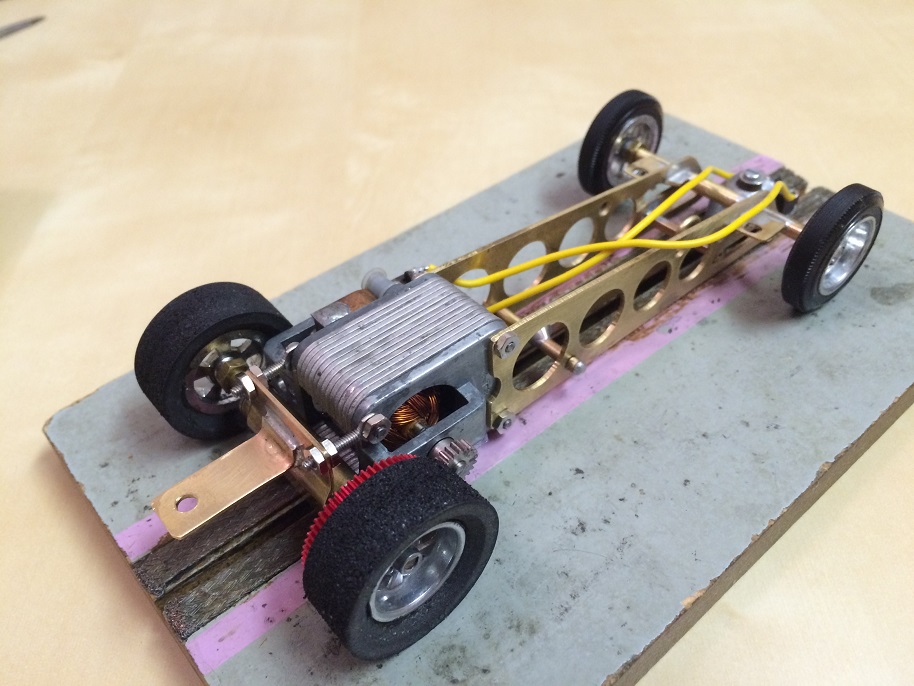

Rodney's been really busy building and restoring LOTS of drag racers. I'll be working back through my emails to share his beautiful cars with you.

Here's a spectacular vintage dragster being crafted by Rodney's in his own words:

