This is going to be a R&C “What If” project. ![]()

What if RAM Engineering fielded a Team in the Rod & Custom Road Race series?

Fellow Slotblogger SlotStox#53 (Paul English) made this project possible with his trade of a very rare (at least for me) RAM Maverick 16D armature. Thanks, Paul! ![]()

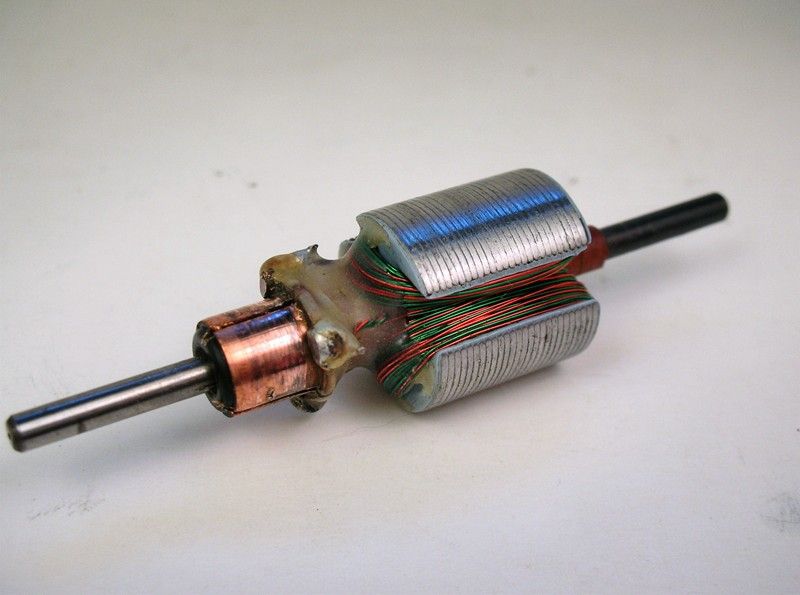

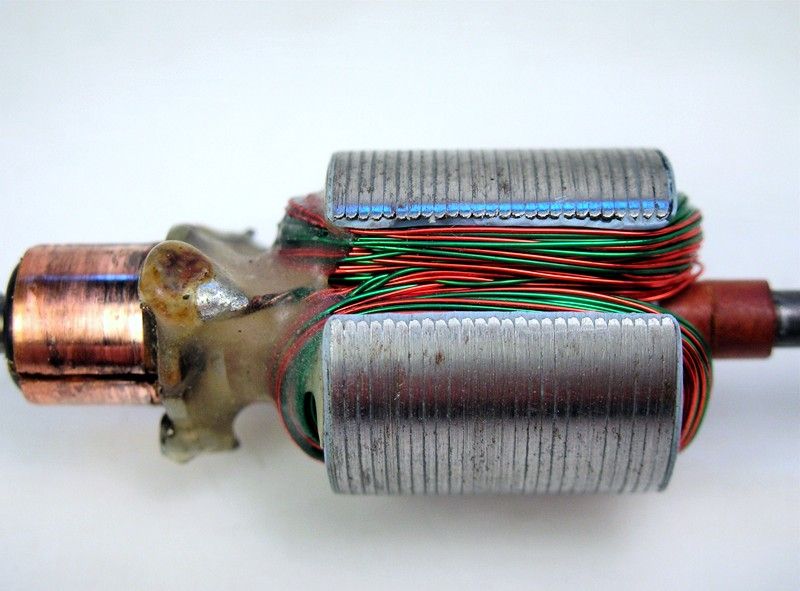

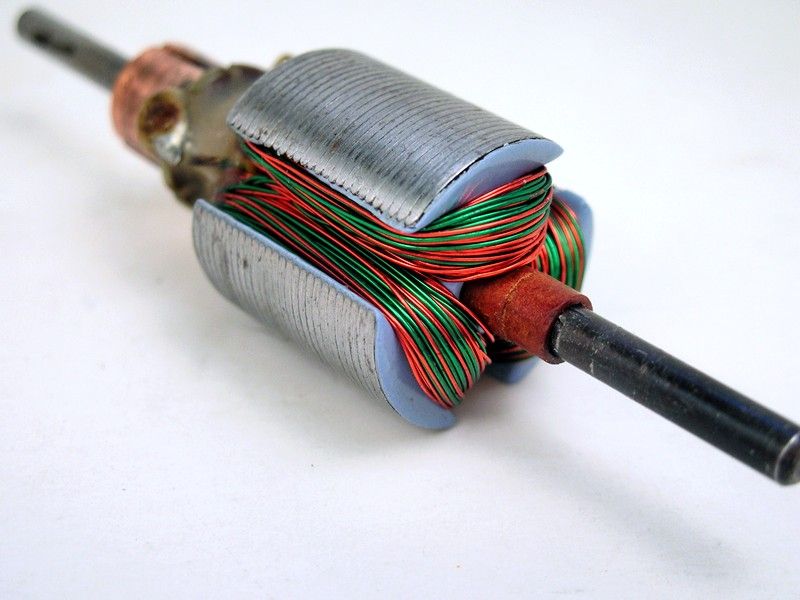

Here’s the beast in the flesh:

We call it the Christmas armature because of the red and green wire in the double wind:

Check out the giant comm with the giant solder joints. Those joints have been cut back on two of the three poles. I don’t know if that was such a good idea. We’ll see if, “she blows!” ![]()

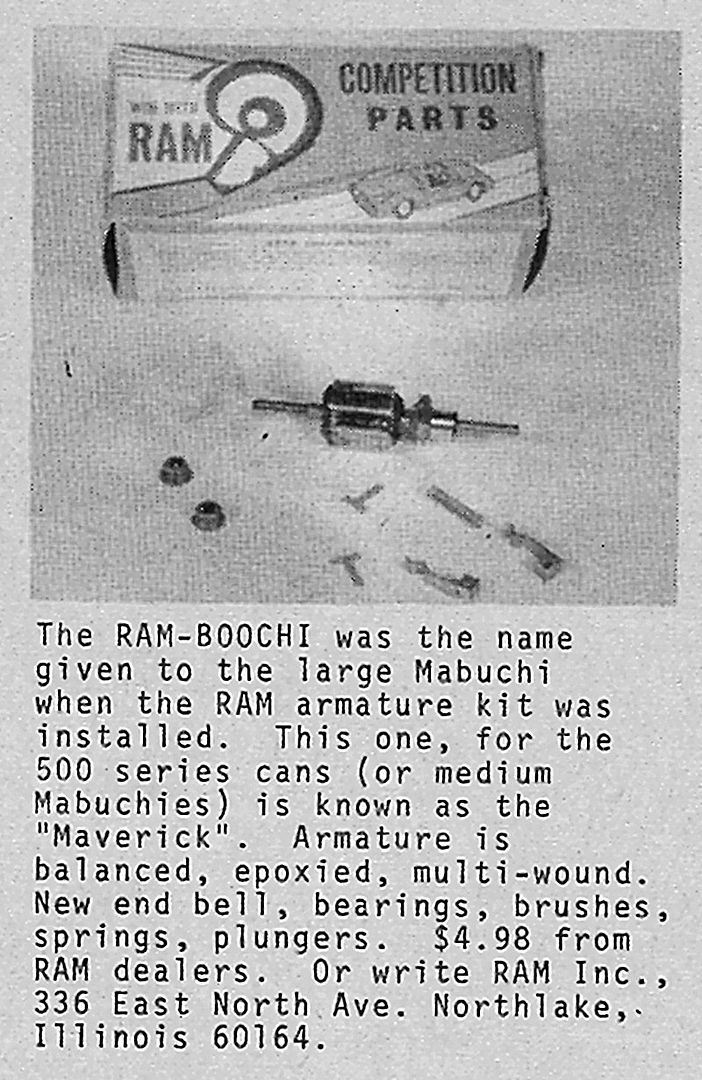

Here is the only ad I’ve found for this rare RAM 16D Mabuchi conversion kit. It’s from the Feb. 1967 issue of Car Model Magazine. The sixth R&C Road Race was covered in the Feb. 1967 issue of Rod & Custom magazine so the timing works:

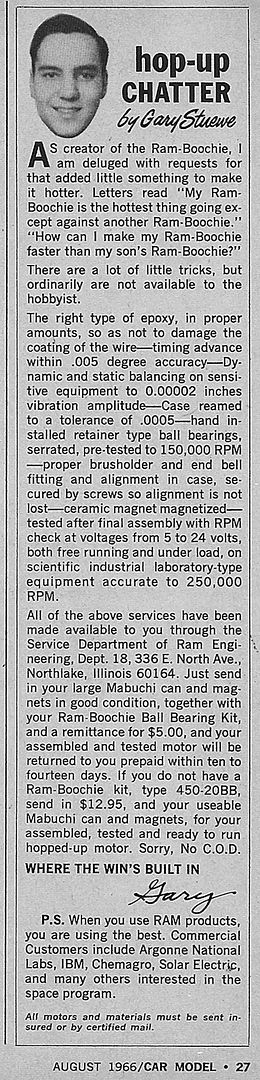

The head of Team RAM will be none other than the inventor of the RAM-Boochie, Gary Stuewe:

Time to build a Team RAM Maverick race motor. The “hop-up kit” came with a pile-O-parts to replace everything in a stock Mabuchi except for the magnets (but I’m ditching those too). All I have is the arm so I’ll be putting my own kit together.

