Man--- I LOVE that poor man's DRO!!! What a great simple way to get that for NO money!! Very nice!!

Sherline #2 lathe is in the house

#26

Posted 23 June 2018 - 11:00 PM

- Phil Smith likes this

#27

Posted 24 June 2018 - 04:59 AM

I was thinking you might want to use one in place of the 3 or 4 jaw chuck and add a bushing in the tailstock chuck/collet if you wanted to accurately turn or grind an armature. Sherline makes a "WW Collet" adapter for both the Headstock and Tailstock.

Oh...now I see where you were going. Nah, there's no way I'll ever be grinding (*or for that matter, dynamic balancing) arms Jay. This stuff is just for "regular" whipping-up of parts. ![]()

#28

Posted 24 June 2018 - 06:58 AM

Back on track here, the difference between the Grizzly and the Sherline is pretty major. Everything is just way more precise, solid, predictable and controllable on the Sherline. Parting-off a lump of metal (*especially steel) is still no picnic, but I'm working on improving that little headache. ![]()

#29

Posted 24 June 2018 - 07:24 AM

Here's a great video with a solution for parting off on a small lathe. And an explanation for why it's a problem on a small to begin with. I've done this with my parting tool set up completely wrong and it still worked great. Pretty amazing!

I linked to the point in the video where the guy demonstrates why it's a problem and how to fix it.

https://youtu.be/-RZRq0olsxM?t=181

- havlicek likes this

???-2/31/23

Requiescat in Pace

#30

Posted 24 June 2018 - 07:33 AM

Hi Phil,

Which is "sort of" where I'm headed ![]() I say "sort of" because the Sherline won't let you reverse direction (*although presumably the machine *could* be modified to accomplish that)....but...they have a cutoff tool riser block that allows for parting from the rear of the piece and would accomplish the same thing (*I think). Anyway, the riser block is on the way.

I say "sort of" because the Sherline won't let you reverse direction (*although presumably the machine *could* be modified to accomplish that)....but...they have a cutoff tool riser block that allows for parting from the rear of the piece and would accomplish the same thing (*I think). Anyway, the riser block is on the way.

- Tim Neja likes this

#31

Posted 24 June 2018 - 07:40 AM

Cool! There are videos of people doing it like that as well, John. I bet that's the best way to do it, but I can't set up on the back side of my lathe. So reverse it is for me.

You'll be amazed at how well it works. I ripped right through 3/4" aluminum in no time at all.

- havlicek likes this

???-2/31/23

Requiescat in Pace

#32

Posted 24 June 2018 - 07:45 AM

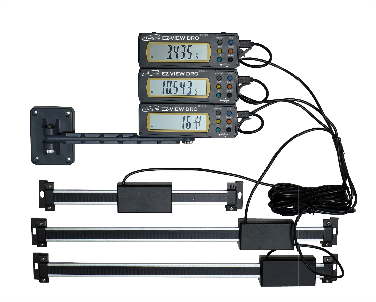

Man--- I LOVE that poor man's DRO!!! What a great simple way to get that for NO money!! Very nice!!

Tim, I haven't done it yet, but that's what I'm going to use with my 7 X 14 lathe. Igaging makes cheap DROs based off of caliper style scales. Not much more than the digital caliper solution. I might go ahead spring a little extra for that.

???-2/31/23

Requiescat in Pace

#33

Posted 24 June 2018 - 08:47 AM

Cool! There are videos of people doing it like that as well, John. I bet that's the best way to do it, but I can't set up on the back side of my lathe. So reverse it is for me.

You'll be amazed at how well it works. I ripped right through 3/4" aluminum in no time at all.

Cool Phil! I had some difficulty with that before, but the real test for me will be 5/8" - 3/4" "free-machining" steel. If it does OK with that, then non-ferrous stuff should be a homerun. Also, Sherline's cutoff tool is about the thinnest I could find, about 1mm, so that should be a help as well.

