The 888 and the 1972 Nats...

#51

Posted 19 February 2008 - 12:40 PM

Oh yeah, 5/8" fronts like PdL's Group 20/7 car. It seems like all the later "pro" cars went with 5/8"s.

Would it be possible for you to post a picture of your center section jig with some measurements??

While my Rick B jig is awesome for D3 stuff, I need to build something else for the center section layout and soldering.

And Bill (from NH) has given me a real Parma drop arm which I'm saving for the No Glue car build.

Is there a certain angle used for the motor box area?? I've got a number of vintage Muras now and wonder how to make sure they fit.

Thanks again.

GTP Joe Connolly

In theory there is no difference between theory and practice.

In practice there is.

#52

Posted 19 February 2008 - 01:15 PM

I'm going to be making a new jig soon and I'll have a drawing I can send you then.

I set the motor angle the way Lee Gilbert did in his Car Model magazine "how-to" articles. I get the motor and gears I'll be using and set them up in the jig at the shallow angle that will still allow the gears to mesh and the magnet to not contact the axle.

I did a complete construction article with a zillion pictures that's now hosed with the current forum. It was my first post with a digital camera and I didn't resize the pictures properly. I will get that post fixed and reposted. In the mean time here is part of that old post that deals with motor angle. The chassis is a three-bearing so that's why I talk about cutting the center out of the rear axle tube. For a conventional two-bearing chassis it would remain just as it is in the pictures:

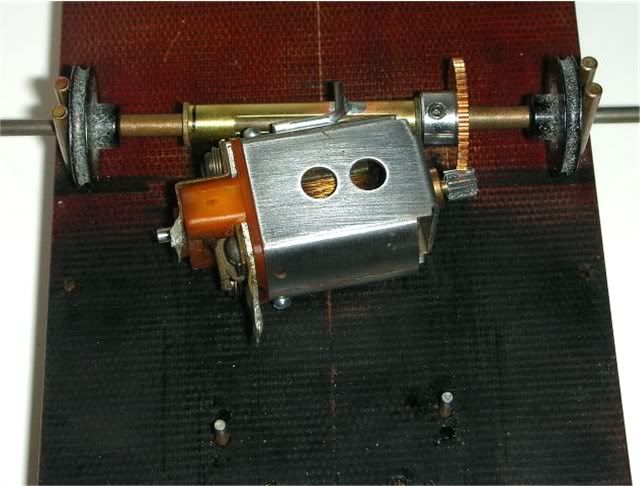

Here's the motor, axle tube, gear, and jig wheels, all centered up in the jig:

The axle motor is temporarily soldered to the axle tube with a wire brace. The axle tube is 1.250" long and is notched for motor clearance. The notch is .100" from the gear side and .250" from the end bell side. The depth of the notch is about half way through the tube. After all the rear axle bracing is installed I'll cut out the center of the axle tube to make room for the third axle bearing.

It's time to solder in the main rails...

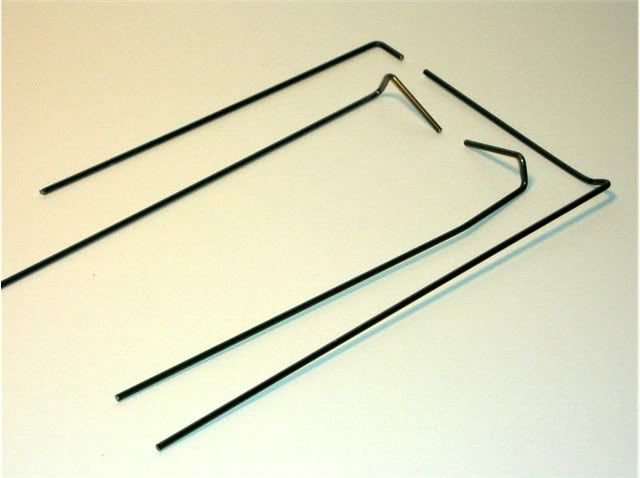

My digital camera skills are still lacking but here goes. Here are the four main rails of the chassis. I leave ends LONG until I've "convinced" them to take the shape I want. Piano wire is cheap. Oh, one thing I noticed with this batch of hobby shop piano wire was that some of the pieces were not straight... kind of wavy. Now I spin each piece with my fingers to see if its straight and running true:

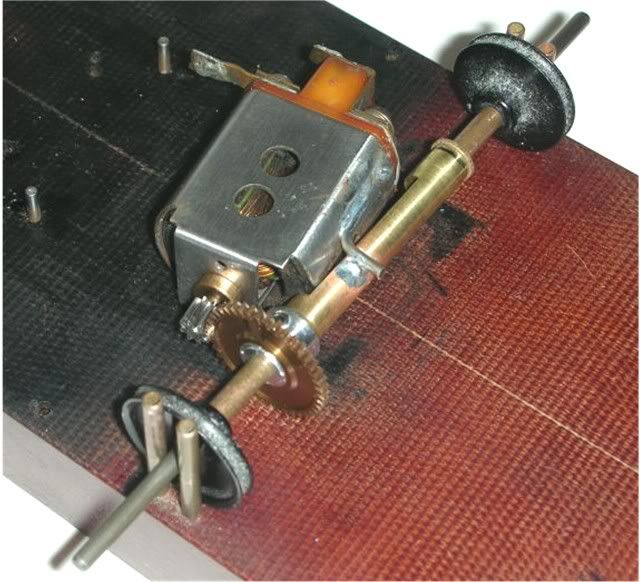

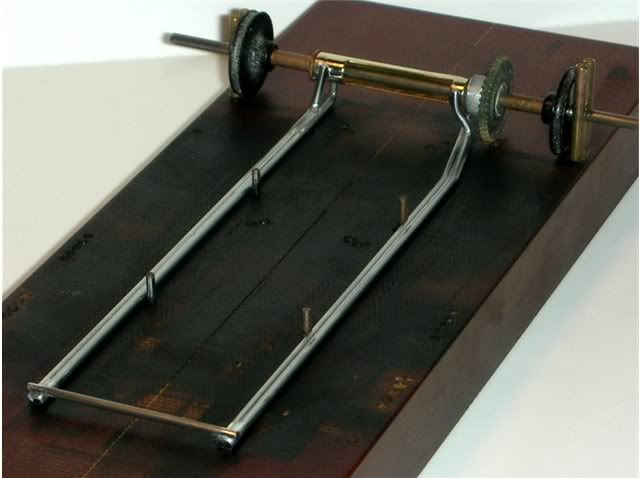

Here's the start of the center section in the jig. Next comes the two rear axle braces and cutting out of the center of the axle tube:

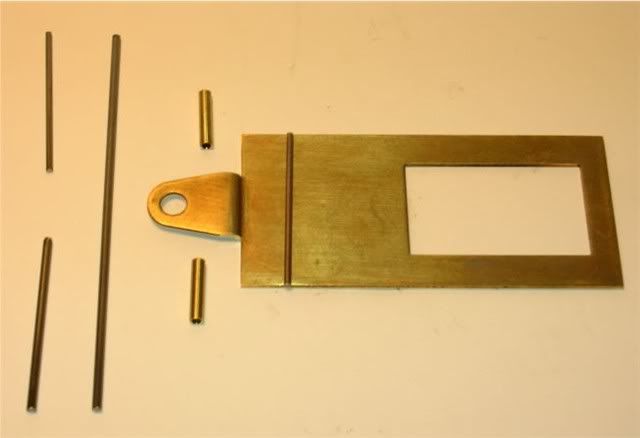

I'll also need to trim the main rails to length. For that I'll need the drop arm with all its plumber hinge tubes and bumpers installed. Here are the parts for the drop arm:

The wire sitting on the drop arm is .047" and is cut to the width of the drop arm. The two 3/32" diameter brass tubes are .475" long. The .062" dIameter wire bumpers are left long to be trimmed even with the pans latter.