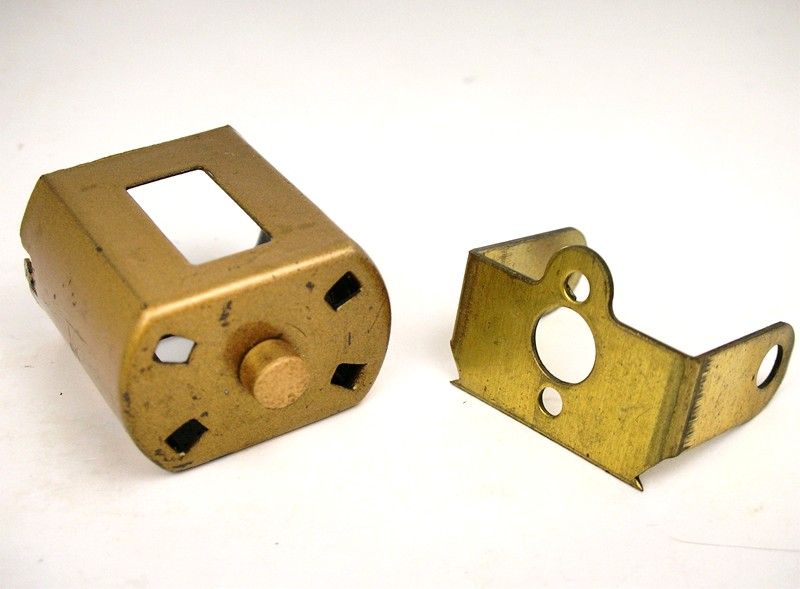

First is the endbell. RAM sold them in at least these two configurations:

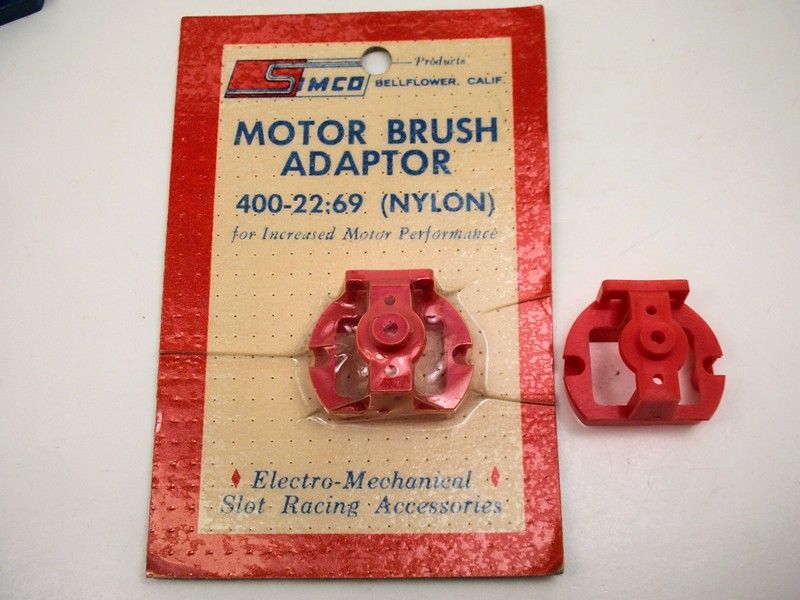

Simco also offered an endbell replacement for the Mabuchi. First there was the nylon version complete with molded bearing:

Then the Teflon version with a real bearing:

There was also this cast endbell-axle bracket piece:

I don’t know who made it:

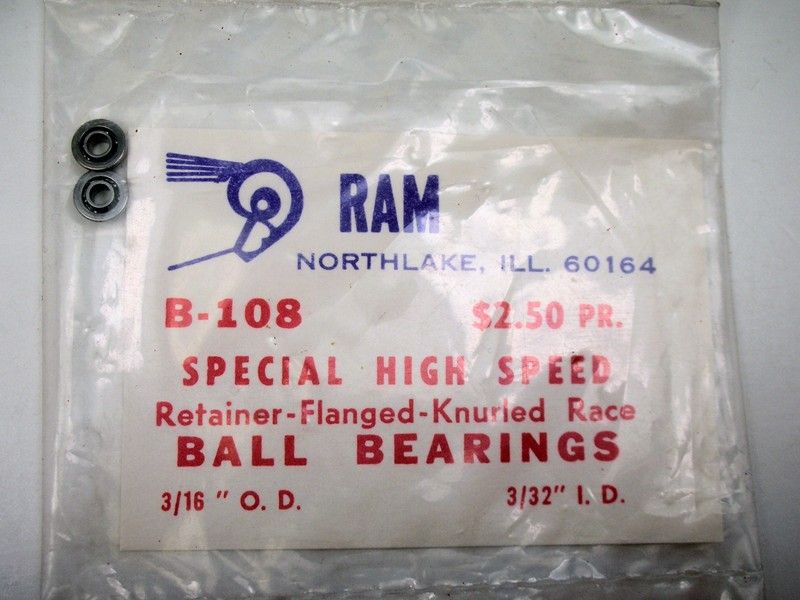

Then we need RAM bearings, not modern 3/32 axle bearings (I’ll get into why this is soon):

