Looks really interesting!! Hope it handles at least as good as the car I borrowed from you on my visit to Chicagoland Raceway!!!

Building a Tripod Can-Am chassis

#26

Posted 06 September 2009 - 10:09 AM

Looks really interesting!! Hope it handles at least as good as the car I borrowed from you on my visit to Chicagoland Raceway!!!

Mike Katz

Scratchbuilts forever!!

#27

Posted 06 September 2009 - 01:22 PM

#28

Posted 06 September 2009 - 01:26 PM

#29

Posted 06 September 2009 - 03:04 PM

Rob !!

VERY sano!!

I need one!

Watch out, Froggenheimer! LOL!

Later!

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#30

Posted 06 September 2009 - 03:06 PM

#31

Posted 06 September 2009 - 05:39 PM

Looking forward to see how it runs.

11/4/49-1/23/15

Requiescat in Pace

#32

Posted 06 September 2009 - 06:34 PM

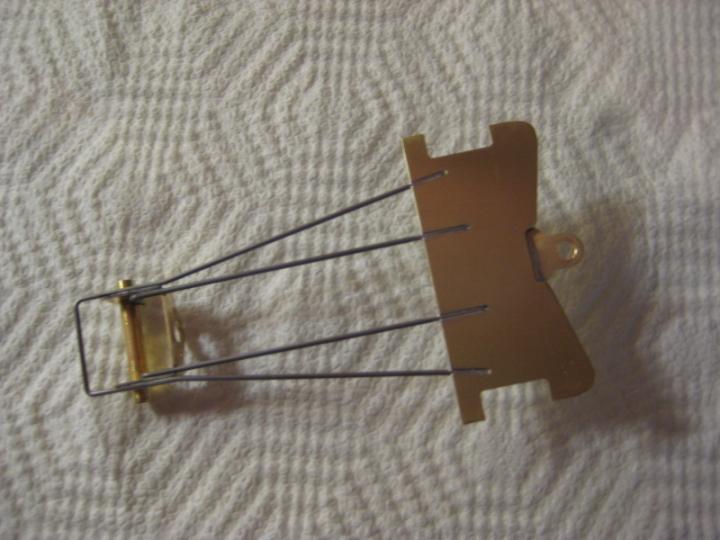

The thin brass nose piece looks like it may not survive me falling off in front of

You telling me I should have made it from .062 Brass and not the .032 the pieces were made from?

#33

Posted 06 September 2009 - 07:51 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#34

Posted 06 September 2009 - 08:25 PM

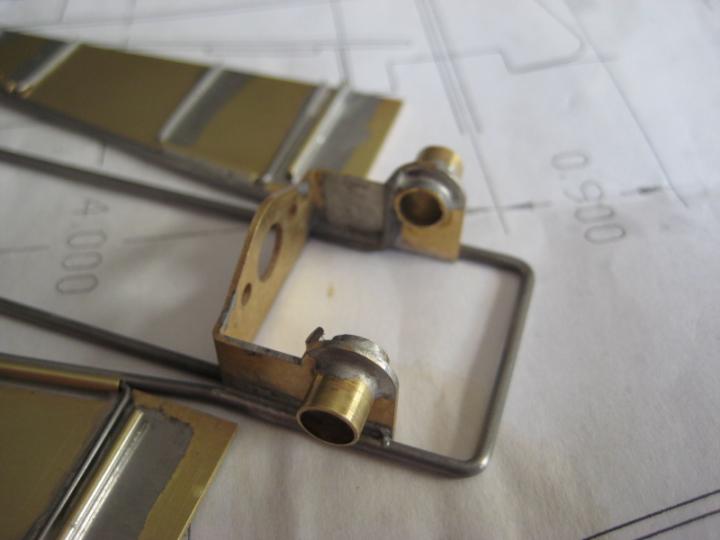

I think when Ray was referring to the nose piece, he meant the guide tongue.

I still would rather race out of someone else's slot box.