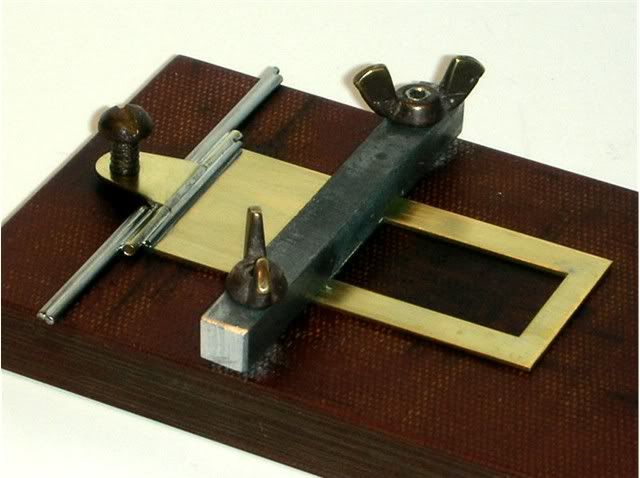

These are the soldered up parts in the drop arm jig:

And the finished drop arm awaiting the Diamond front axles:

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#53

Posted 19 February 2008 - 02:19 PM

Great!

I see now one of the constraints is the 1.250" long axle tube. Get that centered, motor in place and gears meshing, soldered to axle tube temporarily. Then from the last jig pin that's holding the center section that bend to the tube is the angle for the motor. If it comes straight back it misses the tube but the bend goes right in front of the can and attaches to the tube. That's how you're able to build for different motors.

OK, it's coming together now. I won't drill my Garolite till I see your jig setup.

Thanks again!

GTP Joe Connolly

In theory there is no difference between theory and practice.

In practice there is.

#54

Posted 19 February 2008 - 04:22 PM

Usually I add the width of the two rear wheels, the spur gear, bearing flanges, and any spacers I want to use. Then I subtract that from the maximum allowable width (usually 3-1/8" or 3" for older cars). That gives me the length of the rear axle tube. It usually works out to about 1.200" for a 3-1/8" track width.

Have you downloaded the Lee Gilbert Pro Car How-To articles he did for Car Model magazine? The first anglewinder I built I had a lot of trouble with. After reading Lee's articles it all made sense.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#55

Posted 19 February 2008 - 05:08 PM

Philippe de Lespinay

#56

Posted 19 February 2008 - 06:15 PM

So this style was a later version sold to the public? I've had several of these:

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#57

Posted 20 February 2008 - 12:17 PM

Is the Lee Gilbert article posted here on Slotblog??

GTP Joe Connolly

In theory there is no difference between theory and practice.

In practice there is.

#58

Posted 20 February 2008 - 01:27 PM

Pro Motor Build

I'll check to see if I still have the scans and can post them again.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#59

Posted 23 March 2008 - 04:51 PM

Hello Rick, I race with TonyP and Noose. I just wanted to say your restoration work, and duplicate work is incredible. Thanks for sharing them with us...Here's his motor building article. I guess it's the only one left from all the different forums.

Pro Motor Build

I'll check to see if I still have the scans and can post them again.

John Chas Molnar

"Certified Newark Wise Guy since 1984" (retired)