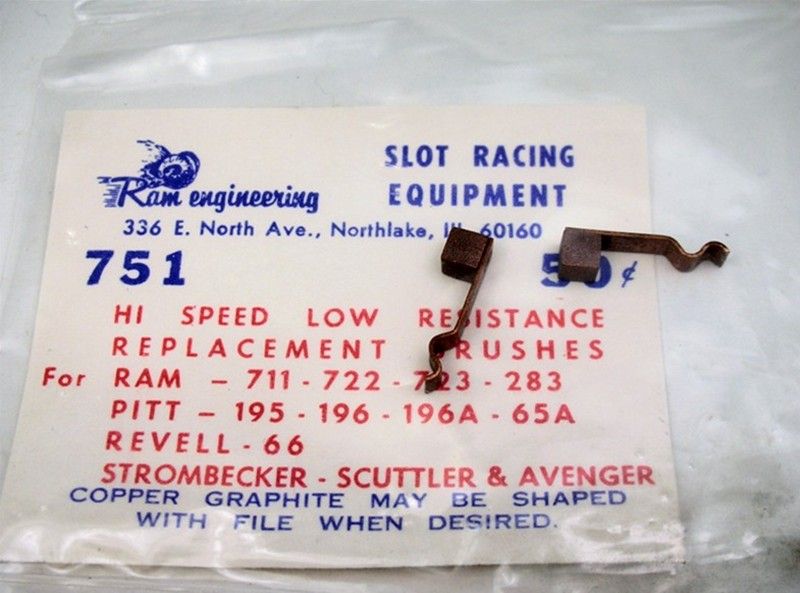

RAM also supplied their hard compound brushes:

RAM also supplied their Pittman style coil brush spring and plungers. Those were ditched in this build for the Simco style spring. Here’s the Simco kit and one from Sharnie’s Superior Specialties…..what in the heck is that! ![]()

Time to start building this motor ![]()

Team RAM R&C road race car

#1

Posted 24 September 2013 - 09:31 PM

- Jencar17, George Blaha and C. J. Bupgoo like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#2

Posted 24 September 2013 - 10:22 PM

I bet it took two and a half weeks to find those parts! ![]() I've never seen the end bell/axle bracket piece either.

I've never seen the end bell/axle bracket piece either.

A very promising start!

11/6/54-2/13/18

Requiescat in Pace

#3

Posted 24 September 2013 - 10:59 PM

Even better seeing all those RAM essential parts to go with it! Especially love the endbell & that all in one cast job, very rare by the looks of it .

Oh sooooo looking forward to seeing this one come together !

Most definitely Onward!!

#4

Posted 25 September 2013 - 01:40 AM

Yea Rick! (cue the cheerleaders!)

Always wanted to see what one of these would look like, and you're making my dream come true...

What a weird arm... And that com doesn't look especially Ram - didn't they usually weld their tabs?

Ditto for that cast rear endbell/bracket part - never saw one of those either.

Don

#5

Posted 25 September 2013 - 06:56 AM

You have GOT to use that endbell/bracket! Talk about monocoque construction! It'll fit right into a '67 race with a David-and-Goliath theme.

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#6

Posted 25 September 2013 - 10:10 AM

Yes that RAM arm is different. It does look just like the double wind in the ad picture....but that comm in UGLY! ![]()

That cast endbell with the axle brackets is saved for a future project. Since it can't melt I going to stuff a HOT arm in it.

I think I still have a 26D version too. After my dentist visit this morning ( ![]() )..........I'm going to get a can for this RAM Maverick.

)..........I'm going to get a can for this RAM Maverick. ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#7

Posted 25 September 2013 - 10:36 AM

#8

Posted 25 September 2013 - 02:24 PM

#9

Posted 25 September 2013 - 05:34 PM

I am betting that the bracket is Pactra.

Regardless... it is too cool not to use for this project Rick!

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#10

Posted 25 September 2013 - 05:41 PM

The RAM arm for the "16D" size motor still retains the 0.093" shaft.