#34

Posted 25 June 2018 - 11:49 AM

Sent from my iPhone using Tapatalk

- Half Fast, Steve Deiters, Tim Neja and 4 others like this

Bobby Robinson RN, BMTCN

"Nobody rides for free." - Jackson Browne, 1980

"Positivity and optimism can overcome a lot of things." - Tom Brady, 2019

"Trying is the first step towards failure." - Homer Simpson

#35

Posted 25 June 2018 - 12:29 PM

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

#36

Posted 25 June 2018 - 12:48 PM

Sent from my iPhone using Tapatalk

- Half Fast likes this

Bobby Robinson RN, BMTCN

"Nobody rides for free." - Jackson Browne, 1980

"Positivity and optimism can overcome a lot of things." - Tom Brady, 2019

"Trying is the first step towards failure." - Homer Simpson

#37

Posted 25 June 2018 - 02:18 PM

Bobby,

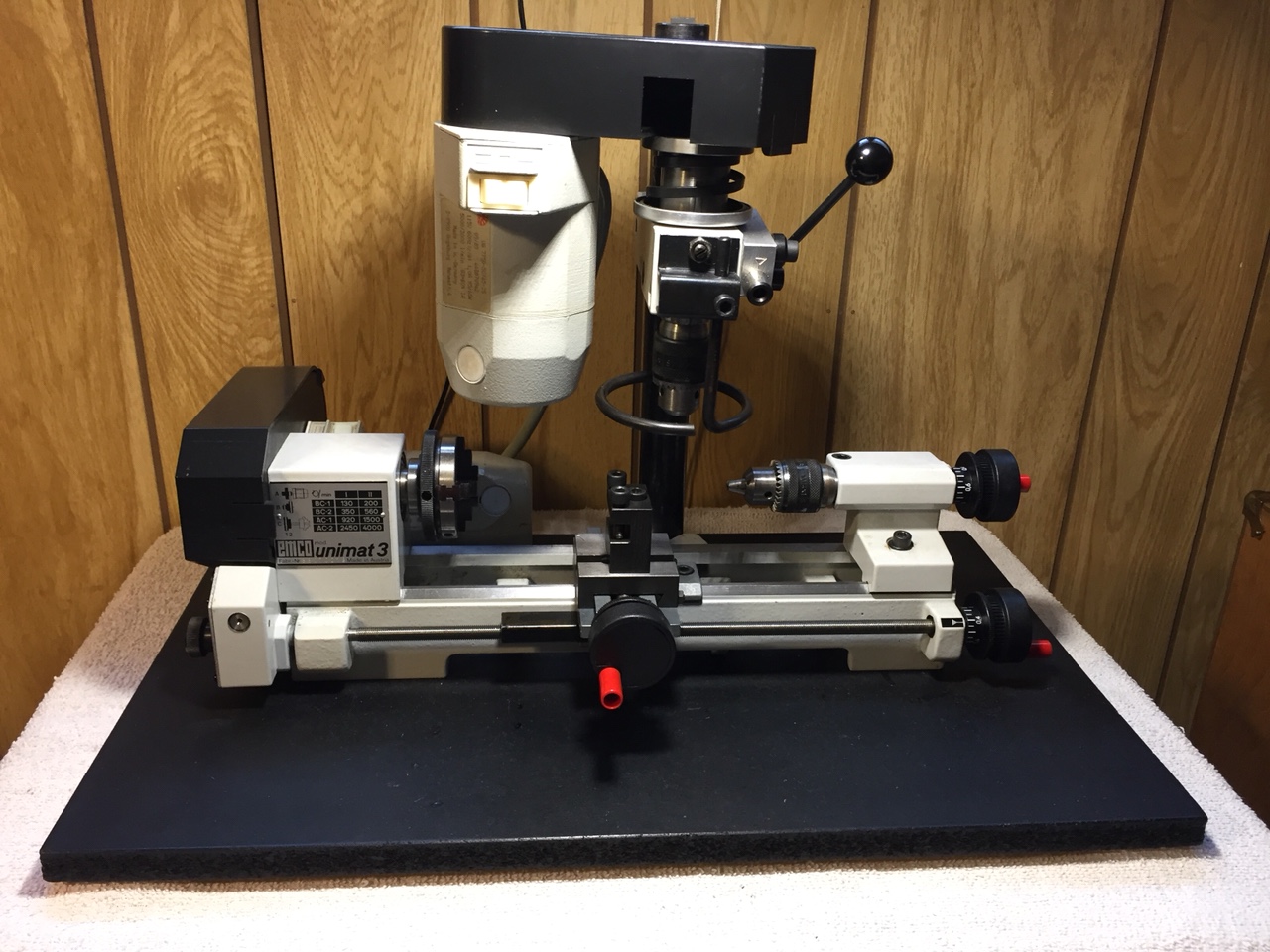

Hardly looks used - good find ![]() .

