Posted 28 December 2021 - 03:15 PM

Posted 28 December 2021 - 03:27 PM

Posted 28 December 2021 - 04:04 PM

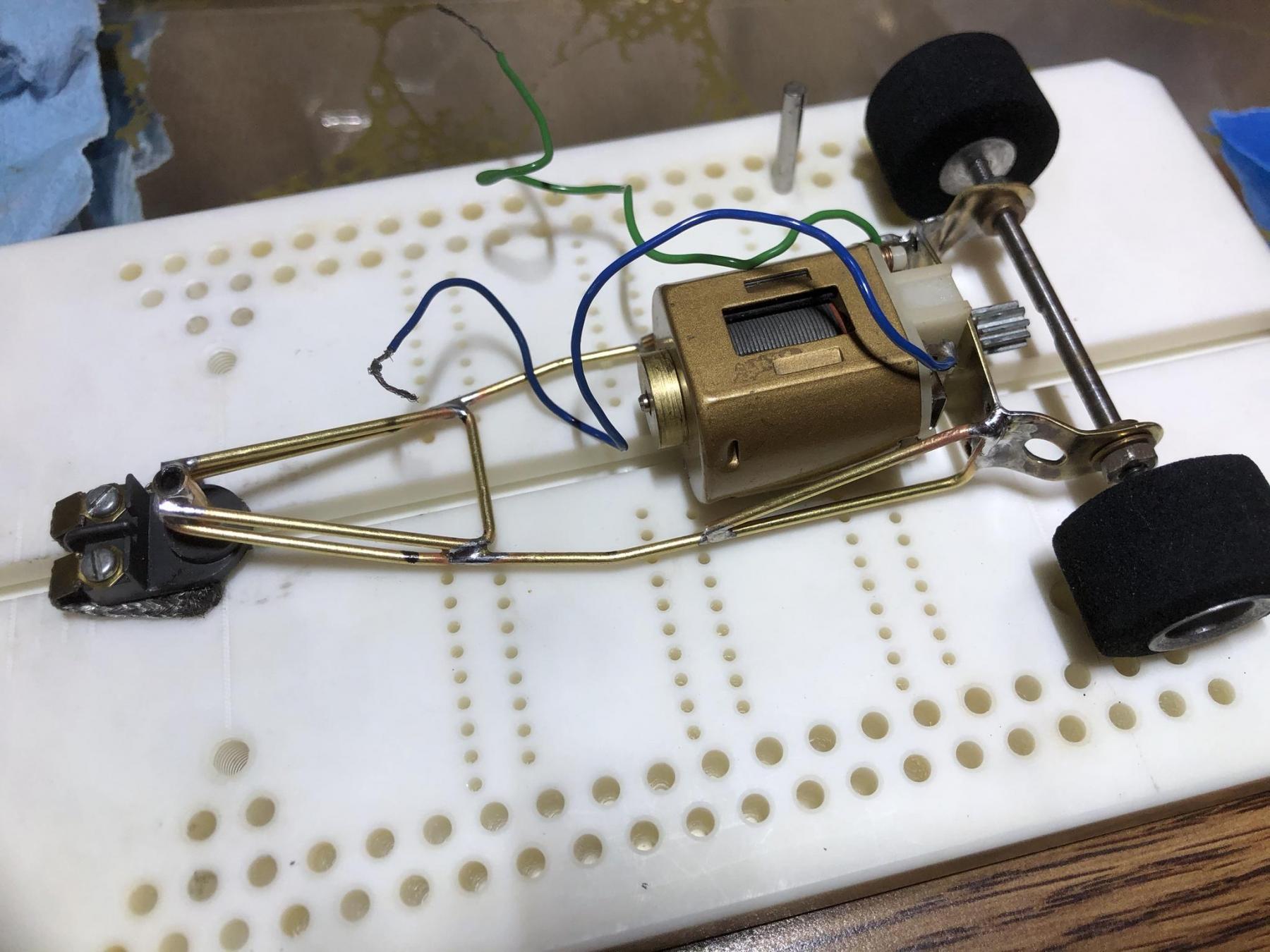

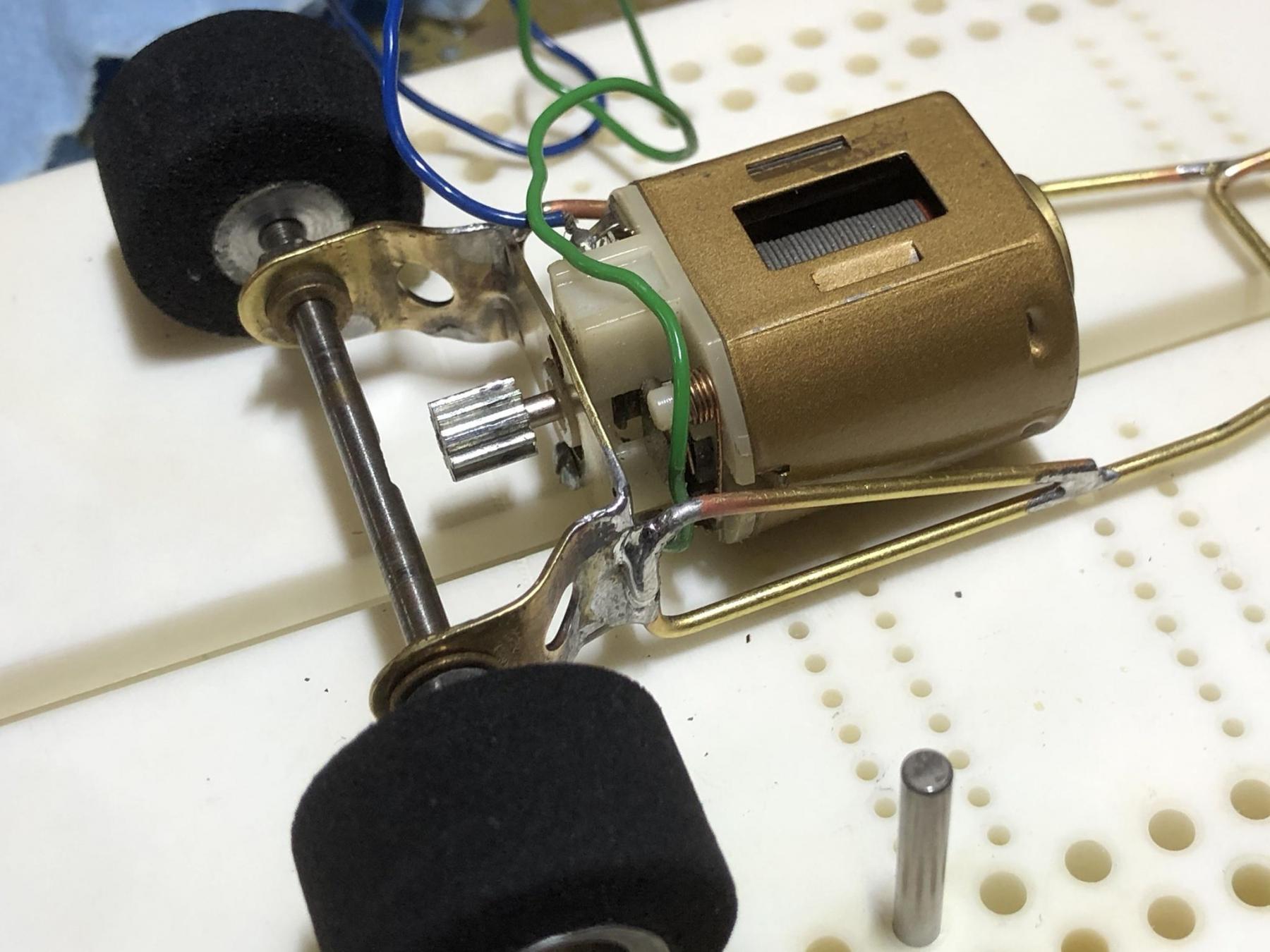

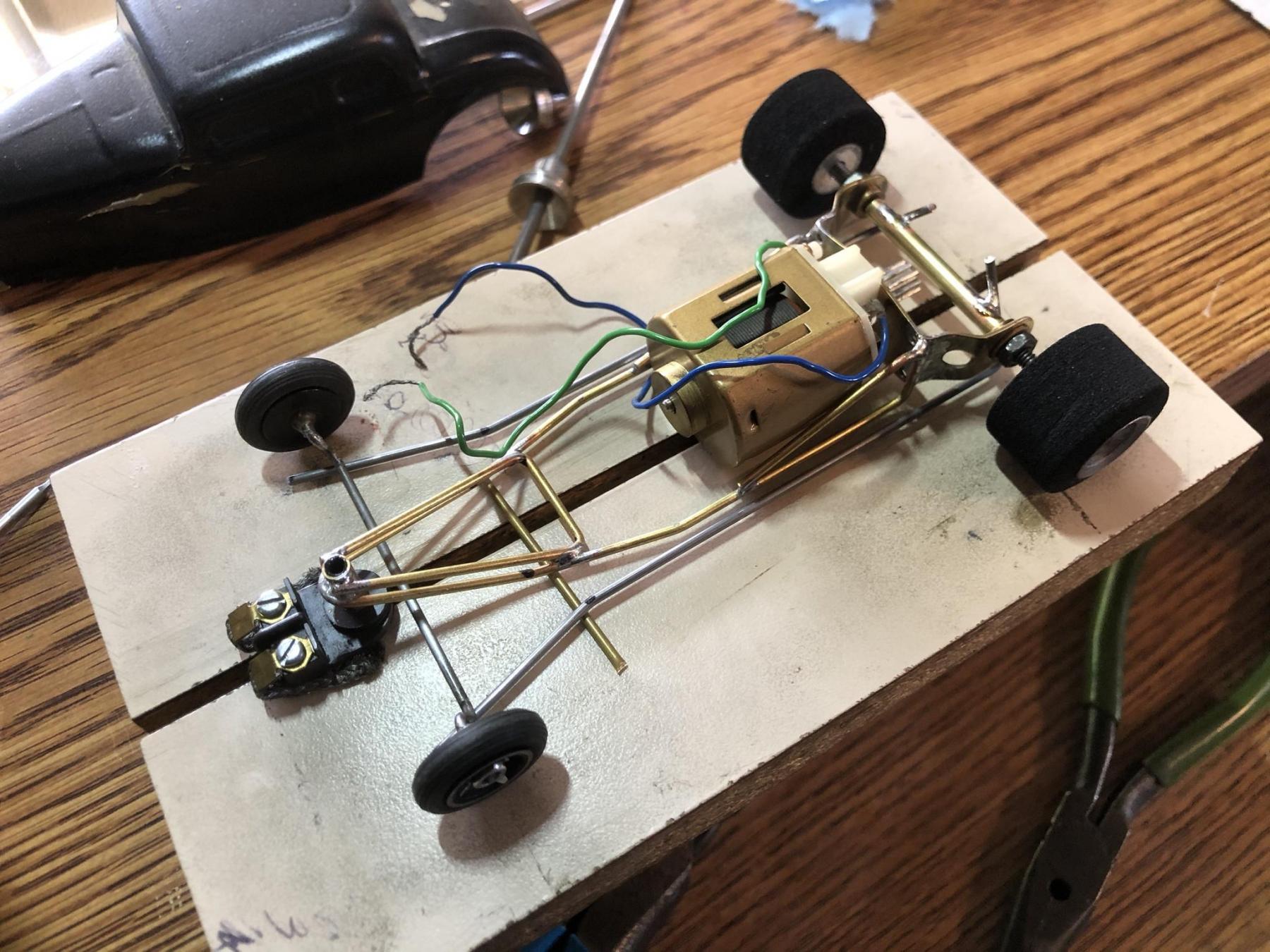

