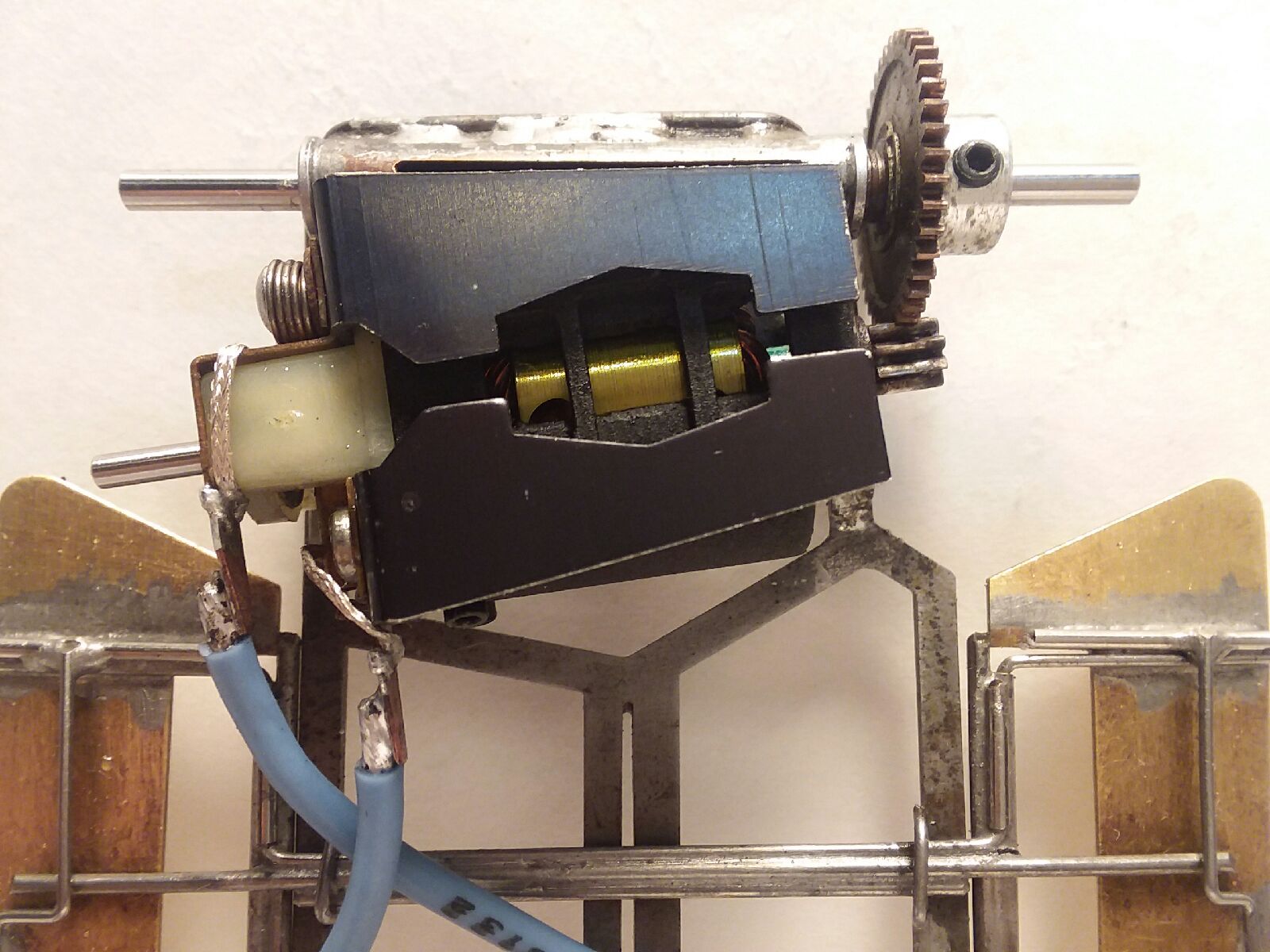

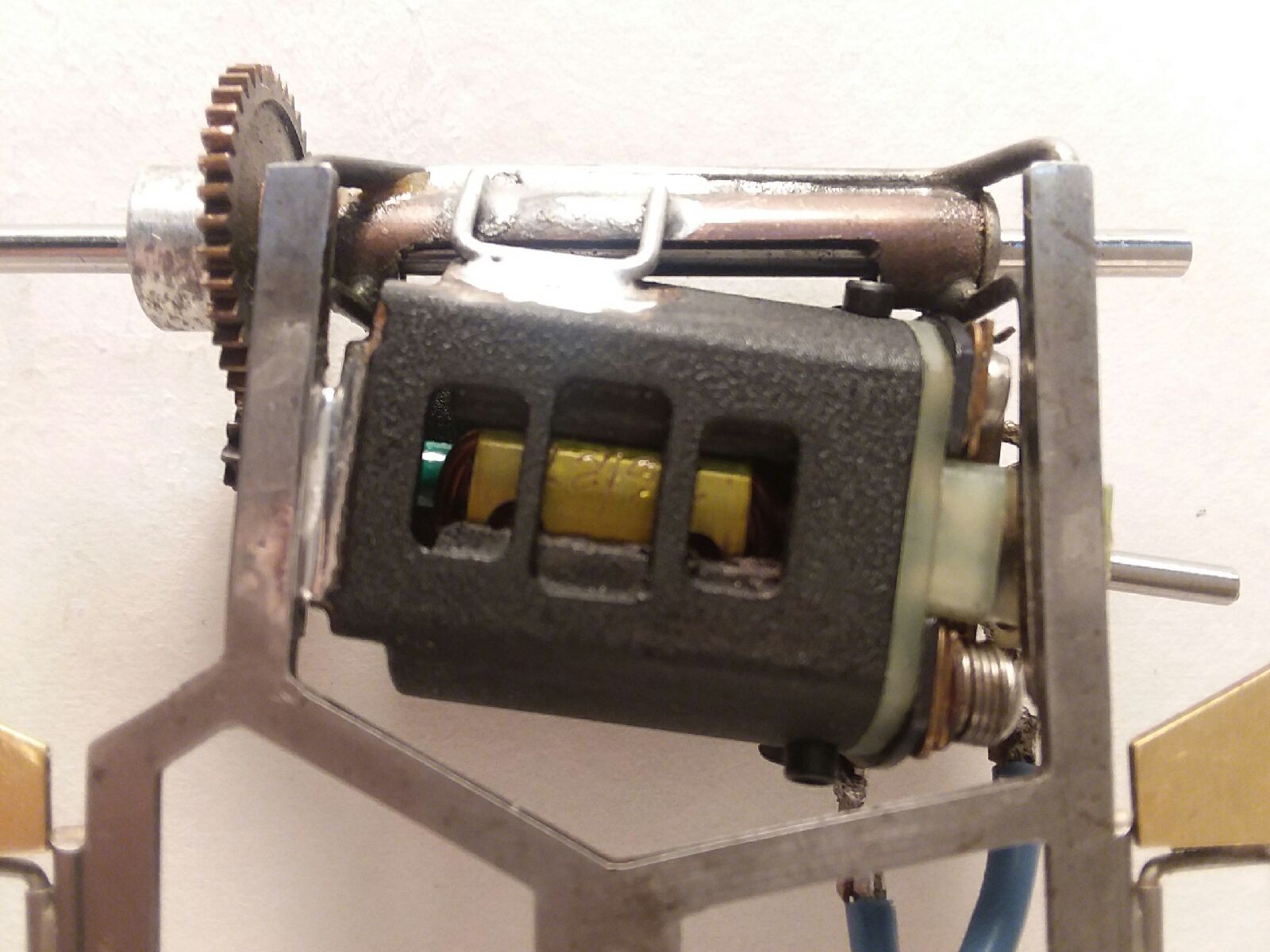

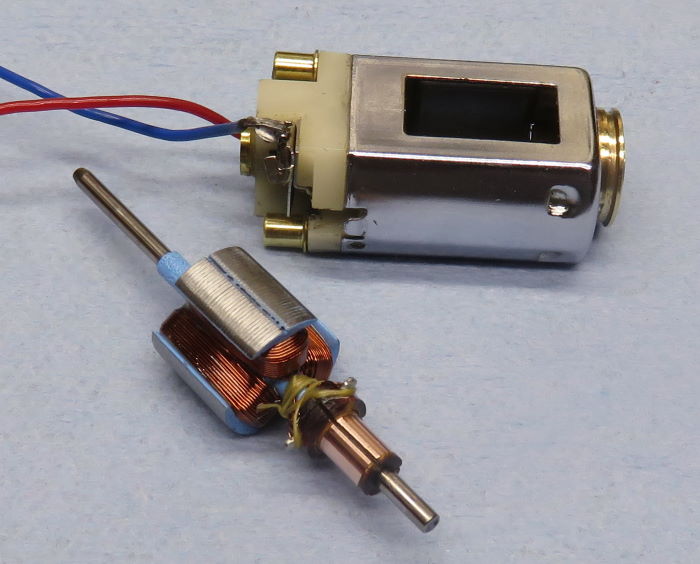

It's also about zipping-along nicely, letting the tail get a little loose coming out of a turn, and imagining you're driving a nifty F1 with the wind in your face and some motor oil on your goggles. ![]() Here's the beginnings of a lovely 13UO, the motor that both attracted and bedeviled me as a kid. The caged can bushing was removed, the hole reamed to accept a new oilite, and a nice snug 2mm x 5mm oilite soldered-in...after which the back end of the brass bushing carrier was milled-down. Inside, a nice set of ceramics were taken-down height-wise to fit the can and epoxied in place. The end bell has "the Mabuchi crack", so that need attention, but the end bell oilite is in excellent shape, so at least there's that.

Here's the beginnings of a lovely 13UO, the motor that both attracted and bedeviled me as a kid. The caged can bushing was removed, the hole reamed to accept a new oilite, and a nice snug 2mm x 5mm oilite soldered-in...after which the back end of the brass bushing carrier was milled-down. Inside, a