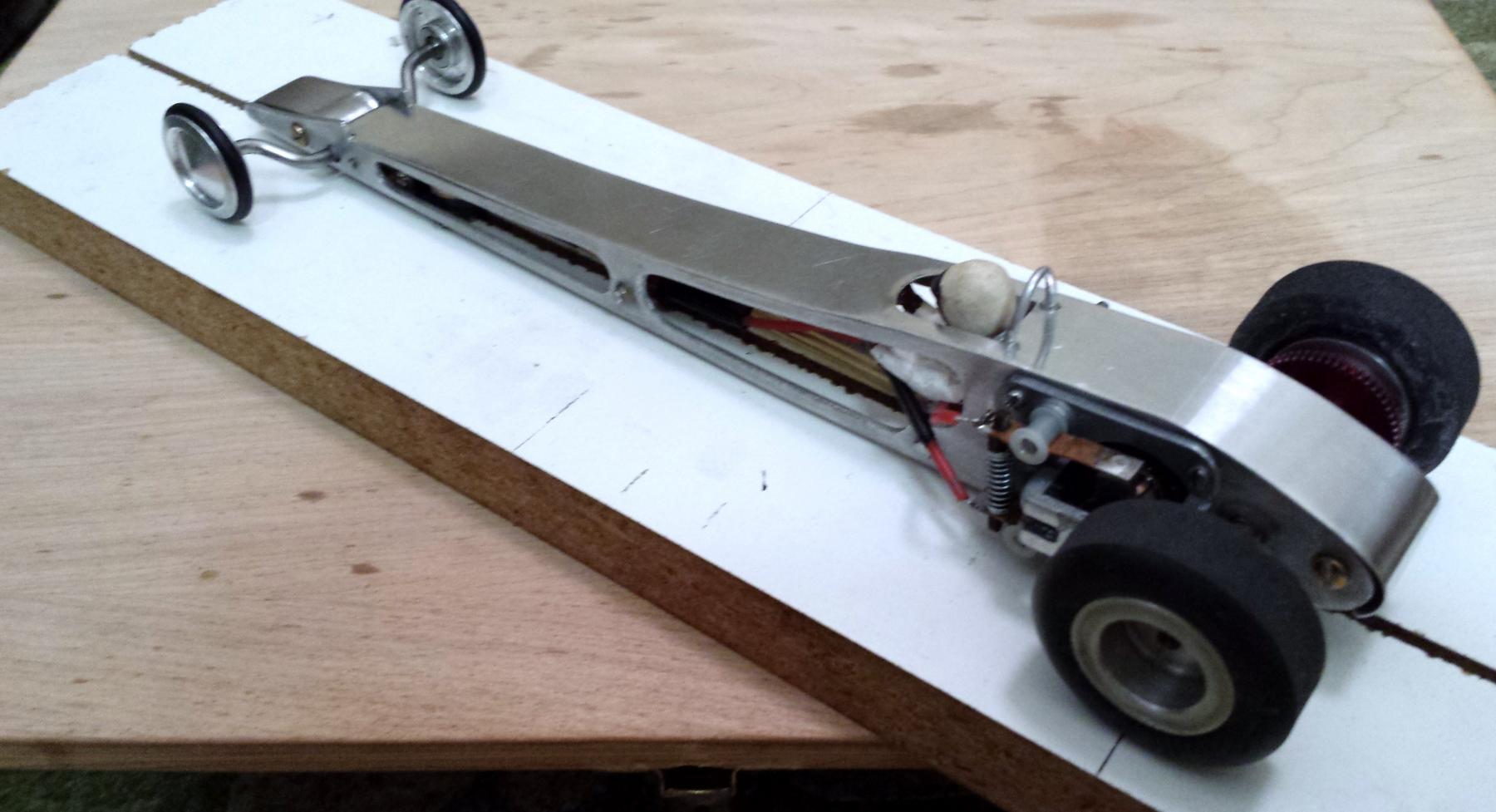

"Drag racer Ron was kind enough to gave me the unfinished rails. I think they were made by Fred who is no longer with us. Ron wanted me to build a car with the frame rails."

"The picture attached shows the two rails bolted together and being ground and massaged on and holes being drilled. The basic shape was already done along with a single hole for an armature and some small random holes to mount a Wilson motor (Eric's guess). I turned the single large hole into an oval and cut four slots for the motor case screws. This allows the motor to slide back and forth to adjust the gears."

