My guess is that it's material related.

Regarding the Starburst guide, I would agree with this.

Posted 25 January 2019 - 09:10 AM

My guess is that it's material related.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 25 January 2019 - 09:25 AM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 25 January 2019 - 10:09 AM

A question for Bryan Warmack.

Have you seen this pocket damage on your cars with the wire loop front bumpers you sometimes use?

I would think not.

Posted 25 January 2019 - 10:34 AM

Posted 25 January 2019 - 10:39 AM

I have noticed the same left side bias as I have lots of guides that have "peeled back" in crashes (and don't recall any that were on the right side!). I don't recall it ever being a wall-related crash associated with the left side damage – it is almost always hitting a de-slotted car that is still moving across the track or has come to rest before I got there. (It sounds like I am not looking ahead to stop for the crashes but I assure you I am looking. In fact, I try to stop far enough away that the marshal does not pick up my car while marshaling the de-slotted car. But this isn't about me...)

I don't believe that most crashes into other cars hit the back of the stationary car; in that case you would hit two wide tires first and it seems that would tend to lift the chassis out of the way. In my experience, most cars that are de-slotted are sideways in my where they present the edge of the side pan to the oncoming nose of the guide and that could, most certainly, shear and then peel back the clip area.

(The most recent one I had was while visiting Downriver Speedway where I had a "cruise" race in the B Main (only Retro car with a RH) and was being very careful not to hit anyone but still did! It didn't seem like the hit should have sheared a guide but it did, evident in losing the LS braid in each subsequent incident afterward. My buddy, my hero, Nelson Swanberg, super-glued the braid in between heats and I was able to soldier on to not lose the slim lead I still had before the race degraded into a de-slot exhibition near the end.)

Enough thread drift to battle stories:

If my theory is correct (that one most often hits the side pan if the impeding car is stopped or sliding across your lane in front of you), that creates a "perfect storm" for this kind of damage with a slicing edge just above the track surface and the guide cannot bounce sideways or turn away while constrained by the slot when you hit. But why so often on the left side?

If we knew more about the molding process, it may be that the plastic fills from the right side and migrates to the left side with cooler plastic meeting on the left side of the cavity (arguably mis-named as a "weld line") where it is no longer molten to adequately "join up" at the seam where they meet. The fix is usually to have the fill gates positioned symmetrically fill from the front/back or top/bottom when the part is symmetric (as the guide flag is).

This is only a theory (and opinion of a possible cause) because I imagine that hits to the guide happen equally to the left and the right of the guide if my crash scenario is valid. Also, I believe the folks that created molds would tend to design the gates for a proper fill but they might not be aware of the strength requirement of the outsides of this "open box" feature.

You were asking for opinions... and this is my 40% of a nickel.

Sorry about the nerf. "Sorry? Sorry? There's no apologizing in slot car racing!"

Besides, where would I even begin? I should probably start with my wife ...

"I don't often get very many "fast laps" but I very often get many laps quickly." ™

The only thing I know about slot cars is if I had a good time when I leave the building! I can count the times I didn't on one two three hands!

Former Home Track - Slot Car Speedway and Hobbies, Longmont, CO (now at Duffy's Raceway), Noteworthy for the 155' Hillclimb track featuring the THUNDER-DONUT - "Two men enter; one man leaves!"

Posted 25 January 2019 - 10:42 AM

I have noticed the same left side bias as I have lots of guides that have "peeled back" in crashes (and don't recall any that were on the right side!). I don't recall it ever being a wall-related crash associated with the left side damage – it is almost always hitting a de-slotted car that is still moving across the track or has come to rest before I got there. (It sounds like I am not looking ahead to stop for the crashes but I assure you I am looking. In fact, I try to stop far enough away that the marshal does not pick up my car while marshaling the de-slotted car. But this isn't about me...)

This would certainly explain the left side taking the brunt of it during my oval racing. Anyone de-slotting is more than likely coming across my left front. I'll try to remember to keep an eye on this going forward.

