#3076

Posted 06 August 2011 - 12:01 PM

So, the part about drilling out coat hanger didn't give you a clue on the HUMOR intended?

Fate

3/6/48-1/1/12

Requiescat in Pace

#3077

Posted 06 August 2011 - 12:15 PM

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#3078

Posted 06 August 2011 - 01:13 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#3079

Posted 06 August 2011 - 05:05 PM

It's not broken in yet...but at 5.5V it positively screams and draws somewhere between 5 and 6 amps.

-john

#3080

Posted 06 August 2011 - 05:11 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#3081

Posted 06 August 2011 - 06:01 PM

(i got'z both.....)

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#3082

Posted 06 August 2011 - 06:26 PM

-john

#3083

Posted 06 August 2011 - 09:08 PM

I intend to live forever! So far, so good.

#3084

Posted 07 August 2011 - 06:22 AM

Thanks very mucho!

-john

#3085

Posted 07 August 2011 - 07:49 AM

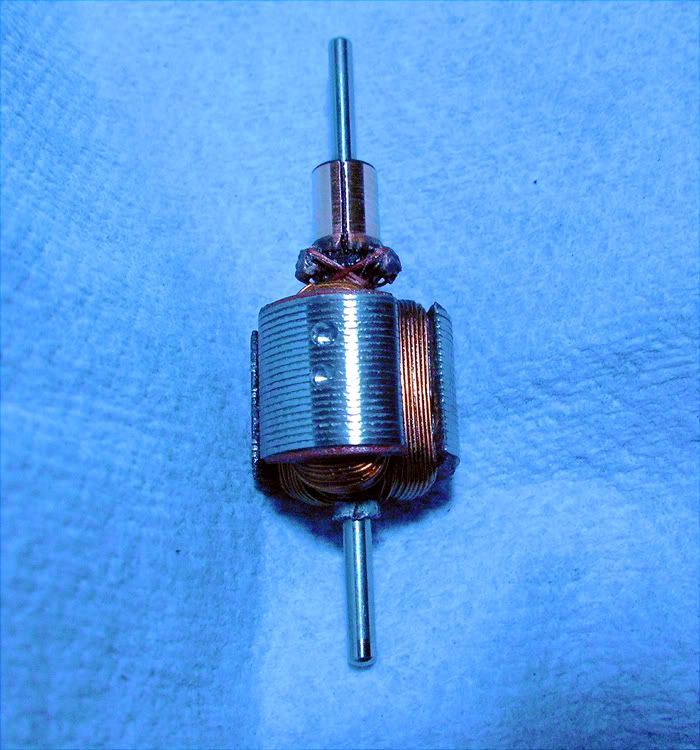

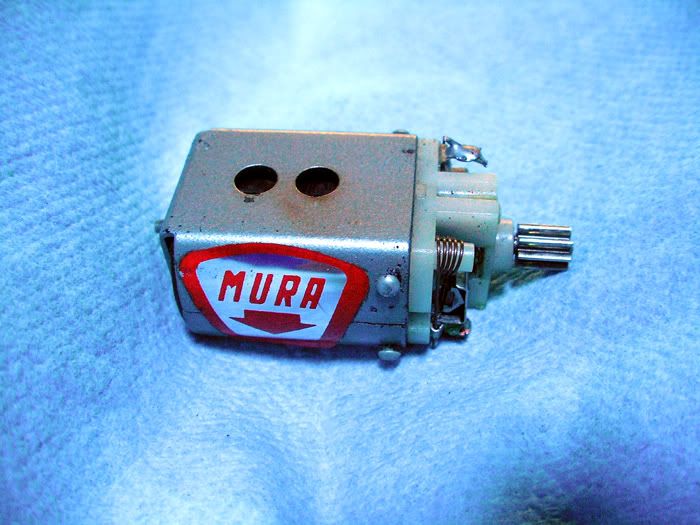

...it should be a real strong runner

...next up a nice old Mura that really fried. Both brush tubes ("heatsinks") have melted into the endbell and cocked a little so it's going to be a challenge just to get them to sit straight again. Not a "special" motor at all for the day, but now a really nice specimen

-john

#3086

Posted 07 August 2011 - 08:59 AM

The 23 Mura came out SWEET !! Hows the heat factor? Im guessing if its pulling that many amps it's prob running pretty hot as well. Your right about breaking it in , in small doses.

I've had a couple that at first ran way hot, but I broke them in just a minute or two at a time and once they settled in and brushes seated they cooled down some. I think you'll find that a motor like this one is prob going to run somewhat hot even after breakin lol.

Still should be a fantastic period drag motor

#3087

Posted 07 August 2011 - 09:10 AM

-john

#3088

Posted 07 August 2011 - 11:10 AM

I was originally going to do 15T/#23 and now that I've run the thing, I'm glad I put the extra 2 turns on there.

May I ask what change in characteristics do you believe would have taken place if you hadn't added the extra 2 turns please?

Thanks John!

Ernie

#3089

Posted 07 August 2011 - 01:02 PM

what change in characteristics do you believe would have taken place if you hadn't added the extra 2 turns please?

