What would be the correct motor and body for this frame?

Thanks.

Richard

Posted 02 March 2022 - 06:45 PM

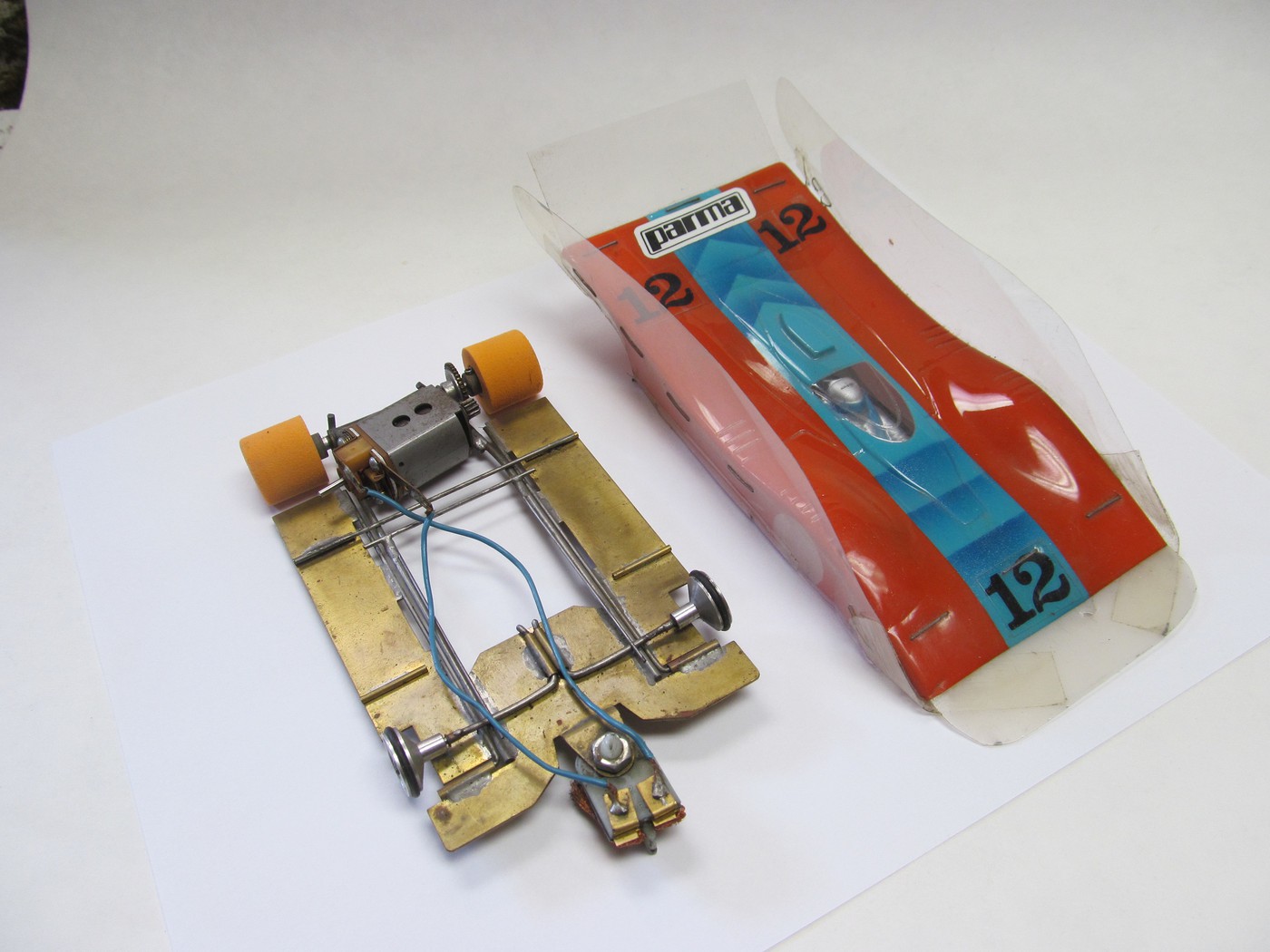

The motor box looks like a C-can. The arm could be anything from Int 15 to opens. When monorail chassis first came out in the mid 70s, they were used for open class wing racing. If you go that route, any wing body would work. A couple that you might have seen in rhe 70s. include the Outasight Ferrari coupe, the Lucas Matra, the Lancer Porsche coupe, & any of the 3 or 4 Associated bodies. You could include the MAC bodies too.

