A Tale Of Two Harvey’s

Then I acquired this Lancer factory painted version. I sent it off to that Viceroy of Vacuum, John Dilworth. He made a mold from it and produces some wonderful repop bodies. Here's the original:

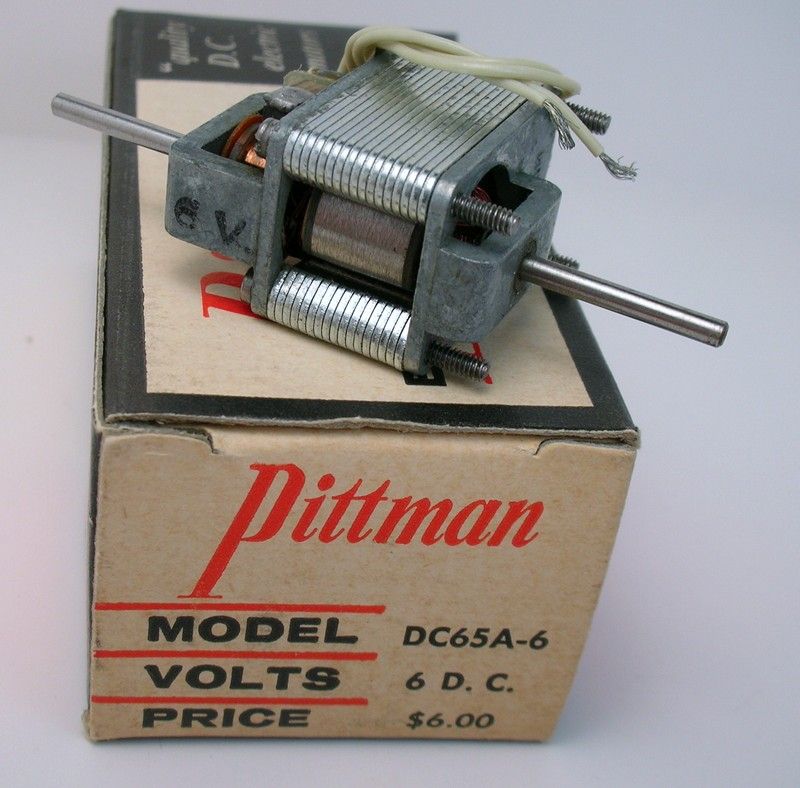

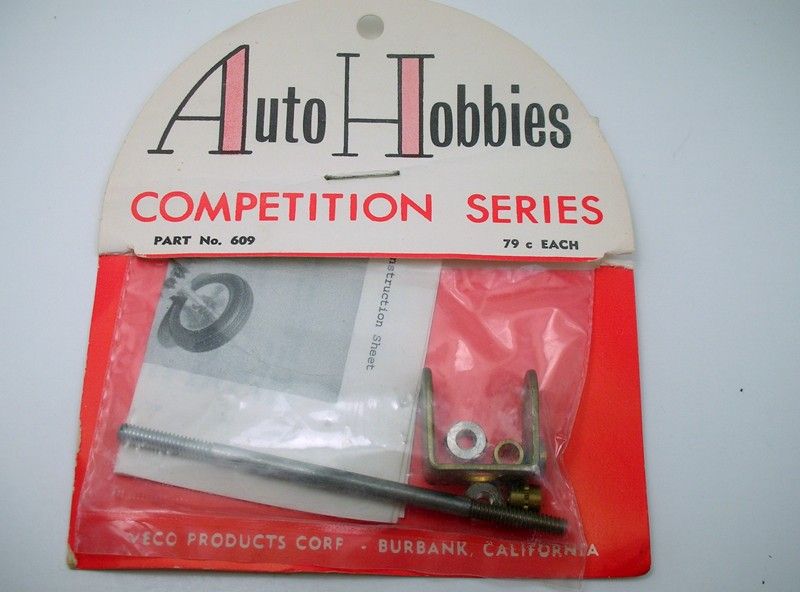

I decided to finish off the Lancer Yellow Boy and bring its journey full circle.... but what motor to use and keep it in the 1965 timeline?

