Much better with more rubber on those wheels ![]()

H-Power 13UO inline wire birdcage chassis Ford GT 40

#26

Posted 30 April 2021 - 06:00 PM

- Pablo likes this

#28

Posted 02 May 2021 - 09:35 AM

question- maybe i'm missing something. if the chassis is that wide (and you're not doing a monogram midget or something), why not just throw a 16D in there?

Steve Lang

#29

Posted 02 May 2021 - 10:07 AM

good work pablo and great attention to detail!

#30

Posted 02 May 2021 - 02:45 PM

Thanks John ![]()

Speedy, unless you missed post #1, no, you're not missing anything. Good question, I questioned the Dallas Jackson car the same way, and Don Siegal talked me into keeping the small motor. Let me explain my thinking:

-I've always liked 13UO motors

-A Havlicek built 13UO is probably a lot more motor than you think

-A lightweight, flexible, spindly chassis doesn't need or want a big heavy torquey motor - it wants a hi-HP lo torque lightweight smooth little motor that won't try and rotate the car upon acceleration and deceleration

-The body has big wheelwells which look good with big wheels (13/16" OD). The motor needs to be tilted up to get a proper gear mesh. I figure as long as I need to tilt a motor it may as well be a small one with less rotating mass

-If it was a wing car body, sure, it could possibly benefit from more power. But it's not

-More power doesn't automatically mean faster lap times ![]()

Those are my thoughts. It sure worked well on the Dallas Jackson car with a Pablo built peanut motor, ProSlot endbell, X12 arm, 13UO can . The entire story is here:

