I started by consulting with an expert on the best body choice. A man who has more experience building these type cars than anyone. His #1 preference is the Dynamic Honda, at 1-3/4" width. So I have an ongoing search for the body. It could be some time before I find one.

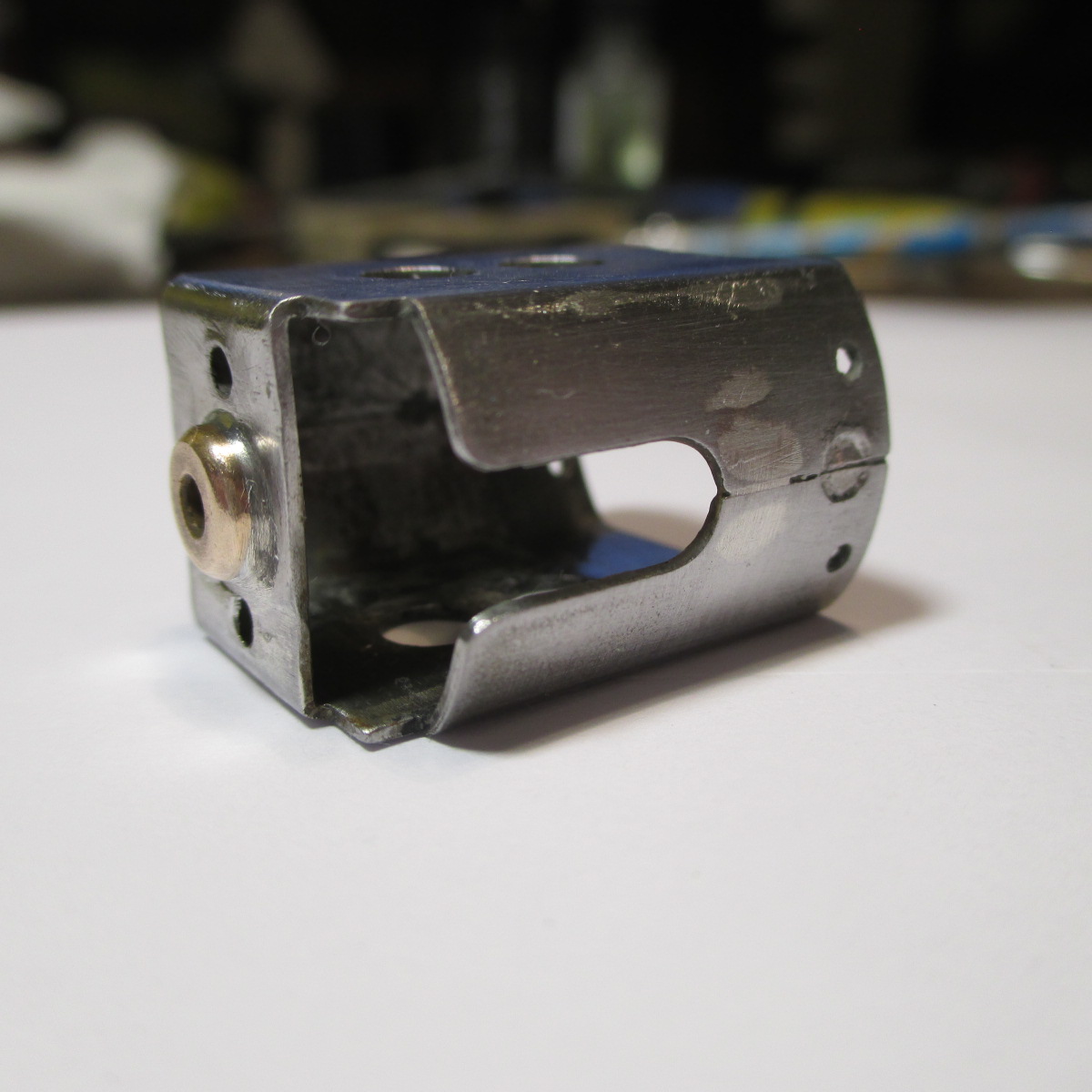

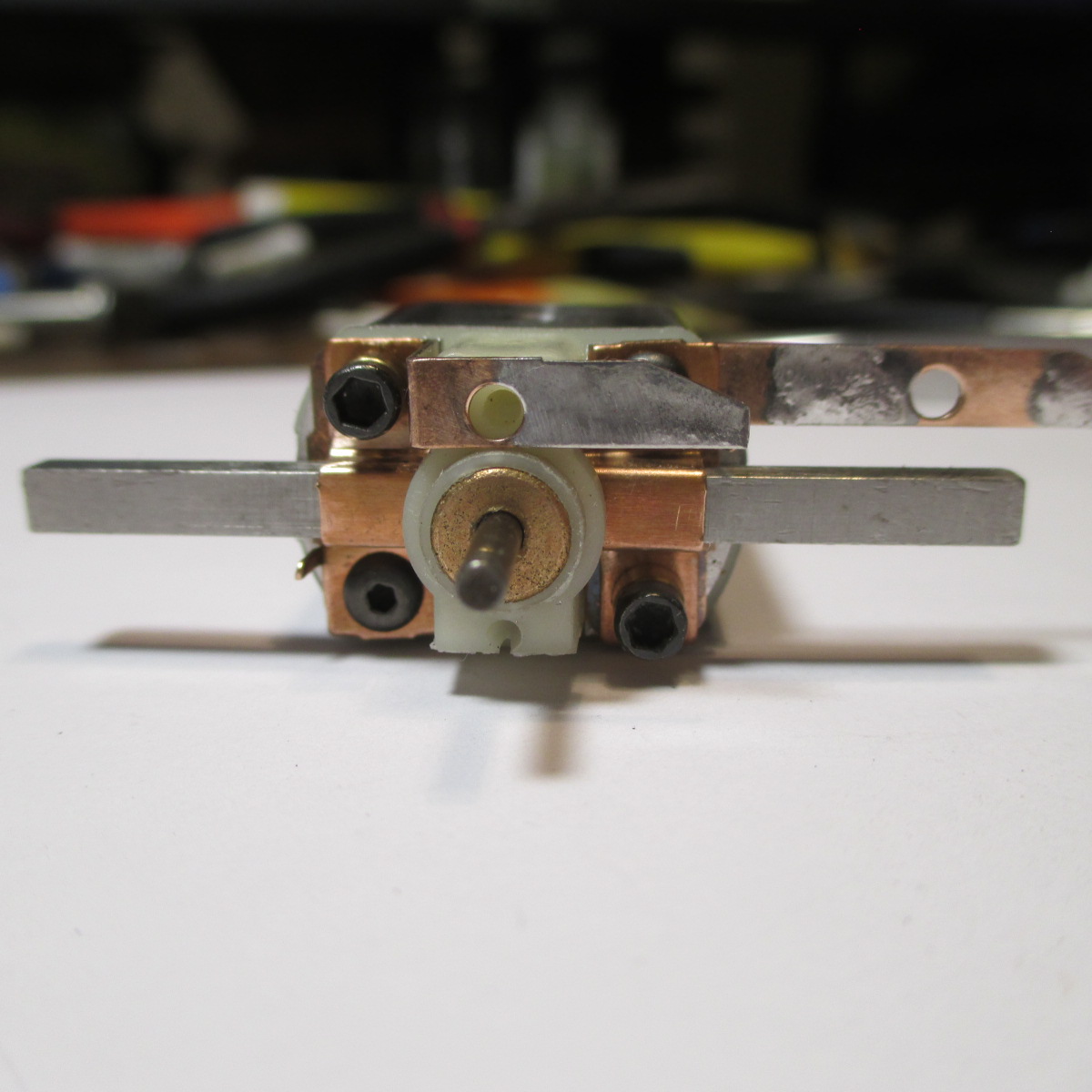

