#601

Posted 22 September 2009 - 05:23 AM

I got your message and sent you a reply.

-john

#602

Posted 22 September 2009 - 10:31 PM

#603

Posted 25 September 2009 - 04:17 PM

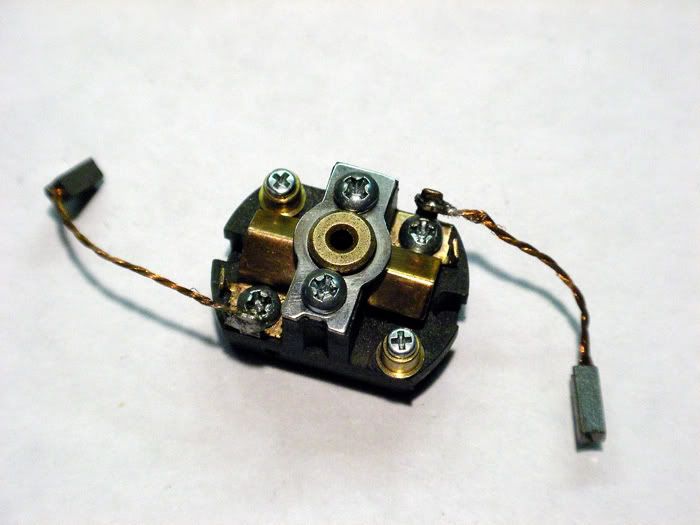

So I tried to figure out a way of solving all that without making things worse than they were (been there done that). So I:

1)Cut off the protruding part of the endbell flush that carries the bushing, but left the remainder of the bushing in place to use as a "center".

2)I then fabricated a "strap" from a piece of tool steel with the endbell mounting holes in place but no hole for the new bushing/bearing. I figured that brass wouldn't be nearly strong enough after I whittled it down, but of course this made things difficult as this steel is very hard and drilling/shaping it is a bear.

3)I then mounted the strap to the endbell with some #2x 3/16" screws and, using what was left of the original bushing to center the new bushing hole. I then flipped the endbell over and ran a diamond engraving point (that just happened to fit the old bushing perfectly) through the old bushing to put a "centerpunch" where I needed to drill the new bushing hole.

4)Using carbide drill bits alternately with cone-shaped grinding points, I drilled a hole opening it up slightly after each pass until the new bushing was a "snap-fit".

5)I then assembeld the can/endbell/arm to see if everything was OK so far and seeing that indeed it was, I soldered the bushing to the carrier strap.

6)Up until now the strap was left long so I could hold onto something, but it was time to cut it to shape and smooth it out as best as I could so it didn't look like a total catastrophe. I mean, it's nice if stuff works, but it's even nicer if it also looks OK. After a bunch of shaping and then polishing...it was ready to mount for real.

7)When final mounting the thing, I put a touch of JB Weld around the back of the strap and then slowly tightened the screws trying the arm as I went to make sure it wasnt binding, and when I got it fully seated wiped of the excess with some acetone. While the JB Weld won't really bond to the endbell material, it will form a hard surface behind the strap for it to sit "true" on.

Like I said, I knew this would be a bear and have put it off for that reason. Total time...almost three hours

-john

#604

Posted 26 September 2009 - 02:58 AM

That thing looks like it would survive a nuclear direct hit!

Nice job and expert craftsmanship...as usual.

Can't wait to see that as part of a motor build. I like shunted brushes. They're cool.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#605

Posted 26 September 2009 - 06:06 AM

Thanks. it's a nice solid mod alright and one that was actually done by at least some back then so I'm just following the trail that others had already blazed

-john

#606

Posted 26 September 2009 - 10:10 AM

"Of course if I had a drill press, I could have cut at least an hour off of the fabrication time..maybe more because my only methods of drilling/fabbing tool steel are caveman-crude."

*****************************

John, I was at the right place at the right time a few years ago. There is a tool store here called Re-Tool. They buy and sell new and used tools of all descriptions. You being a woodworker will recognize the name Shop Smith. They've even had a few of those over the years. Anyway, shortly before Father's Day one year they had gotten in several desktop referb drill presses...for only $25 each! SOLD! To me they looked like new. It's precision isn't to within a millionth of an inch, but it's close enough for what I use it for. I used it just last night to balance some arms. So I feel very fortunate to have one. I hope you can find a bargain on one for yourself soon.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#607

Posted 26 September 2009 - 10:56 AM

Indeed, this is one of my own that dates from... 1966!Thanks. it's a nice solid mod alright and one that was actually done by at least some back then...

yes, it is a bit rough because despite all this armor, the endbell began melting from the heat generated by the 25-single arm fitted in it, and it shows here...

Champion also used a similar setup in 1969 on their production motors, and while the idea was great, the endbell was a disaster because there was not enough plastic to retain the screws without them stripping instantly, and the hole for the bearing was awfully loose.

The biggest problem with such a setup of course is... the motor mounting in a chassis. Unless the plate has been permanently epoxied on the plastic, which is not an easy task as the plastic had polypro in it, a compound that refuses to be attached by anything in the adhesive world. This 1970 Champion "Group-7" shows the plate with the soldered bearing, screwed into the endbell with two self-tapping #1 screws.