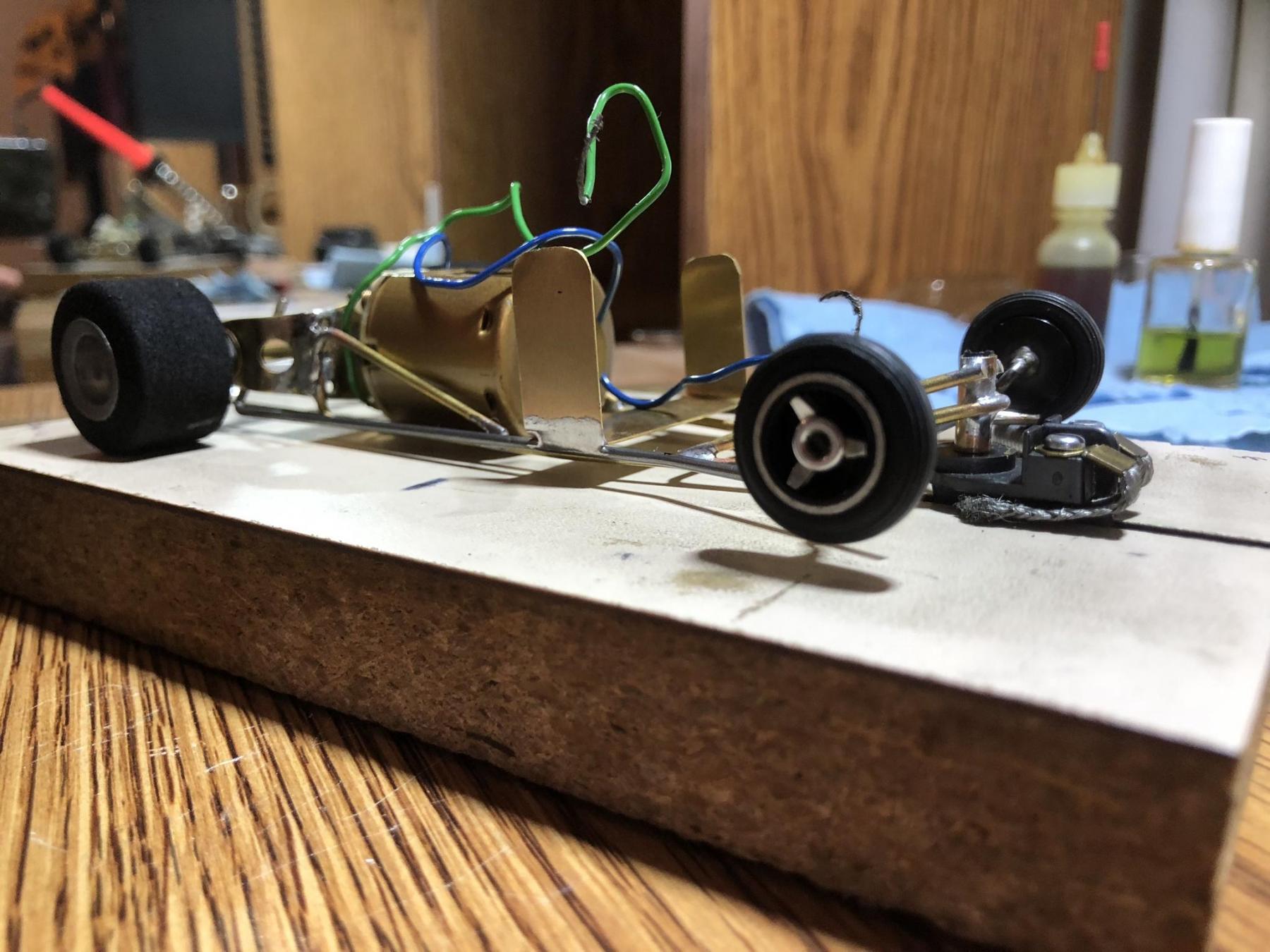

looks like your rear axle is set to a front hub + $.50. I love it. ![]()

Good looking hot rod.

Posted 28 December 2021 - 04:16 PM

Interesting chassis Mike! Let us know how it runs once you've had it on a track. "There's more than one way to bend wire & brass." Nice job on your chassis.

Posted 28 December 2021 - 05:50 PM

Posted 28 December 2021 - 06:13 PM

Posted 28 December 2021 - 07:01 PM

A winner!

