No, there isn't a new Kurtis car proxy round coming up (yet, anyway) so don't get too excited.

Jaak (I like to tease and call him Jaaaaaak ![]() ) from France has been asking nicely for help to improve his game from the start.

) from France has been asking nicely for help to improve his game from the start.

His finishes were not great, but he has a good attitude and wants to learn. Some people have worked on his car a little bit here and there to improve it, like Manta Ray in Chicago. It needs more than that, so I volunteered to receive his car before it returns home to fully critique it and offer my suggestions on improvements.

I did a complete post-race teardown and found some things that keep it from reaching its potential. I think I opened Jaak's mind, especially being sensitive to weight up high and chassis flex.

I decided the best way to back up some of the things I taught him was not changing his chassis, but starting over from scratch. So even though the series is over at present, he will see my work up close in person when I send it to him. My plan is to build a chassis even better than my own #12 Dean Van Lines car, and show Jaaaaaak here everything step by step. I didn't want to cannibalize parts from Jaak's chassis, so some new parts are on order.

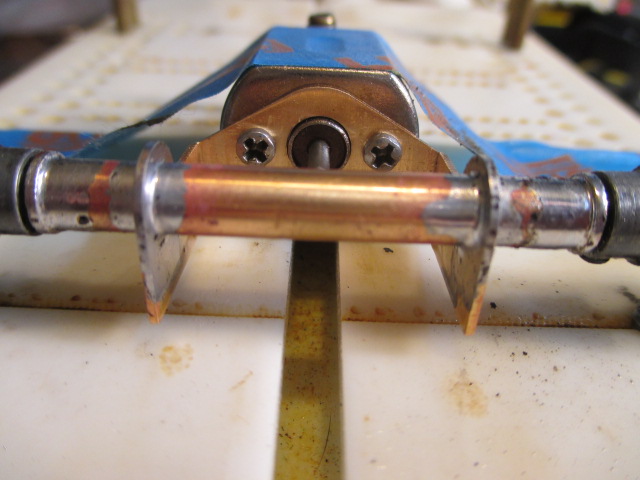

Let's build a race car, Jaak. For now, I can begin prepping some parts. Your flag was the wrong type (cut down), so I swapped it even-steven for a brand new (standard thickness) flag. I ran it through the Cahoza threader a little at a time, cleaning the cut thread pieces as I went, ending up all the way to the hilt.

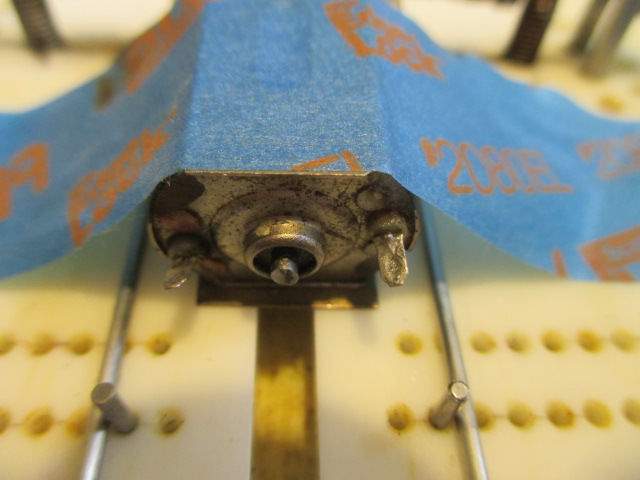

Then I faced the nut and the flag.

Trimmed the post a little (not too much, Pablo !!! ![]() ) then re-cut the first couple threads with the facing tool.

) then re-cut the first couple threads with the facing tool.

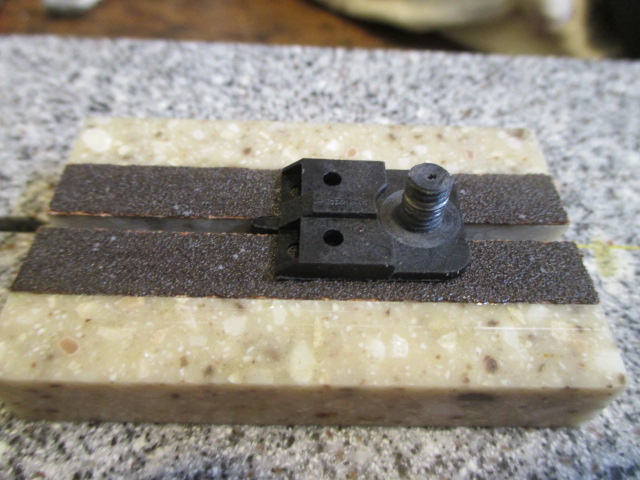

Sanded the braid decks flat

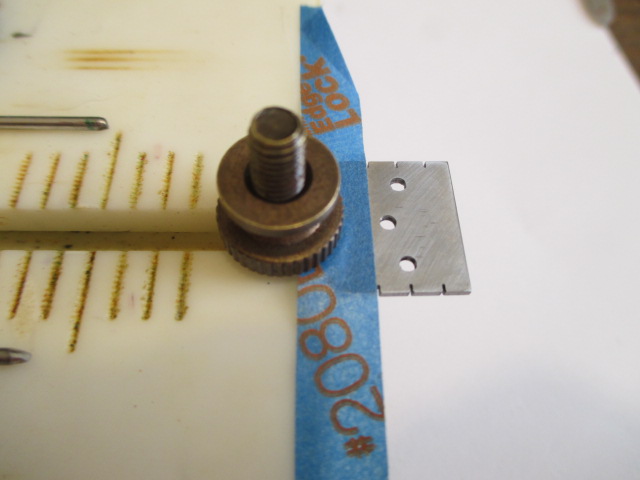

Flag is done. Two 10 thou steel spacers - one will go under the tongue, the other will be over it. That way if you need another spacer during a lane change, no need to go to the pits to get a spacer - it's right there ready to go. John Clow taught me that. ![]()

Onward! ![]()