Fitted in the Champion RTR cars, one can remove the motor by simply... prying it off the chassis, and it does not take much effort to do so!

it was not uncommon while using these RTR models, to have a minor shunt with the wall and when the car was re-slotted, find out thet there was no more drive because the motor had wandered inside the chassis, being barely retained by the body, now being comprehensively ground by the pinion under applied power...

Philippe de Lespinay

#608

Posted 26 September 2009 - 12:27 PM

#609

Posted 26 September 2009 - 01:16 PM

I intend to live forever! So far, so good.

#610

Posted 26 September 2009 - 01:49 PM

Philippe de Lespinay

#611

Posted 26 September 2009 - 03:57 PM

#612

Posted 26 September 2009 - 05:09 PM

Philippe de Lespinay

#613

Posted 26 September 2009 - 06:09 PM

-john

#614

Posted 26 September 2009 - 06:16 PM

Philippe de Lespinay

#615

Posted 26 September 2009 - 07:38 PM

I intend to live forever! So far, so good.

#616

Posted 27 September 2009 - 06:49 AM

-john

#617

Posted 27 September 2009 - 09:17 AM

Philippe de Lespinay

#618

Posted 27 September 2009 - 09:46 AM

. Now what I want to know is how on god's (small g) green earth did you get the cojones to put a 25 in that motor

Simple! The person that won the week before used a 26 wind. How everything gets bigger, faster, slower, smaller...

11/6/54-2/13/18

Requiescat in Pace

#619

Posted 28 September 2009 - 08:39 PM

" I did a couple of #23 rewinds on modern D can arms and coms with soldered tabs and regular Devcon epoxy when I was getting started again."

**************************

John, did they last? How did they hold up? Details please. Thanks.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#620

Posted 29 September 2009 - 09:20 AM

Along with all kinds of other winds on all kinds of blanks (anything I could get my grubby hands on), I did a bunch of 23s and aside from getting the wire on there straight and even, a big problem was getting enough room at the com tabs (unless it was a Kirkwood or modern Mura com) to attach that massive wire. Most all of the early arms I did I either gave away or tossed as I was most interested in finding out what worked and simply at getting better. The 23s would spin like nobody's business and draw a hefty amount of current, but they were pretty crude. As I did more winds, I got a better balancing block (than you RGEO!), better epoxy (Duralco 4461) and better ways of terminating the wires at the com tabs. With those early 23s, I would spin them up all the way to 12V and I never had one blow simply doing that, but I doubt they would have lasted long on the track(?). I haven't done a 23 since then as nobody has asked me to, but just recently did a 24 that came out just great.

-john

#621

Posted 29 September 2009 - 01:34 PM

As I said, there was a lot of money in racing in my circles in the day. And I never did a motor that was expected to last more than the 50 minutes that qualifying and racing took. That said, I did a few 23s, but I wasn't driver enough and didn't have controller that would handle them.

But even a 25 or a 26 would be completely rebuilt in the day every race.

Well, to be clear, when last running flexies with super 16ds for "my team"... I rebuilt the "stock" super 16ds, a mere 28 every race. The bushings in the can were only good for 3 races, the brushes 4 and the arm, because of the soft com, 3 races.

I did convince them ONCE to let me wind up some medium stack 29s whose purpose was to just have some quality bits in the motors, but they didn't like it, ultimately, as a well done 29 with quality stuff is a lot better than a sloppy 28 in a Parma! So I tried talking them into a 30.

Grin.

Fate

3/6/48-1/1/12

Requiescat in Pace

#622

Posted 29 September 2009 - 01:48 PM

Mike Boemker

#623

Posted 29 September 2009 - 03:05 PM

When we finally got cobalt magnets you could run a 23 with the expectation it would last but before that it was pretty tricky.

WHAT IS THAT????

That monster was the fastest motor I ever ran 'till it got too hot and spit the pinion off..

But then there was that skewed blank "thing" that Big Jim tested and on the first lap (it never made a lap) it was going so fast it launched in the bank and hit the back wall of the shop....He just stood there looking at the controller like it did something bad...

"TANSTAAFL" (There ain't no such thing as a free lunch.)

Robert Anson Heinlein

"Democracy and socialism have nothing in common but one word, equality. But notice the difference: while democracy seeks equality in liberty, socialism seeks equality in restraint and servitude."

Alexis de Tocqueville

"In practice, socialism didn't work. But socialism could never have worked because it is based on false premises about human psychology and society, and gross ignorance of human economy."

David Horowitz

Mike Brannian

#624

Posted 29 September 2009 - 03:25 PM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#625

Posted 29 September 2009 - 03:44 PM

That car would have flown 50-60 yards if the wall had not stopped it. The chassis was TRASHED. As far as I know he never ran that motor anywhere again. I have NEVER seen another slot car go down the straight faster than that BJ car did that night. I would have LOVED to try that motor on an Engleman.

"TANSTAAFL" (There ain't no such thing as a free lunch.)

Robert Anson Heinlein

"Democracy and socialism have nothing in common but one word, equality. But notice the difference: while democracy seeks equality in liberty, socialism seeks equality in restraint and servitude."

Alexis de Tocqueville

"In practice, socialism didn't work. But socialism could never have worked because it is based on false premises about human psychology and society, and gross ignorance of human economy."

David Horowitz

Mike Brannian

This topic is locked

This topic is locked