.

- brnursebmt likes this

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#38

Posted 25 June 2018 - 02:25 PM

Bobby, that Unimat 3 looks to be in great shape. I've owned a Unimat SL-1000 since 1970. The only maintence I've had to do is change the belts & repack the bearings. I once was able to order Unimat tooling from the Sears tool catalog, but those days are long gone. If I remember correctly, the Unimat 3 & 4 came out later. I don't think any of them have been made for 15 years or so. There used to be a Unimat users group on Yahoo but I don't know if it's still active.

- brnursebmt likes this

I intend to live forever! So far, so good.

#39

Posted 25 June 2018 - 05:07 PM

So, John. I thought while we were talking lathes I’d show my newly acquired Unimat 3 with milling head. Just got it set up. Can’t wait to start playing!

IMG_0657.JPG

Sent from my iPhone using Tapatalk

Whew...that's one sexy beast! Enjoy!

- swodem likes this

#40

Posted 26 June 2018 - 07:16 AM

This lathe was used very lightly and expertly maintained. I was lucky to find one in such excellent shape. Got all the bells and whistles with it too!

- Tim Neja likes this

Bobby Robinson RN, BMTCN

"Nobody rides for free." - Jackson Browne, 1980

"Positivity and optimism can overcome a lot of things." - Tom Brady, 2019

"Trying is the first step towards failure." - Homer Simpson

#41

Posted 26 June 2018 - 09:10 AM

I use a Unimat PC that I found about 20 years ago - fully fitted out with 3/4 jaw chucks, collets, quick change tool post, rotary table, etc. Iit also has a milling attachment. i have used it and find that it is OK for very light work. The single column support is not particularly rigid. It also has, befitting its "PC" designation, 3 axis steppers, a control and drive board and software. I have never tried this function. (I would need to find an old PC with an ISA slot to accommodate the board) The only failure has been the early 80's design speed/direction control. I have the parts to upgrade to modern electronics but, for the moment, simply run it off my variable bench supply.

EM

#42

Posted 29 June 2018 - 08:03 PM

Well, I got the rear riser block for the Sherline cutoff/parting tool and installed that bad boy ASAP. The result?...I parted off a big ol' lump of steel from my next billet can like "buttah". I mean, the lathe could run as slow as I wanted, and I was able to keep a chip going with almost no noise...amazing (*to me). The only problem with doing things this way is that applying a bit of oil every now and then is a little hit & miss, because the oil is going on after the cut. Still, enough stays on there at such a slow speed to make it all go wonderfully smooth.

***Now, this isn't really because the machine is so much better than the Grizzly (although it is ). The Sherline sure didn't "like" parting from the front or "normal" position either, but did a little better. Running the parting tool from the rear was major. Also, the Sherline tool itself is thinner (*about 1mm) and taller, so it's more rigid in the same axis as the cut.

I'll post a picture tomorrow of the piece as it came off the lathe, and before I sand it. Needless to say, I'm really happy...oh...and, I got a cheap Wen 1X30 belt/5" disc sander to sharpen tools. Changing out the belt and disc to silicon carbide from the supplied aluminum oxide proved this thing can handle very tough steel with relative ease. I was a little worried about an $80 import, but it does everything I need it to. I'm sure I'll find other things to do with it as well.

- Tim Neja and Geary Carrier like this

#43

Posted 30 June 2018 - 04:35 AM

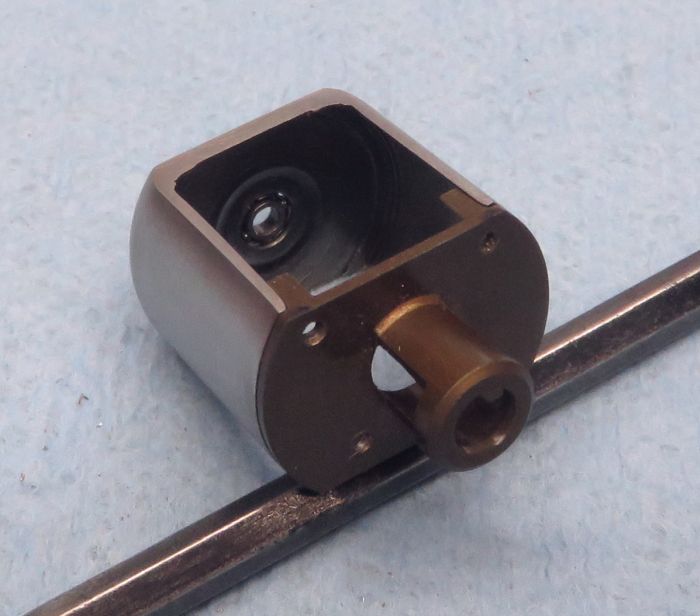

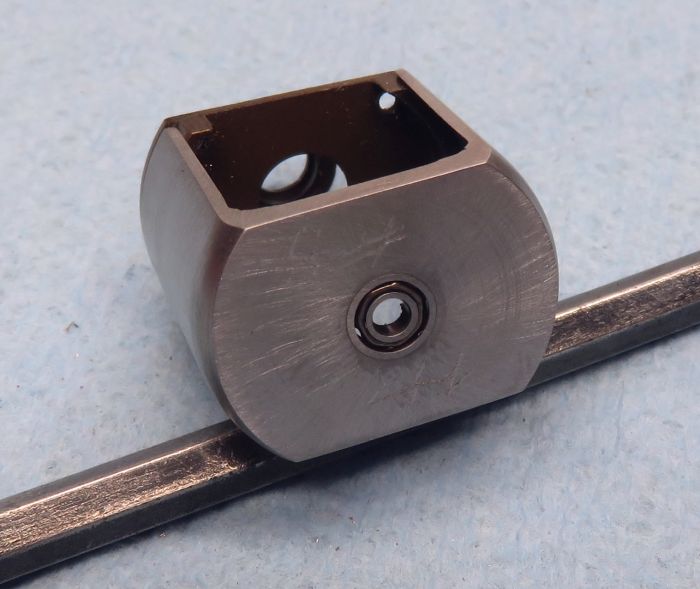

Here's the beginning of another can just after parting the piece:

Here's the lathe with the parting tool and riser block mounted at the rear of the lathe:

So, the Grizzly lathe got me started and I learned a lot just by using it. The above piece was faced, turned, bored and parted on the Sherline right out of the box from a lump of 5/8" steel rod by a ham-fisted carpenter. ![]()

- Half Fast, Tim Neja, Phil Smith and 3 others like this

#44

Posted 30 June 2018 - 08:30 AM

I like self-deprecating humor. And I know some ham-fisted carpenters!

- havlicek likes this

#45

Posted 30 June 2018 - 09:04 AM

I like self-deprecating humor. And I know some ham-fisted carpenters!

Oh I can self-deprecate with the best of 'em Dave...onnacownta there's so much material over here. ![]()