nice set of ceramics were taken-down height-wise to fit the can and epoxied in place. The end bell has "the Mabuchi crack", so that need attention, but the end bell oilite is in excellent shape, so at least there's that. ![]()

Now, all this isn't for making a screamer. I plan on a smooth/solid performer that will run significantly faster than stock, stay cool enough to not vaporize the end bell, and still be perfectly appropriate for any period application of the "littlest Mabuchi".

It's not all about big wire and tire-shredding

#1

Posted 04 November 2019 - 06:58 AM

- Steve Okeefe, slotbaker, Jencar17 and 10 others like this

#2

Posted 04 November 2019 - 07:25 AM

My favorite!

- havlicek likes this

Dennis Dominey

IRRA National Director

#3

Posted 04 November 2019 - 07:41 AM

My favorite!

Me too Dennis! ![]() I tried everything to make these go fast(er), and even with only dewinding them, they never lasted very long. They always appealed to me because of their size, which about perfect for a 1/32 inline. Of course, better magnets didn't exist as far as I knew, and a solid can bearing never occurred to me. Plus, the springs on these are very weak, even by Mabuchi standards. All of that can be fixed now!

I tried everything to make these go fast(er), and even with only dewinding them, they never lasted very long. They always appealed to me because of their size, which about perfect for a 1/32 inline. Of course, better magnets didn't exist as far as I knew, and a solid can bearing never occurred to me. Plus, the springs on these are very weak, even by Mabuchi standards. All of that can be fixed now!

#4

Posted 04 November 2019 - 08:32 AM

We used them in 1/32 scratchbuilt cars when I started in 1971. The smoke did tend to leak out of them even back then!

i have a custom can here that I plan to send you to build up....one of these days!

Dennis Dominey

IRRA National Director

#5

Posted 04 November 2019 - 10:45 AM

I've always liked these little motors as well. ![]()

When I got into racing I-15 in the early '80s it seems there was a small cobalt class motor called a peanut can motor. Had plastic cobalts I think I was told? Were they made out of these?

I never had one of these and my memories of it are very fuzzy, so maybe I have this all wrong.

