The Fowler Deck ready for installation;

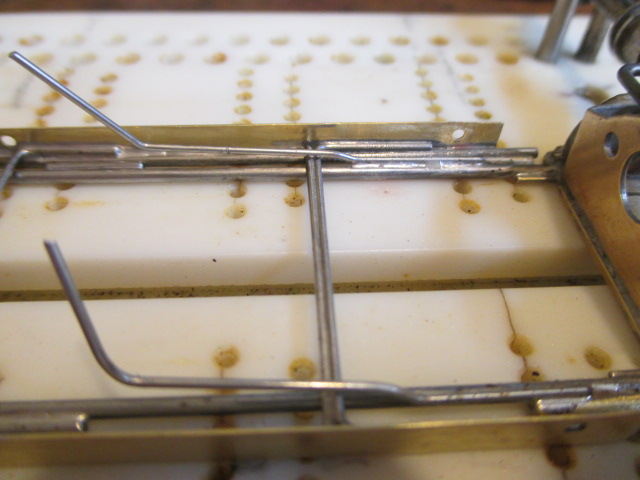

An improvised small piece of .025 steel helps guide the .025 wire pieces into place:

Posted 29 October 2014 - 07:49 AM

Oh wow someone has been busy ![]()

Posted 29 October 2014 - 10:01 AM

When I'm using an iron, any resemblance to being SANO is purely an illusion.

My joints are strong but not picture perfect - here is the secret:

Other Dremel attachments do the same job at removing stray solder, but this is the only one I've found that doesn't leave telltale gouges in the brass.

Nothing wrong with a little stray solder residue, but in the case of the Fowler deck, it was absolutely necessary to allow .032 pieces of lead weight to sit perfectly flat on deck.

She's been in the tumbler now for 7 hours and counting......

Paul Wolcott

Posted 29 October 2014 - 10:57 AM

Where's the "Pablo" plaque going? ![]()

Posted 29 October 2014 - 02:41 PM

After a 9 hour tumble job, she looks nice & shiny:

The question is, will she handle well, or be a tilting pile ? Time will tell.....all the theories in the world can't compare to an actual track test. ![]() Jaak, all I can guarantee is, it's as flat, straight, and precise as I could make it:

Jaak, all I can guarantee is, it's as flat, straight, and precise as I could make it:

Rear end is rigid and strong. If anybody suffers a bent motor box or bound up rear axle in a race, I can guarantee it won't be you, Jaak:

My shakey weight (Fowler Deck) looks like any other, but it's not. Only 15 thou thickness, connected with .025 wires rattling around inside .036 tubing holes, it can tilt, lift, twist, and move fore/aft just a wee bit. Once the car is complete, Jaak, I'll weigh it so you'll know how about much .032 lead you'll need on the Fowler Deck to make it at least 100 grams (like Swiss wisely suggested in the beginning):

This one is for Bill ![]() :

:

Now, where did I put those doggone front axle keepers ? ![]()

![]()

Paul Wolcott

Posted 29 October 2014 - 02:51 PM

Looks sweet! Man, that rear end looks beefy!

Charlie McCullough

Charlie's Speed Shop

Kelly Racing Wanna Be

Posted 29 October 2014 - 03:05 PM

Thanks, Charlie. It's even "beefier" than my "usual" rear ends ![]() You probably saw the way these cars are built at Bill Pinch's raceway - the rules practically demand the bracket be tilted up, creating somewhat of a "builder's challenge"

You probably saw the way these cars are built at Bill Pinch's raceway - the rules practically demand the bracket be tilted up, creating somewhat of a "builder's challenge" ![]()

![]()

![]()

Paul Wolcott

Posted 29 October 2014 - 04:39 PM

My excuse for me being so quiet at the moment.

I have some things to finish and am taking all this information in, reading and rereading and re-rereading tomorrow more.

It is a thing of beauty Pablo! love it.

There is a lot happening in the pictures and am working out how and what etc, I will come with questions and remarks as soon as I figure out how everything works together.

