Fred said he patterned his car after this one. I scanned the pic a 600 dpi but the original magazine photo is so small that I can only seem to enlarge it so far before all you see is a bunch of dots from the original  :

:

Something I'm wondering about Fred. Your original car seems to have all the main rails in front of the front axle tube instead of alternating front and rear. To my eye, so does Mikes car.

What do you think Fred?

PS Congrats on taking fastest lap!

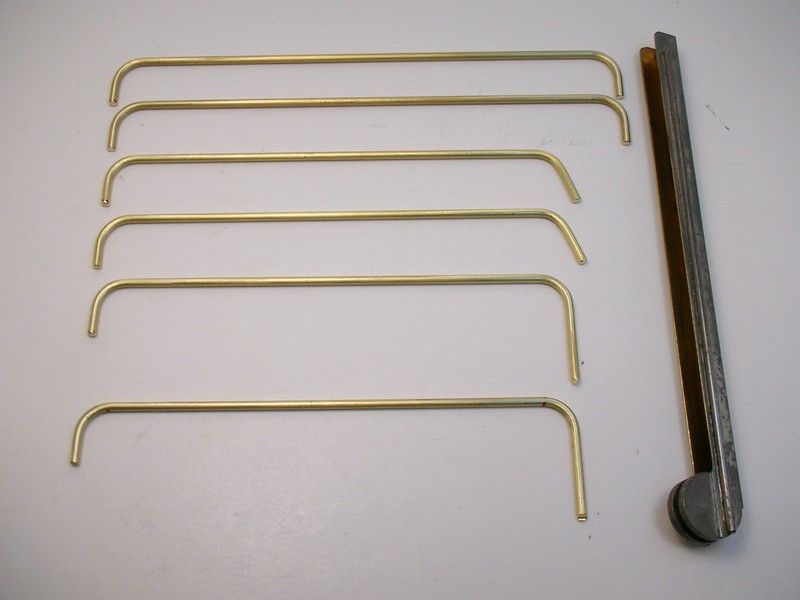

Rick - I retrieved my original chassis and touched a file to the end of the rails to see if I could determine were they tubing or rod.

The 3 original rails are indeed tubing.

And, yes, the chassis/car I borrowed from Mike was also tubing - as can be seen in the photos from the event. I would agree with your comment - on Mike's chassis the rails do all appear to come up in front of the front axle tube.

On the one I have the middle rail rises at about a 45 degree angle and is soldered to the bottom of the front axle tube. The (original) inboard and outboard rails are indeed in front of the front axle tube.

To my mind, this puts in question my memories of the car as I believed that I had built it using 1/16" rod (3 rails) with the 1/8" outboard rail (4th rail) being rod as well.

That leads me to one of two conclusions.

1. My memory is toast and the chassis I built was this 3-rail made using tubing.

2. My memory is toast and this is a different chassis altogether.

A couple of other thoughts wrt this particular chassis.

A. The MkII body would have had the normal 1/16" "pin" tube body mounts. I don't see any evidence of where these would have been soldered to the 3-rails (which supports conclusion #2).

B. the brass plate drop arm is definitely not what I would have used. The arm and hinge tube is not square to the rest of the tubes. Definitely not original to a car I would have built (which is in line with conclusion #1).

C. The "up" stop for the drop arm was added whenever this brass plate drop arm was installed. The "U" shaped brace is not tubing and was added in at a later point (which doesn't lend any support to either of my conclusions).

D. The front of the car appears to have been re-built - it is not square, there are small bits of what looks like thin piano-wire that are laced around the front axle tube and the 1/16" rails as some sort of reinforcement (again, doesn't support either of my conclusions).

E. The rear section of the car IS consistent with what I would have been building at that point in time (supports conclusion #1).

F. It does have a 26D style can.

What I am sure of at this point in time is: I have a old chassis that started life as a 3-rail, 1/16" tube chassis with a prototype Russkit 26D motor.

Wish my memory was more accurate and/or I had a picture of the car from back then...or my brother was still with us and I could ask him...

WRT fast lap. Thanks. The car "worked". Didn't chatter in the 360 that lead to the straight, I could drive it down the straight without having to lift for the dips and could keep it flat thru the banking. It was a great car to drive.

FWIW,

fL