"Certified Tony P Chassis God 2007.2023

Retro Chassis Designer-Builder

#60

Posted 23 March 2008 - 06:08 PM

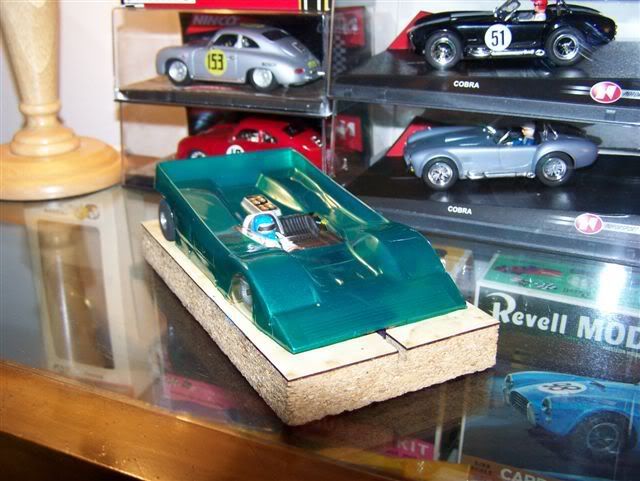

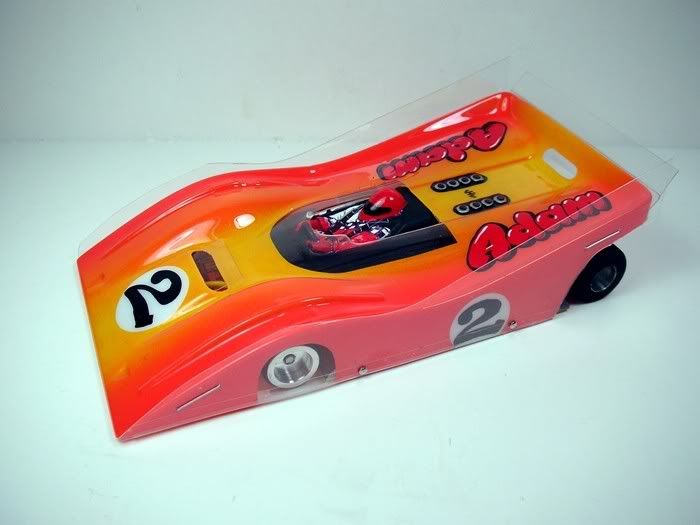

So...here is a car i race using one of the $19.99 REH chassis. I simply use a $8 Cheetah-II motor, and this baby performs well! I do not know anything about chassis set ups, and this car handles great as i got it, no mods at all, except for soldering on a motor to rear axle tube brace to hold the motor in better. this makes for a very inexpensive and fun car to race.

Glenn Orban

NJ Vintage Racing

NJ Scale Racing

C.A.R.S. Vintage Slot Car Club

#61

Posted 23 March 2008 - 07:14 PM

Glenn, these old anglewinder are a lot of fun aren't they

Rick

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#62

Posted 12 April 2008 - 03:44 PM

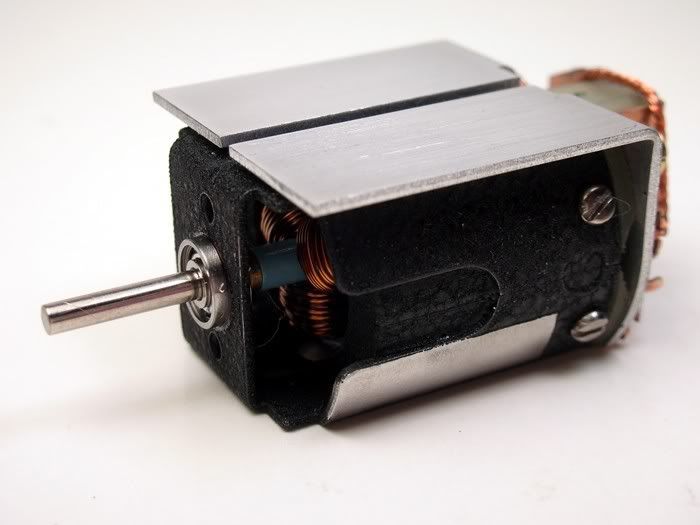

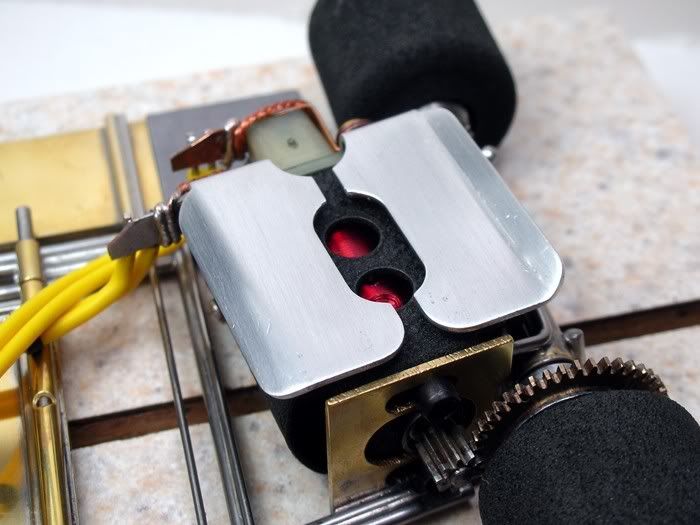

I made one change at Adam's request. He liked the "Aero Style" heat sinks on my Tony P ISO Can Am Turbo motor so I swapped out these Parma clones:

for these modified Mura's:

At the track it handled absolutely bitch'n

Then I decided to compare the 2008-888 with its Koford 20 arm:

to my Starship with it's ProSlot 20 arm:

The ProSlot powered car just seemed a little better all around. It had a little more speed, slightly better brakes and even ran cooler. The armature air gap, brushes, brush springs and gearing are all the same. The Koford also drew more amps during the break in as I remember. I’m not sure how long this motor will last. I’ve absolutely hammered my ProSlot powered Eddie 20 and it just keeps going and going…………..

Maybe the Koford powered motor will pick up with some more track time..........or maybe it will go up in a ball of fire

So if you see this car running at BPR

and it goes POOF! we won't be surprised. We'll just rebuild that good old Mura 2-hole C-can with a ProSlot arm and it will be even faster

ONWARD............

- Jencar17 likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#63

Posted 12 April 2008 - 04:01 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#64

Posted 12 April 2008 - 04:39 PM

#65

Posted 12 April 2008 - 05:37 PM

My current ProSlot is a 44 but it looks like they now only list 35, 38, 40 and 46 at PCH online. My current 44 runs great but I don't trust that 46 degree Koford. When I buy another one I'll take your advice and go down to a 38 (or maybe a 40

Thanks for your input,

Rick

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#66

Posted 12 April 2008 - 06:13 PM

I intend to live forever! So far, so good.

#67

Posted 12 April 2008 - 06:29 PM

I don't have a gizmo to check arm timing. What one do you recommend I buy. Sounds like a nice addition to my "Tools For Retirement"

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#68

Posted 12 April 2008 - 07:00 PM

I intend to live forever! So far, so good.

#69

Posted 14 March 2019 - 02:45 AM

That "plentiful" may have been true 11 years ago, but it's pretty slim pickin's these days!The Mura two-hole C-can setup is plentiful on eBay. I bought this lot...

... which yielded these usable parts:

Did you set aside the "non-usable" cans & other parts, or just toss them? Most of what's on the Bay now doesn't look better than your discards in this pair of pictures, so it's getting discouraging trying to build up some of these cars. I may have to settle for "work-alikes" as Rocky Russo described his motor choices to keep his cars operating.

Marcus

Marcus P. Hagen -- see below, my five favorite quotes: applicable to slot cars & life in general.

[ "Everyone is entitled to his own opinion, but not his own facts.". . Daniel Patrick Moynihan ]

[ "Time is the best teacher. Unfortunately, it kills all its students.". . . . . . . . Hector Berlioz ]

[ "There is a very fine line between 'hobby' and 'mental illness." . . . . . . . . . . . Dave Barry ]

[ "Build what you like to build, they are all doomed." . . . . . . . . . . . . . . . . . . . . Prof. Fate ]

[ "The less rules the more fun. Run what you brung." . . . . . . . . . . . . . . . . . . . . . Larry LS ]

#70

Posted 14 March 2019 - 09:57 AM

Hi Marcus,

I sold off lots of my extra C-can motors and parts over the last couple of years for cheap.......unfortunately! ![]() I even struggled to get $20 for "kits" like this with nice new parts:

I even struggled to get $20 for "kits" like this with nice new parts:

I guess it's just a matter of timing. When I was selling my surplus the demand didn't seem to be there. ![]()

- boxerdog likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#71

Posted 15 March 2019 - 02:11 PM

Rick, you gotta learn how to hoard better lol!

#72

Posted 15 March 2019 - 03:57 PM

John, what Rick has that we don't know about would probably surprise us. ![]()

![]()

- olescratch likes this

I intend to live forever! So far, so good.