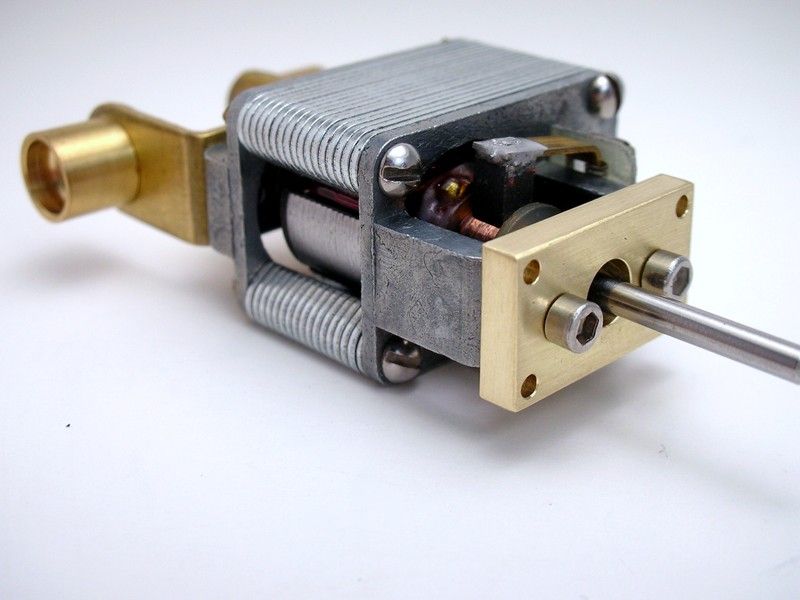

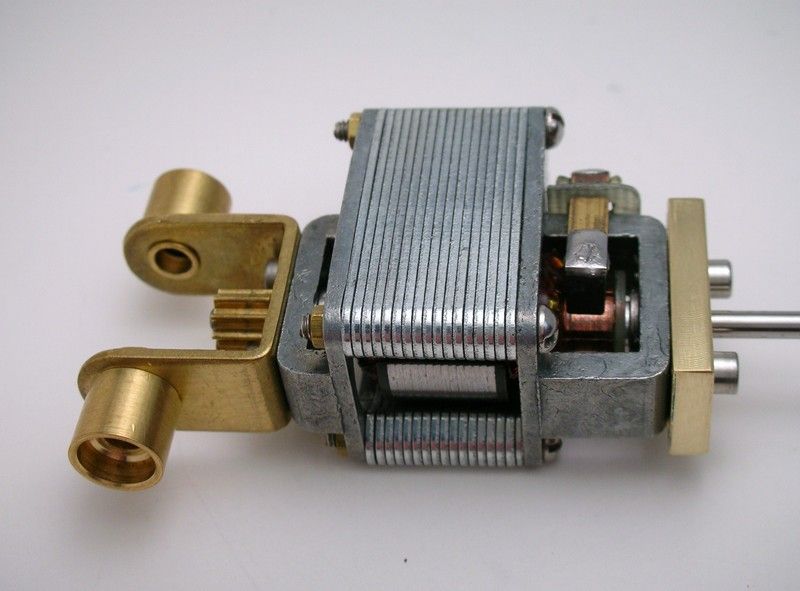

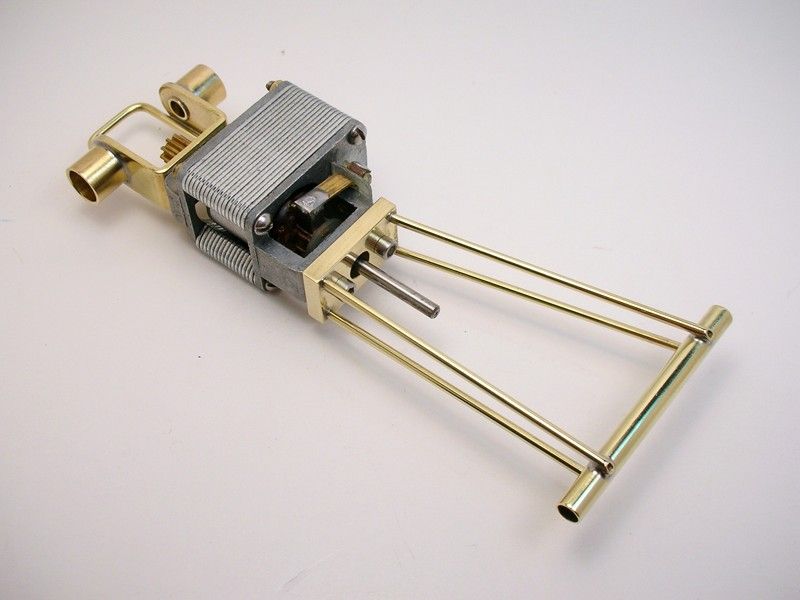

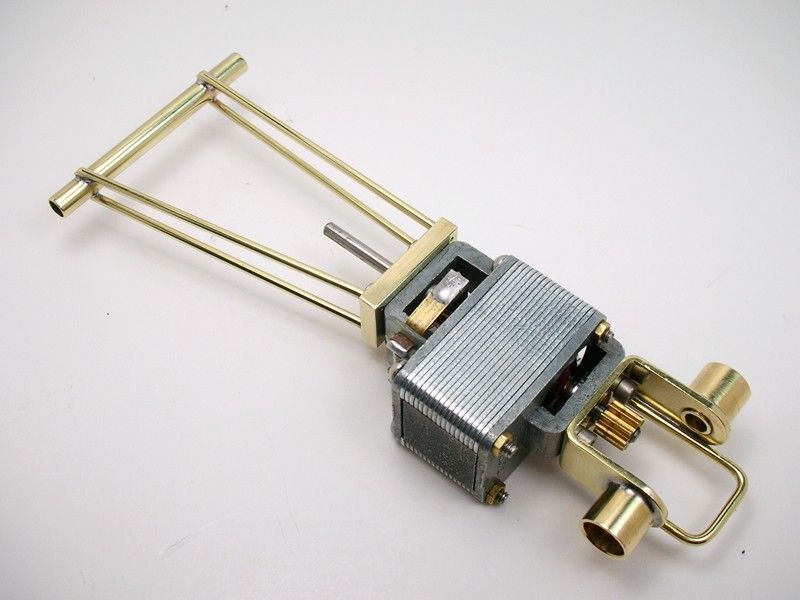

Then BAM! What about this, a Pittman DC-65X:

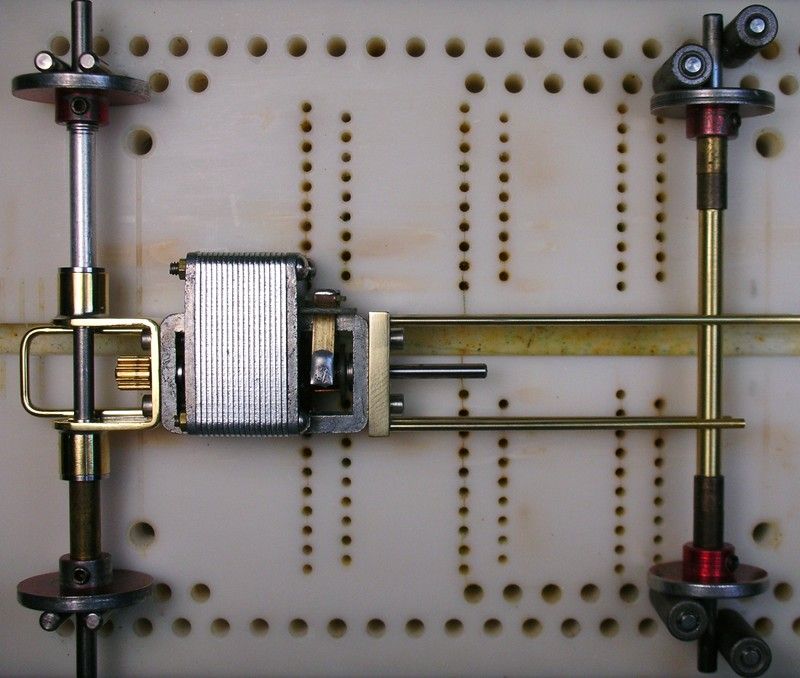

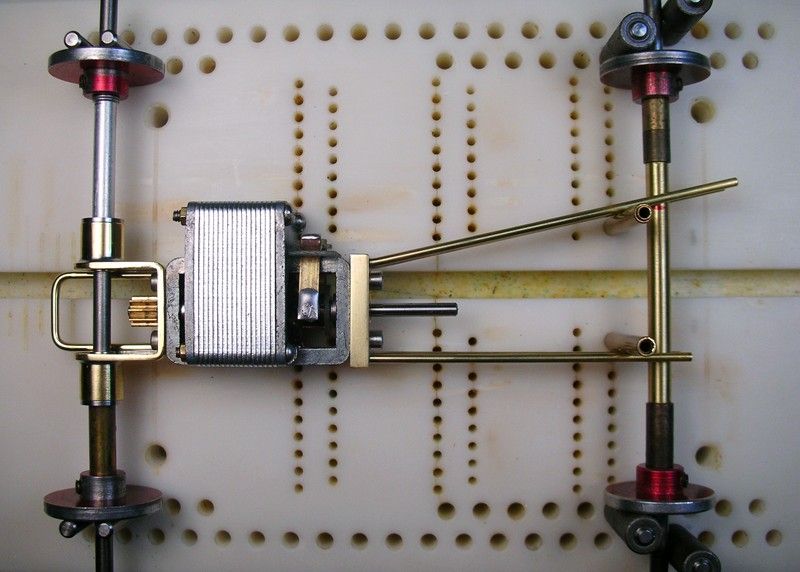

It fit...INLINE!