Found one for now...

Posted 29 October 2014 - 08:09 PM

You need a plaque on each side's plumber rail so as to not upset the precision balance of this chassis. ![]()

Your lawn could use a mowing. At least its not covered by leaves like my lawn is at the moment. ![]()

Posted 30 October 2014 - 03:11 PM

No time to do yard work, Bill, I'm too busy with slot cars ![]()

Jaak, it's done. Too bad she'll probably never get to race.

- Clearance is > .050" front to rear, and the entire car is 100% legal.

- Tires ground down to fresh rubber, trimmed, and trued. Your (independent) fronts spin a little wobbly due to normal wear and race damage. If the car handles evil, this is the first thing I would suspect as being the cause.

- Motor is fully broken-in and tested. Crown gear seated by heating up with a Bic lighter. Oilites, motor bushings, plumber hinges, and front wheels are all oiled.

- Drivetrain tested to my satisfaction.

- Flag self-centers softly the way I like it. First time I tried the SoCal Buena Park kinked lead wire method - it works great!!

Two .022" Slick 7 steel axle spacers on each side gives you room to stick a needle oiler in there to lube the oilites.

Also, Jaak, you can't see it in the photos, but take my word for it, there isn't a millimeter of excess axle length outside the rear wheels. This is a race car. No brag, just letting you know (in the spirit of learning) rotating mass should always be minimized. If you don't take the time to do it, the guy next to you at the track will.

The body is a little tweaked from several races but still in pretty good shape thanks to Jaak's filament tape reinforcements. I punched new holes for the body clips and got it as straight as possible.

Filament tape over the clips is actually mandated by the rules in some forms of racing, and it's just a good idea anyway:

Your completed car weighs 98.5 grams, Jaak, so I will leave it up to you to track test it and add .032" Slick 7 stick-on weight pieces to the Fowler Deck however you see fit. I'd recommend you make it weigh a total of at least 100 grams.

I don't know if you are savvy with body clips as opposed to pins, but you are going to get a lesson anyway. ![]() Clips on a skinny car like this just make good sense, there ain't much room for pins. Plus, an experienced clip guy can have his body off and back on again before a pin guy even blinks twice.

Clips on a skinny car like this just make good sense, there ain't much room for pins. Plus, an experienced clip guy can have his body off and back on again before a pin guy even blinks twice. ![]()

Body removal:

1. Grab the body near the left rear clip hole between thumb and forefinger - pull straight out. If you blueprinted your clips like I do, it will (click) come right out.

2. Grab left front, pull out and towards you at the same time.

3. Left side of body is now off.

4. Repeat this process on the right side and the body is now completely free.

Body installation:

1. Holding the body immediately rearward of the left front clip prong between thumb and forefinger, slide it into the hole and push forward until it stops.

2. Place your right index finger outside the body on the rear of the left clip, and push it into the hole (click).

3. Repeat the process for the right side

Any questions, Jaak? ![]() You patiently, persistently asked for proxy racing help/car critique from the start of the first race, and you probably got more than you bargained for with me

You patiently, persistently asked for proxy racing help/car critique from the start of the first race, and you probably got more than you bargained for with me ![]() Consider yourself "Pablo-ized".

Consider yourself "Pablo-ized".

Now I need to send this thing to you and spend some time with my girlfriend for a change - I had fun building another Kurtis car, but it consumed my life for a little while and she is getting genuinely PO'd at being neglected:

Bye for now... ![]()

Paul Wolcott

Posted 30 October 2014 - 05:17 PM

![]()

![]()

Posted 30 October 2014 - 08:47 PM

Jaak, you ought to see how much this girlfriend aged while Pablo built your car. ![]()

Posted 05 November 2014 - 05:35 PM

LOL, Bill.

Pablo, once again thank you!

When you soldered the brass rods on the Fowler Deck on each sides between the tubes is this to limit sideways play but still allow front and back play?

Will be traveling to London on Friday to meet and stay over at Steve K's house AKA Mr Lowrider and will be a spectator/helper at the Round Britain Whizz Thingie proxy race at Timaru in London.