Well for one thing, this would have resulted in an even lower resistance than the stoopid-low resistance as it stands...think more RPMs. It probably would have also passed more current and got even hotter. Because there's always a balance...a "push-pull" going on between the permanent field of the magnets and the alternating fields of the arm coils/poles, it's also possible that going to stronger magnets might have completely changed everything. In theory, more turns should also result in more torque...but there will be diminishing returns there depending on magnet strength, spring strength, available current. There are so many factors at play in a motor that it makes my head hurt to think about them all, so I leave that to the physics experts.

-john

#3090

Posted 08 August 2011 - 11:33 AM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#3091

Posted 08 August 2011 - 12:18 PM

Well for one thing, this would have resulted in an even lower resistance than the stoopid-low resistance as it stands...think more RPMs. It probably would have also passed more current and got even hotter. Because there's always a balance...a "push-pull" going on between the permanent field of the magnets and the alternating fields of the arm coils/poles, it's also possible that going to stronger magnets might have completely changed everything. In theory, more turns should also result in more torque...but there will be diminishing returns there depending on magnet strength, spring strength, available current. There are so many factors at play in a motor that it makes my head hurt to think about them all, so I leave that to the physics experts.

Thanks for the info John! I appreciate it!

Ernie

#3092

Posted 08 August 2011 - 06:03 PM

Do you feel there would be a significant drop in motor performance if you did not run shunt wires? What is the purpose of shunt wires please? Is it a mandatory practice to employ the use of shunt wire on motors that have certain wire gauge?

I'm trying to understand the use of shunt wire and why some motors have them while others do not.

Thank you for your time.

Ernie

#3093

Posted 08 August 2011 - 07:11 PM

This is a rule just as is the law of gravity or the the one about a fool and his money.

The current will travel from the brush hood to the brush through contact inside the tube for a while. But as the motor runs dirt begins to build up inside the tube as does carbon from constant sparking. Eventually the resistance builds and power will eventually switch to flowing through the brush spring as resistance builds between the tube and the brush. The brush spring is a poor path for the electrical current due to it's small size and resistance equals heat which is bad. The result can be a weakening spring at the least and a melted spring post at the very worst!

A set of shunt wires provide the electrical current a direct path from the lead wire to the brush. This means no carbon build up in the tube (freely moving brushes) and no power traveling through the brush spring. (consistent spring pressure)

They are not necessary as long as the brush tubes are cleaned with a tube brush from time to time, but the use of shunt wires ensures longevity of operation of the motor with little maintenance required.

It's a good thing!

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#3094

Posted 08 August 2011 - 07:24 PM

-john

#3095

Posted 08 August 2011 - 08:56 PM

I appreciate the both of you taking the time to provide me with the technical information I was hoping to acquire.

Really appreciate it!

Ernie

#3096

Posted 09 August 2011 - 05:20 AM

1)Shunts are like guns, better to have them and not need them to not have them and need them. In other words, shunts by themselves (and if installed and functioning properly) will never hurt a motor's performance. When installed on a motor that doesn't "need them", the motor will run just as well as it did without them. So (and this falls in line with Jairus' recommendations), if you have a motor that you think may need them, by all means stick 'em on there.

2)If improperly installed and causing the brushes to get hung up, shunts may not only hurt a motor's performance...they could burn it up. Doing a nice job with shunts is pretty fiddly and often may mean modifying the brush hardware and you may have to reinstall them when you change brushes, so it does add a maintenance thing. I've seen some super-tidy shunt installations here by Rick T and others, so look around for ideas about how to get the job done. I got some teensy-weensy eyelets with crimp connectors on the other end from Kim Lander that would make it possible to connect the shunts under one of the endbell hardware screws...pretty neat! So there are many different variations on how to install shunts. People have even posted pictures here in the past on how they do it and might post some again.

3)If you run the motor no load at low voltage...say around 5V, and you feel the springs getting hot after 15-20 seconds, the motor will probably do better with shunts and spring insulation. That heat is from too much current passing through those skinny steel wire springs.

4)Spring insulation is there to break the current path through the springs. You can put it on the short leg of the spring or the long leg...or even both, any should work but if on the short leg, you have to make sure the spring will still fit easily through the slot in the hoods. You don't want the spring or the brush getting hung up because of the shunt or the insulation. Since electricity will follow the path of least resistance, you would think that spring insulation might not be necessary on a moderately high amp draw motor. Since the shunt wire is a much better conductor than the spring, it would seem like current would mostly flow only through the shunt. It seems though as if current will flow through both if the spring isn't insulated, maybe more so if the motor needs a lot of current. Probably a good idea to always insulate the springs if you're adding shunts.

-john

#3097

Posted 09 August 2011 - 07:30 PM

Thank you for the additional info. I will definitely need to read this a few or more times to fully appreciate and understand what you are stating about shunts.

Thanks again for your time.

Ernie

#3098

Posted 10 August 2011 - 07:17 PM

12/01/54-7/22/14

Requiescat in Pace

#3099

Posted 10 August 2011 - 08:05 PM

On a hemi the wires do not cross over each other at the comm tab.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#3100

Posted 10 August 2011 - 11:20 PM

12/01/54-7/22/14

Requiescat in Pace

This topic is locked

This topic is locked