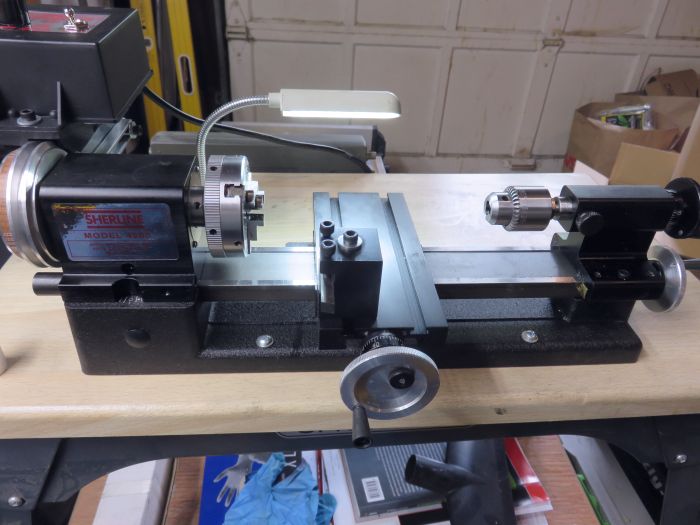

Not much more to say. The Grizzly has served a good purpose, and honestly, if I were only playing with brass and aluminum, I might not have made the jump. It'll still help me by going to flea-market-duty and paying a bit of the Sherline's cost...so there's that!

Sherline #2 lathe is in the house

#1

Posted 22 June 2018 - 01:39 PM

- Jencar17, Tex, Half Fast and 6 others like this

#2

Posted 22 June 2018 - 01:45 PM

Will it cut wood too???

Your machining has improved an order of magnitude...

- havlicek likes this

Yes, to be sure, this is it...

#3

Posted 22 June 2018 - 01:56 PM

I've had a Sherline lathe since the 70's!! Made right in SD the old USofA!! Very nice people and a nice small lathe. Plenty of upgrade attachments if you're into that --like power feeds -- mill table etc. Congrats John

- havlicek likes this

#4

Posted 22 June 2018 - 02:17 PM

Will it cut wood too???

Cut wood? Heck, it'd probably core a apple. ![]()

- Half Fast, Tim Neja and Geary Carrier like this

#5

Posted 22 June 2018 - 02:39 PM

It's hard cider time...

- havlicek and C. J. Bupgoo like this

Yes, to be sure, this is it...

#6

Posted 22 June 2018 - 02:40 PM

At $340.00 the DRO is the best enhancement I've made to my Sherline. Really makes accurate turning easy.

- havlicek and grooverunner like this

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#7

Posted 22 June 2018 - 03:29 PM

I have one too John. It's a good little machine for it's size and cost. I updated to quick change tool holders so I have half a dozen different tools ready to drop in and use.

That DRO sounds nice too Don.

- Tim Neja and havlicek like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#8

Posted 22 June 2018 - 03:51 PM

At $340.00 the DRO is the best enhancement I've made to my Sherline. Really makes accurate turning easy.

The DRO looks like something I could definitely use Don, but I have one thing for the Sherline mill I'm planning for:

I have one too John. It's a good little machine for it's size and cost. I updated to quick change tool holders so I have half a dozen different toolsready to drop in and use.

Hi Rick,

Bingo!...the quickchange tool holder seems like the #1 option to go for...well...aside from more tools! ![]() This was all done with more than a little faith (*based on my experience with the mill) that I could do some work with easy-machining steel without taxing the machine too much. I guess what they say is gonna happen..."we shall see".

This was all done with more than a little faith (*based on my experience with the mill) that I could do some work with easy-machining steel without taxing the machine too much. I guess what they say is gonna happen..."we shall see". ![]()

- Jencar17, Tim Neja and David Reed like this

#9

Posted 22 June 2018 - 06:29 PM

The rotary table is also an excellent piece of tooling to have.

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#10

Posted 22 June 2018 - 09:19 PM

Suggestion: Before you commit to the Sherline mill, take a look at the Taig. IMHO there is an interesting split in small USA made machine tools..For lathes, the Sherline is better thought out and has a wider range of accessories and more capability. In mills, just the opposite obtains. The Taig is far more robust and rigid (perhaps the most important quality in a mill) As an example, the Sherline uses 1/4" leadscrews, the Taig's are 1/2" You can even get the Taig with ballscrews for greater accuracy and precision and finally, conversion to full CNC is easy.

EM

#11

Posted 23 June 2018 - 04:45 AM

Suggestion: Before you commit to the Sherline mill, take a look at the Taig. IMHO there is an interesting split in small USA made machine tools..For lathes, the Sherline is better thought out and has a wider range of accessories and more capability. In mills, just the opposite obtains. The Taig is far more robust and rigid (perhaps the most important quality in a mill) As an example, the Sherline uses 1/4" leadscrews, the Taig's are 1/2" You can even get the Taig with ballscrews for greater accuracy and precision and finally, conversion to full CNC is easy.

EM

I've had the Sherline for a while now, and it's why I got their lathe. ![]() I really strongly doubt I will ever go CNC , although of course the Sherline can.