Special phenolic material endbells were also produced by RAM for these arms and motors. They fit overhead Pittman-SimCo-RAM-Strombecker brushes (all the same, all produced in Japan by the same company).

Not a clue of who produced that endbell bracket and I had never seen one before but it looks pretty cool!

Philippe de Lespinay

#11

Posted 25 September 2013 - 05:52 PM

Thanks for the correction Philippe ![]() Was in shock when I found the arm for sale

Was in shock when I found the arm for sale ![]() and Rick made me an offer I couldn't refuse, never got round to using it & forgot the info on the shaft you gave me back when I got it

and Rick made me an offer I couldn't refuse, never got round to using it & forgot the info on the shaft you gave me back when I got it ![]()

#12

Posted 25 September 2013 - 06:55 PM

Onward to building a Team RAM Maverick motor. I'm using a Russkit 22/23 (Mabuchi) can and I'm going to attach it can-drive (like the period Hemi's) to the ubiquitous Russkit axle bracket:

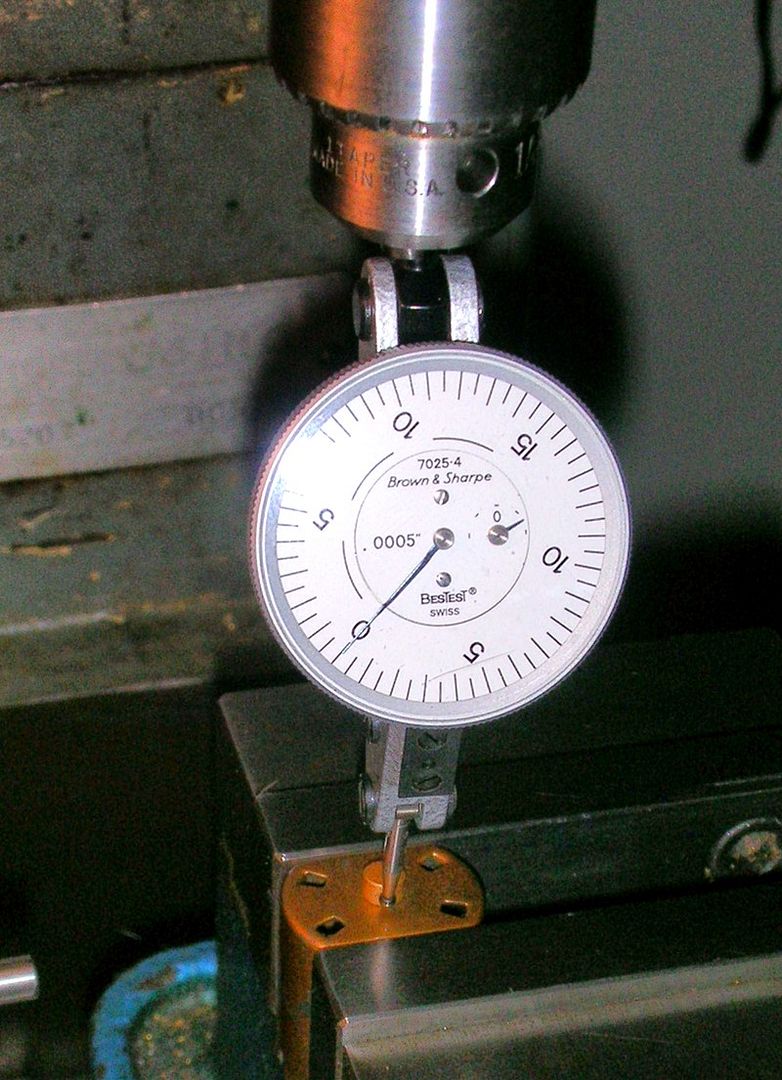

Since I'm a 63 year old Journeyman Machinist who has traveled back in time to 1966, I'm going to use my 1959 Clausing milling machine on this job.

If you don't know what I'm talking about please read or reread post #1 here:

A celebration of the R&C Series

The can is clamped in the mill's vise and a dial indicator is used to center the machine spindle over the can bearing:

The machine accurately places the bracket mounting holes in the can:

Mr. Cruddy Blind Bearing is snipped off.......

Then a 3/16" reamer opens the hole up for the RAM ball bearing:

For endbell mounting holes in the can, I scribed their location with dial calipers. Note, this is not the intended use for such a precision tool......but it works so good and is so easy!