http://slotblog.net/...3uo-sports-car/

- Rotorranch likes this

Paul Wolcott

#31

Posted 02 May 2021 - 07:09 PM

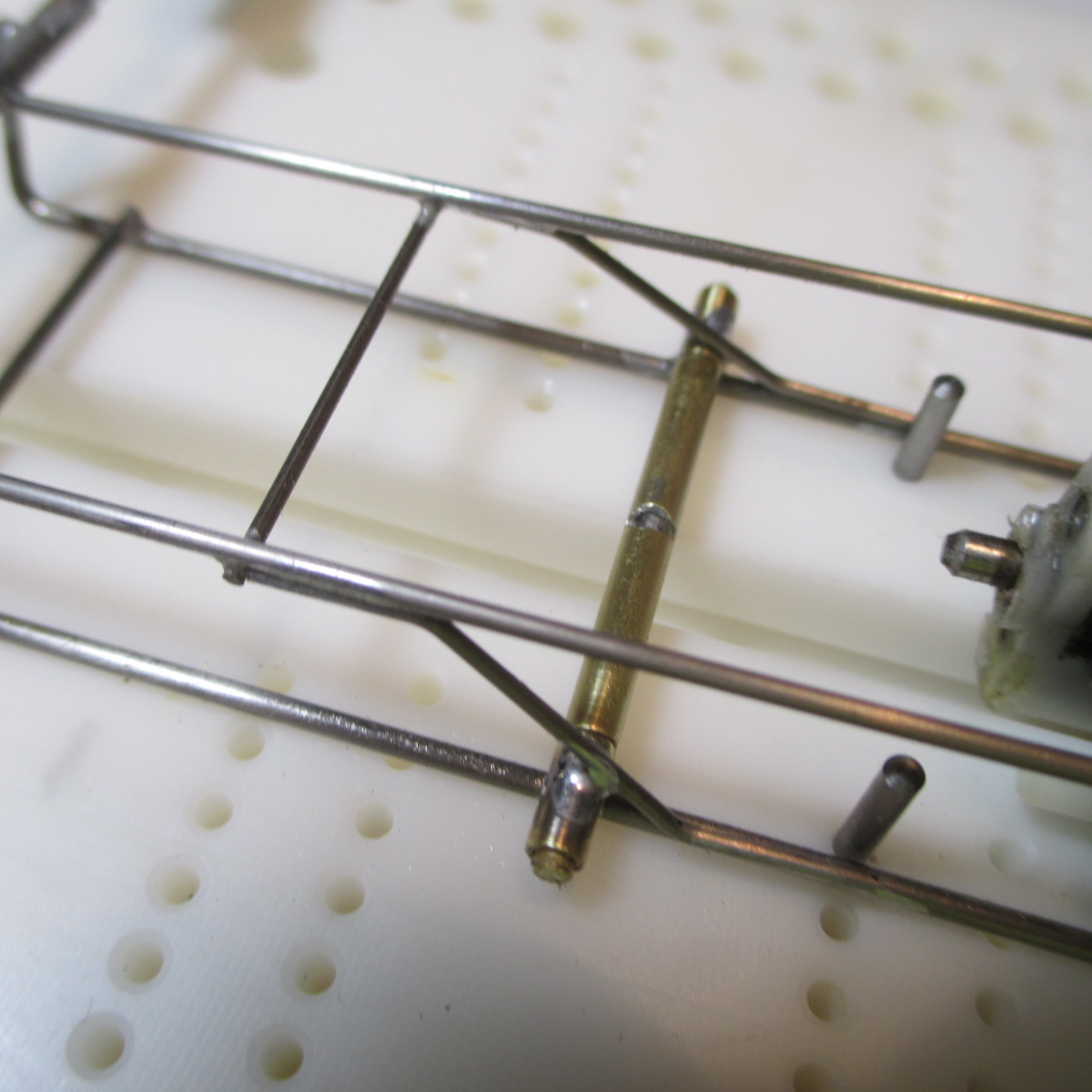

Is it starting to look like a birdcage? Everything is just tack soldered. Upper rails are .039. Dummy front axle is set to give the front wheels .032 front clearance. It gets a little stronger every time I add a wire piece.

The front axle connections will all be wire-wrapped together once the "real" 2mm axle is installed

- Peter Horvath likes this

Paul Wolcott

#32

Posted 03 May 2021 - 05:29 PM

Birdcage architecture continues. Speedy, are you still out there? Ya don't have to agree to all my theories to stay at the party ![]()

The lower crosspiece up front does triple duty - anti-spreader, strengthener, and upstop for a drop arm. The upper piece is a simply an anti-spreader and strengthener. No CAD drawings, no plans, I'm just enjoying building it as I go

Redundancy is what gives this chassis it's ability to be strong enough - you'd have to break several solder joints to have a failure. Whoever built the original was a thinker.

The can (on the real motor) will be soldered on bottom where it meets the bracket face. The "stabilizer" attachment point I promised for the front end of the motor is very simple, light, and strong. Up top, a short piece of wire on each side is soldered to the top rails. The final installation of the motor will be a solder point (adjacent to the comm tabs) on both sides

- Tex, Peter Horvath and John Luongo like this

Paul Wolcott

#34

Posted 04 May 2021 - 07:03 PM

Looking great Pablo ... starting to come into focus! Speaking of which, I clearly need to take some photo lessons from you as your pictures are sharp as a tack. I've never owned or built a birdcage but I love that it is so akin to the tubular chassis of an actual sports cars.

#35

Posted 04 May 2021 - 07:51 PM

Thanks Larry ![]() But don't kid yourself, the only good thing about my photography is the speed at which I can take a pic and get it up on Slotblog. You want good photo lessons, look to dc-65x

But don't kid yourself, the only good thing about my photography is the speed at which I can take a pic and get it up on Slotblog. You want good photo lessons, look to dc-65x ![]()

Glad you like the birdcage style, I do too ![]()

- Larry Horner likes this

Paul Wolcott

#36

Posted 05 May 2021 - 09:09 AM

i'm still here, Pablo. you do very nice work.

don't mind me- i once squeezed a 26D in a 32nd F1. so i was just thinking, why use something with such thin magnets unless you had to, that's all.

Steve Lang

#37

Posted 05 May 2021 - 11:39 AM

Speedy, again It seems you are underestimating my 13UO Havlicek motor. It's a completely different animal than stock. As far as the magnets being "thin", do you consider Neo mags weak?

