Here at Electron Raceway, we race True scale, plastic model cars with production chassis and sealed motors. I have chosen this route to flatten the learning curve for racers new and old and provide fun and close racing at a reasonable cost.

During my last visit to the Phoenix, AZ area, I met up with some old friends from the AZGR (Arizona Garage Racing) club for some slot racing fun. They race scale 1/24 and 1/32 cars at private tracks in the Mesa Arizona area. Dave Deuble, a tireless promotor, track owner and dedicated slot head is the honorary AZGR rule maker (a thankless task at best).

I was fortunate enough to attend several AZGR races over the span of more than a month. Dave and his crew were always kind enough to provide competitive rides. I cannot blame my poor showing on equipment, just incompetence

Of the several scale cars we raced, I was intrigued by their Indy Car class. The class is based upon an inexpensive H&R chassis. The chassis is modified for the proper wheelbase and the front end modified to accept an axle tube for a 1/8 inch axle. Power is provided by a 25K, long can Scaleauto motor. These open wheel cars were fun to drive and great looking to boot.

Below are a few images of a passel of AZGR Spec Indy Cars in various stages of construction. See the appendix for AZGR Indy Car specs.

I thought it would be fun to develop an Indy Car class for racing at my track, Electron Raceway. Some of our racers have spare copies of the old ProTrack brass chassis which is a non-adjustable wheelbase version of the H&R. The ProTrack was my starting point. The ProTrack chassis wheelbase is a bit too short for the Indy class and required some modifications. Custom axle hangers must be fabricated and soldered to adjust the ProTrack wheelbase. For those who don’t have an old ProTrack gathering dust, or do not want to expend the additional effort required for a ProTrack build, an inexpensive H&R is in order.

OK, enough talk about the class of cars. It is time to get building. The first order of business was to acquire an Indy car plastic model kit. Out of production for many years, I turned to E-Bay. Monogram 1/24 kits come with several liveries and can be had for about $20 (including shipping) if you look hard and are patient. My starting point was the Mac Tools Lola (see image below). These kits are quite detailed. Unfortunately, there are, by my count, at least ten parts comprising the body. In addition, some of the underside of the model’s plastic chassis had to be cut away in order to sit flush on the H&R or ProTrack chassis. Assembly was time consuming and lots of plastic welder was required. Follow this link and watch a Youtube video of a Monogram Indy car review. It will provide some insight into the complexity of the build. https://www.youtube....h?v=gW_hFfrHaUU

Whether one chooses to use the ProTrack or H&R chassis, the first order of business is to assemble the model. Once the body is assembled, it must be modified to fit what will be the chassis. The bottom pan of the model must be cut to remove its center section which would otherwise interfere with mounting the body. See images below

Whether one chooses the ProTrack or the H&R, the “ears” of the chassis must be cut to follow the contour of the Indy body. Below is an image of the stock chassis.