Posted 28 December 2021 - 07:15 PM

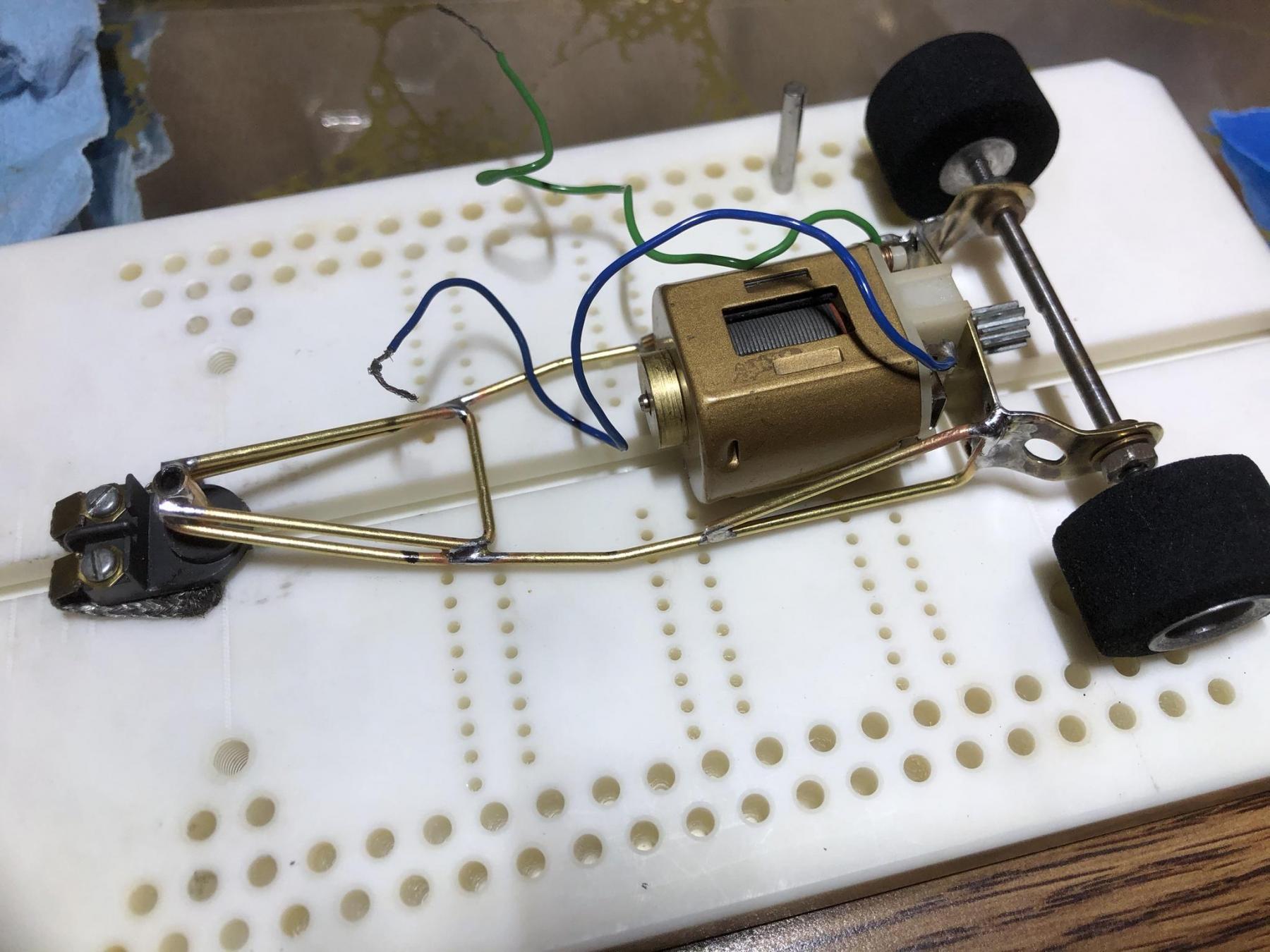

thanks! Those are womp womp front wheels hah.looks like your rear axle is set to a front hub + $.50. I love it.

