Thanks, Tom.

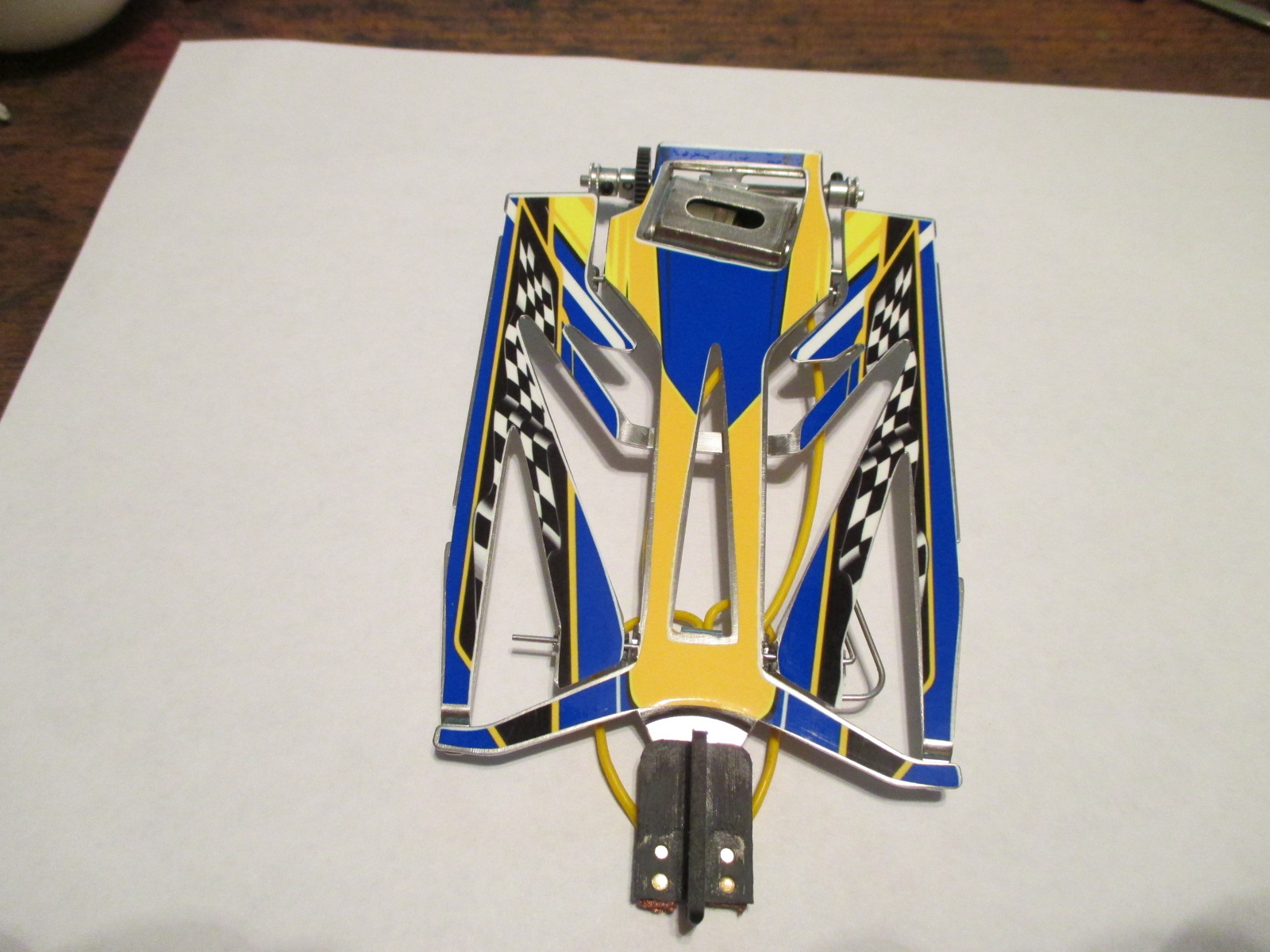

The rest of the assembly was easy, no problems, nothing special other than the usual "Wolcott Ranch" race car attention to detail:

- pan doesn't need nursing to attach it - drop it over the center section, insert bite bars with a click, done. Brilliant design.