Later that week I will get my first introduction to F32 Brass chassis racing at the North London slot club, looking forward to meeting Steve and Kate and family and seeing some of the others racers ![]()

When I return I will have some time on my hands and bug you with a lot more questions, trying to work out exactly how and what...

Jaak ![]()

Posted 05 November 2014 - 08:37 PM

Take your time Jaak. The .032 brass rod pieces govern left/right movement exactly as you thought, and strengthen the Fowler Deck. ![]()

Paul Wolcott

Posted 05 November 2014 - 10:21 PM

Jaak, have fun with those F32 cars! Perhaps Pablo could build you a F32 chassis, if you get hooked. F32 is a class that interests me, but with no commercial raceways in the area, there would be no place to run such a wild thing. In case someone doesn't know, F32 is a 1/32 scale brass/wire anglewinder chassis, Grp. 20 arm with ceramic magnets in B or C-cans, & a retro scale body without wings. All the chassis I've seen photos of used drop arms. I don't know whether tripods would be legal or not.

Posted 14 November 2014 - 10:08 AM

Thanks Bill the plans changed a bit.

Although I did get the chance to drive Steve's F32 for a bit and these are lethal little bombs.. wow.

Instead of going to North London we went to the Bolton Slotcar club for another round of the Thingie proxy "Round Britian Whizz"

Some more info here:

https://www.facebook...e=like&source=1

Will be back here asap just need to get some things sorted that happened while I was away.

Posted 14 November 2014 - 10:44 AM

I got a similar clip lesson from Terry Tawney (pro racer at The Raceway.biz) ![]()

Blueprinting the clips? Pablo - tell us more! ![]()

- only difference I noticed in Terry's training was to bend open the front clip a tiny bit and sharpen it...blueprint the rear part of the clip too?

Charlie McCullough

Charlie's Speed Shop

Kelly Racing Wanna Be

Posted 14 November 2014 - 11:45 AM

Not much more to tell about clips - I open the front angle like Terry taught you, sharpen both ends, and tweak as necessary to achieve a "click in - click out" action that is neither too hard or too easy - just right. You can also make your own clips from thinner (.025) wire and have them as long or as short as you want.

Paul Wolcott

Posted 14 November 2014 - 02:23 PM

What does the term blueprinting actually mean?

Posted 14 November 2014 - 06:37 PM

Pablo how much play do you let these up stops have in general?

Is there such a thing as a standard playroom, I mean one close to perfect that might need a little tweaking depending on the build.

Posted 14 November 2014 - 08:09 PM

What does the term blueprinting actually mean?

It is where you tune/match all of the parts to the best possible fit/performance, within the manufacturers tolerances.

When mass produced components are designed, the manufacturing methods have to be considered in the overall cost.

The tighter/smaller the tolerances, the more sophisticated/expensive the machinery needs to be.

Because of the tolerance, some parts will be larger/small than others, and when you get mating parts at each end of the tolerance range, the assembly will still work to the manufacturers ecpectations, but may not perform as well as mating parts that are closer to the perfect designed fit.

Blueprinting is just the term used when parts are selected/adjusted to combine for the 'perfect' assembly.

Race car engines are good examples of blueprinting.

Does that help?

![]()

Steve King

Posted 14 November 2014 - 08:31 PM

Thanks Steve ![]()

Jaak, there are no standard amounts of freeplay, or slop, wiggle, lift, or tilt in scratchbuilding.

Generally, smooth high speed swoopy tracks like less play and tight, flat, technical tracks like more.

The act of uncoupling assemblies is probably more important that the actual amount of play.

Although, a loose chassis can always be tightened up with tape, pieces of lexan, whatever - a tight one cannot.

Paul Wolcott

Posted 14 November 2014 - 09:03 PM

Thanks Steve,

It certainly does ![]()

10-4 Pablo,

Better a little bit more loose then too tight, I guess this is where practice testing and experience come into play.

Thank you ![]()