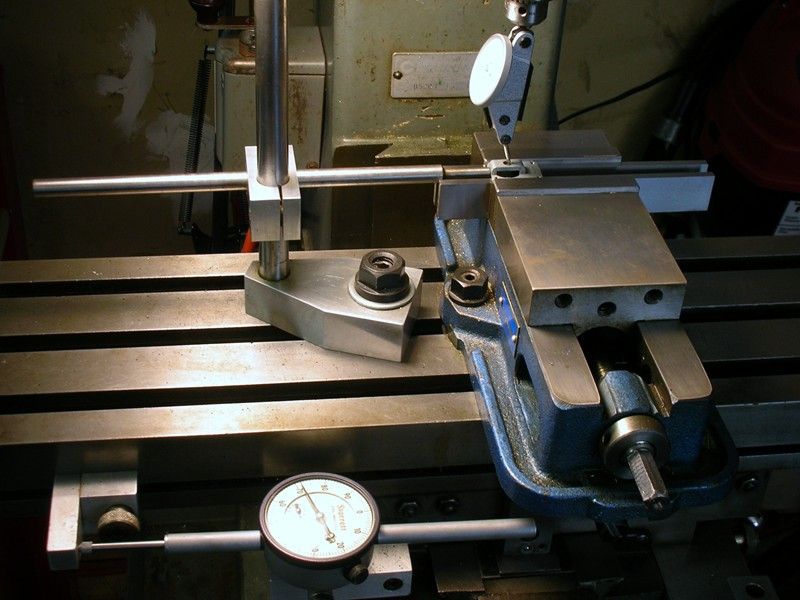

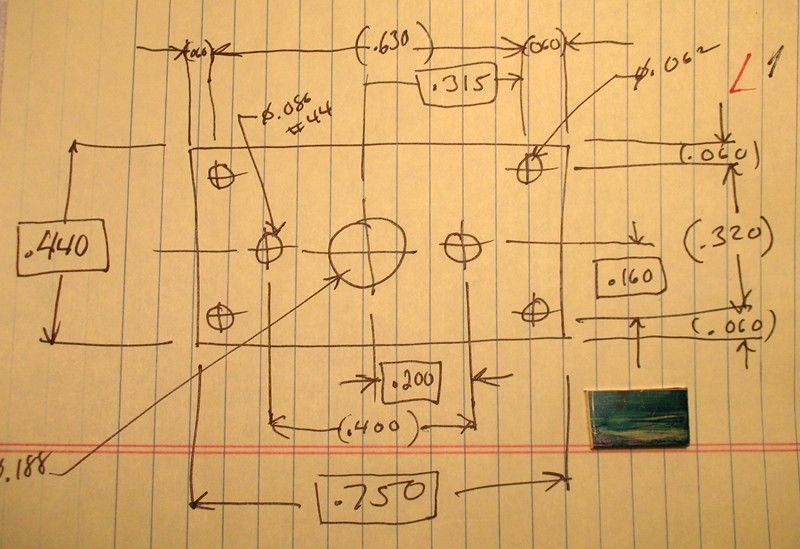

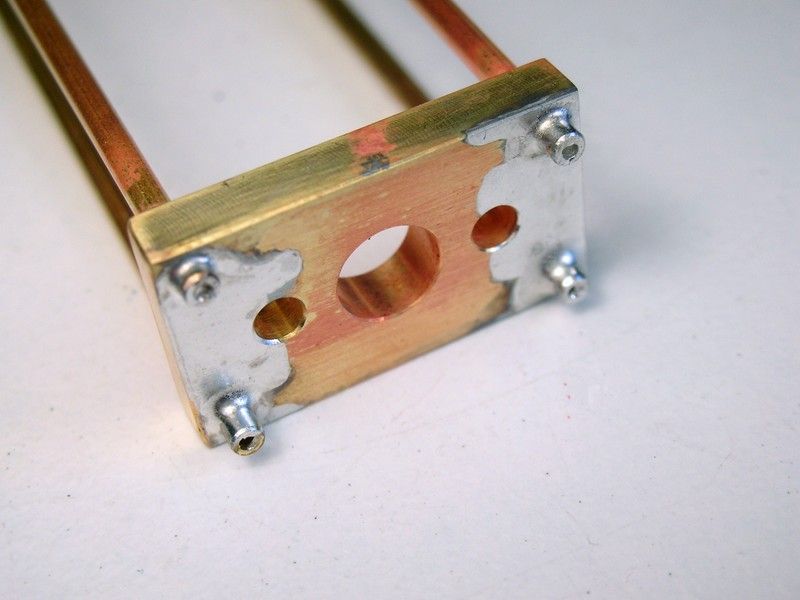