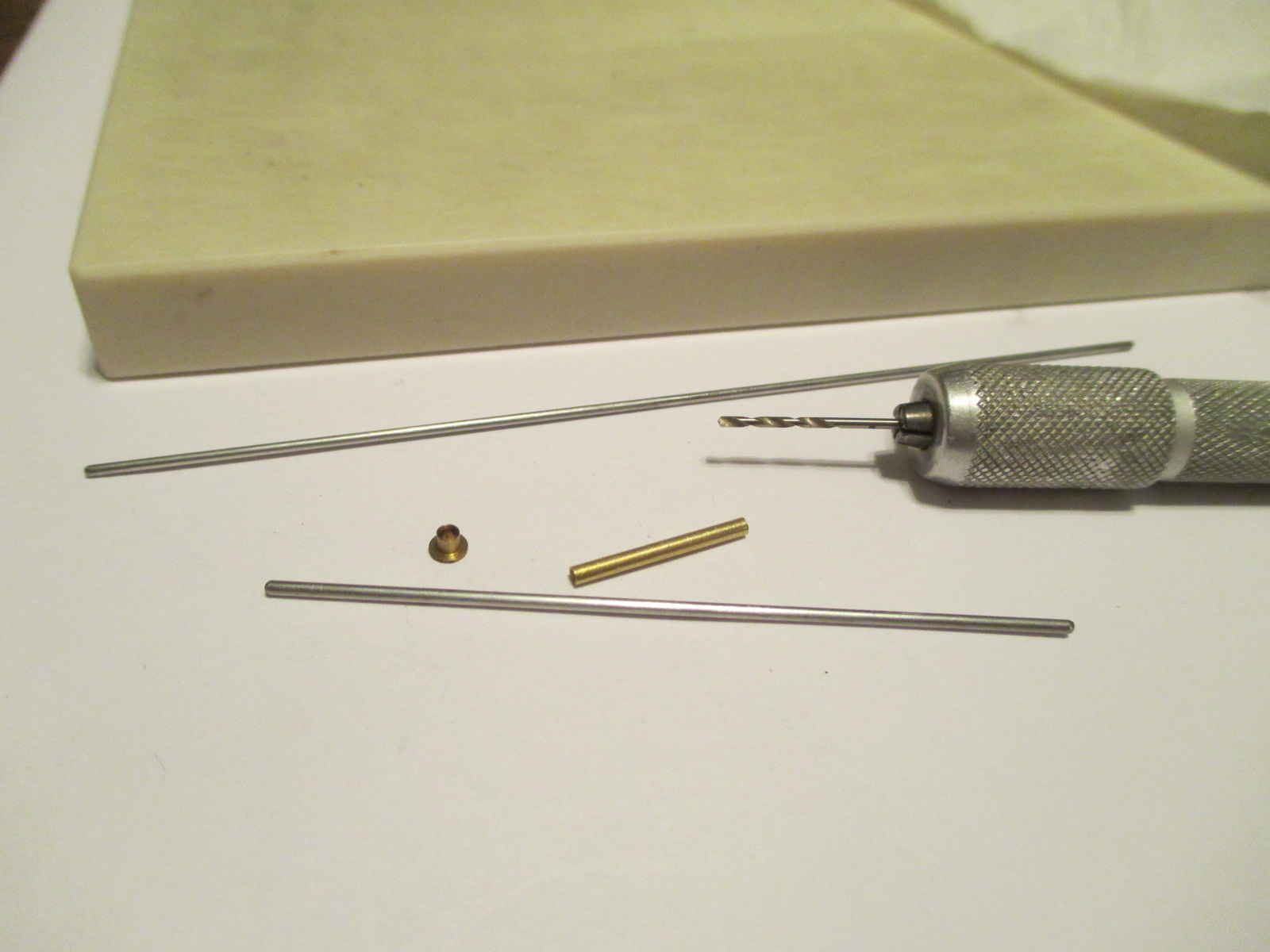

- Parma flag blueprinted, all rotating surfaces faced, Koford aluminum drilled nut and two 10 thou bronze spacers for tuning (one top one below to start), Slick 7 wires, TQ clips, Prime braid, Koford axle.

- spur gear balance tested using the BBs on the car – screw was the heavy point – tried a few different screws until I found the one that made it happy.

The wheels I'll be using are .680" OD Alpha Wonder rubber on carbon fiber hubs and are .800" wide. I used a single thin spacer between spur and BB, a couple thin spacers between spur and (left) wheel, and two 20 thou spacers on the right side. Look close and you can see my marks aligned.

My opinion is, the C43 has raised the bar in many ways and it's probably the easiest flexi chassis to make race ready of any I've ever built.

I give it three thumbs up (that's the max Cheater Wells allows).

![]()

This topic is locked

This topic is locked