Putting C mags in a D can is tricky - the usual approach is flattening, or removing, the louvers on the can,

then shimming top, bottom, and sides. This time I tried something different.

Can ID is .610"; magnet height is about .545", a difference of .065", /2 = .033".

The louvers extend about .050" vertically and I wanted to partially close them to make it .033".

I placed a "C" can straightener inside with the can louvers down, held a big screwdriver on top of the tool inside the cooling hole, and "Bap!"

The first tap took them down to .042", the second tap got it about .035".

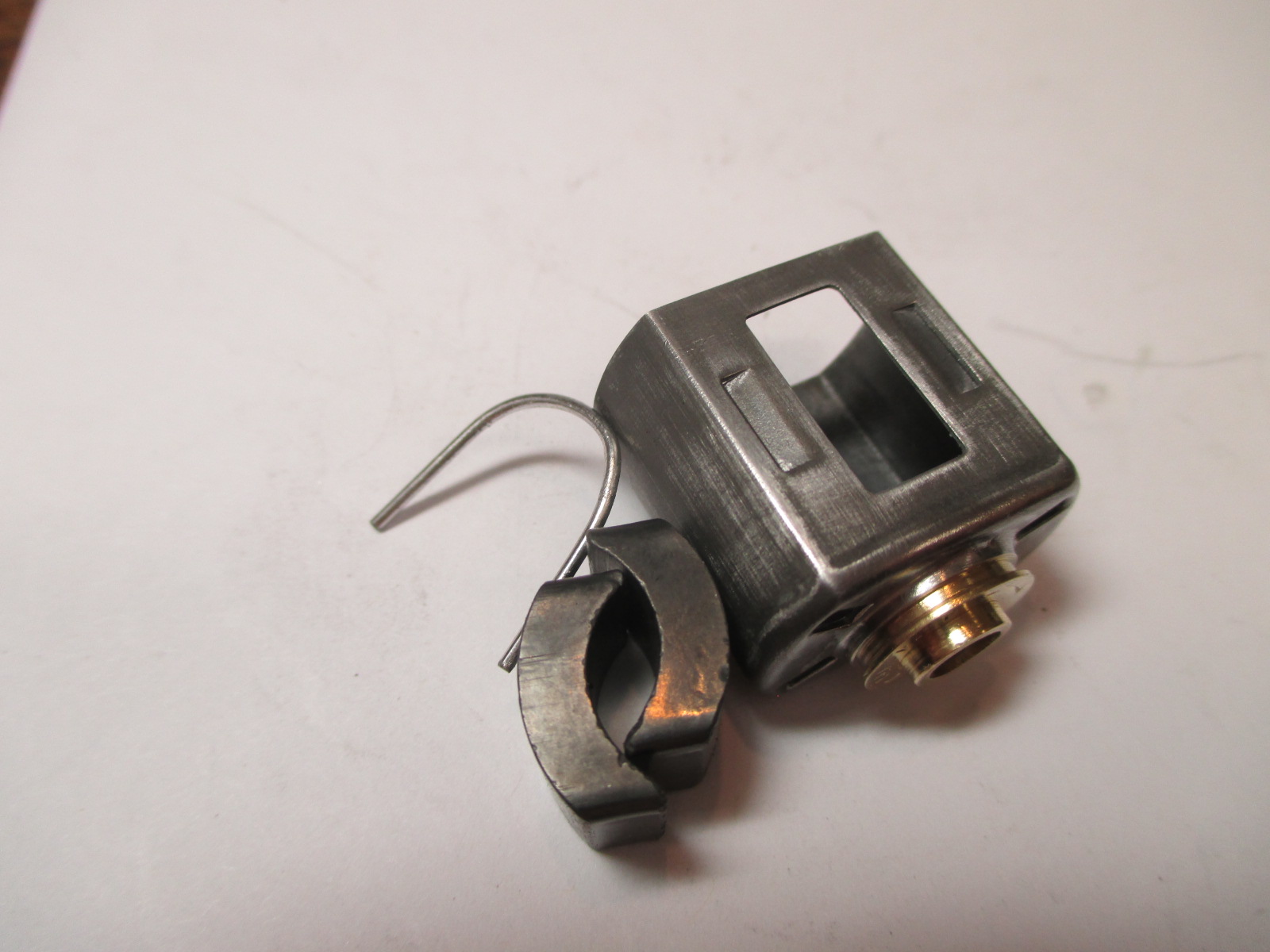

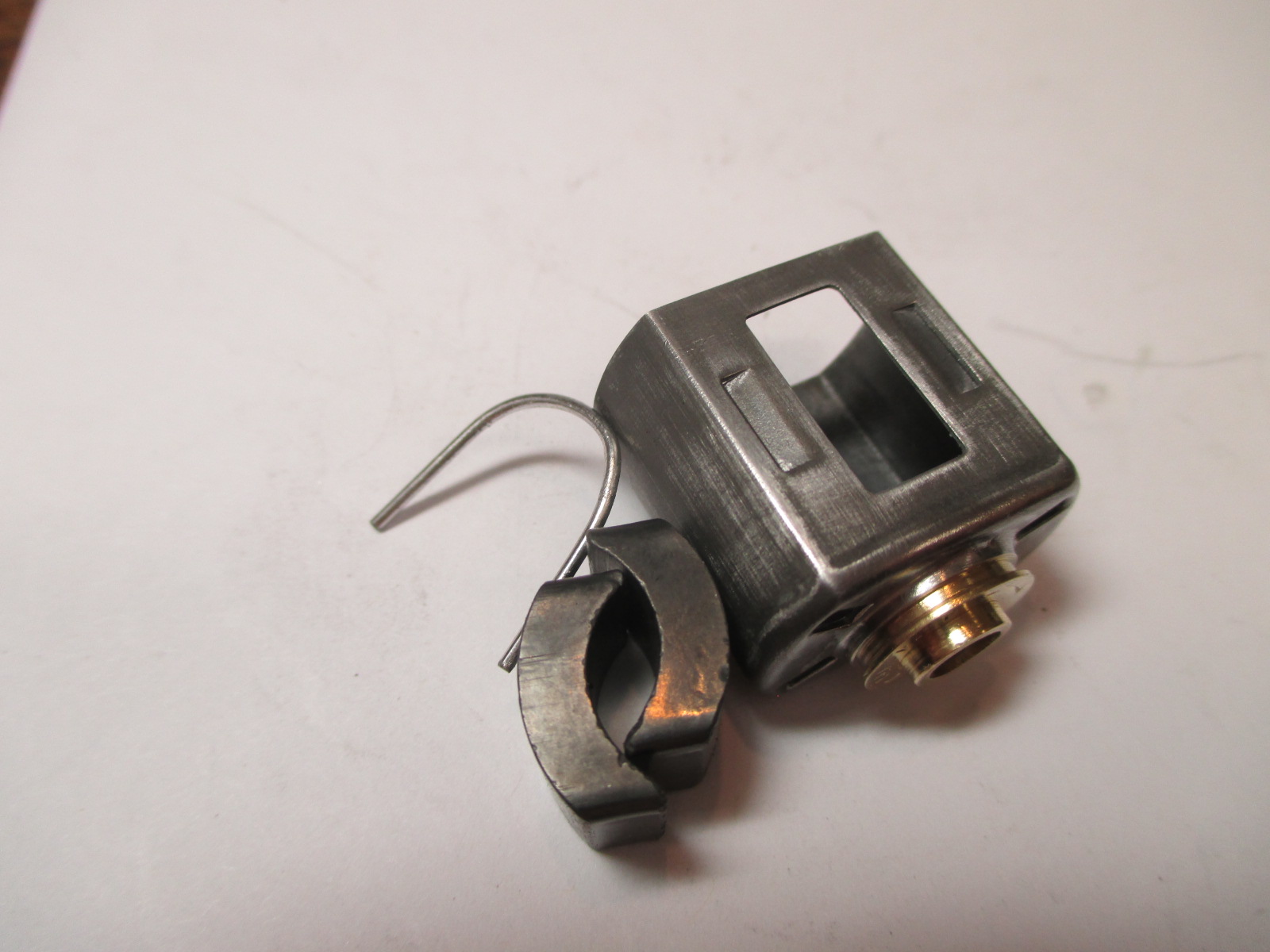

Then I tinned a piece of .032" wire and made a clip for the other end that fits between the mags and can.

In the end, I decided to shorten the can all the way. "in for a penny, in for a pound"

Inserted mags with a .535" Goat Boy slug slathered in ATF and went crazy with the Krazy Glue.

Then honed them to .538" giving me a total airgap of .023".

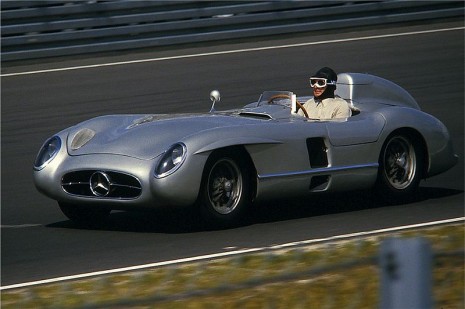

Motor is done and it sounds like just what the doctor ordered - good smooth revs - not a lot of torque.

Can will be painted later with VHT Burnt Copper.