Then a 1/2" metal rod is clamped into a vise. The can slips over the rod and the hole locations can be center punched without distorting the can:

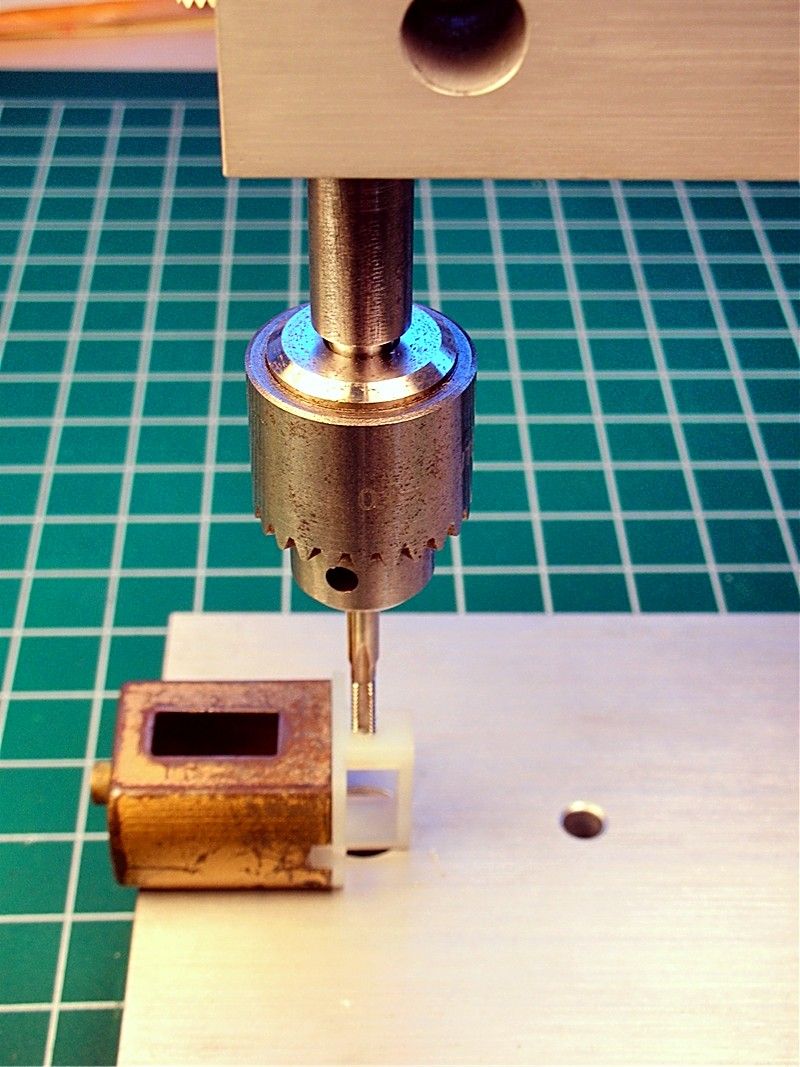

The mini drill press and adjustable angle block make it easy to accurately drill the holes:

Using sheet metal screws to mount the motor can potentially strip out and, or distort the motor can causing bearing misalignment.....or not ![]() .

.

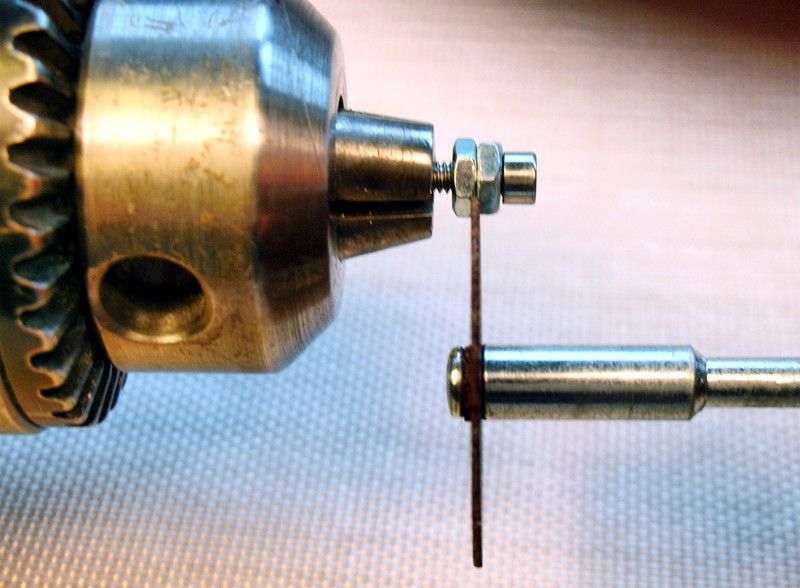

Anyway, I don't like them so I mounted a couple of 2-56 nuts on to a screw and ground them down:

They are ground small enough to clear the ball bearing flange and then soldered into the can along with the ball bearing:

Here's what it looks like from the inside also showing the magnets installed:

Those magnets are (hopefully) "broken ARCO's" as described in the R&C #6 race report:

More to come.......

