I realize we are all guests on this forum. It is however, my post. As such, I feel compelled to say something about my intentions for the topic of my post:

My friend Adam REALLY loves early '70s pro cars and he has a short list of ones he'd like recreated. One of them was the 1973 Western States Championship

WINNING Neat Things "Diamond" of Philippe de Lespinay. With PdL's help of pictures and technical advise I was able to do my best to make that car. Thank you, Philippe

.

Here is a link to

the Diamond build (dial-up beware!).

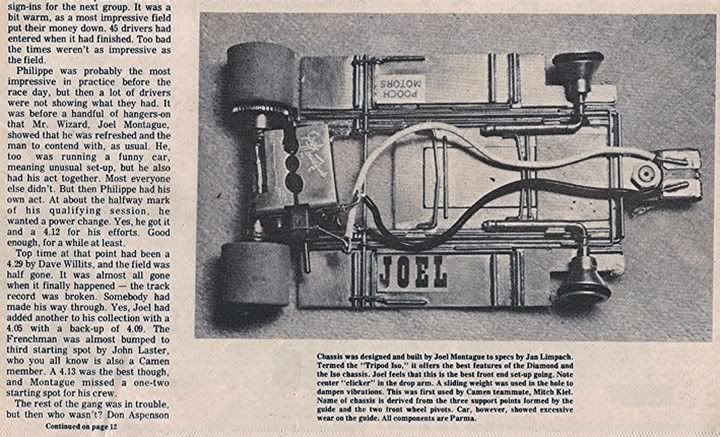

Another car on "the list" is the 1973 National Championship

WINNING car of Joel Montague. With the help of my good friend Steve Okeefe I had the opportunity to get in touch with Joel by email. He, too, has been super helpful in providing me with pictures and technical information that I am attempting to share with everyone here. Thank you Joel

.

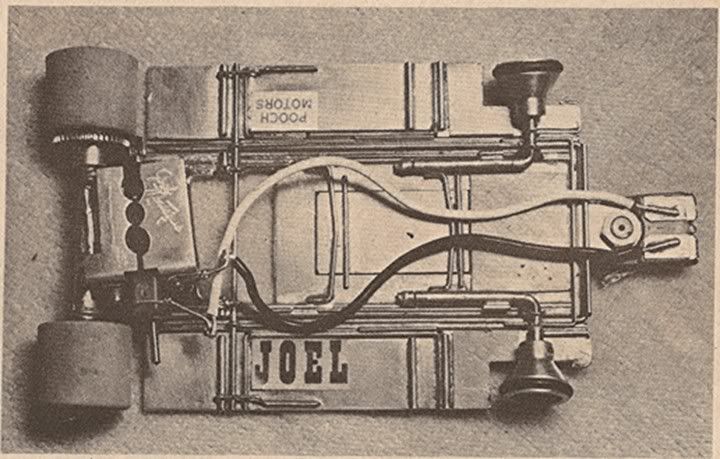

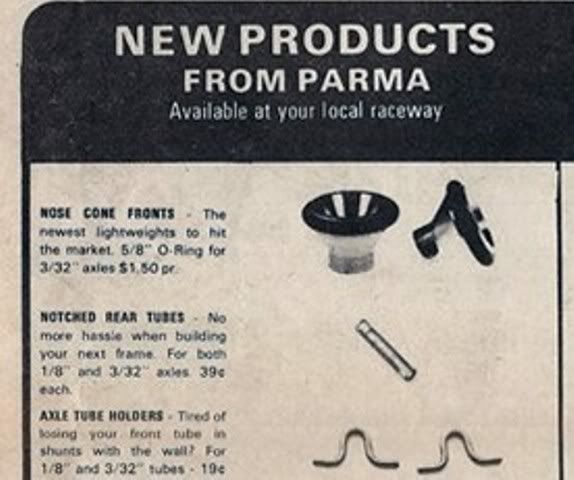

Now, as Isaac Asimov wrote, "I am but an egg", meaning I'm not a famous pro racer. I am a mere enthusiast and student of a HOBBY I love. However, having built PdL's car and being in the process of building Joel's I must say that if both cars were the same I wouldn't bother posting this build. Yes, they are both of the next evolution of pro car (which I believe PdL pioneered) with fixed drop arms and independent front suspension. But, to my eye they are as different as a 1963 Ferrari GTO (PdL's Diamond) and a 1963 Corvette Grand Sport (The Montague Missile).