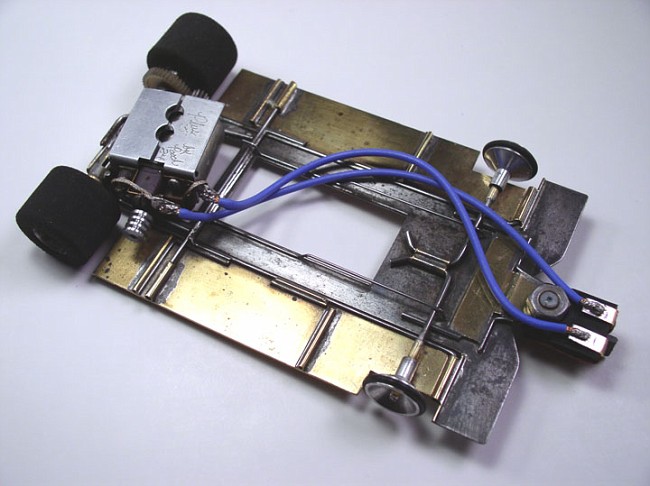

I'm going to start with the motor. It needs to be short and compact and I've been wanting to do a "shorty C." It has to be early '70s parts with enough horsepower to push a heavy plate chassis. Probably needs a custom Havlicek short-stack made to custom fit the setup. The body will surface later and the chassis will follow. ![]()

And away we go...