If you guys will forgive me for getting a little technical, perhaps it will be meaningful to discuss silver soldering in a bit more detail.

There is a lot of confusion between regular tin/lead soldering and silver soldering, which is more accurately called silver brazing.

The solders we use in building slot car chassis are more accurately called silver-bearing solders, not silver solders.

"Soft soldering

Soft soldering is characterized by the melting point of the filler metal, which is below 400°C (752°F). The filler metal used in the process is called solder.

Different combinations of tin, lead and other metals are used to create solder. The combinations used depend on the desired properties. The most popular combination is 60% tin, 39% lead, and 1% alloys. This combination is strong, has a low melting range, and melts and sets quickly. A higher tin composition gives the solder higher corrosion resistances, but raises the melting point. Another common composition is 11% tin, 37% lead, 42% bismuth, and 10% cadmium. This combination has a low melting point and is useful for soldering components that are sensitive to heat.

Tin/lead solders (soft solders) are commercially available with tin concentrations between 5% and 70% by weight. The greater the tin concentration, the greater the solder’s tensile and shear strengths. At the retail level, the two most common alloys are 60/40 Sn/Pb which melts at 370°F or 188°C and 63/37 Sn/Pb used principally in electrical work.

Hard Soldering

"Hard soldering" or "silver soldering", performed with high-temperature solder containing up to 40% silver, is also often a form of brazing, since it involves filler materials with melting points in the vicinity of, or in excess of, 450°C. Although the term "silver soldering" is used much more often than "silver brazing", it may be technically incorrect depending on the exact melting point of the filler in use.

In silver soldering ("hard soldering"), the goal is generally to give a nice, structurally sound joint, especially in the field of jewelry. Thus, the temperatures involved, and the usual use of a torch rather than an iron, would seem to indicate that the process should be referred to as "brazing" rather than "soldering", but the endurance of the term "soldering" serves to indicate the arbitrary nature of the distinction between the two processes."

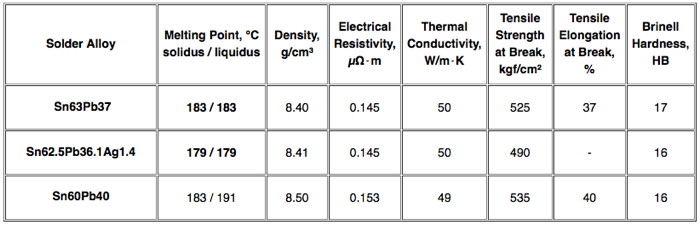

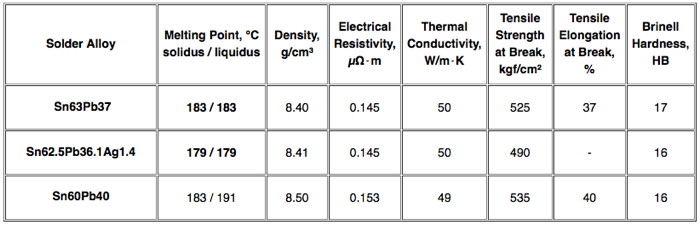

Here's a chart showing the melting points of some common solder formulations.

I've greyed the boxes for the solders you should probably be using for chassis building: 60/40, 63/37, and what is commonly labled Sn62. This last contains 2% silver and was developed for soldering silver-plated metals, as the presence of silver in the solder prevents the plating from migrating into the solder. It flows beautifully because of its lower melting point and its tensile strength is almost 92% of the 60/40.

Slot car suppliers have at times offered silver-bearing solders with silver percentages as high as 8%; I know because I have some.

Yeah, I know, probably too much info...