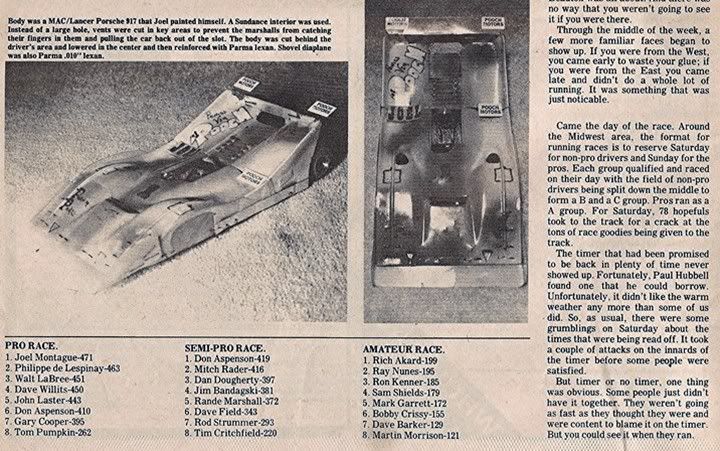

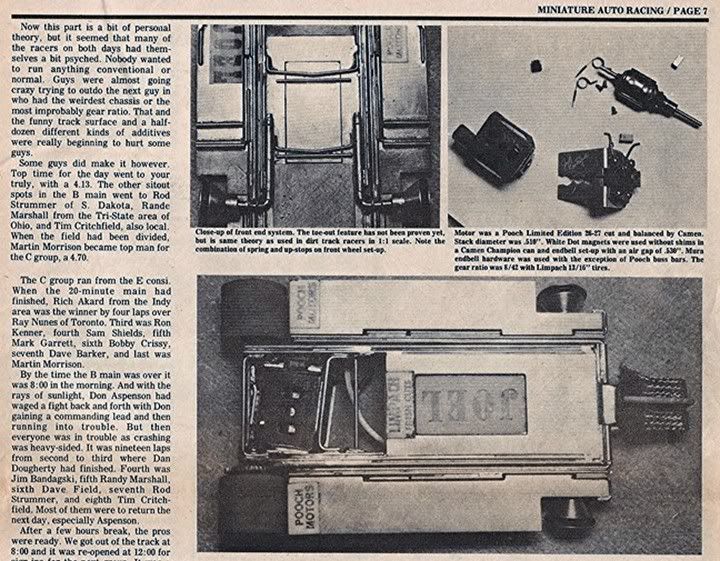

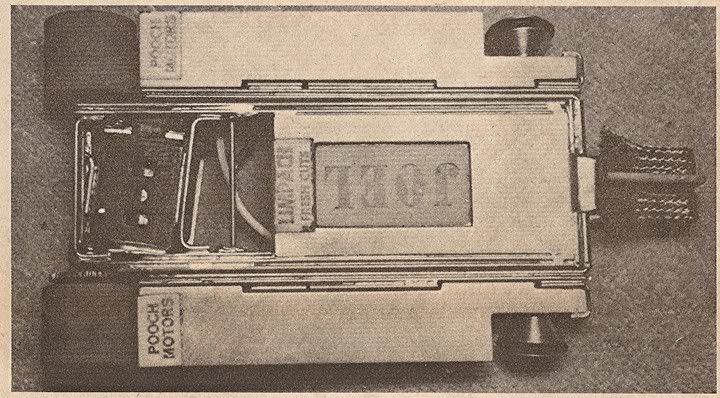

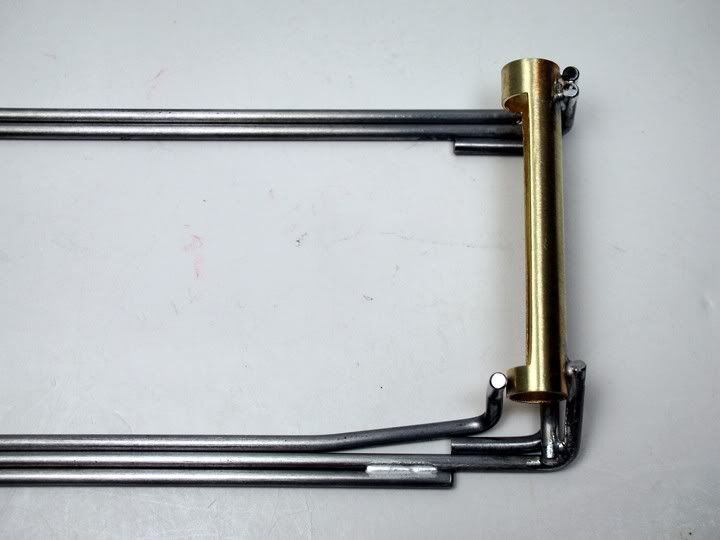

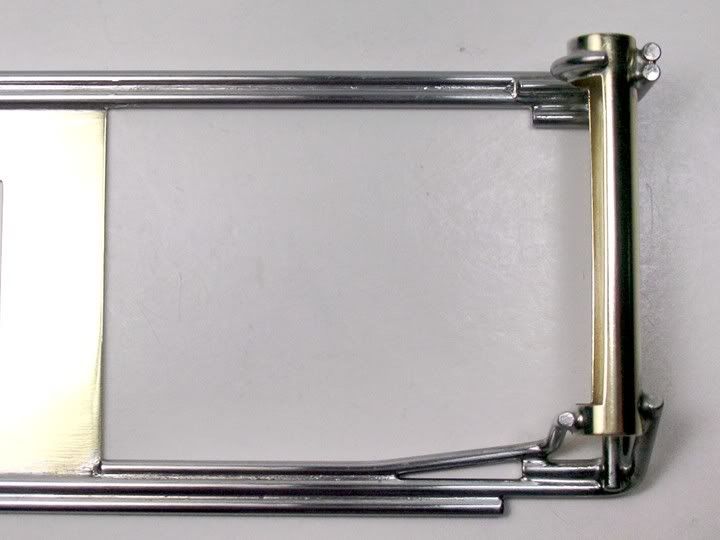

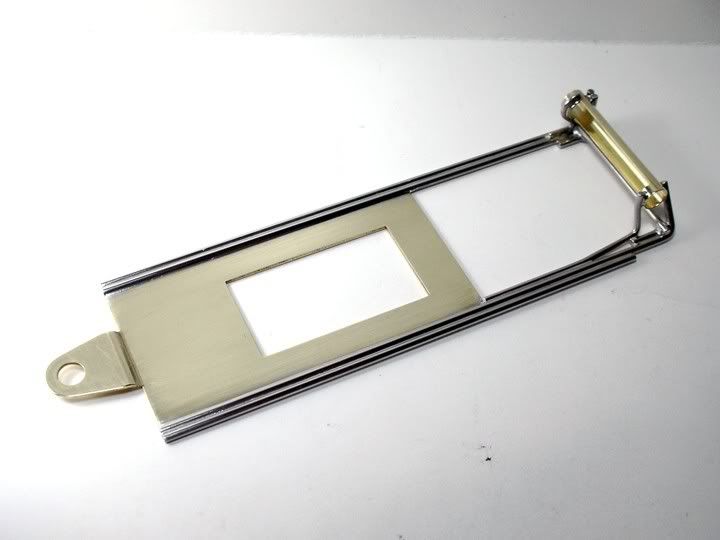

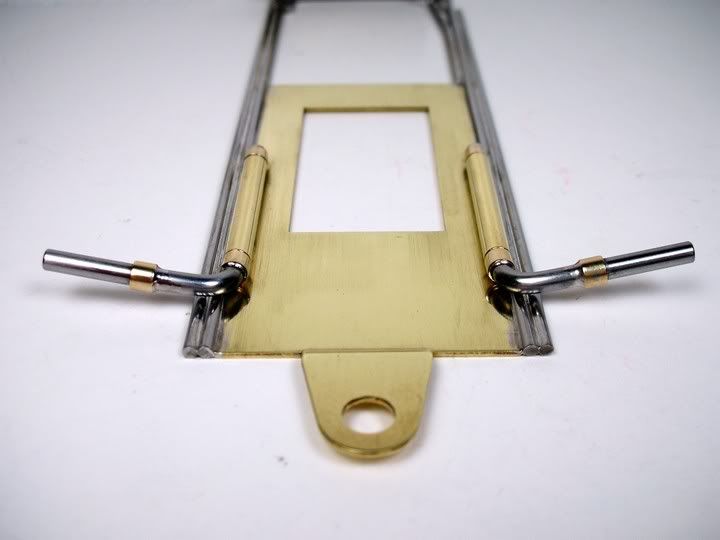

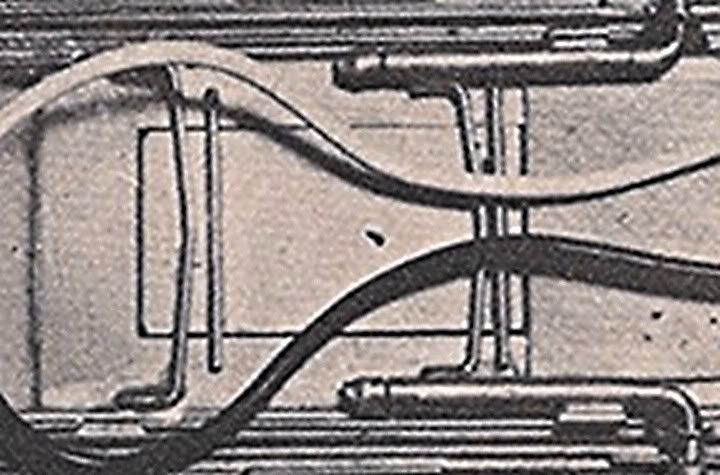

Look at the difference in the front suspension. The Diamond uses elegant .062" piano wire A-arms with .030" piano wire braces reinforced with fine wire wrapping. These A-arms are nested together and pivot in the center of the drop arm and toe the wheel inward. The Missile uses just a single massive .093" wire L-arm pivoting outboard on each side of the drop arm and toeing the wheels outward.