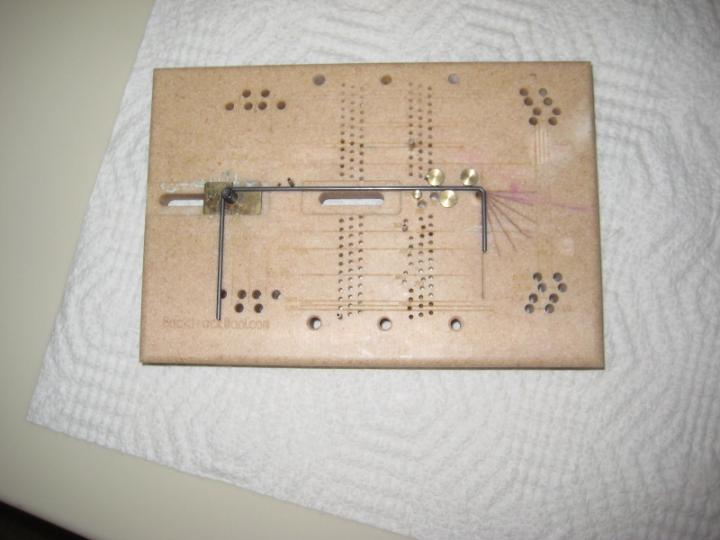

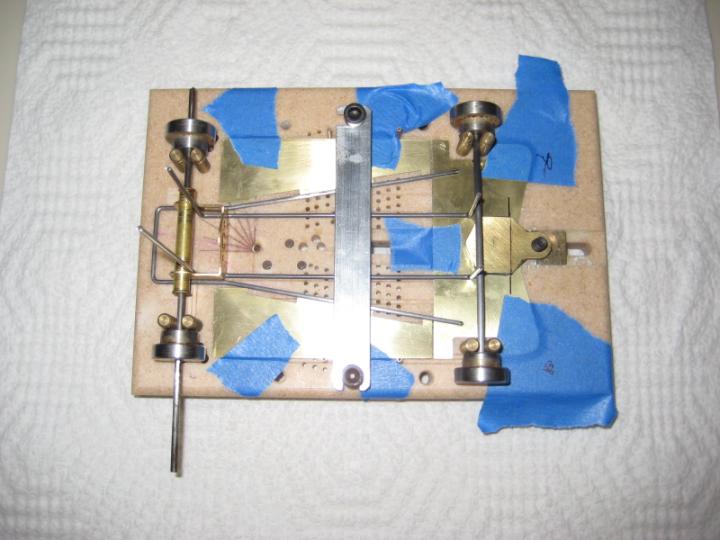

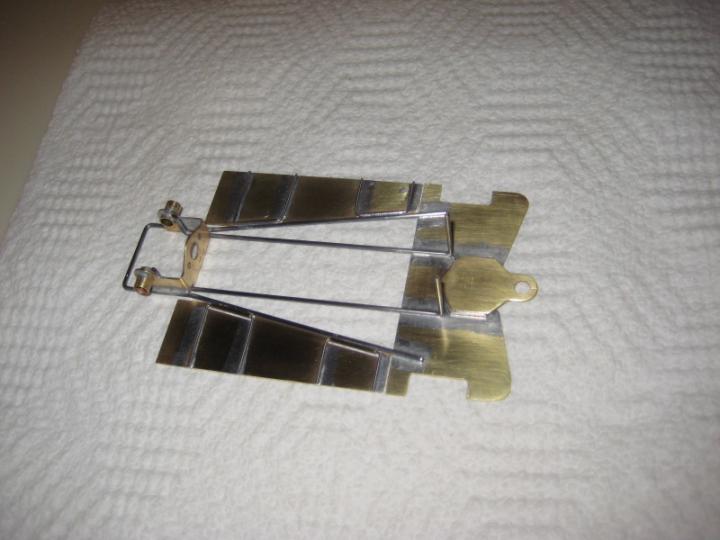

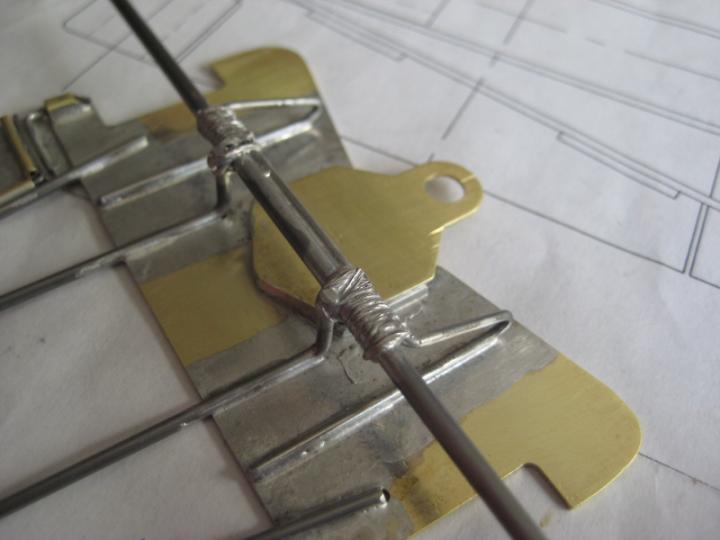

Anyway, back to the build. Soldered the pans on. Would have liked them to be a little cleaner, but have an 8 year old who "helped" me with build.

#35

Posted 06 September 2009 - 08:45 PM

Lookin' real nice! I have a question: Were the brass pieces CNC machined, or did your friend follow your drawing, and do them by hand?

I am not a doctor, but I played one as a child with the girl next door.

#36

Posted 06 September 2009 - 09:16 PM

Rob,

Lookin' real nice! I have a question: Were the brass pieces CNC machined, or did your friend follow your drawing, and do them by hand?

Thanks,

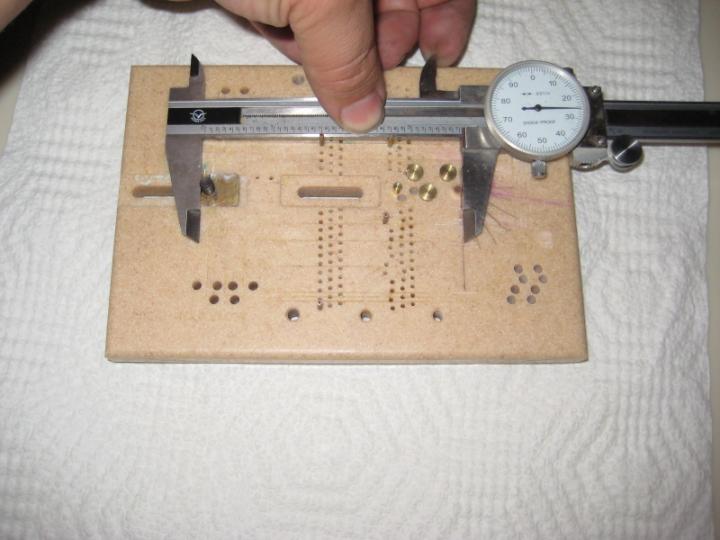

These were made "old school machinist" (red dye, scribing lines using calipers.....)on a something like a $500 Micro-Mark Mill from a drawing of just the pieces with a bunch of dimensions. Even though it would have been easier to CNC, Waterjet or at minimum use a Mill with a digital readout, we wanted to make them with equipment that an average hobbist had at their disposal to show what could be done.

#37

Posted 07 September 2009 - 06:22 AM

Once again, Great build Rob........

11/4/49-1/23/15

Requiescat in Pace

#38

Posted 07 September 2009 - 11:55 AM

Now off to cut my grass and eat some lunch.

Later I'll start on my build. Don't know if I will post or not?

#39

Posted 07 September 2009 - 12:33 PM

It looks like that front axle is going to stay on.

I like that you let your son use the soldering iron a bit.

I won't even check into the Somonauk child labor laws.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#40

Posted 07 September 2009 - 12:46 PM

I designed it to be robust. Tearing up a car in practice on Saturday reinforced that robust designs are good

Not too bad for a couple of hicks living out in corn field country 60 West of Chicago?

#41

Posted 07 September 2009 - 12:54 PM

looks like you got that soldering iron very hot!

Hey....Nice joints........lol

11/4/49-1/23/15

Requiescat in Pace

#42

Posted 07 September 2009 - 01:50 PM

Looks good.

It looks like that front axle is going to stay on.