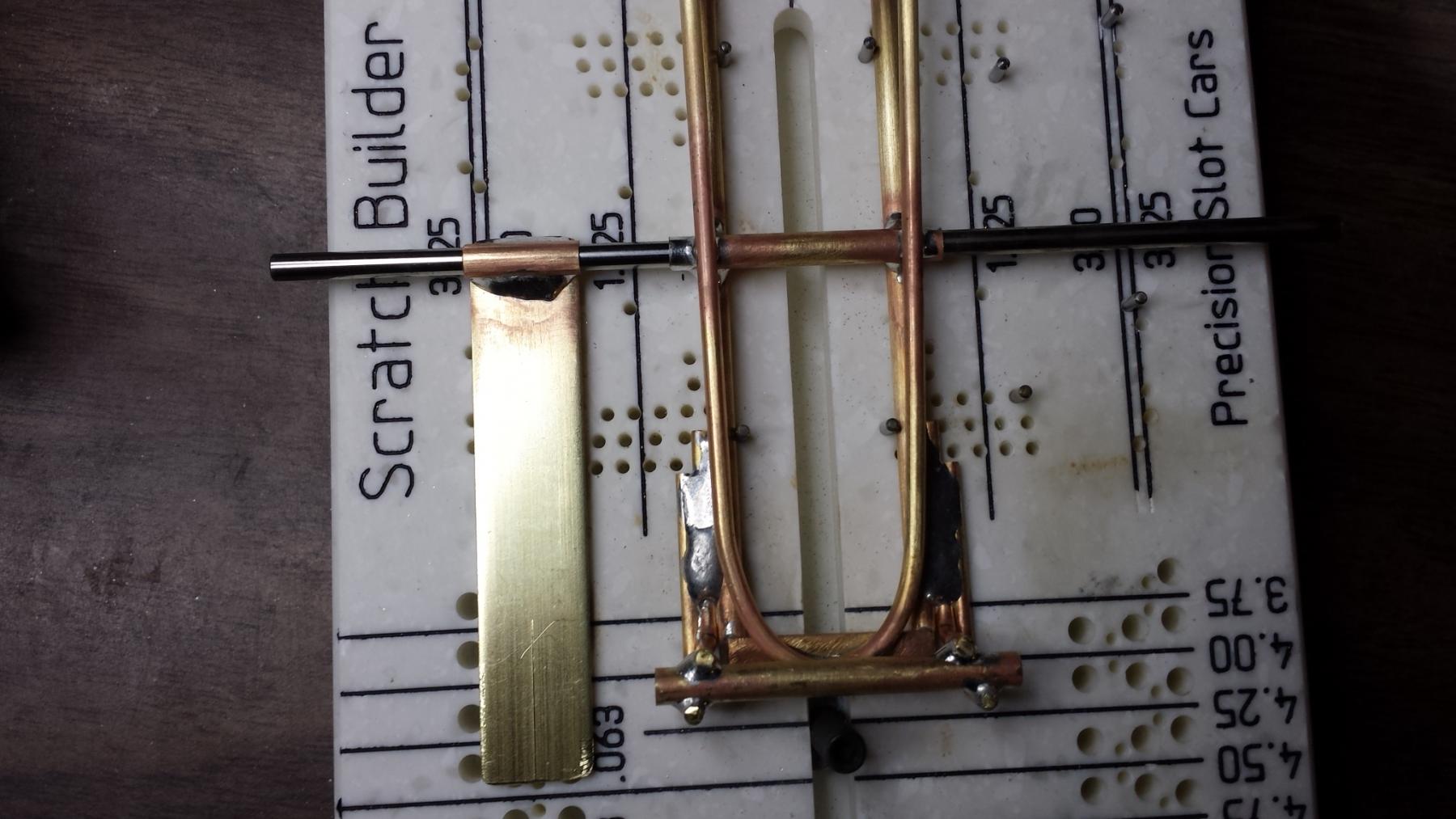

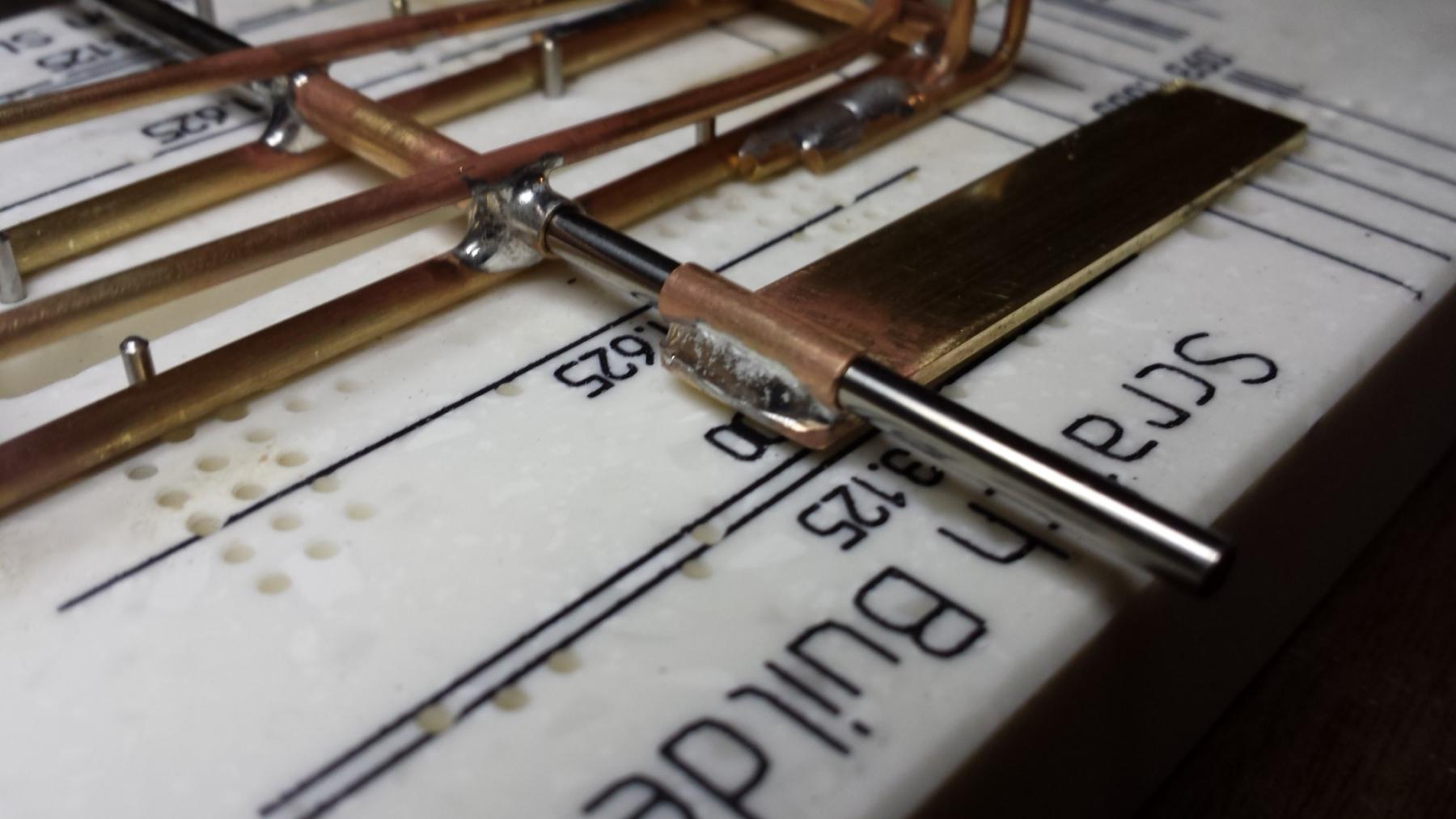