- boxerdog likes this

Paul Wolcott

#38

Posted 05 May 2021 - 12:05 PM

Pablo, I like this build. It reminds me of the MESAC club sports car class that was for the 13UO-based motors only. My friend who ran in these races built motors similar to yours. He also liked running inline chassis cars.

- Pablo likes this

#40

Posted 05 May 2021 - 02:44 PM

The car looks great so far.

Thanks for using my plated wire on it.

- Pablo likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#41

Posted 05 May 2021 - 04:50 PM

Thanks Mike, but I should be thanking you instead. Not having to tin my own wire saves lots of time. Plus, your plated wire is stronger, and I know it's straight. On this type build, that's a big deal ![]()

The holes on the Dynamic gizmo got hogged out, and in, for more strength

Rotating surfaces top and bottom faced with Magnehone

Drop arm wires are .047 (of course). I secured the gizmo in my vice, turned the Hakko 601 on full power, flooded the wires and holes with acid, and soldered away. Precise alignment isn't needed here because the wire sets are going to get bent anyway ![]()

- MSwiss and Peter Horvath like this

Paul Wolcott

#42

Posted 06 May 2021 - 10:45 AM

well, if they're neo's, never mind. i see.

i've always wanted to try some rare earths in my 13D's. but that would obsolete all the other ones in my midgets and formula cars.

Steve Lang

#43

Posted 06 May 2021 - 11:53 AM

You'd need to build new arms for neo's. Otherwise, it wouldn't work too well using them with a stock arm ![]()

Paul Wolcott

#44

Posted 06 May 2021 - 12:01 PM

You'd need to build new arms for neo's. Otherwise, it wouldn't work too well using them with a stock arm

Why?

I just built a couple of S16D motors with poly neos. Did I do bad?

Rotor

"Kinky Kar"

#45

Posted 06 May 2021 - 12:15 PM

If using stronger magnets alone would make better motors, life would be simple - you could just swap all your motors over to neos and be good to go. It ain't that simple. Tame armatures run well with tame magnets. Big wire arms with lots of timing need stronger magnets.

Putting neos in a stock 13UO motor with neutral timing and cobweb wire would be a disaster. Rotor, I don't have enough details on your motors to know. But the idea that stronger magnets is a universal improvement just isn't true.

You guys are welcome to start a new thread in the "Motors" forum if you want other opinions. Back to my birdcage construction ![]()

Paul Wolcott

#46

Posted 07 May 2021 - 10:28 AM

My (first) drop arm assembly failed. I dialed in too much heat on the FX-601 and the tongue shifted. Trying to fix it failed. So I removed the works, sucked the solder off the hinge, and started over.

New improved design - .047 riser bends are now up tight to the tongue. Jig flag stud setup is nut/tongue/nut with a 10 thou flag spacer wedged in up front to give "some" up tilt to compensate for a slight .032/.050 clearance difference.

This method of the "riser" bends in the wires works much better than the swoop angles I used previously. Much easier and more precise to get the wires to lay flat ![]()

- Peter Horvath likes this

Paul Wolcott

#47

Posted 07 May 2021 - 10:40 AM

Whew ... I thought I was having a senior moment when your first post was gone! ![]()

I like your mechanism for angling the tongue. Not sure if that was common back in the day but angling the tongue is probably even more important for a drop arm design.

Also I buy that same blue masking tape by the case!

#48

Posted 07 May 2021 - 11:12 AM

![]() A slight amount of tilt is never a bad thing, period. It becomes mandatory to introduce more of it when you start making a chassis "slope" like a retro race car - 50 thou rear, 15 thou front. Back in the day, scale car clearance was .063 level front and rear, no slope, so they didn't need much tilt.

A slight amount of tilt is never a bad thing, period. It becomes mandatory to introduce more of it when you start making a chassis "slope" like a retro race car - 50 thou rear, 15 thou front. Back in the day, scale car clearance was .063 level front and rear, no slope, so they didn't need much tilt.

Larry, you have entered The Twilight Zone, do not attempt to adjust your TV set ![]()

Paul Wolcott