I'm not sure if having the 2 straight rails tie into the front axle and motor bracket are a good thing? I figured it would either make it strong or take out the chassis in an accident. I guess time will tell?

#43

Posted 07 September 2009 - 08:41 PM

61.9 grams

#44

Posted 07 September 2009 - 09:59 PM

A motor is only as fast as the chassis it's in.

Dominic Luongo

Like Dominator Custom Chassis on Facebook

NERR photos from 2012-April 2016

NERR photos from 2016 to now

#45

Posted 08 September 2009 - 04:07 PM

Really nice design. Did you use .055 wire all around for the rails?

Thanks,

I used .063

I'm building another with 2 piano wire and 2 brass .063 wires. .055 isn't a bad idea for one of the others.

#46

Posted 09 September 2009 - 04:23 PM

Bill and I intended purpose of this thread was to show that professional or purchase finished quality parts / chassis could be produced with a simple $500 mill available to most hobbyists. We wanted to provide inspiration or challenge those who already have the equipment to take it to the next level. For those on the fence thinking, "I would like a mill but what can I make?" it was a demonstration of the potential. While the drawing was produced using CAD software the same results could be obtained with pencil, paper, calculator and basic drafting equipment.

That being said the design; key design elements and their legality are inconsequential to this thread. We are asking that pontification posts about it's legality to please be moved to the IRRA rules discussion thread before it expodes to the point that the thread requires being "closed"

We also believe that those who contributed their builds, tips, or designs are value added and should remain and are appreciated as they provide or challenge thought to future creations.

Thank you,

Hinge legality talk has been deleted.

Mod

#47

Posted 09 September 2009 - 04:46 PM

I think I strained some neck vertebrae at this one. Half a grand, simple?Bill and I intended purpose of this thread was to show that professional or purchase finished quality parts / chassis could be produced with a simple $500 mill available to most hobbyists.

Well, I'm a tool & die maker & I've been reading along with this thread, all the while plotting how I'd do it at HOME. I may machine a tool now and again for myself, but mostly I want to leave the machinery at work. That's just me. Maybe having CAD/CAM available to me makes it easier to disdain home-shop stuff. Pretty provincial, if that's how I'm thinking.

The great thing about this build is, it got me thinking in some very interesting new directions, and I'd reeely like to go at one with Moto-Tool, nibbler, & file!

Thanks for putting it all out here.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#48

Posted 09 September 2009 - 08:43 PM

Allthough I do not have a Mill as of yet, I do have a Sherline lathe that could be converted to a mill. Yes it would be pricey no matter how you go about it. My point is that I appreciate this thread for a different approach to the build. I constantly review all these threads on the blog and have picked up countless tips and tricks and ideas from many posters that are willing to share their builds or just pictures of a finished product. I have been watching this thread as well and I am now more curious to here about the results of when the "Rubber meets the Road" so to speak. Cant wait to see the next few or more that people construct based on this "Mike Steube" inspired build.MODERATORS:

Bill and I intended purpose of this thread was to show that professional or purchase finished quality parts / chassis could be produced with a simple $500 mill available to most hobbyists. We wanted to provide inspiration or challenge those who already have the equipment to take it to the next level. For those on the fence thinking, "I would like a mill but what can I make?" it was a demonstration of the potential. While the drawing was produced using CAD software the same results could be obtained with pencil, paper, calculator and basic drafting equipment.

That being said the design; key design elements and their legality are inconsequential to this thread. We are asking that pontification posts about it's legality to please be moved to the IRRA rules discussion thread before it expodes to the point that the thread requires being "closed"

We also believe that those who contributed their builds, tips, or designs are value added and should remain and are appreciated as they provide or challenge thought to future creations.

Thank you,

Hinge legality talk has been deleted.

Mod

Keep em comin Rob!

Build it, Race it, Break it, Fix it !

Don't Outsmart Common Sense !

#49

Posted 09 September 2009 - 09:06 PM

I don't have street cred here, but I do bring a bit of craft to the discussion--and one of these days I will put up some work to share; and I hope to approach the way that guys like Hanson, Thigpen &c. &c. do it. Pretty tall order, and a very worthy one.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#50

Posted 09 September 2009 - 09:25 PM