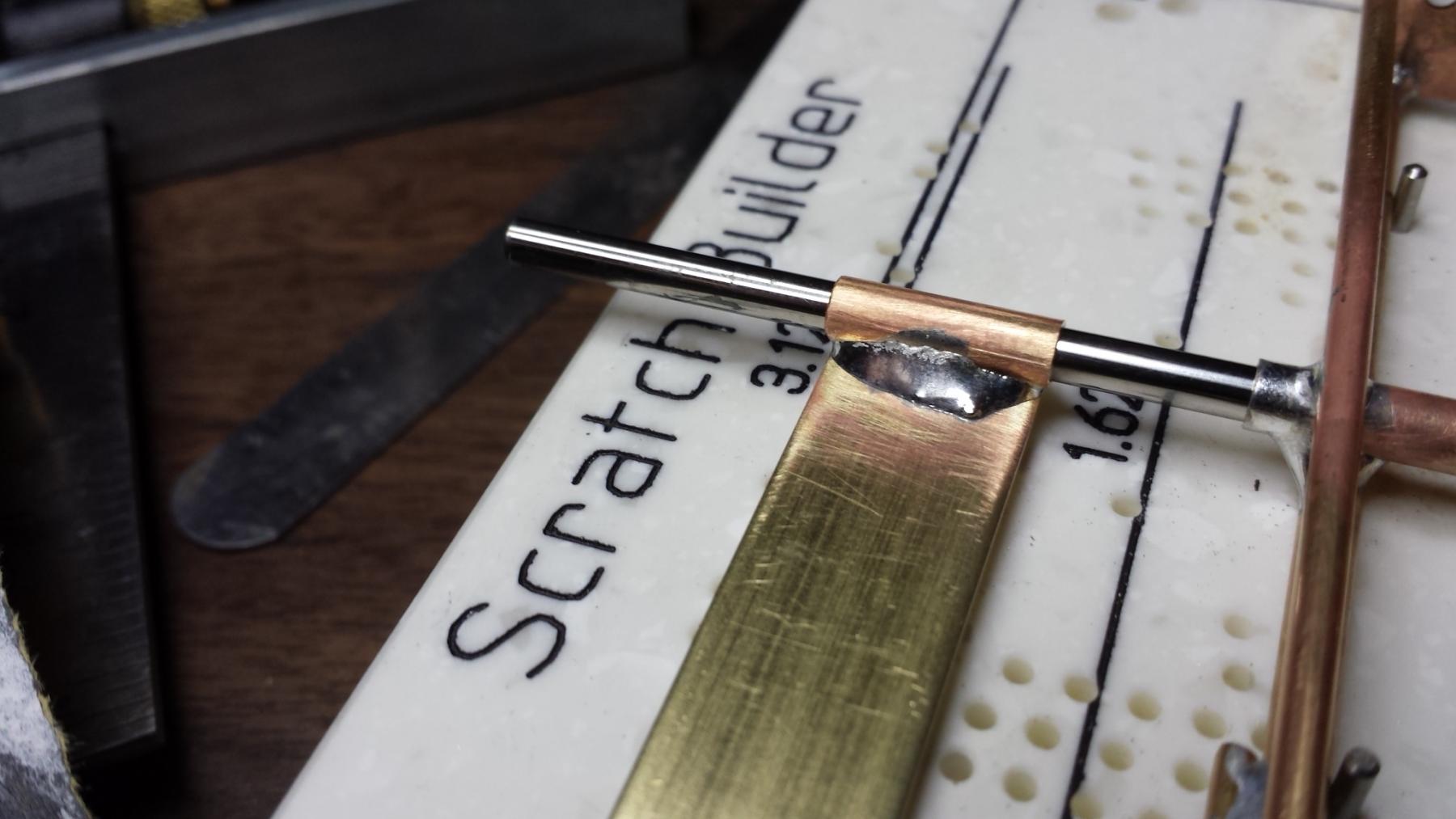

![]() ) heat from your torch joints, yet your best joints are those up off the jig.

) heat from your torch joints, yet your best joints are those up off the jig.