Posted 25 January 2019 - 10:45 AM

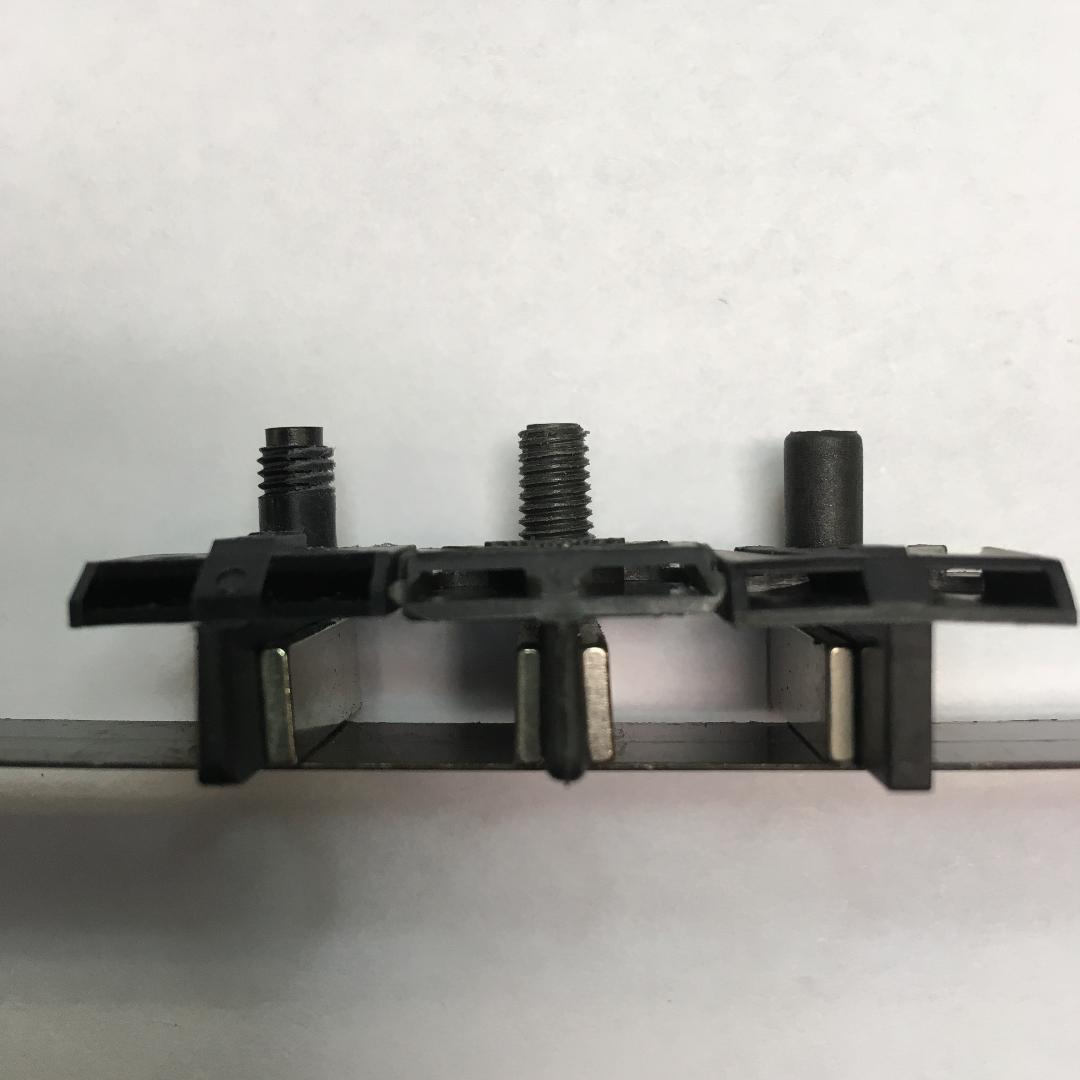

If you look at the profile of the flag the braid comes out and folds under and the clip comes out and folds up. Between the two a notch is created that can catch an object in a crash and the force is caught by the upper step causing the damage. Smoothing this step so that the object slides over the top rather than catching between the two parts would be the natural solution. Can you design a better clip to do this?