Look at the main rails. Each has two rails per side soldered to the drop arm and extending back to the rear axle tube. The Diamond's rails on the can side of the motor are bent at an angle to accept the motor. No half rails are used. The Missile's main rails are all straight. The motor angle is established by a half rail inside the two main rails. Again, very different approaches.

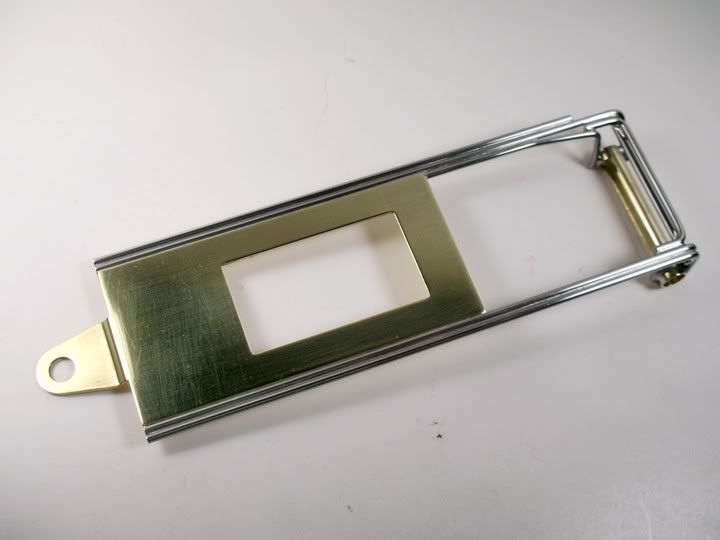

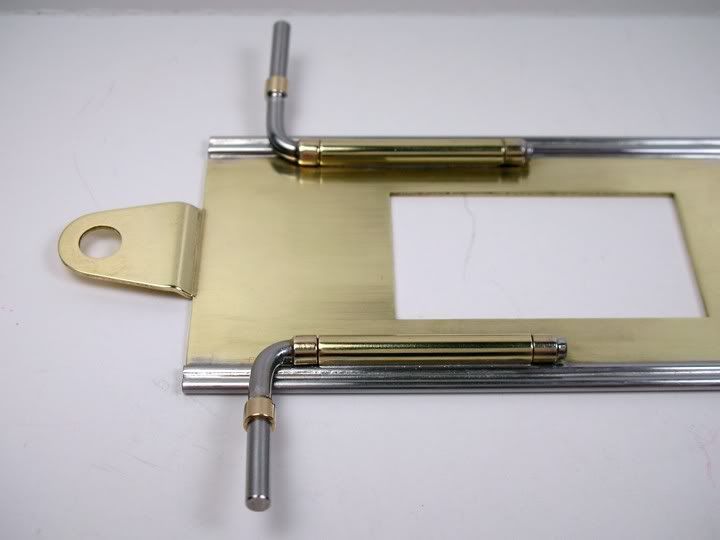

Look at the "clicker" I pictured above. It's certainly a novel item that the Missile has and the Diamond doesn't. I don't know if helps performance or not but it makes the chassis different and I can't wait to make it! Those are some of the differences so far and I just started construction.

So, back to my intentions in this post. With the help of the actual builder of this really cool Missile, I hope to show its recreation to the best of my ability. The hidden details will be revealed that you just can't see in the grainy vintage pictures. I hope this will help others to build there own versions or at least give an insight to what it took to create the 1973 National Championship winning car of Joel Montague.

I only have time to work on my hobby on the weekends so Saturday I hope to show details of making the "clicker".

Onward to the fun of scratchbuilding