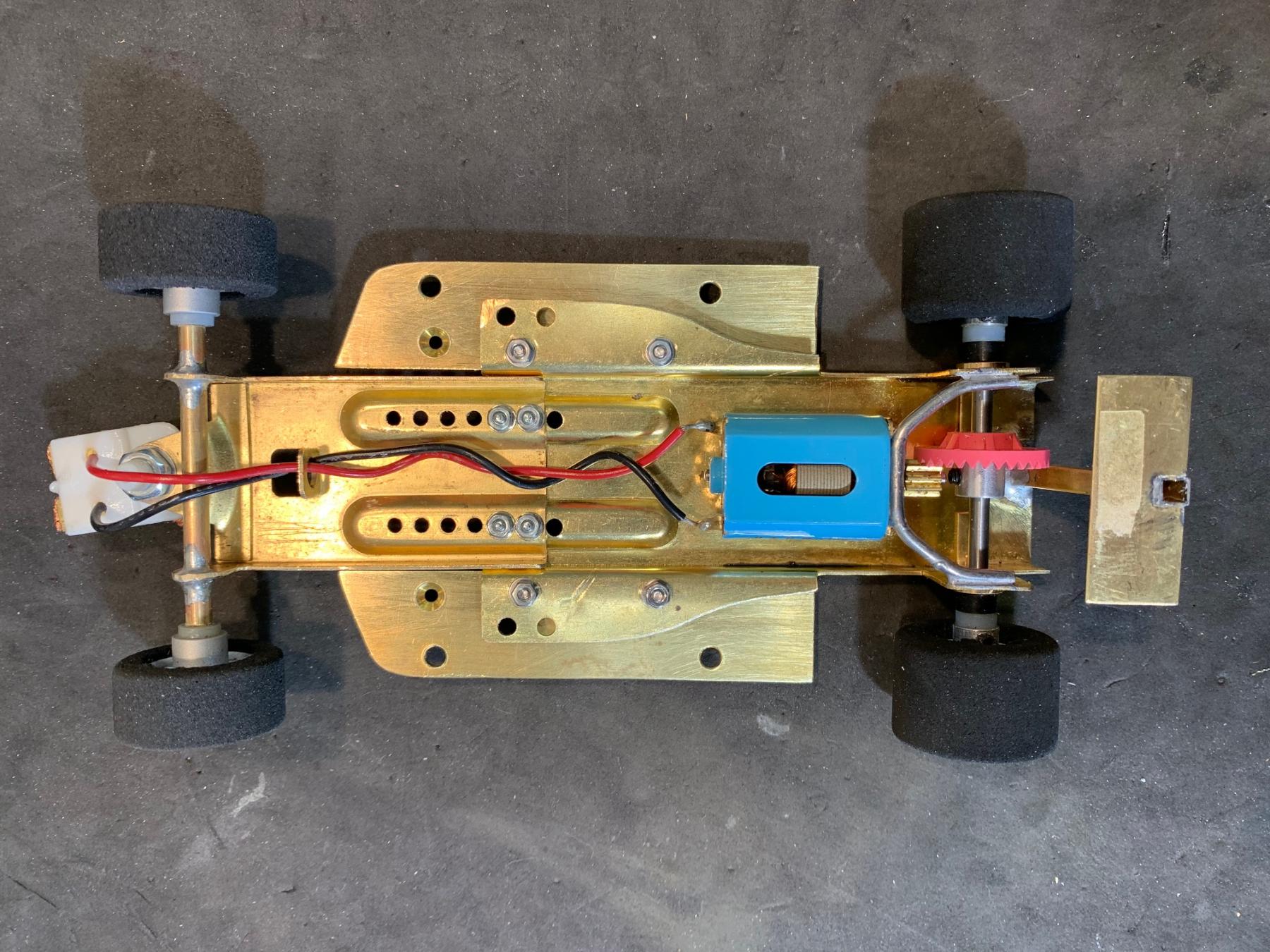

Below is an image of the modified chassis and body as shown from below.

Ron came up with an easy way to add side pans without soldering. The methodology is described in the following paragraphs.

Holes were cut in the ears of the modified chassis and used as attachment points for the custom brass pans. The holes were just large enough to accept the bolts used to attach the ears of the chassis to custom fabricated pans. Ron cut the brass pans out of .062 inch thick brass to conform to the shape of the body. The pans were held against the chassis in the proper position and marked from above to line up with the holes drilled in the ears of the chassis. The pans were then drilled and countersunk. See image below for the pans with attaching bolts and for images of the chassis with side pans attached. Note that the nuts shown here act as spacers so that when the pans were attached to the ears of the chassis, the pans sat flush with the bottom of the chassis. Note the larger hole drilled adjacent to the front bolt. This hole will be used as an access point to the ear of the chassis. The body is mounted to the ear of the chassis using a screw from the bottom of the ear into the plastic body.

Note that the nuts on top of the ears would prevent the body from sitting flush on the ears. To remedy this problem holes were drilled in the body pan. See image below

Below is an image of the chassis as shown from the bottom. Note the access hole and body mounting screw.

Wing mounts are a matter of preference. I decided to use piano wire and tape to mount the rear wing. Below is a close up image of the mount

Ron used a different approach. See images below

With the guide flag and associated wire, the front wing mount was a bit trickier. I wanted to fabricate a mount that would allow the front wing(s) to breakaway in the event of a crash. I used a piece of thin brass sheet as the mounting platform. A small amount of hot glue was used to attach the wing to the brass platform. See images below

Ron used a carbon fiber strip attached to the body and then used double sided tape to secure the wings. Both methods allow the wings to detach in the event of a crash protecting them from breakage.