Posted 25 January 2019 - 10:46 AM

I don't really know this issue and I'm probably way off here. But has anyone considered this might have something to do with electric current? It seems several of the pictures have melting around the broken area. We have all seen arcing damage on the left braid and it would explain prominent left side damage. Just a thought....

If it's not a Caveman, It's HISTORY! Support Your local raceways!

Posted 25 January 2019 - 10:49 AM

My 2 cents on this - not an answer, but contributing factors:

- note one braid always "burns" more than the other. Is heat (heat from electrical resistance) a factor in material fatigue to contribute here (or conversely, is it improving the other side)?

- Material - nylon vs. graphite? graphite more brittle than nylon.

My inexpert opinion. But I think AJ Hoyt may also have a contributing factor there with the manufacturing process.

Posted 25 January 2019 - 12:24 PM

Mike Schlien hit on what is generally normal engineering practice. That is to use fillets and radii whenever possible. It is amazing how even a small radius can eliminate breakage in an inside corner? This would mean a modification to the side cores of the injection mold that create the holes that the braid fits into. An .015 inch radius might clear up the problem, or at least lessen it.

But what is interesting is that most of the broken guides are broken on the left side. I believe that track configuration does, in fact, effect which side breaks most.

Posted 25 January 2019 - 12:46 PM

- Material - nylon vs. graphite? graphite more brittle than nylon.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 25 January 2019 - 01:07 PM

What brand of guide is that, Howie?

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 25 January 2019 - 01:14 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 25 January 2019 - 01:58 PM

interesting thread. I have also had some braid pocket breakage with the RF. There have only been a few but percentage wise more than when I used the Parma. In fact, I can't remember ever having any braid pocket damage on the white Parma guide. Of course that is a full height guide opposed to the cut down and those don't fit on too many chassis so they haven't been used near as often.

I do (usually) boil the RF guides in order to possibly minimize post shearing. I wonder if that has something to do with the fact that I've had relatively few? I couldn't guess whether any that I've boiled have peeled the braid pocket. I never marked them in any way.

Posted 25 January 2019 - 02:13 PM

As an aside, a former trackowner whose main gig was working for a company that made molded nylon electrical connectors told me several times that boiling nylon guides in antifreeze (i.e. a solution of ethylene glycol) would make the material measurably stronger. I never tried it nor boiled them in water, which is also said to improve the material's strength.

I did pin my Parma guide shafts for many years (as detailed HERE) and don't recall ever breaking another guide shaft off.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 25 January 2019 - 03:28 PM

If you take a look at the guide in post #25, there is a sign of something going on with the left pocket that isn't going on with the right. It appears to be heat related. Why that is occurring may be the cause of all the breakage if the cause of the distortion isn't from soldering wires to the clip while it's in place.

Posted 25 January 2019 - 03:35 PM

Probably my poor soldering at the time. I was using an iron that was too big and hot for soldering leadwires to clips back then.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 25 January 2019 - 03:41 PM

As an aside, a former trackowner whose main gig was working for a company that made molded nylon electrical connectors told me several times that boiling nylon guides in antifreeze (i.e. a solution of ethylene glycol) would make the material measurably stronger. I never tried it nor boiled them in water, which is also said to improve the material's strength.

I did pin my Parma guide shafts for many years (as detailed HERE) and don't recall ever breaking another guide shaft off.

Steve Meadows

Posted 25 January 2019 - 04:38 PM

Right. We used to boil our nylon suspension parts when I raced R/C. It does help for nylon, can't speak for graphite impregnated nylon, though.

Posted 25 January 2019 - 04:56 PM

The Starburst and the Parma are thicker above the braid pocket, with the Starburst being the thickest.

