The PS endbell is fine (as is the Hawk), but you'll need shortened brushes and you should check the arm length as the spacing between the can and endbell may or may not work with some arms (probably fine with the Falcon arm).

-john

Posted 14 January 2013 - 12:37 PM

The PS endbell is fine (as is the Hawk), but you'll need shortened brushes and you should check the arm length as the spacing between the can and endbell may or may not work with some arms (probably fine with the Falcon arm).

-john

Posted 26 May 2013 - 11:22 AM

Just thought I'd share this video with regards to machine winding. I'd like one of these!

Posted 26 May 2013 - 12:22 PM

Would like to see how the comms are installed.

George Ewing

Retired USAF, retired Ford service tech.

Posted 31 May 2013 - 12:10 AM

Hi John,

When you build an armature from scratch, salvaging lams from different used armatures, when pressing the lams onto the armature shaft to create the stack, what do you use to straighten the stack prior to winding the wire?

I know you showed us a photo of your neat tool you made to remove and press on the lams. I'll need to go back thru the pages to find the photo.

After a number of lams are pressed onto the armature shaft to create the stack, how do they remain in place? Do you glue them to one another as you press each lam onto the shaft? Or is the tolerance of the press fit "snug" enough to retain it's position and then when the wire is wound and epoxied remains stable?

Pardon me for asking. I tried searching for this info to no avail.

Thank you for your patience!

Ernie

Posted 31 May 2013 - 11:43 AM

When you build an armature from scratch, salvaging lams from different used armatures, when pressing the lams onto the armature shaft to create the stack, what do you use to straighten the stack prior to winding the wire?

Hi Ernie,

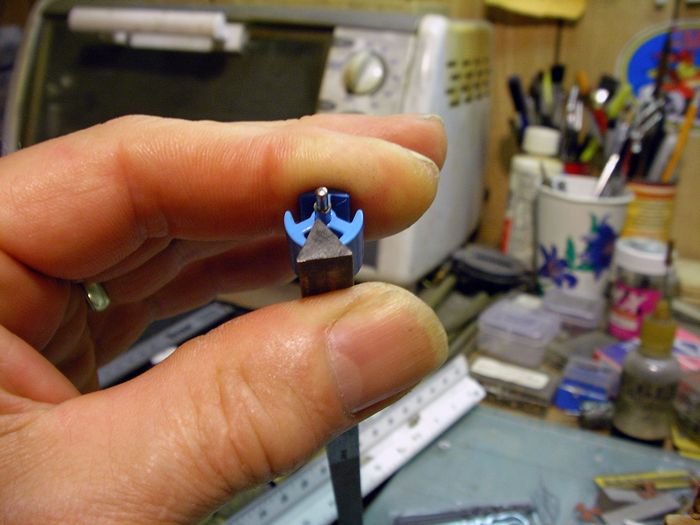

I use a triangular piece of tool steel to do the "final arrangement" for either straight or skewed lam stacks. The reason is that a triangle will both get tighter as you press it into the space between poles, and it will exert equal pressure on both sides. For a skewed lam stack, I just start twisting the stack as I press and wiggle the triangle into the space. Then for either straight or skewed lam, I go around to all three spaces and keep pressing the triangle in there until things line up nicely. I'm sure there are some nifty jigs/guides that the arm makers have come up with so the lams are straight as they fall from the rod, as my method wouldn't be practical for large production runs.

I know you showed us a photo of your neat tool you made to remove and press on the lams. I'll need to go back thru the pages to find the photo.

For pressing new shafts or for pressing-out old one, I use a small arbor press. Costs like $30 from Harbor freight and works OK.

After a number of lams are pressed onto the armature shaft to create the stack, how do they remain in place? Do you glue them to one another as you press each lam onto the shaft? Or is the tolerance of the press fit "snug" enough to retain it's position and then when the wire is wound and epoxied remains stable?

New lams are made to be a snug fit on the shaft and will generally stay put well enough so that powder coating (and then winding later on) only makes the stack even stronger. When I reuse old lams, they generally don't fit the shaft that well the second time around. For those, I use some small battery clamps to hold the stack together and then "set it" with some of the same very thin (low viscosity) hi temp epoxy I use for finishing the arms. After coating the stack very lightly, I remove as much of the epoxy as possible (the rest seeps into the stack amazingly well) and then 15 minutes in the oven to cure is all. If I can see any epoxy after removing the clamps, I use a wire wheel and the rotary tool to take all of that off before powder coating.

-john

Posted 31 May 2013 - 12:57 PM

Guys,

Pardon the interruption, but this thread is getting a bit too large. IPS advises that when threads get too large, it can cause problems.

So here's what's going to happen: when this thread ticks over to 120 pages, I am going close it and edit the subject to indicate "Arm winding, part 1" and I'll open a new thread titled, as you might guess, "Arm winding, part 2".

