To relieve pressure..... where the braid tab bends over on the under side, cut 3/4 of it off so it doesn't extend and lap on top of where the braid attaches to the clip.

Posted 28 January 2019 - 10:29 PM

Pin the front of the blade. Leave enough piano wire hanging out of the front to block any impact damage from a front end collision.

If you are saying pin it ,horizontally, with the tip sticking forward, how could that possibly help?

A-whatever you would hit, would pivot off of that minuscule .032" -.043" tip, and still bang the braid pocket on either side.

B-it would be more likely to help break the blade (bad)

C-stab a turn marshal (real bad)

The Red Fox braid pocket is a tight fit with braid and a wire clip inserted. That is putting pressure on the top of the guide. Are you better off to run braid without the dimple or possibly flatten out the dimple taking a little pressure off?

I agree the Red Fox has a tight braid pocket.

The brand of braid clips that were advertised as .012", but came in as .015", were useless with them.

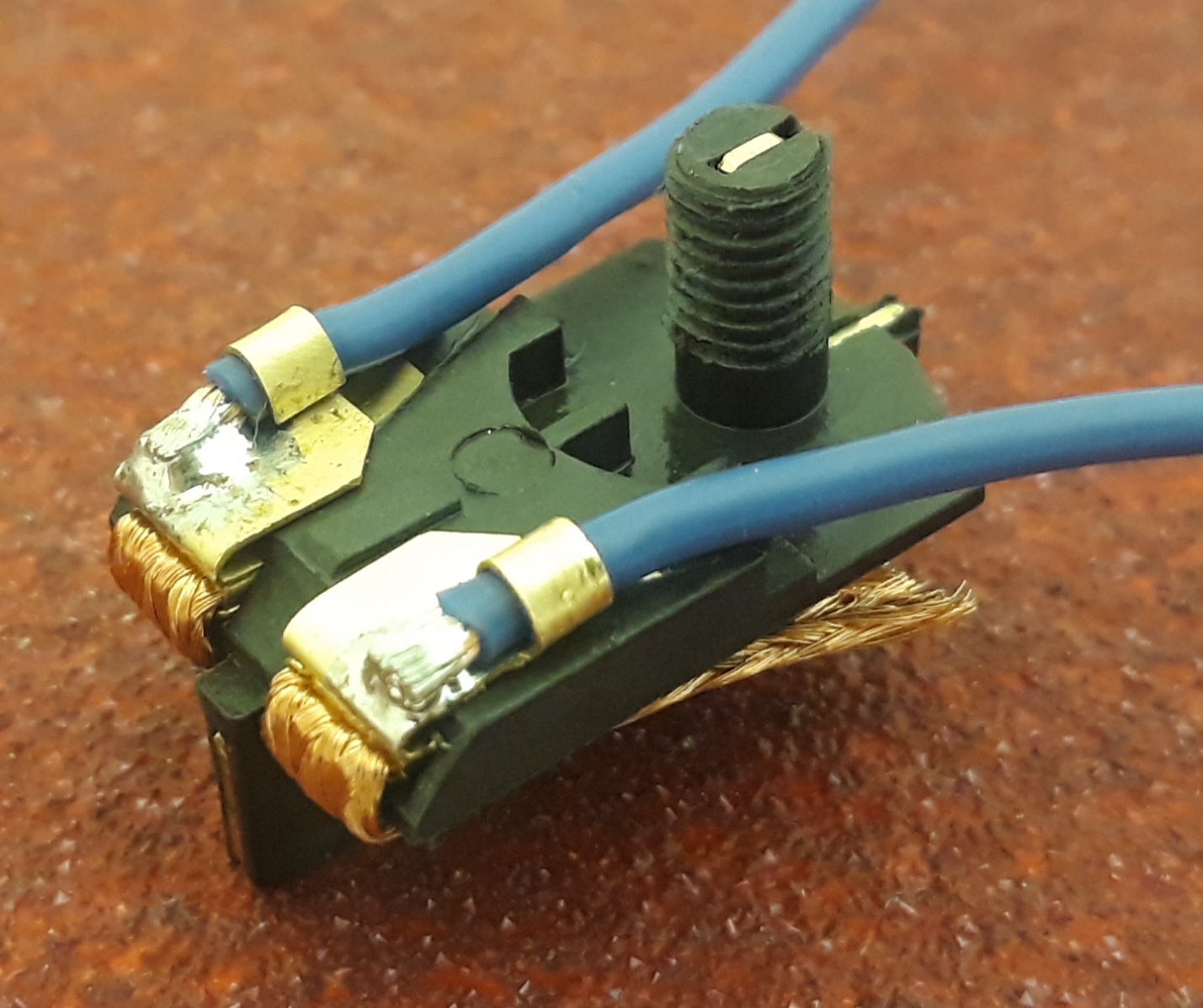

But with TQ, the virtually identical JK, or my new brass ones, the fit is about perfect.