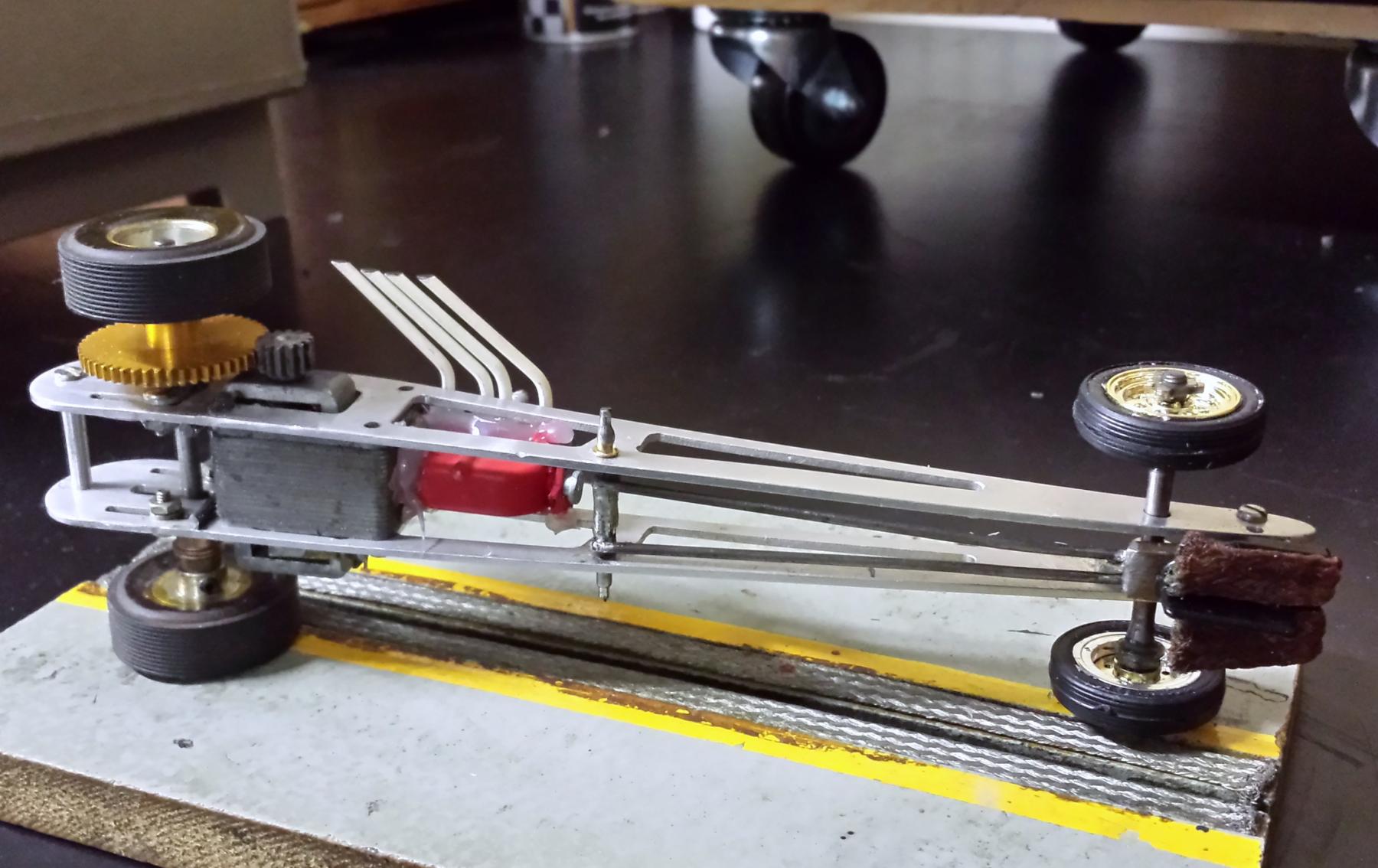

"This cars motor came from a car with a chassis that looks like two meat cleavers bolted together. The meat cleaver cars frame rails are too corroded to restore. I will build it back with another motor anyway."

Making the dragster body:

"I cast the nose weight out of solder":

"Took awhile to figure out how to use the chassis plates from Ron. Eric thinks it was made for a Wilson type round motor. Decided to integrate the chassis into the motor like the '55 Chevy I built earlier. The motor slides back and forth for gear ratio changes."

"The Ram motor came from an eBay buy of a big pile of corroded parts from N.Y. The armature is a 3 volt and draws amps like your motor. It's an 857, fine magnet lamination version."

Here is the first track test report on the Fred Dragster:

Rick,

The "Fred dragster" presented some challenges when tested last Sunday.

I had the 2.5 to 1 gears still installed. The car was measured for the smallest gears with slots in the chassis to change to large gears. This ratio does not work with a hot armature. Tires affect the gearing too and the car runs very large diameter tires.

A heavy tension motor brush spring came installed in the motor. From a stop car was like your Cobra 3V and drew a zillion amps. When launching the car on the drag strip, the "hairy braid" would create a fire ball!

What to due???

I checked the gear ratio in my J&J dragster which seems to be perfect. It's ratio is 3.1 to 1. So, I installed a 69 tooth Weldun gear in the "Fred dragster" to make 3 to 1.

I also cut two coils off of the motors brush spring. There is still lot of tension but running the motor on the power pack there is lower amp draw on start up now.

Switching to some Parma braid required soldering and drilling them to use with the Cox guide.

I also insulated the inner chassis rails around the guide with 3M electrical tape.

Will test again next Sunday.

WOW!

More cool dragsters to come..........