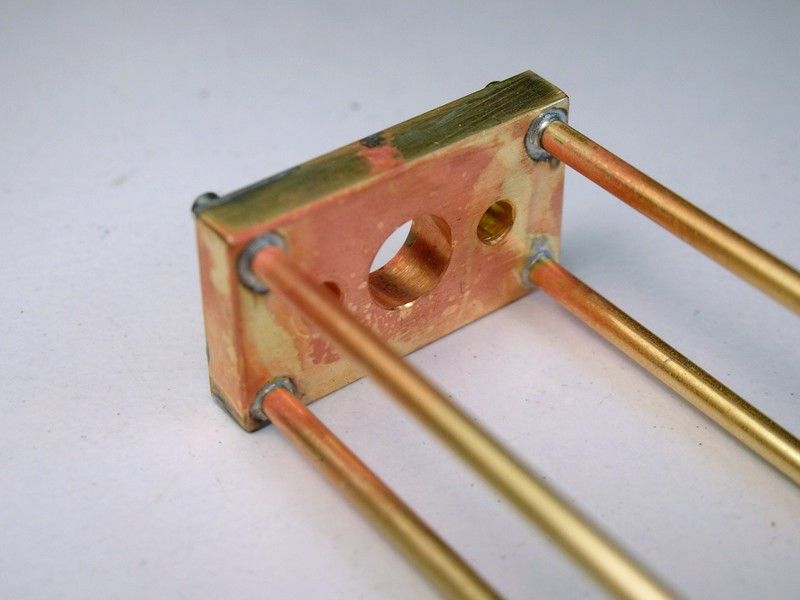

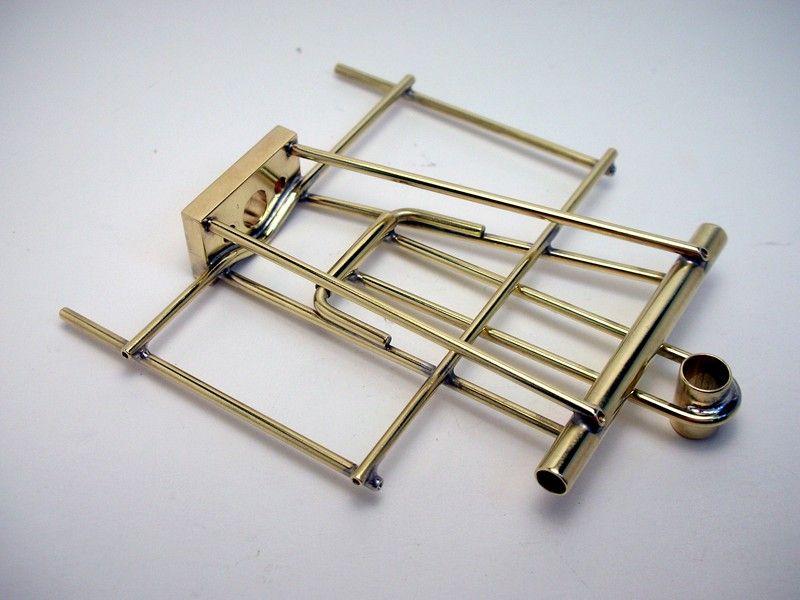

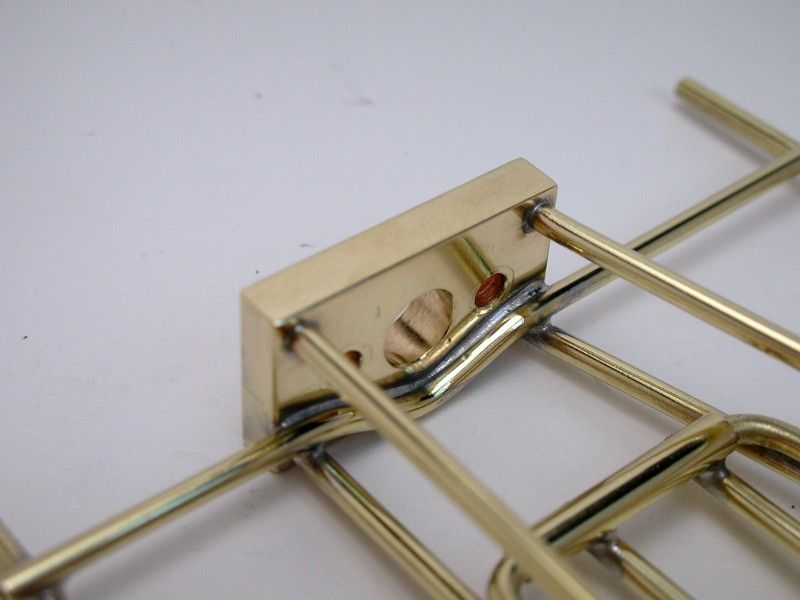