The limitation on thread size is based on the disc space the thread takes up, not on number of posts, so I don't know exactly when it could start causing issues. Call this a pre-emptive strike if you wish...

Anyway, here's your head-ups on what will happen in a bit.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 31 May 2013 - 02:11 PM

Hi John,

Thanks for the info.

And thank you for the heads-up, Greg - You're an awesome administrator!!

Ernie

Posted 31 May 2013 - 02:18 PM

Cool, Greg. Actually, a LOT of this thread is really only restating things that may have been stated a bunch of other times. It probably should be condensed to like 20 pages... but I sure ain't gonna tackle that one!

-john

Posted 31 May 2013 - 03:34 PM

I use a triangular piece of tool steel to do the "final arrangement" for either straight or skewed lam stacks.

Posted 31 May 2013 - 04:19 PM

Posted 31 May 2013 - 05:04 PM

Hi John,

You're so generous! Thank you very much for making the time to post the pictures I requested. I sure learn so much with your explantations and follow up pix.

Thank you again for your time John - I truly value your assistance!

Ernie

Posted 07 July 2013 - 05:42 PM

John,

Probably not anything you are interested in, but a cheap motor I came across today.

I guess I was intrigued it had a metal, "slot car style", endbell.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 07 July 2013 - 05:48 PM

Posted 08 July 2013 - 01:32 AM

That's a Russkit 25...

Has some of the oddest brush hardware I've ever seen...metal and plastic endbell, and the brushes ride on plastic and float in the hoods...the spring "posts" (?) are part of the hoods (a bent over tab)... ![]()

Tom Hemmes

Insert witty phrase here...

Posted 08 July 2013 - 06:13 AM

Hi Mike,

As they said, that is a Russkit and there are also some around that were of the same configuration but not marketed by Russkit. The pretty cool thing about the setup (besides the metal end bell) is that both ends of the motor come off with those side clips. I forget the story on them (I'm sure Philippe knows), but after screwing around with one or two it seemed to me to be a quite heavy (for a "can" type) motor with no performance advantages...an interesting "blip" or footnote in slotcar history. There were one or two other odd Russkits (at least one was a "36D" sized motor) too that never went anywhere. It's been a couple of years since I played with one, but I'm not sure the endbell hardware on yours is "stock". It could be my memory, but the ones I had might have been a little different.

-john

Posted 08 July 2013 - 07:19 AM

I guess I was pretty vague.

It's a "current" motor I got from a surplus joint for 75¢.

It had a short wire with a spade connector that I cut off.

It has a real small dia 7 or 8T pinion on it.

I didn't pull it off, but I think the shaft dia. might be reduced.

It weighs about 32G compared to 22G for that particular FK, a Falcon III.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 08 July 2013 - 01:03 PM

Does anyone know how i can tell the difference between a Proslot PD 75 turn arm and a 80 turn arm in resistance?

Where exactly are the readings taken/

Thanks All JJ

Jersey John Molnar

"Certified Tony P Chassis God 2007.2023

RETRO EAST 2025 Constructor Champion

Posted 08 July 2013 - 03:24 PM

Does anyone know how i can tell the difference between a Proslot PD 75 turn arm and a 80 turn arm in resistance?

Where exactly are the readings taken/

Thanks All JJ

Burn the arm, then count the winds. ![]()

![]()

Seriously John, a quick PM to Dan Debella might be in order to see if there are any visual differences that can be easily seen. ![]()

Posted 08 July 2013 - 04:32 PM

Hay Billy I sent him one and got no reply..I figure one of our top motor heads would know LOL

Jersey John Molnar

"Certified Tony P Chassis God 2007.2023

RETRO EAST 2025 Constructor Champion

Posted 08 July 2013 - 04:34 PM

John,

Do you have an arm meter?

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 08 July 2013 - 08:51 PM

I guess I was pretty vague.

It's a "current" motor I got from a surplus joint for 75¢.

It had a short wire with a spade connector that I cut off.

It has a real small dia 7 or 8T pinion on it.

I didn't pull it off, but I think the shaft dia. might be reduced.

It weighs about 32G compared to 22G for that particular FK, a Falcon III.

Here's a few more pics, for the heck of it.

An 8T pinion, before I chopped it off.

I thought it looked small. The shaft is reduced to .055".

A shot of the goofy brush setup.

Another shot of it.

What did they look like on the Russkit motor ?

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 08 July 2013 - 09:41 PM

Here's a Russkit 25. Brush setup appears the same.

Posted 09 July 2013 - 05:29 AM

Hi Mike and Bill. Looks like the brush setup is the same...but it IS goofy for sure ![]()

-john

Posted 09 July 2013 - 07:15 AM

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap