Stunning Rick !!!!

Total Performance - Baldwin Motion King Cobra

#26

Posted 18 June 2014 - 07:02 PM

#27

Posted 18 June 2014 - 08:00 PM

Superb wheels Rick ![]() You really have got that technique sorted for machining down beautiful threaded wheels, & fitting them inside the set screw wheels... Excellent

You really have got that technique sorted for machining down beautiful threaded wheels, & fitting them inside the set screw wheels... Excellent ![]()

#28

Posted 18 June 2014 - 09:15 PM

"Drive it like you're in it!!!"

"If everything feels under control... you are not going fast enough!"

Some people are like Slinkies... they're really good for nothing... but they still bring a smile to your face when you push them down a flight of stairs.

#29

Posted 19 June 2014 - 11:44 AM

I really like the way the wheels turned out too. Unfortunately, the rears might have to be changed, More on that to come.........

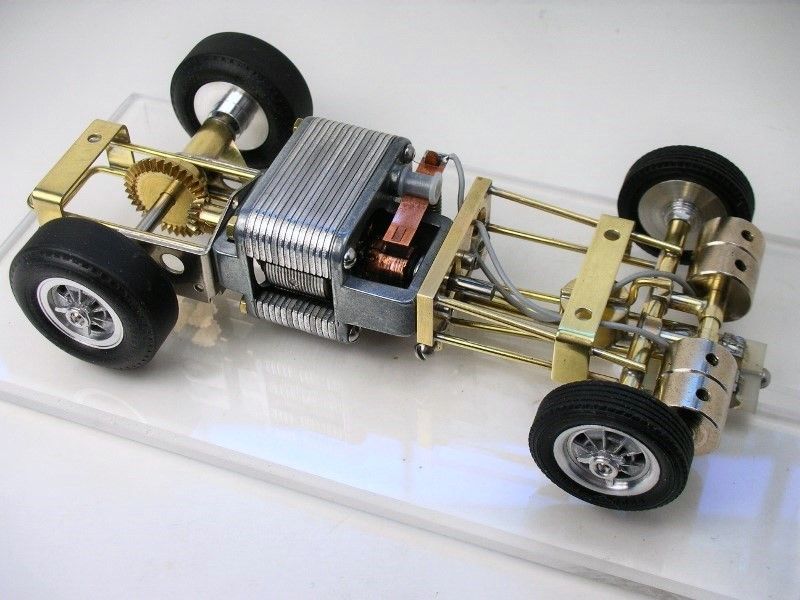

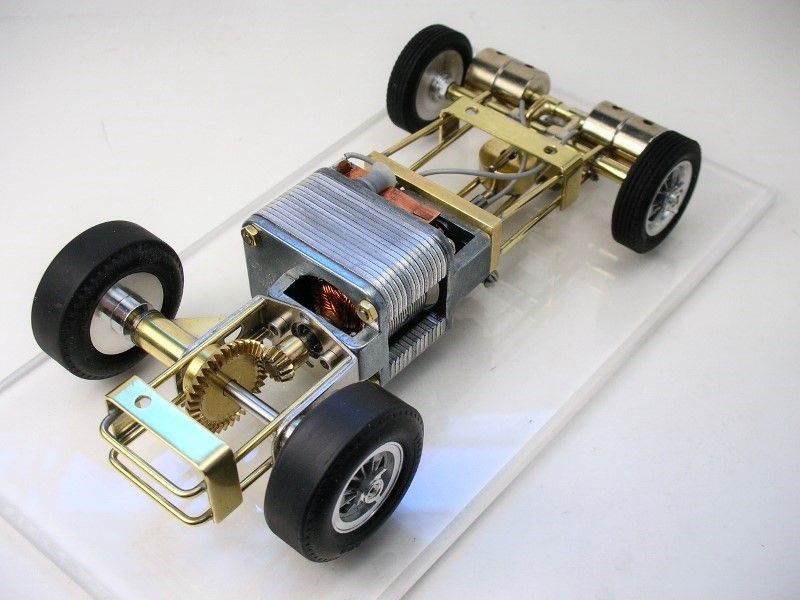

First, here's my idea for an "anti-wheelie" adjustable weight system. The pieces, parts:

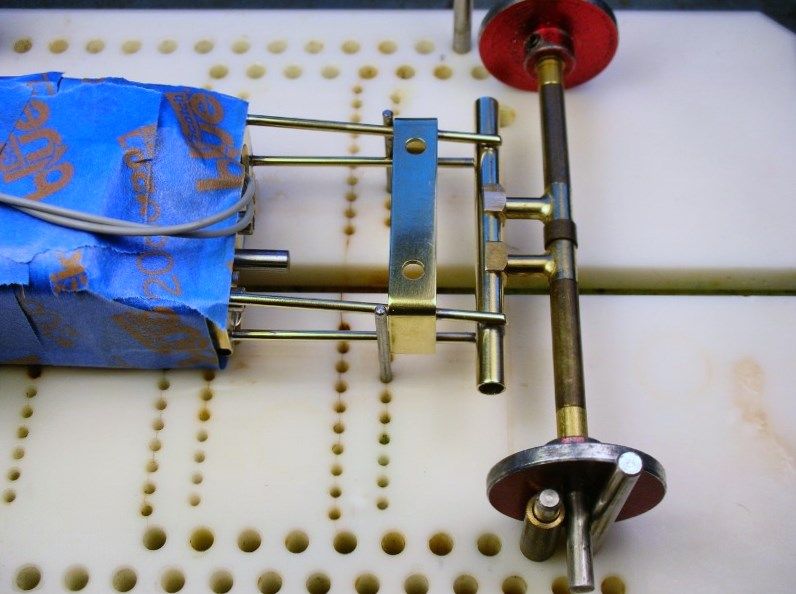

I cut the back half of the Kemtron fitting off so it would fit over the front axle tube. Then the Aristo-Craft T-fitting was slipped over it. Here it is in my Rick's Jig that can align almost anything:

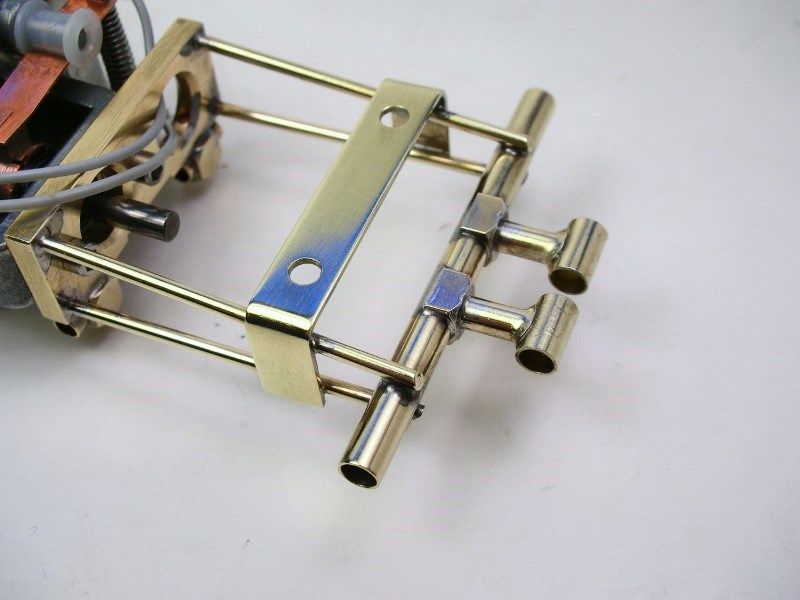

All soldered up:

Here is the maximum amount of weights installed:

The weights are on the front axle centerline:

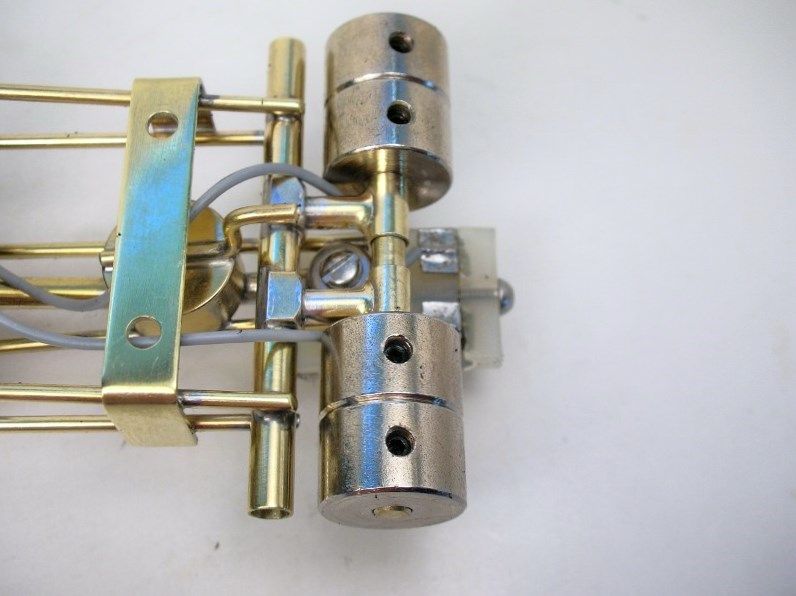

The guide flag is a Russkit Small Slant Guide. The lead wires are Cox Fuse Wires. The gears are K&B 3:1 Bevels. There was no screw mounting hole drilled and tapped into the crown gear ![]() I took care of that:

I took care of that:

Here's a closer look at the Mystery front axle:

Time to screw it all together and go for a test drive.....

- MarcusPHagen likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#30

Posted 19 June 2014 - 12:19 PM

Got a few of those free wheeling front axles Rick , think they're from the Japanese company that begins with A.... can't remember the name

#31

Posted 20 June 2014 - 02:38 AM

Rick,

Question: what soldering iron, solder and flux do you mostly use for chassis building?

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#32

Posted 20 June 2014 - 10:02 AM

Hi Doug,

I found this post of mine from an earlier thread:

Hi Stefano,

Thank you and Marty for the kind words and welcome to Slotblog. There are many opinions of what is "best" for our hobby. You can do a search on the forum and get many other ideas but this is what I use and I'm very happy with:

My jig is made by Rick from R-Geo:

R-Geo Products

I don't see them on his web site. You can PM him here under his user name "Rick"

For soldering equipment I use a Weller (formerly known as Ungar) Number 33 50 Watt heater. They can be had for under $40.....

.....And a Weller Number 7760 handle:

The heater lasts a long time if you use a temperature control like this Inland Number 60014 and keep the iron turned off when you're not actually soldering:

I gave up on sponges to keep the iron's tip clean and REALLY like this Hako Number 599B tip cleaner:

For solder and flux I use Stay-Brite silver solder and Stay-Clean acid flux:

Note that the flux is indeed an acid and as such must be handled accordingly. But it does make the solder flow like crazy especially with all the heat available from the 50W 1100F degree iron.

For bending wire and rod I mainly use an assortment of pliers. R-Geo and others do make benders.

As for where to get this stuff, an internet search is you best bet. For the vintage parts like the UGO brackets you mentioned it's a never ending hunt on EBay. You can also look at the sponsors of this blog like Electric Dreams for parts.

This doesn't seem to appeal to lots of scratch builders. There's a "Retro" alternative if you check out the "Scratch Building" and "Retro Racing" sections on this forum.

Lastly, a great source of information is on Steve Okeefe's web site:

THE INDEPENDENT SCRATCH BUILDER

In my humble opinion he is one of the best scratch builders there is.

Hope this helps and welcome to SCRATCH BUILDING!

Rick

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#33

Posted 20 June 2014 - 08:48 PM

IT'S A BEAST!

This 3 volt RAM armature is crazy fast for a padlock motor. On the first test lap, I parked it square on the main straight then punched it. It reared up and hopped for a few feet then jumped out of the slot and started doing 360 degree spins in the air before coming to rest on the main straight's inside wall. ![]()

After that excitement I tired various vintage silicone tires. Too much wheel spin and bouncing. Then I tried modern ProTrack drag tires. Mucho traction but high speed bouncing. I think they might be too soft for this massively heavy beast.

Then I tried Paul's of Canada XPG soft urethane replica Cox Firestone tires. They seem to have plenty of traction and little bouncing at high speed. I machined a new set of Russkit drag wheels to the same dimensions as Cox rear Chaparral wheels that fit these tires.

The problem I'm still having is the launch off the line. I've got the traction but with such a short wheelbase and so much torque and power it's still trying to wheelie even with all the weight up front. I burned off the first set of braid in minutes.

When I locked up the drop arm it worked best so far. That allows all the weight of this beast to be on the guide.

I made up some body mounts and epoxied the body on. When it cures I'm hoping the extra weight of the body will help tame the beast.

I'm seriously thinking I need to back down to a 6V RAM armature and save this beastly 3V for a longer wheelbase car.

We'll see................

- Peter Horvath likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#34

Posted 21 June 2014 - 07:23 AM

Maybe too flexible fore and aft, causing it to get too much rear bite and the chassis gets the "leaf spring" effect ? I had an F1 that was hopping like a bunny down the straights; I replaced the entire drivetrain piece by piece with no change. Added another rail to each side, end of hopping. The funny thing is, Jay Guard's F1 was doing the exact same thing and was fixed by the same thing. Note to self, the track at Peachtree City does NOT like flexible F1's ![]() Stiffening it up will give it less bite. Will it work for you, I don't know. Maybe you could rig something temporary up to test it.

Stiffening it up will give it less bite. Will it work for you, I don't know. Maybe you could rig something temporary up to test it.

Paul Wolcott

#35

Posted 21 June 2014 - 08:24 AM

Maybe try some German sponge? Maybe a different gear ratio to counteract the insane power from that arm, what ratio have you got it at Rick?

Or as you say save it for a longer car, should do well in a period top eliminator rail like the magwinders, K&B etc

Or even a Rick T original rail

#36

Posted 21 June 2014 - 05:47 PM

Maybe too flexible fore and aft, causing it to get too much rear bite and the chassis gets the "leaf spring" effect ?

Hi Pablo,

Thanks for the input. I checked the chassis for flex and the thing seems stiff as a board. I mounted the body last night and I thought I'd try the car with the body mount screws cinched down tight. Thought that might stiffen up the chassis to see if that helps. I mounted the body on 1/4" Evergreen plastic tubes with vintage 4-40 threaded inserts:

The mounting posts were screwed to the chassis and trimmed to length to get the body to sit right. A blop of JB Weld epoxy on top of each post and the body was set on the chassis to let dry overnight. Here's what it looks like before the posts get reinforced:

I tested the car this morning with its tight fitting body and the bouncing was gone. ![]()

When I removed the body it was back to bounce city again ![]()

I put the body back on and left it loose for a rattle fit; the bounce was gone again and the car handled even better than with the tight fitting body.

My test track really got a workout with this one. I've been thrashing on this thing for days! Anyway it seems fairly "happy" now. It sometimes arcs the braid a bit off the line as the front end tries to lift. I still may have to swap arms to a lesser 6V. I need to test it on a real drag strip at Eddies.

Sounds impressive

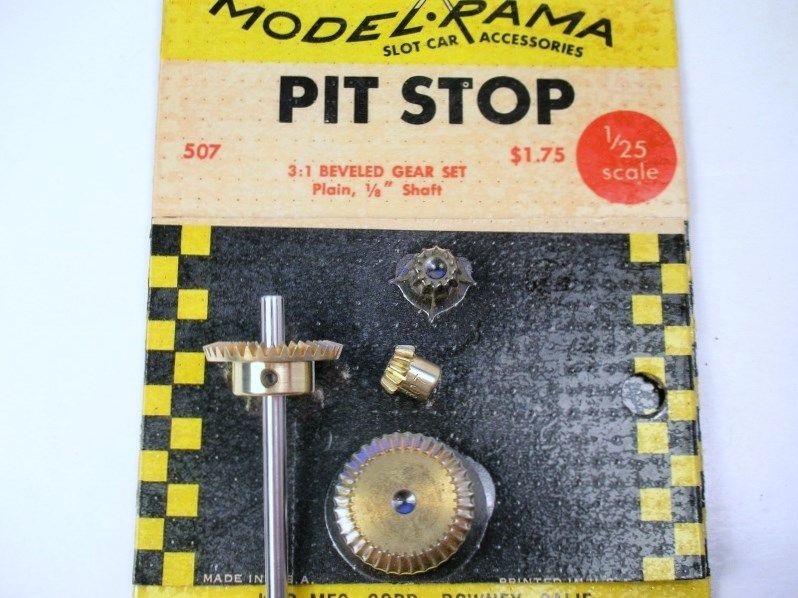

........ Maybe a different gear ratio to counteract the insane power from that arm, what ratio have you got it at Rick?

I took your advice about gearing your VW. You thought it might work better at 3:1 so that's what I'm geared. I can't wait to see what it will do on a long straight. It seems to just be getting going by the end of my short straight.

Anywho, here's what it looks like at this point.

- Joe Mig and Peter Horvath like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#37

Posted 21 June 2014 - 06:04 PM

Ooo that Cobra has got the perfect stance ![]()

looking at all the Dragsters that ran in the Proxy, the standard Kemtron X503 ran by Bob got fastest MPH @ 3:1 , the rails with DC85 types won the lowest E.T at around 2.5 - 2.8:1 and probably had more in them with 3:1.. The VW with the weak magnet was held back @ 2:1 , with reports of running out of steam half way down the track and getting hot. General opinion it would of been great at 3:1...

With so much more magnet power and ooomph in your RAM/Cobra Rick you could even probably get away with over 3:1 ? Smoother off the line and with enough power in the arm to pull top speed..

#38

Posted 21 June 2014 - 06:14 PM

"Very nice looking" is an understatement, of course ! ![]()

![]()

![]()

Interesting how the body eliminated the bouncing as you predicted. Do you have a slot car crystal ball, Capt. Rick ? May I have it, please, Sir ? ![]() (Edo humor)

(Edo humor)

I reckon that's why we love these things so much; black art meets science, math, and physics. ![]()

![]()

I just can't get over how cool that thing is ![]()

Paul Wolcott

#39

Posted 21 June 2014 - 06:15 PM

My guess is the weight of the body calmed it down.

The chassis looks dead stiff and I don't think the added rigidity of the body tying the front and back half was what got the car to settle down.

Easy to prove, weigh the body and add lead to the front and rear body mount brass plates.

You sure did nail the stance..... now that you took the Baldwin Chevy out of it.... LOL

Rick, Is Eddies a scale 1/4 mile ?

Bob Israelite

#40

Posted 21 June 2014 - 06:53 PM

With so much more magnet power and ooomph in your RAM/Cobra Rick you could even probably get away with over 3:1 ? Smoother off the line and with enough power in the arm to pull top speed..

That's an interesting idea.

Interesting how the body eliminated the bouncing as you predicted. Do you have a slot car crystal ball, Capt. Rick ?

![]() No crystal ball Pablo, just grabbing at straws. It was my last hope!

No crystal ball Pablo, just grabbing at straws. It was my last hope!

You sure did nail the stance..... now that you took the Baldwin Chevy out of it.... LOL

Rick, Is Eddies a scale 1/4 mile ?

Yup, it's a full scale 1/4 mile strip.

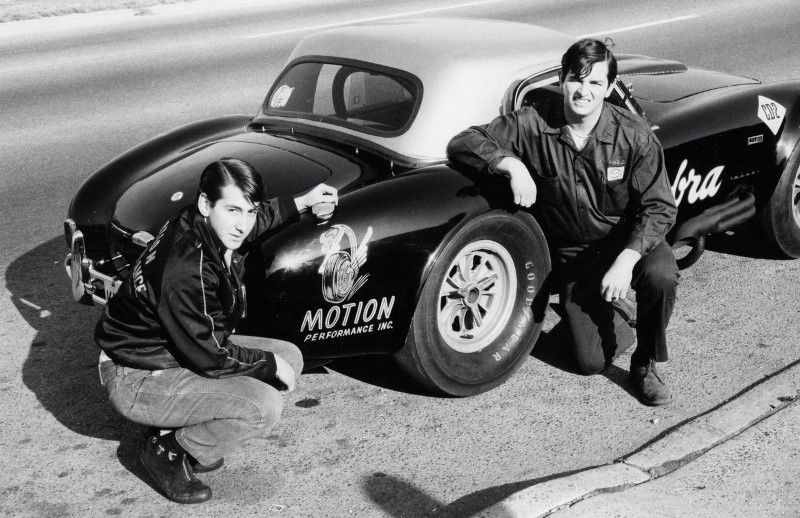

I always associated Baldwin-Motion with Chevy too. This picture shows a "Motion Performance Inc. sticker on the rear fender???

Maybe Motion Performance is different than Baldwin-Motion and Revell screwed up naming their kit.

I don't know the history, I just think the Cobra is bad a$$ looking. ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#41

Posted 21 June 2014 - 07:04 PM

All I know is I now want to build a Cobra ![]()

![]()

#42

Posted 21 June 2014 - 07:15 PM

Scale 1/4 should be a blast, 3:1 would most likely be as 'tall' of a gear you would want to run with the tire O/D that fits those wells..

Is it a neo magnet? If so you might want to bring some gear sets to head back towards 2:5 --> 2:1.

Yup, Baldwin Performance and Motion Chevrolet were two separate companies that joined forces to build dealer sold 'factory' Chevy supercars including COPO cars starting in late 1966.

From Corvairs, Camaros, Covettes, Novas to the big block Vega in the last days.

A relationship kind of like Shelby did for Ford and Hurst did for Mopar street Hemi dealer sold race cars.

Bob Israelite

#43

Posted 21 June 2014 - 07:41 PM

Looks to be stock as a rock RAM magnet Bob ![]()

#44

Posted 21 June 2014 - 08:15 PM

Yes, it's all RAM except for the modern 1/8" ball bearings.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#45

Posted 21 June 2014 - 08:24 PM

NICE !!!

Bob Israelite

#46

Posted 21 June 2014 - 08:41 PM

Looks really fine, Rick. I am especially fond of the wheels. ![]()

Paul is right about the "stance" of the car looking right. I was talking with Bob Hanna just yesterday about our new "True Scale" classes. Even running big Protrack hubs and 1-inch+ tires, they don't look quite right because we don't run true scale ground clearance. We still sacrifice scale appearance for speed.

Fortunately, with a Drag car, high cornering ability is not critical. ![]()

#47

Posted 21 June 2014 - 09:51 PM

Hi James and thanks,

The drag Cobra is SOOOOOOOO heavy the brakes are a bit weak. But for a car with a CG that is SOOOOOOOOOO high it surprisingly can be coaxed around a road course.

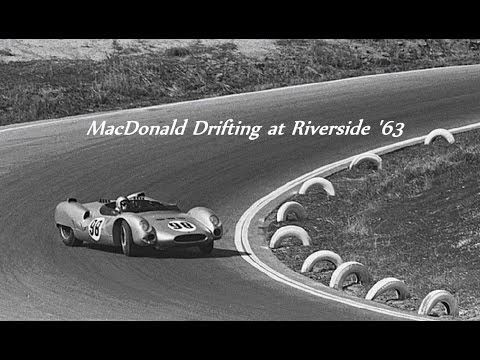

Better for a road course is my scale road race Cobra:

Hmmmmmmmmmmmm...................

James, I'm sitting here wondering. ![]() I'm wondering if you, Bob and the guys would find it fun to race something different along with your regular classes. Something that went around the track slower than the regular cars. But all the cars would be equal so the racing would be side by side and just as intense.

I'm wondering if you, Bob and the guys would find it fun to race something different along with your regular classes. Something that went around the track slower than the regular cars. But all the cars would be equal so the racing would be side by side and just as intense.

They would be slower than usual because they would have to be "drifted" through the turns rather than "punched". They'd be sliding through the turns because they'd be using modern reproduction scale urethane tires and modern reproduction scale wheels.

Those wonderful scale model kit bodies would have their wheel wells full of scale wheels and tires and the racers would be side by side banging fenders battling for the win! ![]()

- Peter Horvath likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#48

Posted 21 June 2014 - 10:17 PM

Now that Total Performance Cobra you built is just plain Sexy ![]()

![]() Those side pipes

Those side pipes ![]() Was thinking of building a Cobra after seeing the progress on this Drag racing beast.... now its a Gotta build a Cobra

Was thinking of building a Cobra after seeing the progress on this Drag racing beast.... now its a Gotta build a Cobra ![]()

#49

Posted 21 June 2014 - 10:54 PM

Rick -

In reply to your wondering... (and everyone else, please pardon the thread drift)... I agree with the idea that slower is no less fun than faster, as long as the cars are evenly matched. For instance, I have often advocated against running Super-16Ds in the two classes at Pelican Park that use them. (Supers + hardbodies = increased breakage). ![]()

I don't know if I could convince the other racers to adopt a slower class though. Speed is kinda addictive. I think that lower traction tires would also necessitate a less powerful motor than the Deathstar, again to reduce wreckage. Are Urethane tires compatible with a track that is spray-glued and has some natural rubber buildup?

Anyway, it is an interesting concept; certainly worth discussing with the guys.

Back on topic - I followed your build on the red Cobra... it is absolutely gorgeous !!! Once again, the wheels are superb !!! ![]()

(although I would have darkened the door/hood/trunk lines, but that's just me)

- James

#50

Posted 21 June 2014 - 11:24 PM

I don't know if I could convince the other racers to adopt a slower class though. Speed is kinda addictive. I think that lower traction tires would also necessitate a less powerful motor than the Deathstar, again to reduce wreckage. Are Urethane tires compatible with a track that is spray-glued and has some natural rubber buildup?

Yes you're probably right. The entire concept hinges on a driver enjoying drifting his car around the turns. I grew up with slot cars in the 60's and that's the way it was. It was great fun for me as that is what the real race cars of the time were doing.

Anyway, the tires work fine on spray glued tracks like mine and Bob's. The motors should be less powerful like they were back then. A lower power modern "mini motor" would be in order. But the reality is the guys wouldn't be interested.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...