They also have more setback on the front of the braid pocket, which means the stress of a hit is moved further back and may be absorbed more by the bending of the braid clip rather than being directly transmitted to the plastic.

As others have noted, the track and where one hits is relevant... busting the braid pocket happens rarely when hitting the walls on my Engleman and is probably more likely to occur when running into another car.

That said, I believe both the Parma and Starburst graphite guides are stronger than the Red Fox and probably hold up better on a King track.

Jim Honeycutt

"I don't think I'm ever more 'aware' than I am right after I hit my thumb with a hammer." - Jack Handey [Deep Thoughts]

Posted 25 January 2019 - 05:53 PM

Maybe one thing to asertain is are these guide breaking primarily on a King track? If so the most likely, and maybe the only location for very high speed impact would be coming out of the bank. If it launches in the turn the guide is already turning to the right making the left side pocket more "vulnerable."

Posted 25 January 2019 - 06:05 PM

Posted 25 January 2019 - 09:56 PM

interesting thread. I have also had some braid pocket breakage with the RF. There have only been a few but percentage wise more than when I used the Parma. In fact, I can't remember ever having any braid pocket damage on the white Parma guide. Of course that is a full height guide opposed to the cut down and those don't fit on too many chassis so they haven't been used near as often.

I do (usually) boil the RF guides in order to possibly minimize post shearing. I wonder if that has something to do with the fact that I've had relatively few? I couldn't guess whether any that I've boiled have peeled the braid pocket. I never marked them in any way.

As an aside, a former trackowner whose main gig was working for a company that made molded nylon electrical connectors told me several times that boiling nylon guides in antifreeze (i.e. a solution of ethylene glycol) would make the material measurably stronger. I never tried it nor boiled them in water, which is also said to improve the material's strength.

I did pin my Parma guide shafts for many years (as detailed HERE) and don't recall ever breaking another guide shaft off.

Cheater,

Boiling moulded nylon after it’s been moulded reduces its brittleness. Kind of like tempering (steel).

I recommended doing this to all the coloured new RF guides when they came out and racers were having breakage problems.

We have some components moulded at work by a specialist moulder and they boil it all post-moulding for this reason.

Right. We used to boil our nylon suspension parts when I raced R/C. It does help for nylon, can't speak for graphite impregnated nylon, though.

I emailed Stu earlier and he said as I expected, there was very little graphite in a Starburst "graphite" guide, and he doubts it does much.

He also mentioned what I have noticed.

That boiling the guide, to add moisture, is temporary, as the water will evaporate.

When I boiled the pre-graphite, new Red Fox, they would become noticeably more flexible.

That would make sense as they were warm.

But even hours later, long after they cooled, they were still more flexible than stock.

But a day or two later, they were back to being as stiff as they were, before boiling.

So if the stiffness is related to the brittleness, boiling is not a permanent fix.

On R/C car forums you get a million different opinions on boiling, some positive, some negative.

Here was an interesting one;

been at this for years, and i no longer boil.

it isn't metal. It won't realign the carbon makeup to form stronger bonds with their neighboring molecules... it does the opposite.. it weakens the bonds between polymers plastics are chemical in nature, not rigid. the right mixture of chemicals makes a plastic compound rigid.. heat breaks down the chemical bonds.

Short answer - yes it makes parts more flexible.. this may save a part that would break on impact, but in general - you're getting a weaker part.

I've noticed that any of the parts ive boiled (especially when it comes to brittle or cheaper plastics) - i'd wind up with tearing at the mounting locations.. not cracking, but tearing, at the screw or bolt eyelets.

higher quality plastics like delrin will boil better... but they are already pretty flexible.. limited benefit.

There are plenty who do this however... and the only place i could see it being okay are often replaced parts anyways.. might get an extra few jumps out of it.. like a arms and such.. but never do any chassis parts or permanent duty parts, or plastic gears, etc.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 26 January 2019 - 12:40 AM

Steve Meadows