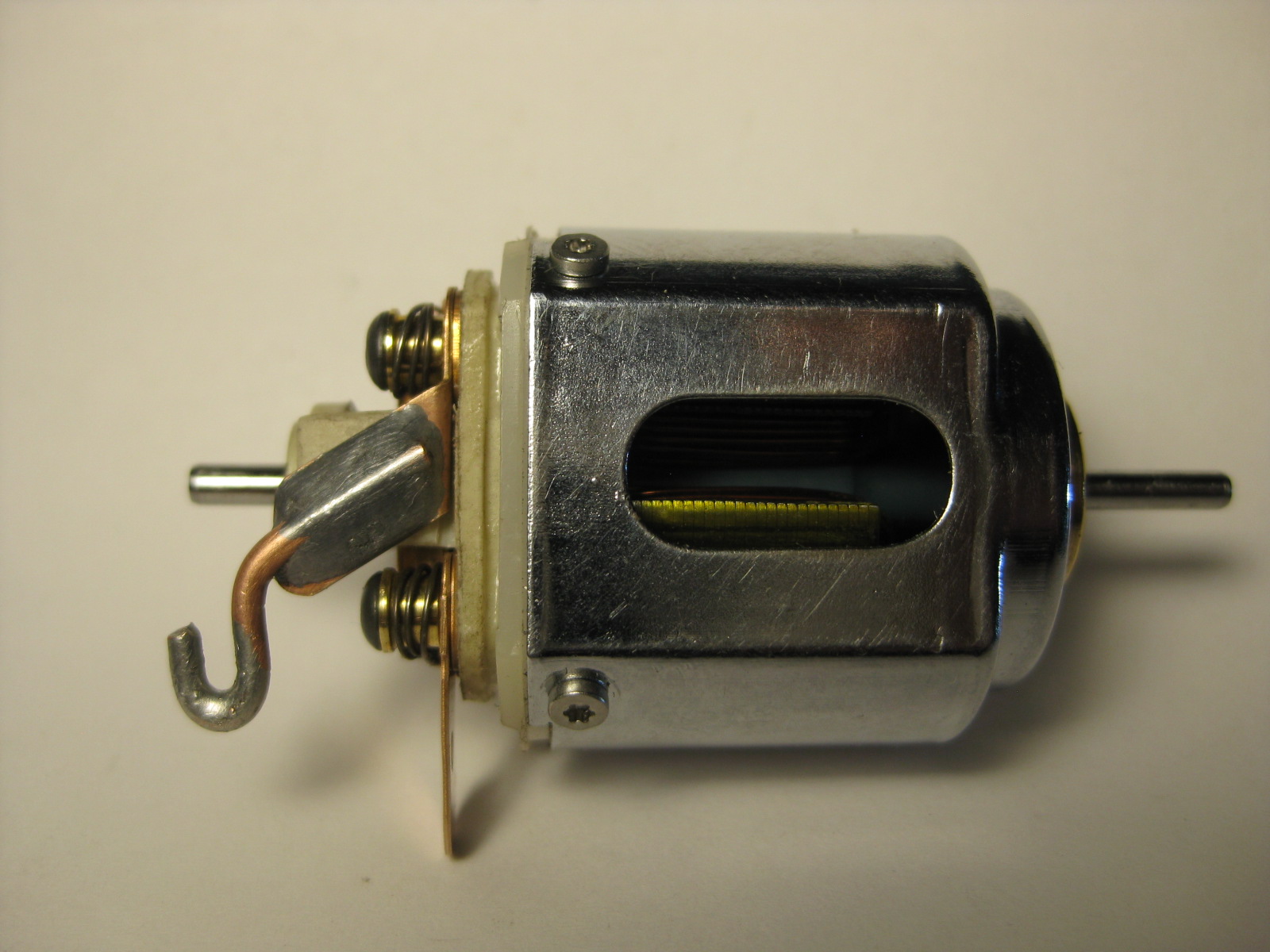

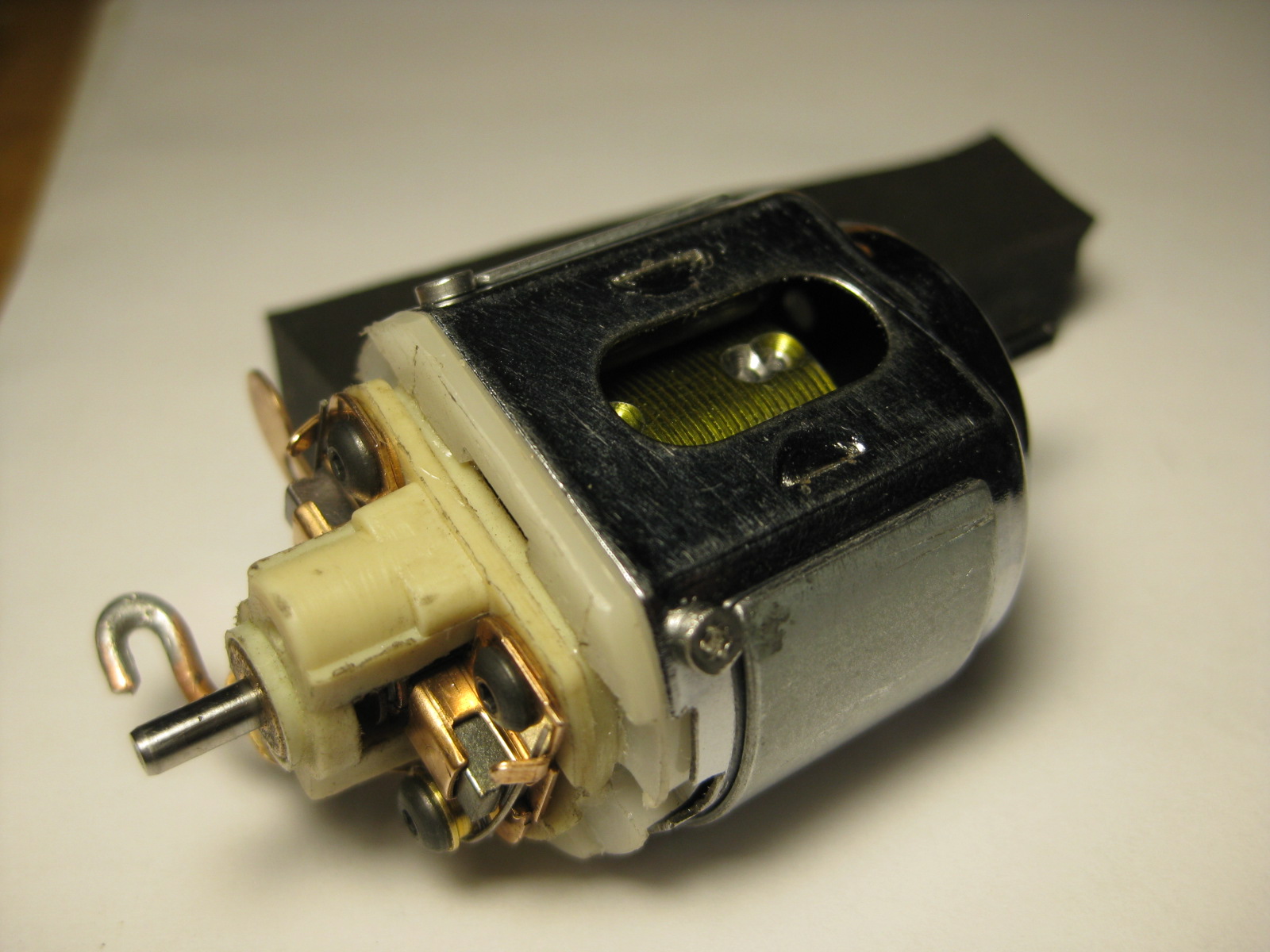

well, for what it's worth regarding melting, that looks like a nice big com, and if you shunt the (good-quality) brushes there shouldn't be too much loss in the current path near the plastic. it seems to me that 22-25 isn't all That steep, and those are pretty long turns to boot- if it were like a 64 with cobalts, I'd start to think about it.