I really strongly doubt I will ever go CNC , although of course the Sherline can.

#13

Posted 23 June 2018 - 10:57 AM

Good choice, John, in hobby machines. You can even get retro-fit CNC for them.

DON'T cut wood in it. Nor cast iron if you can help it. The shavings mix with the way

oil and make lapping compound. You would be surprised just how abrasive wood dust is.

#14

Posted 23 June 2018 - 01:42 PM

My understanding of DROs is:

DROs that read off of the feed screws are not ideal. Reading off of scales eliminates feed screw back lash error, which is the main reason for having a DRO.

You can use digital calipers and magnets to make a poor man's DRO that eliminates back lash error for very little money.

- Tim Neja and Geary Carrier like this

???-2/31/23

Requiescat in Pace

#15

Posted 23 June 2018 - 03:08 PM

Not only does a DRO eliminate leadscrew error, it essentially eliminates any layout effort. I would use a very simple babyCad program or even a pencil sketch to note hole position, corners etc. all referenced to a single point, clamp the work, find two edges, zero out the DRO and then simply "crank to the numbers". Obviously, if there is a tool change, the Z axis needs to be re-zeroed. (milling)

EM

- Phil Smith likes this

#16

Posted 23 June 2018 - 03:10 PM

You would be surprised just how abrasive wood dust is.

Not really! I used to run a print shop and our main paper cutter was a large (*I forget, but around 28") sonofagun, with equally impressive knives. I had the best knives for that thing, and after coming back from sharpening would spend an hour or so installing them. Just cutting paper, we had to get them sharpened every 1-2 weeks (*depending on how busy we were).

Understood and sorry - When I looked back, it occurred to me that there are two ways to read your comment:

but I have one thing for the Sherline mill I'm planning for:

and I read it the wrong way.

EM

No big thing Alan. Probably my number one big ticket item (*possibly) for the mill is that rotary table though, but I would also need a three jaw chuck for it, so the cost goes up even more. That means it's "further on up the road". ![]()

#17

Posted 23 June 2018 - 03:14 PM

The 3 jaw from the lathe fits on the rotary table with an adaptor

- havlicek likes this

#18

Posted 23 June 2018 - 03:17 PM

Also they have a nice collet fixture for the rotary table that uses lathe collets.

So many parts in the Sherline system are interchangeable !!

#19

Posted 23 June 2018 - 03:39 PM

The 3 jaw from the lathe fits on the rotary table with an adaptor

...and the four jaw as well Bill ![]() But I would rather not be swapping the chuck every time.

But I would rather not be swapping the chuck every time.

Also they have a nice collet fixture for the rotary table that uses lathe collets.

So many parts in the Sherline system are interchangeable !!

Yes...and yes! ![]()

#20

Posted 23 June 2018 - 04:40 PM

Hey John:

If you are looking for real precision (which I know you are) collets are definitely the way to go. With a good bit more effort you can get there with chucks but it's just a lot quicker and more precise to go with collets. In your case I would think that you normally wouldn't be dealing with many sizes of collets so the cost would be "reasonable".

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#21

Posted 23 June 2018 - 07:35 PM

Hey John:

If you are looking for real precision (which I know you are) collets are definitely the way to go. With a good bit more effort you can get there with chucks but it's just a lot quicker and more precise to go with collets. In your case I would think that you normally wouldn't be dealing with many sizes of collets so the cost would be "reasonable".

Hi Jay,

Yes, I use them where I can and it's convenient...but where on the lathe would I use them for what I do? Mostly, I'm using a live or dead center on the tailstock when not using a drill chuck.

#22

Posted 23 June 2018 - 08:09 PM

I was thinking you might want to use one in place of the 3 or 4 jaw chuck and add a bushing in the tailstock chuck/collet if you wanted to accurately turn or grind an armature. Sherline makes a "WW Collet" adapter for both the Headstock and Tailstock.

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#23

Posted 23 June 2018 - 08:16 PM

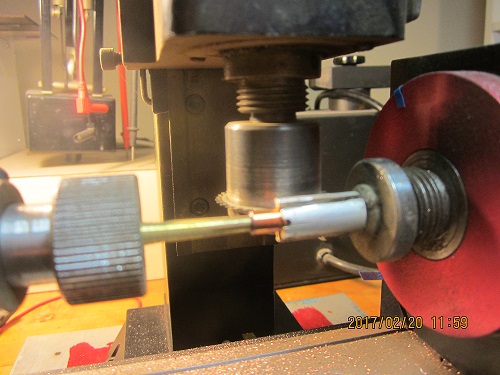

I am often turning or od grinding armatures, armature slugs, cans, endbels on 2mm

shafts or fixtures mounted on 2mm shafts. You can , make fixtures mounted on 2mm shafts to hold cans and endbels.

(When you get your rotary table, you can use such a fixture on the mill to precision drill endbel mounting holes in cans)

Back to the lathe, I use a 2mm ( 5/64 works too) in the headstock

and the Sherline adjustable tailstock collet fixture with a 5mm collet and a 2 x 5 mm oilite in the tailstock.