A little tight, the first few braid installations, but about perfect, after that.

It needs some tightness or the braid falls out too easily.

To relieve pressure..... where the braid tab bends over on the under side, cut 3/4 of it off so it doesn't extend and lap on top of where the braid attaches to the clip.

With .010" clips, way too loose.

Losing your braid in moderate hits doesn't solve the problem.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 29 January 2019 - 01:03 AM

I need needle nose pliers to get them in. No problem yet. They are very snug.

Posted 29 January 2019 - 01:09 AM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 29 January 2019 - 11:48 AM

^^^^^^

Koford

.01

snug but not crammed (in your LCoG guide flag)

Posted 03 February 2019 - 02:03 PM

Mike, I think it's time for you to manufacture a sturdy guide of your own.

Posted 03 February 2019 - 02:09 PM

^^^^^^

Koford

.01

snug but not crammed (in your LCoG guide flag)

I got a new micrometer and the clip is .018

Posted 03 February 2019 - 02:13 PM

I have broken several different brands of guides. Seems to happen when hitting another car, retro or flexi. I tried using internal lead clips and still broke the pocket.Greg,From the type of split, and type of car you raced, your assumption makes a bit of sense.But Retro cars don't have that type of a back of a car.Also, in the case of the Red Fox, they split or peel up on the top, like my picture.IMO, they are breaking from intense shock.John Austin broke one, on the original Red Fox guide, about a year ago, hitting my hand while marshaling another car.My hands are not like a dull knife. They are soft as the leather on an expensive woman's glove.

Posted 03 February 2019 - 07:21 PM

Ok,triage nurse whats the Diagnosis & Treatment plan?

Posted 31 July 2019 - 12:47 PM

Posted 31 July 2019 - 12:57 PM

Quick question. I see so many guide flags with angled slots in the top, but have never seen them used in person or in photograph.

I'd assumed it was to sink the lead wires into, but never seen it done.

Why/why not?

I do it all the time. I've had the top of the clip break off several times.

I usually use a full clip cut in half. But I have a package of ProSlot PS-625 that I'm going to try.

Rotor

Rotor

Posted 31 July 2019 - 03:50 PM

I think those slotted guides were originally made for wing car racers so they could get the nose of a body as low as possible. I don't recall who made them first, probably either Koford or Slick 7. I've made my own using a small end mill in a Dremel.

Posted 31 July 2019 - 04:08 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 31 July 2019 - 05:12 PM

Plus it made changing a broken guide flag, harder.

Yup. If you break a flag in a race, you don't have time to be fiddling with those slots. Could be the difference between podium and last place.

Paul Wolcott

Posted 31 July 2019 - 07:49 PM

Those slots can also be used without half-clips & solder. Ask Roman K..

Posted 31 July 2019 - 07:58 PM

As Mike Swiss and Pablo indicated, on the top clips make for the fastest guide change.

Wire soldered to internal clips or just wire into the guide with no clips make it slower and more painful when you're in a hurry, regardless of their other positive aspects.

Of course if you want to get fiddly and still have a lower profile, you can solder the wire onto the other side of the clip at the perfect angle so that it fits in the slot on the guide and you can still just pull the clip out with the wire attached.

Jim Honeycutt

"I don't think I'm ever more 'aware' than I am right after I hit my thumb with a hammer." - Jack Handey [Deep Thoughts]

Posted 31 July 2019 - 08:02 PM

This thread being resurrected inspired me to finally do something I think I mentioned in this thread.

Purposely bend the clip on the long side, to create a gap in front of the edge that peels back in bad wrecks.

Not sure if it will help or hurt, but I did a couple extra for Howie, N/C, to try out.

Being able to push the clip further back in a guide, to do the longer bend, required more effort than I hoped.

The thought is the inside of the braid pocket, absorbs most of the hit, in a big impact.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 02 August 2019 - 12:09 PM

Don't know if this will make any sense but here goes. I would imagine that most racers install the braid in the guide flag with the dimple on the top, yes I have seen them installed with the dimple on the bottom. If it takes excessive pressure to get the braid all the way in it would seem like you are preloading the braid pocket. If that's the case it wouldn't take a hard hit only a hit in the right place to split the guide. You don't need a lot of pressure to hold the braid in place just enough pressure to do the job. What I do is take a pair of pliers and put a reverse dimple in the production dimple. You will notice that the braid can be installed by hand, without excessive force, and it won't come out in a wreck. Sad to say I've been doing it this way since the early 90s and I have never broken a guide in the braid pocket area no matter what brand I've used. Bent some guide clips ,chipped a blade, and even broken a post or two but no real damage in the guide pocket to where the guide was no longer useable. By the way to those of you who install the braid with the dimple on the bottom, check out the underside of the guide when you do.