- havlicek likes this

???-2/31/23

Requiescat in Pace

#6

Posted 04 November 2019 - 02:42 PM

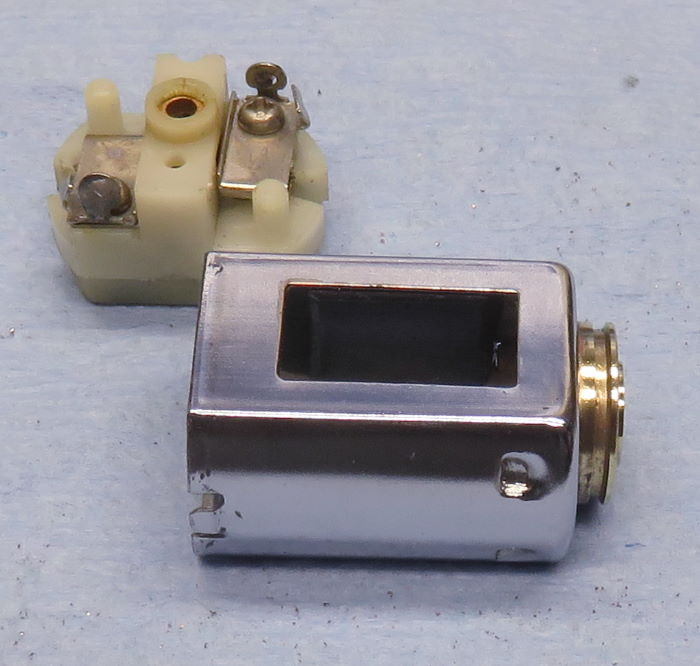

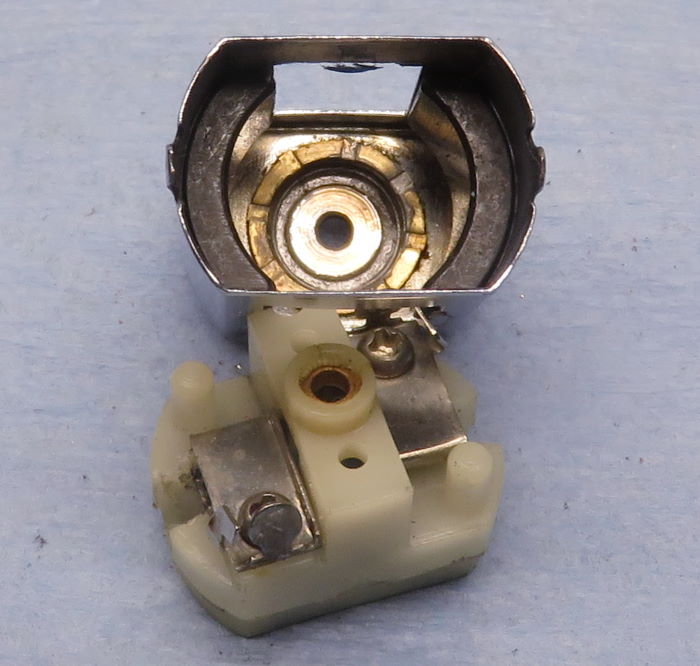

As far as I know Phil, the "peanut" motors were all made from 13UO Mabuchis, but the ones I have seen used Mura C-can end bells turned-down to fit. The stock end bells would have vaporized. ![]() I recently did one, but with ceramic magnets instead of the soft cobalts, and it's part pf a group of motors I showed in this thread:

I recently did one, but with ceramic magnets instead of the soft cobalts, and it's part pf a group of motors I showed in this thread:

http://slotblog.net/...-of-old-motors/

- Phil Smith likes this

#7

Posted 04 November 2019 - 04:27 PM

Dennis Dominey

IRRA National Director

#8

Posted 04 November 2019 - 05:19 PM

As far as I know Phil, the "peanut" motors were all made from 13UO Mabuchis, but the ones I have seen used Mura C-can end bells turned-down to fit. The stock end bells would have vaporized.

I recently did one, but with ceramic magnets instead of the soft cobalts, and it's part pf a group of motors I showed in this thread:

http://slotblog.net/...-of-old-motors/

John, nice looking peanut setup! Thanks for the info and link.

???-2/31/23

Requiescat in Pace

#9

Posted 04 November 2019 - 05:37 PM

The Peanut motors started out, using 13 size Mabuchi cans.As far as I know Phil, the "peanut" motors were all made from 13UO Mabuchis, but the ones I have seen used Mura C-can end bells turned-down to fit. The stock end bells would have vaporized.

I recently did one, but with ceramic magnets instead of the soft cobalts, and it's part pf a group of motors I showed in this thread:http://slotblog.net/...-of-old-motors/

Even with the soft/plastic cobalt mags, they ran too hot.

The last generation of peanut motors, before Koford started using small hard cobalt mags, the Trinity Peanut, and the Camen Pony Express, were made from sectioned Mura cans.

Those soft cobalt mags were interesting.

While the 1 pair I had, from Parma, were used full size, in a normal C can, I was told they could be trimmed to size with a sharp X-Acto blade.