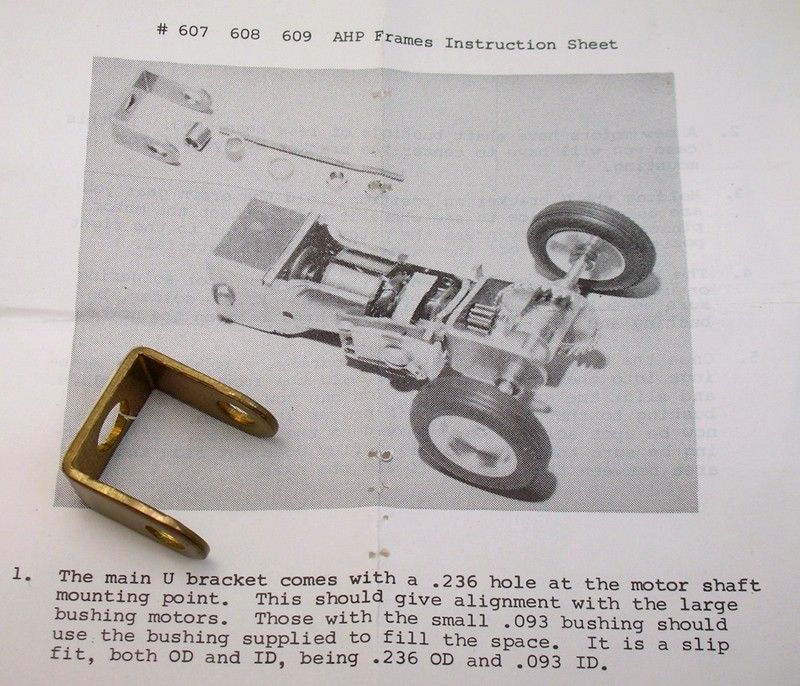

The bracket was designed to solder onto an inline motor.