Good looking hot rod.

Posted 28 December 2021 - 08:14 PM

Mike Katz

Scratchbuilts forever!!

Posted 30 December 2021 - 04:51 PM

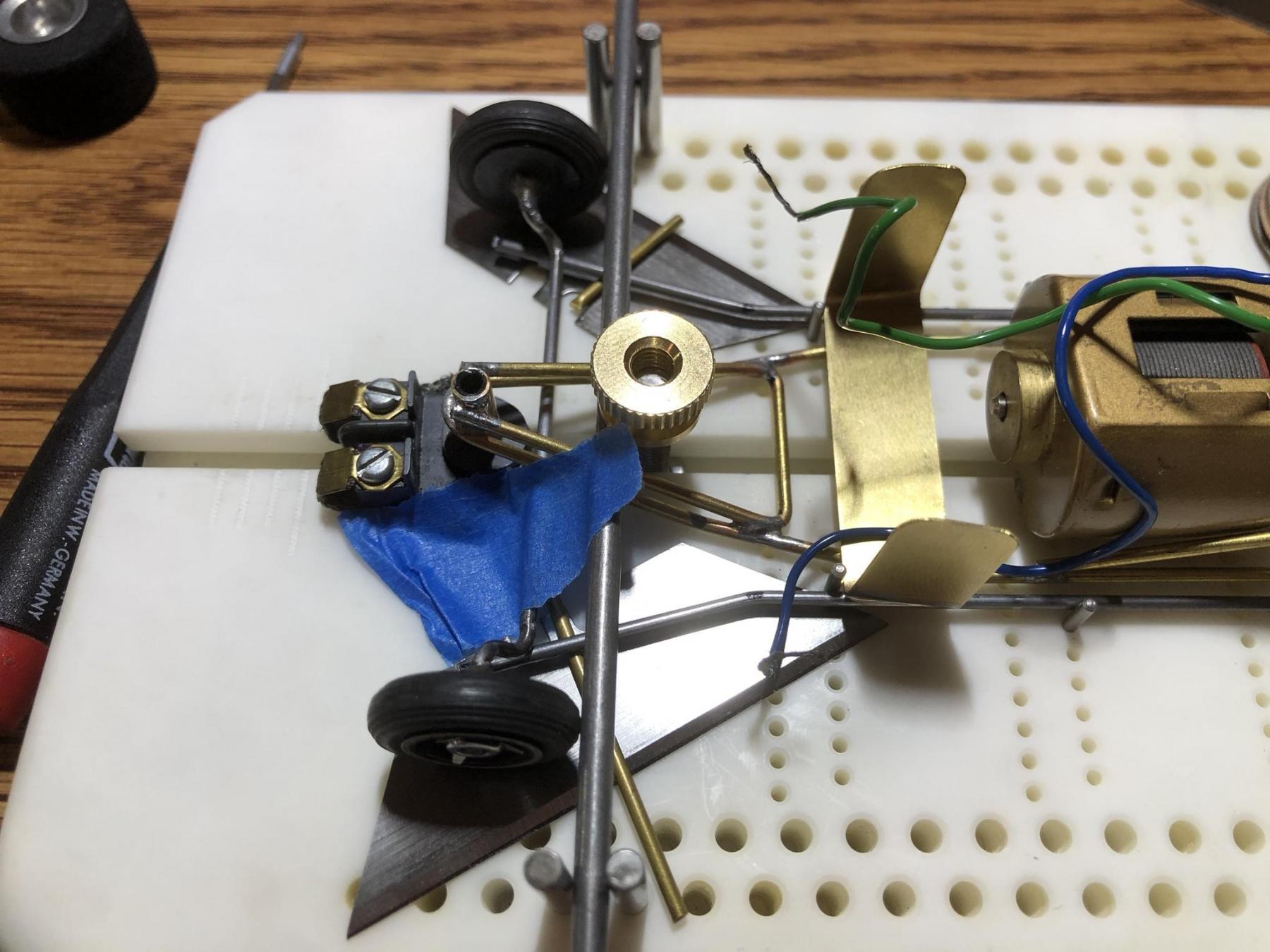

The completed car looks great Mark!

