I have read/re-read on different slot car forums, the discussions that compare the advantages/drawbacks of inline vs anglewinder motor drive configurations.

Quite interesting to read and the thought came to mind to see if it was possible to "cross-breed" the characteristics of the two motor drives on one chassis.

I had wondered about this for a long while, but did not know how to approach such a build.

The past couple of weeks I had been tinkering away, attempting to configure such a chassis, finally fabricating a couple of prototypes that I call "X-Drive"; which is my abbreviation for "Cross-Drive".

I chose the word" Cross" because it is a cross of inline and anglewinder, combining the characteristics of the two different motor drives.

As I mentioned, I prototyped 2 versions of my X-Drive chassis; one configuration is a short shaft (SS).

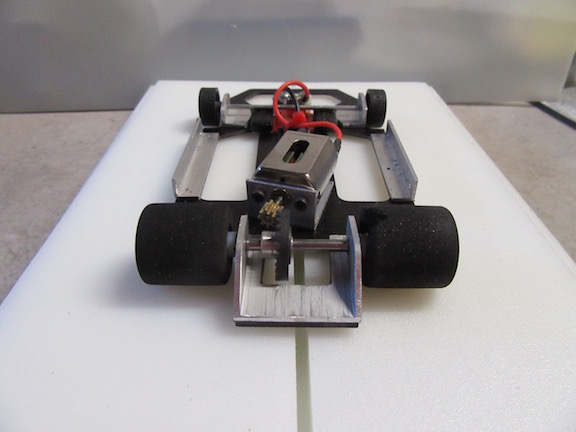

Here are some pictures of my prototype X-Drive SS Chassis:

Even with the added ballast, it is still fairly light.

I always wondered about the possibility of placing a motor mid-chassis or as close as possible to the middle, without having to fabricate a driveshaft.

As I was rummaging through my surplus of motors, I was excited to find an FK-180 motor with a very long shaft length of approximately 3/4" long.

This CCW motor helped to inspire the 2nd chassis, X-Drive Long Shaft (LS) chassis.

Test Run

NOTE: Concerning the pinion angle to Crown gear mesh; just like setting the mesh on an inline drive - it feels smooth!

My wife and I went to the track earlier today and had the opportunity to put both chassis on a test run.

X-Drive SS:

The SS chassis handled very well - surprisingly so!

I ran it for a few minutes, getting acclimated and attempting to push it, and it remained very stable.

My wife drove this chassis and she shared the same observation of how well it handled - she liked it!

X-Drive LS:

I did not know what to expect when I placed it on the track.

To my amazement, i could see a definitive difference in handling performance - even better than the SS.

Perhaps due to the motor being placed mid-chassis?!

Tracking around the hairpins, I noticed the "grip" was so tenacious with the rear tires I had on, that the tires would "chatter" with no fishtailing.

This reminded me of Mike Swiss test driving the Direct Drive prototype chassis, where he mentioned the grip of the rear was such that you did not need that wide of a rear tire; at least that is what I recall.

I stand corrected if I had misread what Mike mentioned on that thread.

I'll put on narrower rear tires for the next test run to see if there is a difference in handling performance.

The only distraction for me was that the new gears were noisy and I need to break them in, but I was very pleased that my efforts to fabricate the chassis were rewarded with positive results.

There is plenty of fine-tuning to be done, but for the maiden voyage, I felt it was a good test run.

Thank you for looking.

Ernie