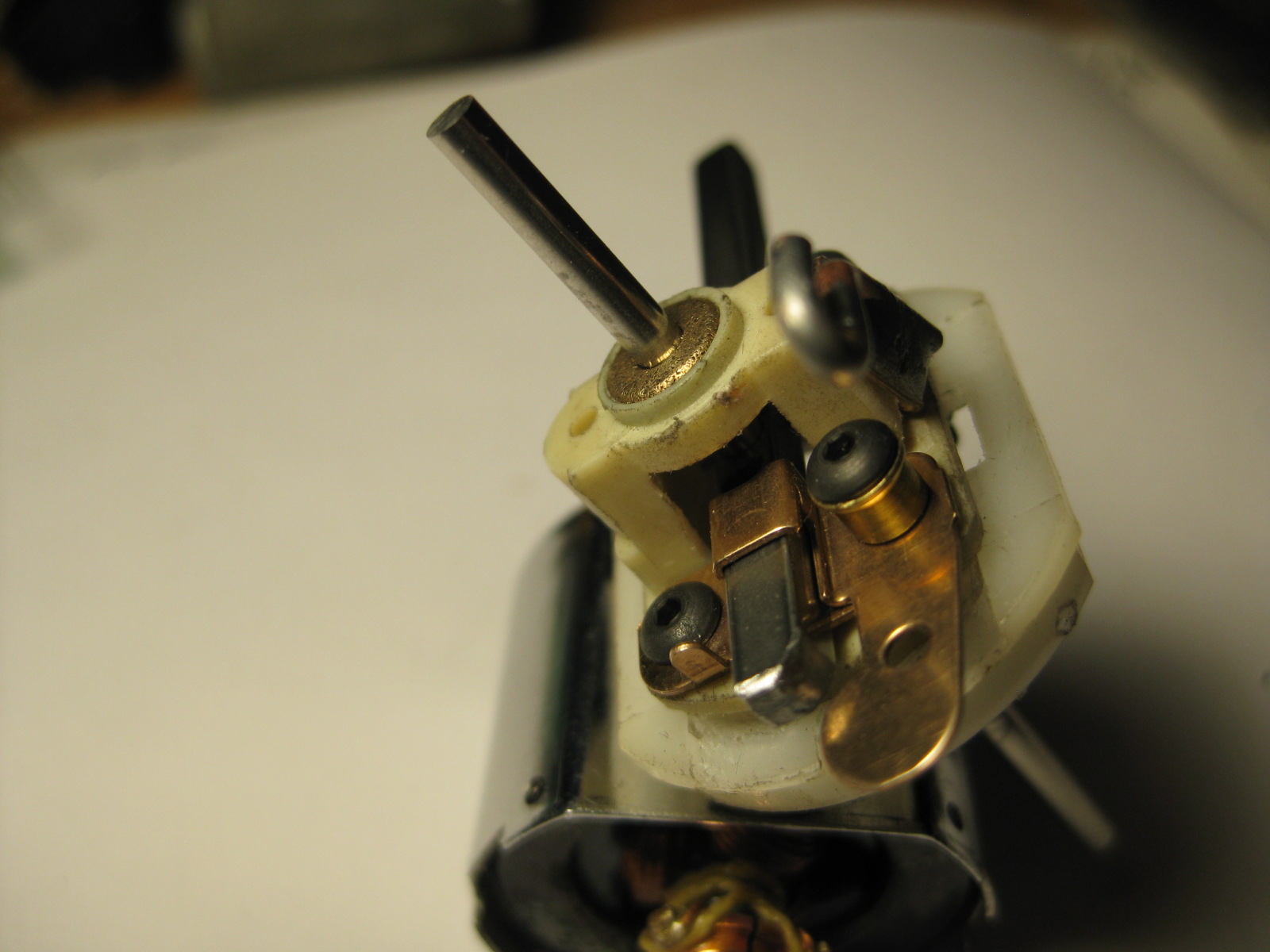

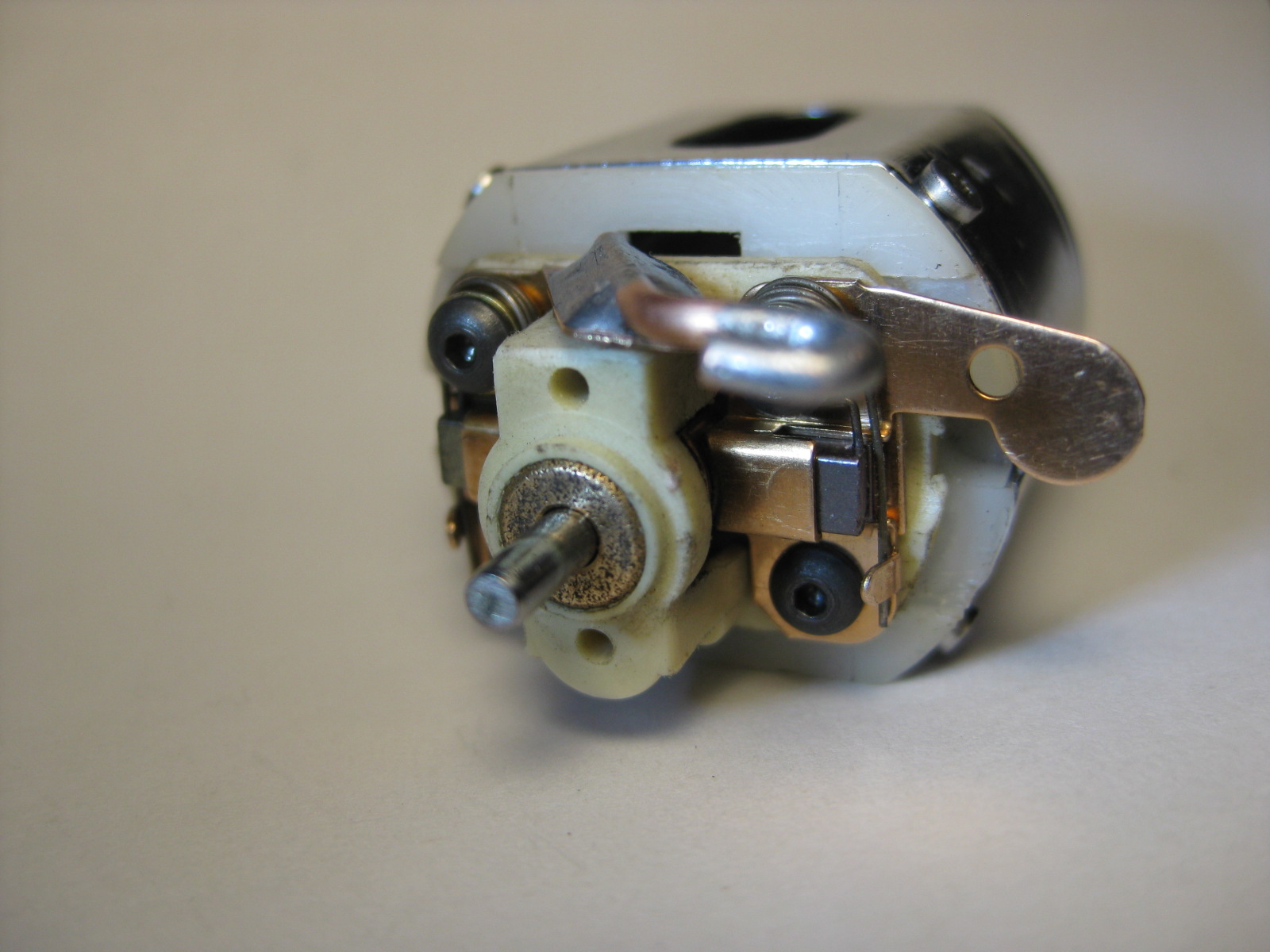

there's also elephant ears if it really gets bad, but it looks pretty darn good to me as is. you've done a very professional job.

I haven't wound any arms since the 60's, but I did get fairly decent at putting together G7 and Euro motors. look for the current to fall off during low-power break-in. I don't see the more experienced motor builders saying "watch out".

you might try putting a smaller pinion on it for its first road test to let it breathe a little. if it gets too hot then (or at break-in), then you gotta problem.

speedy