Posted 02 March 2022 - 07:05 PM

Posted 02 March 2022 - 07:14 PM

Posted 02 March 2022 - 07:48 PM

Parma sold this chassis into the early 90's and used it for their Group 15 and 20 ready to runs through the 80's until they introduced the Patriot shuttle chassis. This chassis has plumber hinge only. The G27/G7 chassis I've seen had double hinged pans. About any Mura or Champion C-can would be correct for this chassis, particularly G15 and G20. Since Parma sold the chassis ready to run, Parma wing bodies would also be correct, and I'm sure plenty of O/S bodies were also used.

Posted 02 March 2022 - 08:20 PM

Here's mine.

It was an RTR in 1979.

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

Posted 02 March 2022 - 08:37 PM

Posted 02 March 2022 - 10:14 PM

Posted 02 March 2022 - 10:16 PM

Posted 02 March 2022 - 10:21 PM

The first monorails I saw in the 70s were built by Tony P. Pros did not use them for long. Not a pro, but I have a half built one from '73 or 74.

Mark, the steel chassis that replaced them were not laser in the Northeast. They were hand cut. I cut one, then went back to using piano wire.

Posted 03 March 2022 - 01:17 AM

a hawk 6 motor would be perfect for this chassis. not too powerful & handles great with the right body.

Posted 03 March 2022 - 11:18 AM

Posted 03 March 2022 - 11:28 AM

Ok, late to the party.... I agree with a lot of the above comments.

My 2 cents: the back end / tube has been tinkered with. These were orgiinally set for 13/16 rear tires using that tube. I recently refurbed one of these, and jigged it to use .790 tires instead. But whatever is going on with the mount of that tube isn't stock and looks like it needs some attention.

Posted 03 March 2022 - 05:53 PM

Yes, the rear tube has been messed with.

Posted 04 March 2022 - 02:32 PM

Posted 04 March 2022 - 07:38 PM

What's reddeath quality?

Posted 05 March 2022 - 07:13 PM

I wasn't active in the 70's, so I've only seen this chassis as the Parma Monorail and in their RTRs in the 80's. This chassis wasn't well soldered, and I've seen several come apart at the joints. If you had one very long, it ended up being completely re-soldered. The rear axle tube looks like there's been an attempt to beef it up to prevent broken axle tube joints. It's pretty straight-forward with some jig wheels to un-solder the axle tube and reposition it for different size rear tires. As mentioned, the first one I had was set up for 13/16" tires, but I believe the later ones used .760. I've built some axle tube chassis of similar rear layout since switching to 96/4 (tin/silver) solder without any broken joints, but this design in 60/40 (tin/lead) solder needed some additional bracing of the axle tube to main rails to prevent broken joints.

Posted 05 March 2022 - 10:48 PM

Silver soldered joints are stiffer than those made with 60/40. I built a number of "all silver soldered" chassis & it always took 3 or 4 races before their optimum handling showed up. Dennis "Foamy" Hill from CA agrees with me on this.

Posted 06 March 2022 - 06:43 AM

we use to use 95/5 solder for repairing/replacing ac components. never had separation or other issues even on the high pressure side (450psi).

Posted 07 March 2022 - 12:41 AM

Team Burrito, I think he is going for period correctness.

if you need a period correct motor, i've got a 70's style mura gp15 motor with over/under springs & buss bars. let me know if you're interested.

Posted 07 March 2022 - 01:08 AM

Posted 07 March 2022 - 01:24 AM

Posted 07 March 2022 - 01:25 AM

Posted 07 March 2022 - 01:33 AM

Posted 07 March 2022 - 04:46 AM

John L. You don't use phosphorus bronze ?

not back then. this would be in automotive service and refer units. if the 95/5 wasnt the best solution, then we brazed. usually brazed valve bodies and hard fittings that may have to hold up to a lot of twisting torque by a technician with gorilla arms, or to support heavy piping. the brazed components seldom gave any trouble even after years of service.