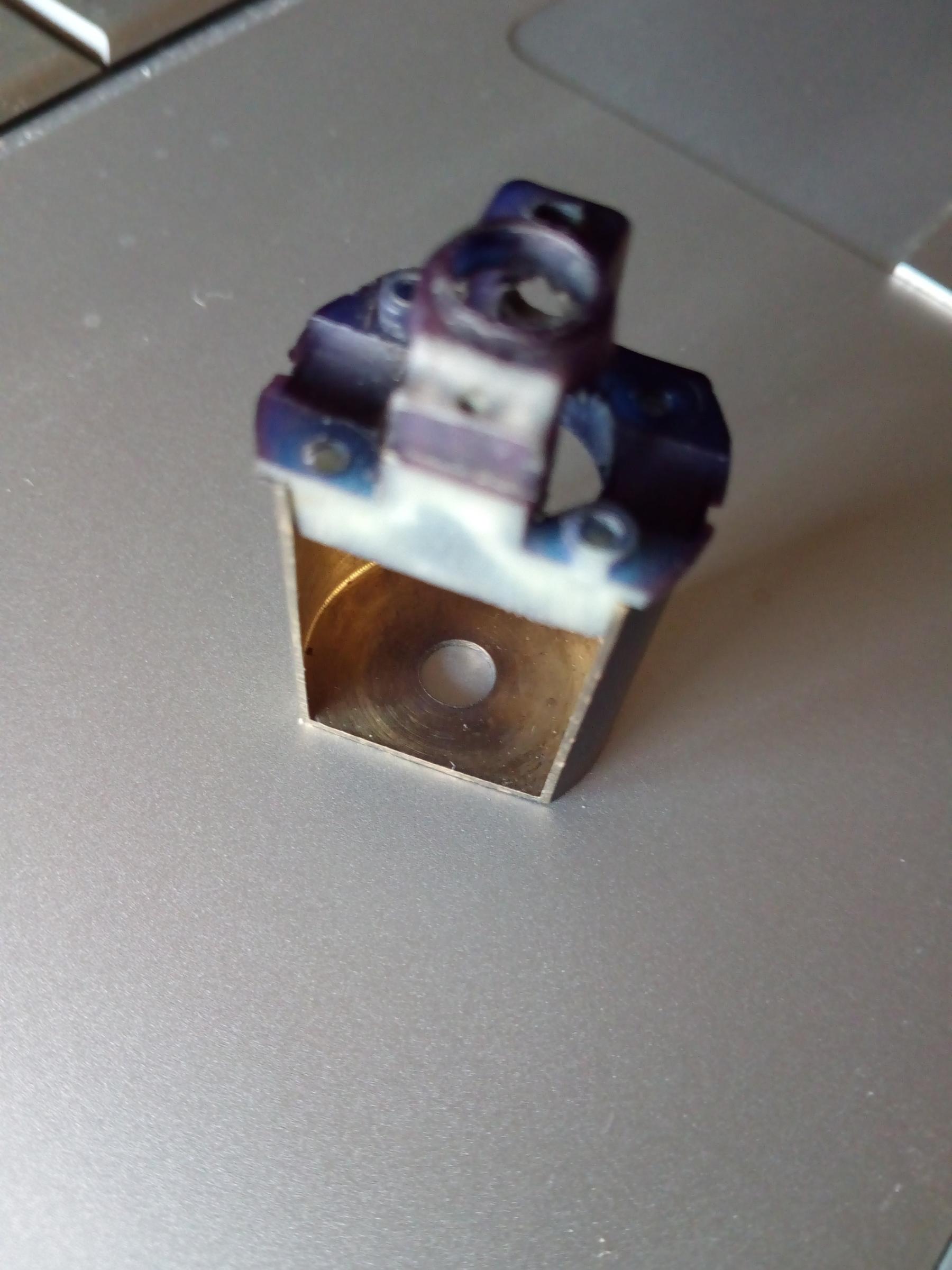

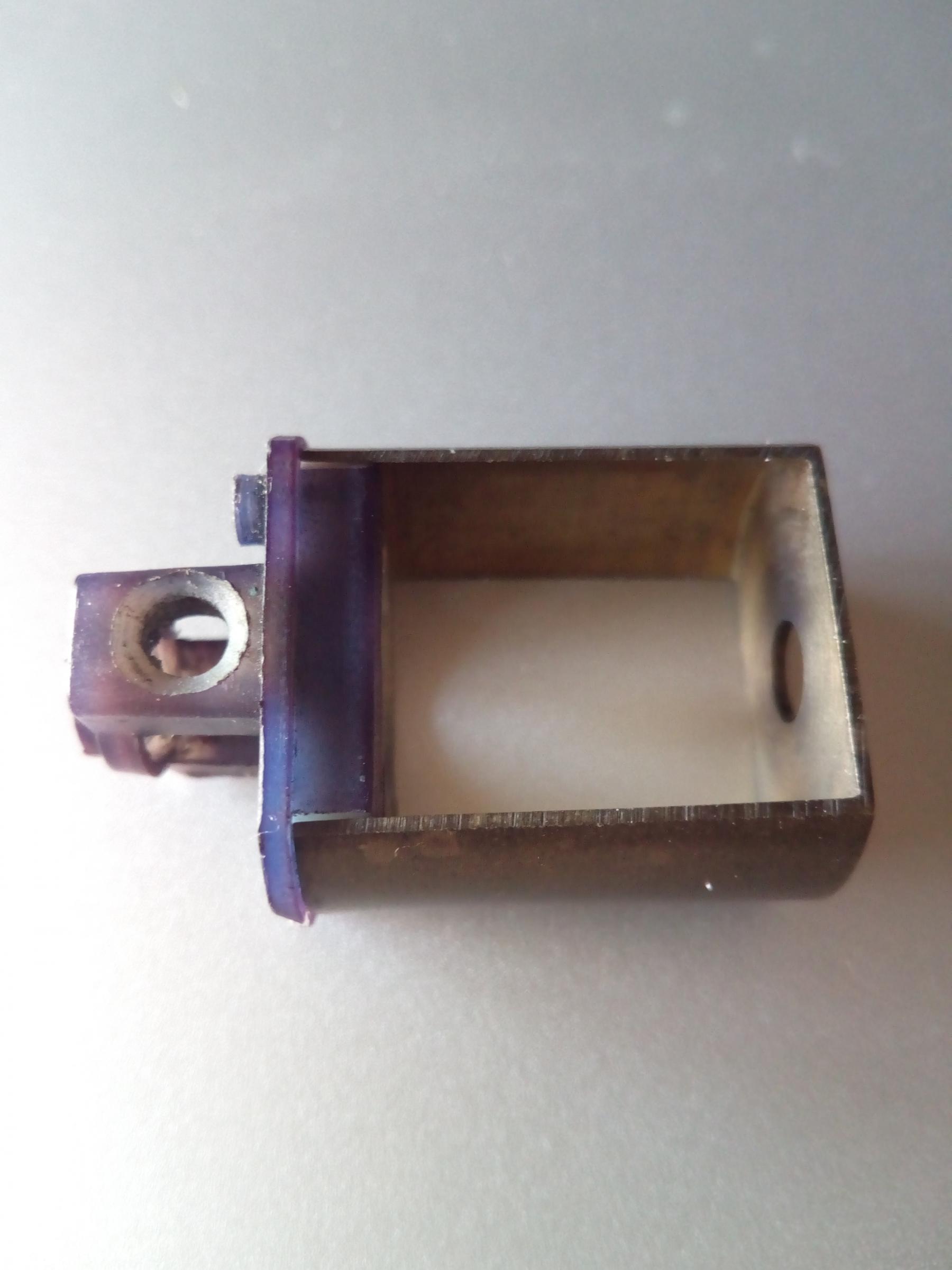

Moving right along, I lopped-off the top and bottom of this nascent billet can, and soldered-in a 2mm x 5mm bearing. It's almost looking like something at this point. I still have to drill end bell mounting holes (ARGH!) and then decide on what magnets to use, and stick a pair of those (*whatever they might be) inside, but the machining part of the deal is finished. Much easier, predictable, controllable, accurate yada yada yada. Thank you Mr Sherline. ![]()

- MarcusPHagen, brnursebmt, Tim Neja and 5 others like this

#46

Posted 30 June 2018 - 10:25 AM

Very nice John ![]()

- havlicek likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#47

Posted 30 June 2018 - 11:18 AM

There's a certain symmetry to all this, that just fits quite well...

- havlicek likes this

Yes, to be sure, this is it...

#48

Posted 30 June 2018 - 11:38 AM

Thanks Rick and Geary ![]() I laugh when people mention getting into a full-blown CNC setup, and making Swiss watches, when I'm stoked just to able to do something like this.

I laugh when people mention getting into a full-blown CNC setup, and making Swiss watches, when I'm stoked just to able to do something like this.

- Tim Neja likes this

#49

Posted 30 June 2018 - 11:44 AM

Very nice John ! With that artifact you're just recalling early seventies in my area when we are still playing those stoopid ultralight chassis (cucaracha, mini dream). I attempted to soften mura magnet field drilling brass cans....

- havlicek likes this

#50

Posted 30 June 2018 - 12:00 PM

That's looking BEAUTIFUL John!! Kinda fun turning out stuff on the lathe huh?? I loved making little parts for my 1/12 scale RC cars when I was racing them. Just fun making something precision that you can't buy and using it in your rides!!

- havlicek likes this