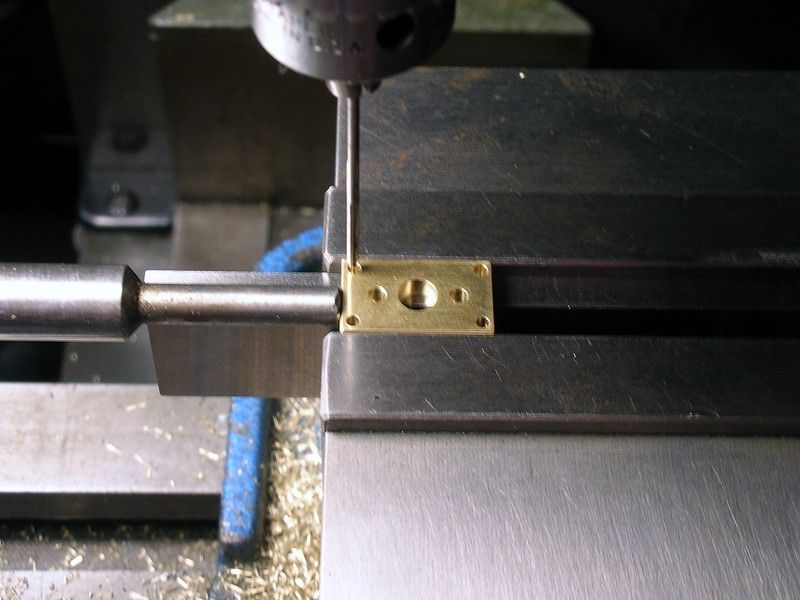

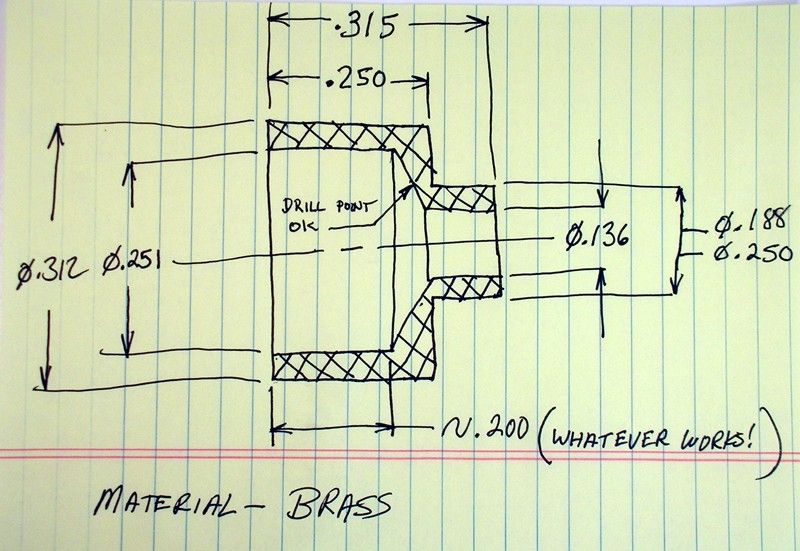

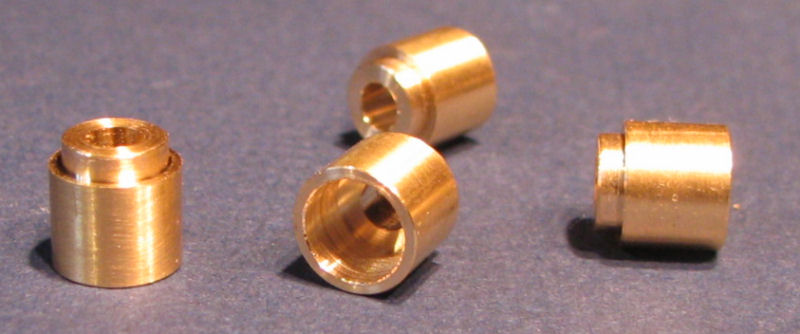

I just needed to drill a couple of holes in the axle bracket. Howard's Hobby House bearing retainers are doubled up and fit to the bracket:

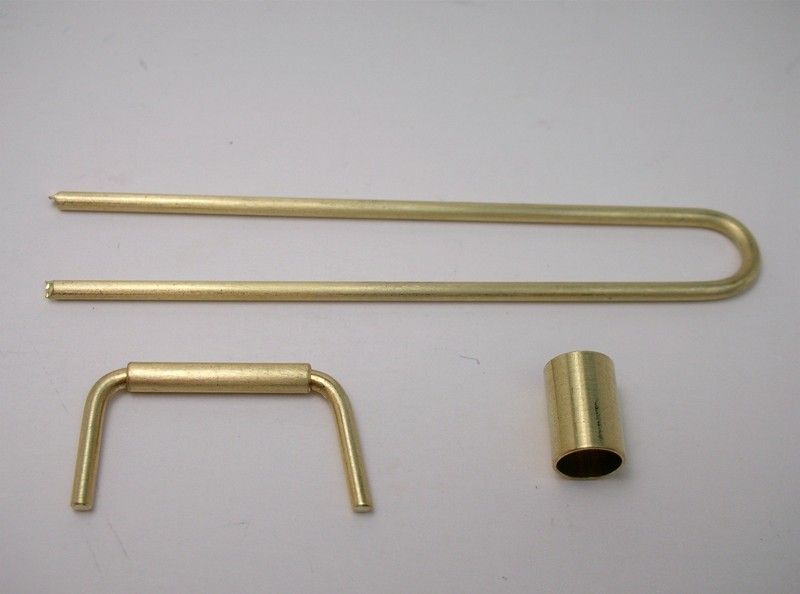

To drill and tap holes in the motor end pieces I wanted to take the motor apart.....but I didn't want the zillion little stamped "pole pieces" falling apart

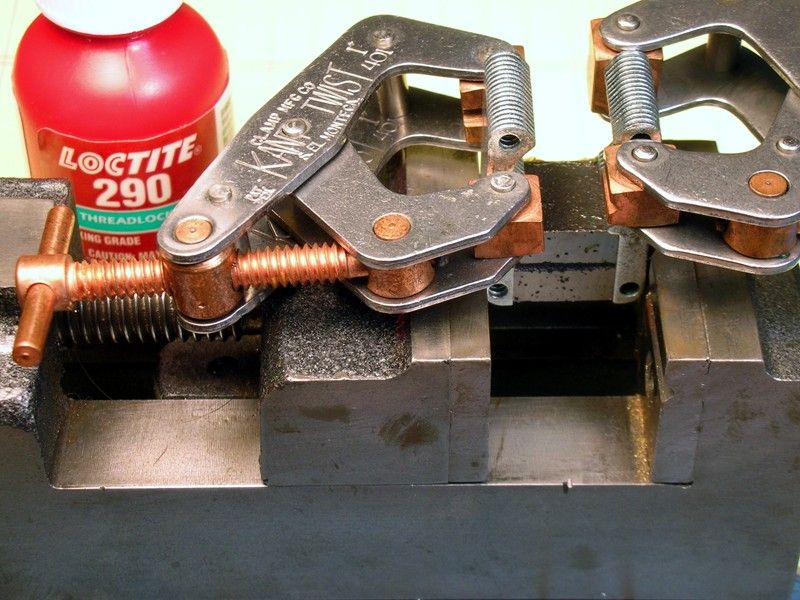

"Wicking grade" thread locker was brushed onto the outside of the motor being careful to keep it away from the endplate screws.

After that cured overnight I CAREFULLY dissembled the motor, clamped it up and painted another coat of thread locker all over it:

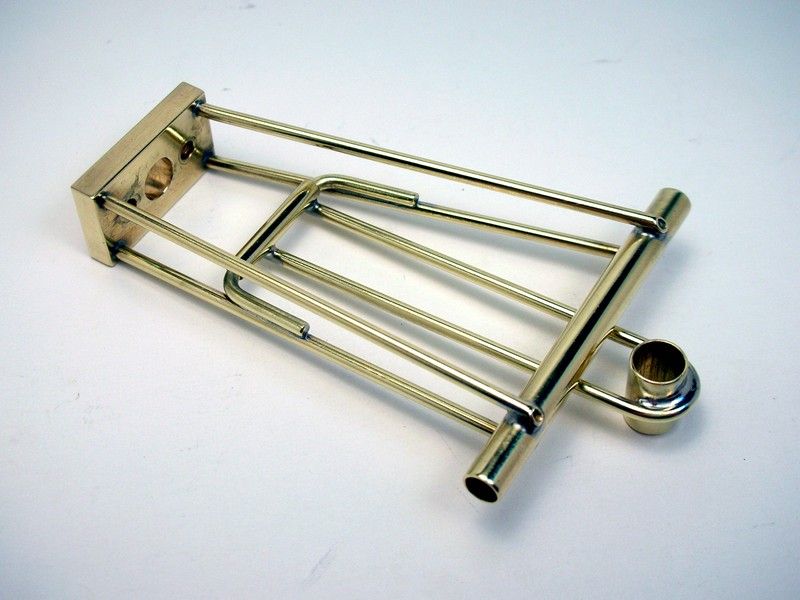

Here's the result:

It's not super strong but strong enough to hold together in one lump while I worked on the arm and endplates

To be continued..........