- Phil Smith likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#10

Posted 04 November 2019 - 06:35 PM

Indeed you could cut them down with sandpaper in a few minutes by hand to fit the 13d. Like cutting plastic.

After the year was up the magnets became available to more people. P A Watson was the first to cut them down and use in a 13d.

Those first peanuts had no brakes and ran really hot because when just cutting down the height and honing in the can for air gap the tips were too close to each other. Once people figured this out and simply sanding back the tips, they had punch, brakes and did not blowup in a couple of laps.

Ray Kallio went one better and used HO cobalts in a 13d can and that’s was the way the motor technology went.

Sent from my iPhone using Tapatalk

- Phil Smith likes this

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#11

Posted 04 November 2019 - 06:38 PM

#12

Posted 04 November 2019 - 06:42 PM

I’m not sure if they came charged or not.

Sent from my iPhone using Tapatalk

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#13

Posted 04 November 2019 - 07:23 PM

Some of my Tjets have crazy HO poly-cobalts in them. When doing some clean-up and maintenance on them, tweezers, brushes, springs, lighters etc. go flying all over the place!

Smooth!

Mike

Mike DiVuolo

C.A.R.S. Vintage Slot Car Club

"Prosecutors will be violated"

#14

Posted 04 November 2019 - 07:28 PM

Built a few for 1/32 BSCRA sports and F1 back in the early 80's, had better results when i started using the 1.0.1 Infinity can. Remember the polymer magnets came ready to fit, however you could buy a cheap hone/ cutter tool which consisted of a 2mm shaft and a small boss with an adjustable cutting tip which made light work of getting the required air gap! think it was available from SCD.

[oneofwos]

Requiescat in Pace

#15

Posted 04 November 2019 - 08:27 PM

Not a great pic, but a Trinity Peanut can be seen here.

http://slotblog.net/...ion-for-tony-p/

I don't quite remember what happened to the car.

Maybe Mark Mattei has it.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#18

Posted 05 November 2019 - 05:51 AM

How did you cut down the magnets? Just curious what cutter was used and how did you handle the magnet dust?

Hi Chris,

After reading through all this, I realized you may have been asking me how I cut the ceramics down for this 13UO. I use inexpensive diamond wheels that you can buy with 1/8" shaft mandrels. As hard and brittle as modern ceramics are, they will cut/grind the material fairly easily, they will also cut solid or "sintered" neo and cobalt magnets, BUT you have to be really careful with those as the dust will ignite. The softer "poly neos" can be sanded, but again, the dust is something you need to watch carefully. ***When cutting or grinding the ceramics, you also have to pay attention to the direction the wheel is turning relative to the magnets. If the wheel is turning perpendicular to the magnet edge for example, you can blow off chunks of the magnet. If you have the wheel face running along the edge, you can minimize of even eliminate that problem. I go slow and keep checking the size as I do each edge, and the the dust can be removed with magnet putty, plumber's putty or even masking tape before installing them. If the magnets are being honed (*which also uses diamond-abrasives), I clean everything out as best as I can using whatever "sticky stuff" I have around, then I hold a small solid neo magnet with a pair of needle nose pliers and stick it in there and play it around. Since these magnets are far stronger than even the best ceramics, they will grab up more dust that was hiding in the nooks and crannies. Then you can pull the neo out, clean it off and repeat until nothing more comes out. Ceramic dust is very hard and abrasive...PLUS...each particle is a little magnet and it will stick to everything in the motor. It's important to get as much of it out of there as possible. Interestingly, you can also finish-up by sliding any small piece of magnetic material...steel or even stainless steel that is slightly magnetic across little creases and joints where the magnets meet the can, and some magnet dust will stick to the steel. It's good to be anal-retentive about this stuff. ![]()

- Geary Carrier and Jesse Gonzales like this

#19

Posted 05 November 2019 - 06:00 AM

Thanks to those who posted the peanut pictures above! I've had some come across my bench, and they were pretty cool little motors. I had one of the Trinity ones come with a matching turned-down Mura end bell, and that was an awfully nice can.