Posted 30 December 2021 - 05:36 PM

Very cool, I like the little bumper. ![]() Now you've gotta find a rewind for it!

Now you've gotta find a rewind for it! ![]() A Champion 707 would be pretty cool.

A Champion 707 would be pretty cool.

Posted 30 December 2021 - 06:31 PM

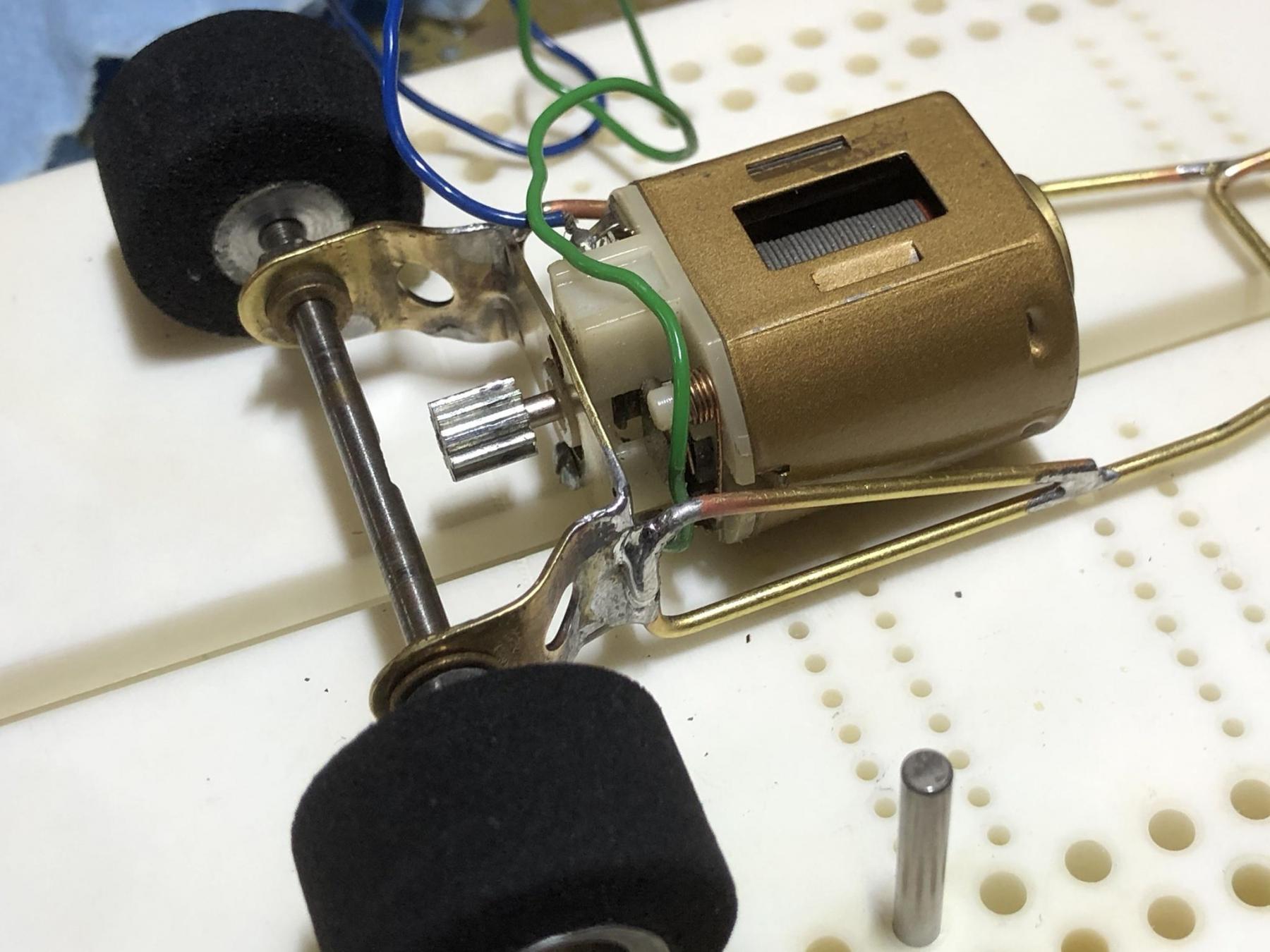

I might put in a balanced classic 26d since this 36d isn’t meant for the motor bracket so it has pretty bad gear mesh.Very cool, I like the little bumper.

Now you've gotta find a rewind for it!

A Champion 707 would be pretty cool.

Posted 30 December 2021 - 06:34 PM

The completed car looks great Mark!