- Jencar17 likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#13

Posted 25 September 2013 - 07:07 PM

Can see your new Mini drill press is coming in handy already ![]() That angle block is an awesome bit of kit too , makes those endbell mounting holes so much easier.

That angle block is an awesome bit of kit too , makes those endbell mounting holes so much easier.

Really sweet progress on the motor can RIck.... ![]()

#14

Posted 25 September 2013 - 07:19 PM

Rumor is that the Russkit Team was the first to receive the "secret" mags. Check the team's results and see how the Arcos magnet bound their motors. It took three or four months to find the winds that worked with the harsh magnetic field.

11/6/54-2/13/18

Requiescat in Pace

#15

Posted 25 September 2013 - 07:35 PM

Interesting info on the mags Don, do the "Broken" 36D Arco magnets use a kind of a shim to fit in the 16D can or just with the clips?

#16

Posted 25 September 2013 - 08:52 PM

Rumor is that the Russkit Team was the first to receive the "secret" mags. Check the team's results and see how the Arcos magnet bound their motors. It took three or four months to find the winds that worked with the harsh magnetic field.

That's interesting Don. I remember hearing that now. I chose the broken ARCO's mostly because the darn arm is BIG in diameter, about .535". All the other period high performance magnets were too thick for the arm to fit. It will fit with stock Mabuchi magnets though. I think I'll try both

Thannks

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#17

Posted 25 September 2013 - 10:57 PM

Another way to check the "broken" Arcos is they DON'T fit the radius of a 16D can as they were made for the larger 36D.

They do not use a shim though, just the big strong clips. I bought a lot of Charlie Morito's items when they sold on ebay. Charlie was a Team Champion driver and Car/Model author so he had a lot of early Champion Arco cans, magnets, end bells, arms, ect. All these setups just used clips but the arms fit quite well.

Maybe a variable air gap would work well today. But who has an off-set slug to grind the magnets? LOL

11/6/54-2/13/18

Requiescat in Pace

#18

Posted 26 September 2013 - 06:55 PM

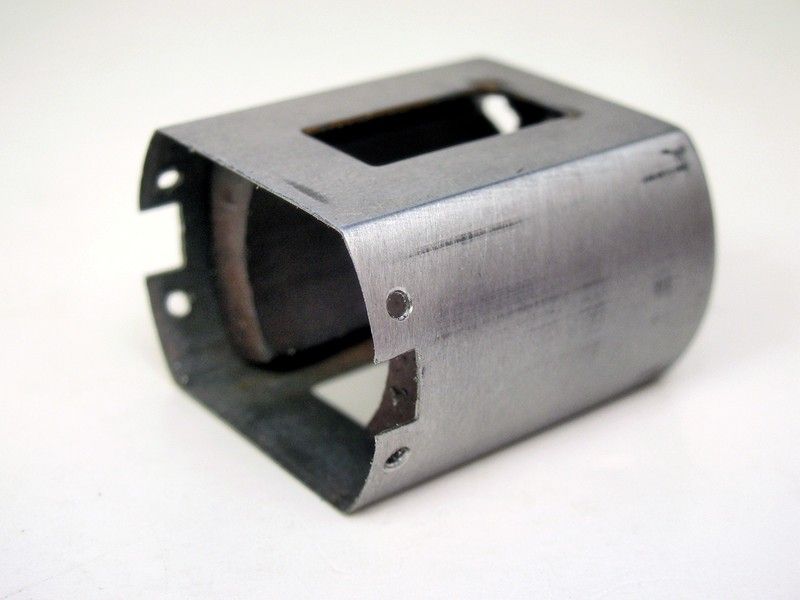

Here's a view of the finished can and it's endbell mounting holes.

I located the holes on the sides of the can because that's where they work best. Then I remembered lots of guys put their screws in the top and bottom.....SNAP! ![]()

Luckily I found that John Anderson used the sides of the can in his "much modified Russkit 23" in race 5. He used just one screw on each side but at least their on the side of the motor.

For and endbell I'm going with a modified RAM piece. That neato metal job (that won't melt) I showed is going into a 1967 car with a HOT arm.

