CNC: Desktop mill

#3

Posted 12 January 2018 - 10:58 AM

So what slot car parts are you going to make on it?

Don

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#4

Posted 12 January 2018 - 11:06 AM

Dennis David

#5

Posted 12 January 2018 - 11:15 AM

How about cut to fit weights to fit in existing plastic frames.

Larry D. Kelley, MA

retired raceway owner... Raceworld/Ramcat Raceways

racing around Chicago-land

Diode/Omni repair specialist

USRA 2023 member # 2322

IRRA,/Sano/R4 veteran, Flat track racer/MFTS

Host 2006 Formula 2000 & ISRA/USA Nats

Great Lakes Slot Car Club (1/32) member

65+ year pin Racing rail/slot cars in America

#6

Posted 12 January 2018 - 11:19 AM

Dennis David

#7

Posted 12 January 2018 - 06:54 PM

Sent from my XT1650 using Tapatalk

Michael Colvin

- Pit dads of the world unite! -

#8

Posted 12 January 2018 - 07:37 PM

The one above which is the Yoda 2.0 from Source Rabbit in Greece. 440mm x 500mm.

Kool Mist

http://www.penntoolc...AiABEgKKivD_BwE

Dennis David

#9

Posted 16 January 2018 - 08:46 PM

World of Clamping

Steel T-slot plate 4030 (400 mm x 300 mm)

https://www.worldofc...oduct&info=1277

https://www.worldofc...oduct&info=1310

- slotbaker likes this

Dennis David

#10

Posted 16 January 2018 - 08:49 PM

- slotbaker and chaparrAL like this

Dennis David

#11

Posted 16 January 2018 - 09:24 PM

- slotbaker likes this

Dennis David

#12

Posted 16 January 2018 - 09:38 PM

- slotbaker and chaparrAL like this

Dennis David

#13

Posted 16 January 2018 - 09:56 PM

Dennis David

#14

Posted 16 January 2018 - 10:51 PM

- slotbaker likes this

Dennis David

#15

Posted 17 January 2018 - 12:33 AM

And the sum of the above is ~ 50% of the basic mill price - I told you so!

EM

5/17/36-1/25/24

Requiescat in Pace

#16

Posted 17 January 2018 - 01:15 AM

Haha, Is this where you say I told you so? Still not all of it has to be bought at once. The purpose for listing these items here is to give people some idea of accessories they may want to purchase.

Dennis David

#17

Posted 17 January 2018 - 02:16 AM

- slotbaker likes this

Dennis David

#20

Posted 20 January 2018 - 02:03 PM

You may have already have this handled: make sure you have more Z-axis travel than you think you need. Some of the tooling above takes a large amount of Z space thereby limiting the spindle travel or spindle tooling. Rarely is there a need to have the spindle within 4" of the table. You can *always* raise the part.

Most people concentrate on the X & Y table travels.

I once had a small CNC mill and its Z travel was very limited. I thought I would machine a 4" spacer to place between the bed and column but having to extend all the servo, power, control wires and modify the sheet metal housing just made the job harder (many of the wires were elecrically/magnetically shielded and made the job not worthwhile).

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

#21

Posted 20 January 2018 - 04:00 PM

Yes i have already come up against this so the Tormach vice is probably out. Luckily most of my work is 1 inch tall or less. i've also been keeping my eye on tool length.I think a part of my initial work will be in creating my own fixtures.

Dennis David

#22

Posted 25 January 2018 - 11:42 PM

What a phenomenal workshop you have Dennis!

Ernie

#23

Posted 27 January 2018 - 11:19 PM

Ernie this is still coming together. ![]() My Mill is still in Greece being built, but I want to give everybody a look as I "gear up". Once I am up and running I will describe all of my work with photos and videos.

My Mill is still in Greece being built, but I want to give everybody a look as I "gear up". Once I am up and running I will describe all of my work with photos and videos.

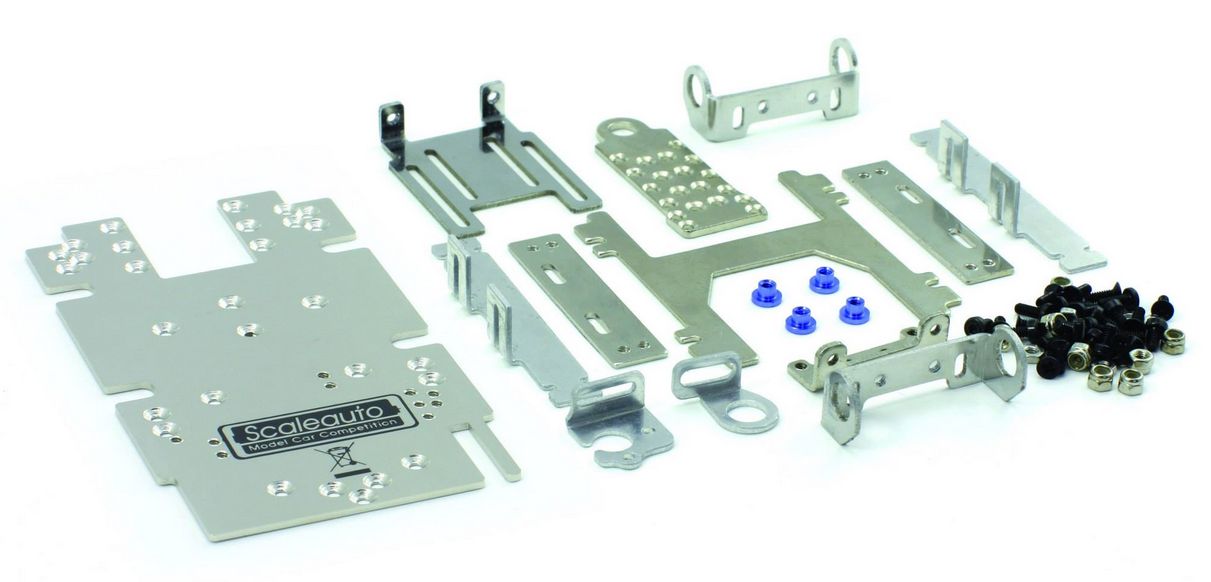

I will be using a combination of Shapeways and my CNC mill to build chassis, etc.

Dennis David

#24

Posted 28 January 2018 - 09:41 AM

Very interesting. I love technology, looking forward to see your works..

#25

Posted 28 January 2018 - 10:48 AM

http://carbide3d.com/nomad/detail/

The table moves along the Y-Axis

Dennis David