Posted 30 December 2021 - 06:51 PM

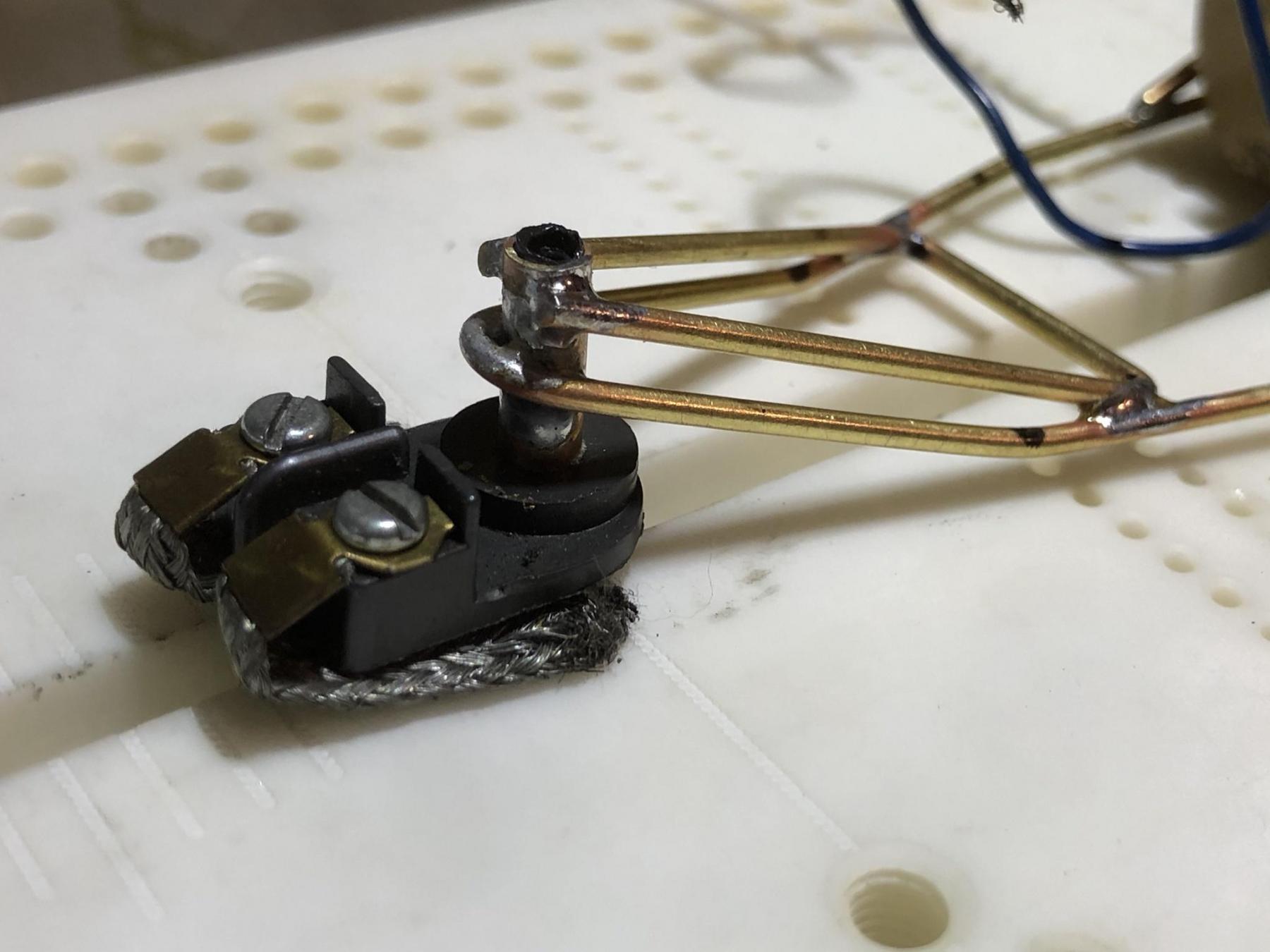

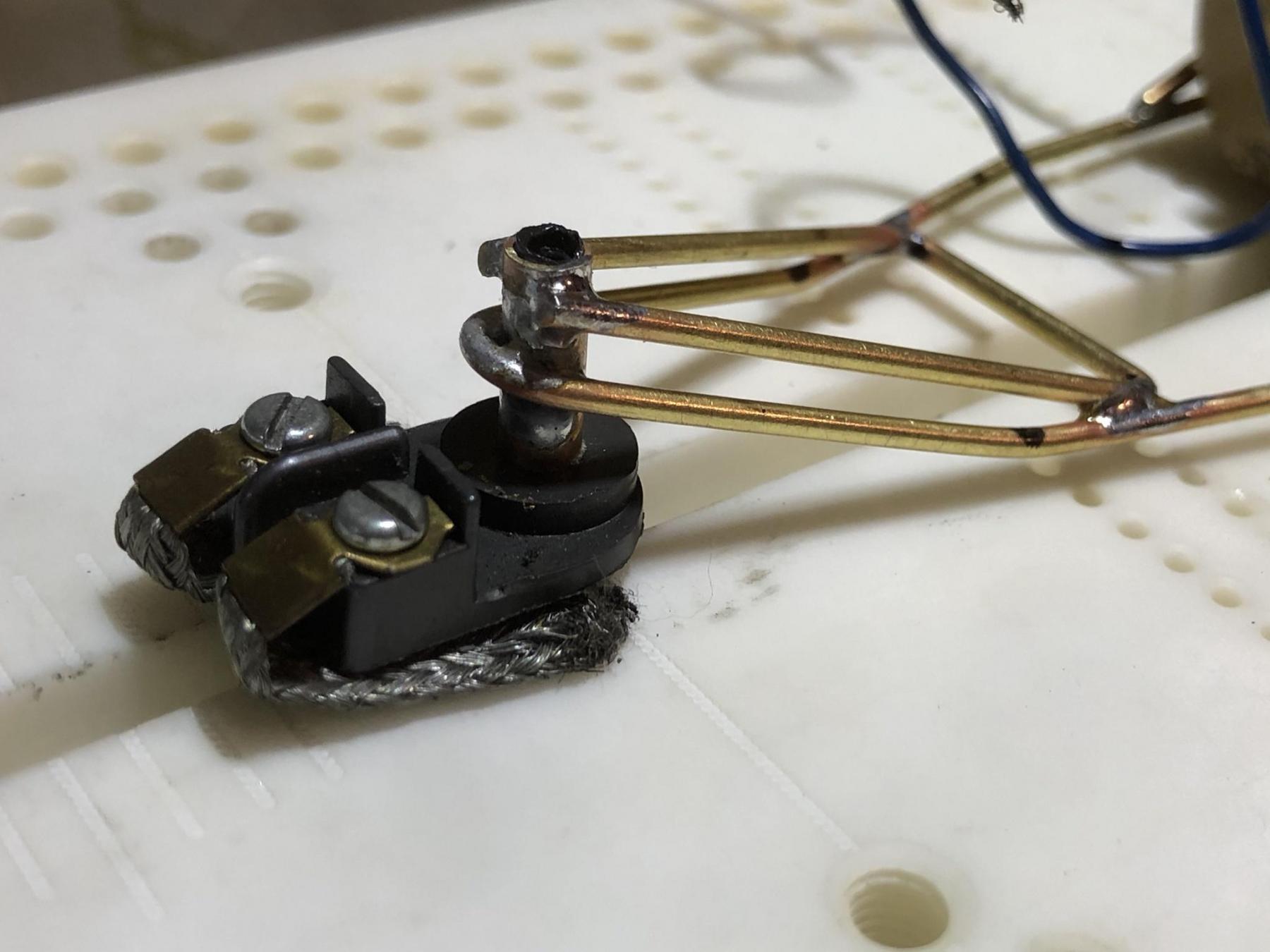

Mark, clean it with something such as fine sandpaper, steel wool, or the green synthelic pot scrubbing pads before soldering. You need to remove the oxidation & get the surfaces down to a clean, bright metal first. Then it'll stick okay.

Posted 30 December 2021 - 07:53 PM

Mark, clean it with something such as fine sandpaper, steel wool, or the green synthelic pot scrubbing pads before soldering. You need to remove the oxidation & get the surfaces down to a clean, bright metal first. Then it'll stick okay.

Posted 30 December 2021 - 08:35 PM

Very cool Mark. Imaginative design and clean workmanship. Scratch building at its best. ![]()

Like Bill advised, cleaning the heck out of the wire and lots of flux really makes soldering easier. I switched from sandpaper to Scotch Brite pads as it seems easier and faster for me.

Oh, and I personally haven't had good luck with those white plastic crown gears either.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 30 December 2021 - 09:11 PM

Agreed, lots of flux and scotch-brite. The Wilson crown gears have a noisy mesh, a few have also cracked on me.

Posted 30 December 2021 - 09:23 PM

Very cool Mark. Imaginative design and clean workmanship. Scratch building at its best.

Like Bill advised, cleaning the heck out of the wire and lots of flux really makes soldering easier. I switched from sandpaper to Scotch Brite pads as it seems easier and faster for me.

Oh, and I personally haven't had good luck with those white plastic crown gears either.

Posted 30 December 2021 - 10:58 PM

Hi Mark,

Suggestion on soldering piano wire and brass rod or tubing.

First wipe the wire with a paper towel that has some rubbing alcohol on it, this will remove most of the gunk from the wire.

Then I use some 1000 grit sandpaper folded over the wire and sand it till the wire has a nice shine.

And then another wipe down with the paper towel and alcohol to remove the sandpaper dust from the wire.

Posted 01 January 2022 - 07:32 PM

Posted 01 January 2022 - 08:47 PM