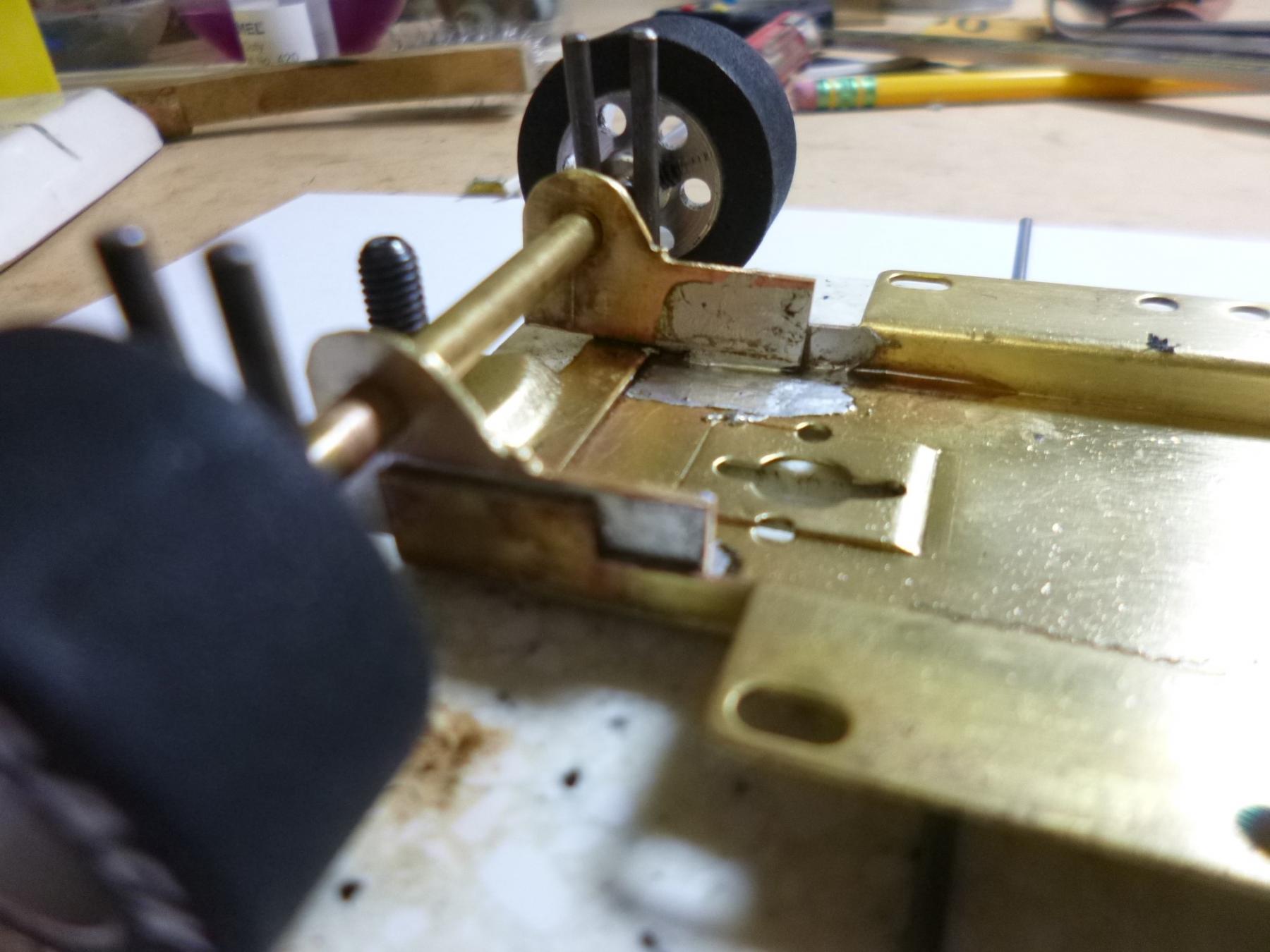

As mentioned above, the ProTrack chassis wheelbase was a bit too short for the Indy cars and presented a bit of a challenge. Since I used the ProTrack chassis as a basis for the Indy car it was necessary to fabricate custom axle hangers along with an axle tube. These were soldered in place. See images below for front end detail

Below is an image of the rolling chassis with side pans attached.

Ron, Bob and I chose to create custom decal sets instead of using those provided in the kit. Ron selected a Target livery, I chose a Shell livery and Bob selected a Goodwrench livery. Finished products are shown below

Appendix – AZGR Indy Car Class Specs.

Bodies; Monogram 1/24th bodies work best, the 1/25th stuff sits too high on the chassis and look too small.

Tires and wheels; ProTrack Daytona (for NASCARs) - Rears 1-1/8” X 7/8”. Fronts are 27mm X 10mm. Both with 1/8’ axle. Wheelbase is 4-7/8” and Track is 3-3/8” rear and 3-3/16” in front.

Motors - We are using a 25k long (S) can motor by Scaleauto (you may want a 40K motor if more power is desired).

Gearing - We use a BRM “917” 11t (6.5mm dia. X 6.5mm length.) pinion and a 26t crown. The long pinion lets me use any crown gear without re-positioning the pinion on the motor shaft plus if it gets worn on one end you can reverse it and get fresh metal.

This combo is tall enough for Steve’s top straight with the 25k motor and may work on your track.

Chassis – We use H&R soldered together and with a piece of 3/16” X 1/4” brass bar soldered in the Bottom center. I don’t remember how long but use as much as will fit in the recess. I cut back the front uprights as shown and we tube the front axle.