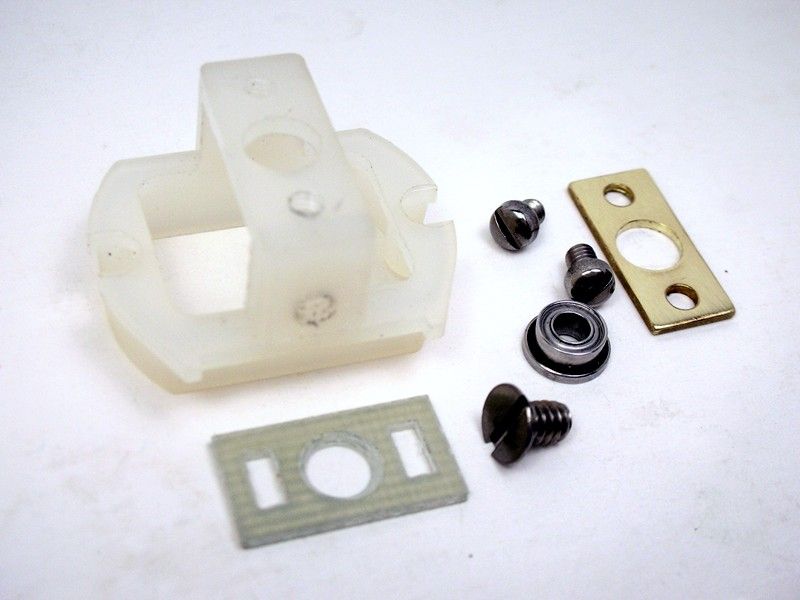

So here's the pieces, parts for the job. The RAM endbell and glass fiber brush holder, a 4-40 undercut flat head screw to hold it on (instead of the unexpanded rivet RAM used), ball bearing, a 1/4" brass strip bearing mount and two 2-56 fillister head screws to hold it on:

OK, what about the brass strip bearing mounting plate I made up. They became commercially available in 1968 or so. In the Nov. 1965 issue of Model Car Racing News, Al Cape did an article where he made endbells out of brass sheet for various Mabuchi motors so why not a bearing mount?

I didn't think it was really rocket science beyond the imagination of a machinist in 1966 to drill 3 holes in a piece of brass strip to mount his bearing to. So that's what I did.....your results may vary. ![]()

I used the tapping fixture to tap all the endbell hardware holes nice and square:

Here's the finished piece:

I started out with the hard RAM brushes and a Simco spring:

I put the stock RAM arm in the setup and fired her up..........YIKES! The thing vibrated and buzzed like a $1 electric tooth brush ![]()

![]()

The saga continues.........

- endbelldrive, Jencar17 and George Blaha like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#19

Posted 26 September 2013 - 07:22 PM

As for the first fire up... and BUZZ!!!

- George Blaha likes this

#20

Posted 26 September 2013 - 07:31 PM

YIKES! The thing vibrated and buzzed like a $1 electric tooth brush

Needs dynamic balancing... ??? they really were not!

Philippe de Lespinay

#21

Posted 27 September 2013 - 04:26 PM

Why not just send the arm to Hershman or Beuf or Dan ?

- George Blaha likes this

Paul Wolcott

#22

Posted 28 September 2013 - 07:39 PM

Any luck with the arm/motor Rick?

#23

Posted 28 September 2013 - 09:36 PM

I think he was just pointing out the difference between the two arms.That's how I took it. I did not know the difference till now.

On topic: I plan on building a R&C car as presented here. Not being a motor expert,can a list of period correct motors with pictures be posted? I have tons of UOS(used old stock)but I am not sure what it all is.

- Gator Bob likes this

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#24

Posted 28 September 2013 - 11:38 PM

Sam,

The overwhelming majority of motors used in the R&C races were some flavor of Mabuchi 16D, chiefly FT-16D types 1 and 2, rewound and built up by drivers and builders, and a few Igarashi Hemi motors, which were of course very similar to the Mabuchi.

There were a few Tyco and Pittman sidewinders in the first race, and one in the second, but that's all. The Race Reports and Tech Charts can be very helpful with this information.

To get you started indentifying what Mabuchi and Igarashi motors you've got, check here.

Maybe Rick could help with more detailed information.

Steve Okeefe

I build what I likes, and I likes what I build

#25

Posted 29 September 2013 - 12:26 AM

A period motor is as simple as a Russkit 23, the one with the heat sink brush holders, with a 65 turns of 30 gage wire is period correct.

During the series French magnets and then Hemi mags became popular and the winds got a bit hotter. I believe Russkit started using Arco mags in the last couple of races but the builders needed time to find the hot winds to match the Arcos. John Anderson won the third Car/Model race in 1967 using Hemi mags, if the tech sheets could be trusted.

The Hemi stack was popular as it was a better steel than Mabuchi's. Some used the Hemi end bell but the Hemi brushes and springs lacked quality.

In 1966 there just wasn't much "speed equipment" to choose from. Even Team Russkit used some Lenz motors. The early Lenz was a mild 1.6 ohm motor, probably a 32 wind that was static balanced and whole arm dipped in high temperature shellac up to the comm. The end bell was stock Mabuchi.

11/6/54-2/13/18

Requiescat in Pace