Back on the little Mabuchi here, the end bell got the crack fix and I pressed-up an arm blank with wider crowns. The ceramics I installed are a little thicker than the original Mabuchi "magnet-like things" ![]() that were in there. Coupled with the larger O.D. .518" lams, the air gap is now nice and snug and the arm spins beautifully in the setup with enough "tug" from the magnets to let me know everything is dandy in 13UO land. These ceramics measure up to ARCO strength...at least. While a #30 wind doesn't sound like much, it will make for a dandy and reliable runner for sure.

that were in there. Coupled with the larger O.D. .518" lams, the air gap is now nice and snug and the arm spins beautifully in the setup with enough "tug" from the magnets to let me know everything is dandy in 13UO land. These ceramics measure up to ARCO strength...at least. While a #30 wind doesn't sound like much, it will make for a dandy and reliable runner for sure.

Dennis' suggestion about the poly-neos would take things even further, and those work really well in these little motors, but this little guy will have brakes and enough torque to make all the other vintage guys sit up and take notice! ![]()

- Pablo and Geary Carrier like this

#20

Posted 05 November 2019 - 08:54 AM

IOW, you can have a well designed motor, that has very little tug, but is very strong magnetically.

Or a poorly designed one, that tugs/cogs like mad, but is very weak magnetically.

And to say the magnets you have are as strong as Arco's, unless they are identical in profile, height, length, and thickness, you are only guessing.

Gauss meters are only accurate for comparing identical magnets.

A super-prominent G7 racer was blowing up motors and complaining about raceway's power.

He made the offhand comment "my stronger setups are the ones with shorter magnets".

He actually was just being fooled by the gauss meter, and how a shorter cobalt mag of the same size/design (thickness, height and profile), will read higher.

- tonyp, Phil Smith and Geary Carrier like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#21

Posted 05 November 2019 - 01:05 PM

Tug from the magnets has more to do with their orientation vs. the crown of the particular arm, than their actual strength.

IOW, you can have a well designed motor, that has very little tug, but is very strong magnetically.

Or a poorly designed one, that tugs/cogs like mad, but is very weak magnetically.

Yes, I understand all that. You will just have to trust me when I say that, after many many hundreds of these things, I have a good idea of what's going on with a particular set of magnets and can type.

And to say the magnets you have are as strong as Arco's, unless they are identical in profile, height, length, and thickness, you are only guessing.

***See the above answer.

Gauss meters are only accurate for comparing identical magnets.

That is only partly true, but I don't use gauss meters for their "accuracy" in any case.

- MSwiss, NSwanberg and Geary Carrier like this

#22

Posted 06 November 2019 - 07:30 PM

Arm is done. I wound 74/31awg for the little guy. It should scoot real nice. I was reminded while doing this that winding arms is a funny thing. The thick wire is tough, but so is the skinny stuff.

- slotbaker, Samiam, Geary Carrier and 3 others like this

#24

Posted 07 November 2019 - 05:47 AM

You really do need to stay focused and pay attention with these Geary. It's not just the turn count though, replicating the patterns across three poles can get pretty tough. Sometimes I will get distracted and have to undo the whole thing and start back at pole one. I will write myself little notes when winding like "74/31 +2 +2 +1" for this one, as a way to keep the patterns straight, but sometimes even that doesn't work. Tensioning the wire is also a little more tricky with the thin stuff. I limit the frustration though by not having any wire thinner than #31awg. That seems to help! ![]()

- Geary Carrier likes this

#25

Posted 07 November 2019 - 10:07 PM

Tug from the magnets has more to do with their orientation vs. the crown of the particular arm, than their actual strength.

IOW, you can have a well designed motor, that has very little tug, but is very strong magnetically.

Or a poorly designed one, that tugs/cogs like mad, but is very weak magnetically.

And to say the magnets you have are as strong as Arco's, unless they are identical in profile, height, length, and thickness, you are only guessing.

Gauss meters are only accurate for comparing identical magnets.

A super-prominent G7 racer was blowing up motors and complaining about raceway's power.

He made the offhand comment "my stronger setups are the ones with shorter magnets".

He actually was just being fooled by the gauss meter, and how a shorter cobalt mag of the same size/design (thickness, height and profile), will read higher.

Interesting. I did not know that.

This reminds me of my brief foray into racing 27's in the ~ mid '80s. Everyone where I raced ran Camen setups that virtually had no cog at all. We took this as big plus, reasoning that the heavy cog of other cobalt setups somewhat held the arm back. Made sense to me until someone much more knowledgeable than I pointed out that spinning the arm by hand is not how the motor works when the arm is energized. This made perfect sense and I was a bit embarrassed because the guy was laughing while he was explaining it to me.

???-2/31/23

Requiescat in Pace