My sexy new JK C43 GTP car - step by step

#26

Posted 05 December 2016 - 12:18 AM

#27

Posted 05 December 2016 - 07:51 AM

- Ramcatlarry, Tim Neja, Guy Spaulding and 1 other like this

I intend to live forever! So far, so good.

#28

Posted 05 December 2016 - 08:23 AM

Clips - so yesteryear

The Russkit RTR cars used clips.

Is there an echo in here? ![]()

#29

Posted 05 December 2016 - 09:03 AM

Clips can be adjusted to give the body movement just like floating pin tubes. As this is not Pablo's first rodeo I think he's got the clips down pat.

- Ramcatlarry, Tim Neja, Danny Zona and 1 other like this

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#30

Posted 05 December 2016 - 09:52 AM

- Wizard Of Iz likes this

You're never fast enough!!! 💯

Preparation leads to separation.

Success is never owned but rented, and the rent is due every day.

KELLY RACING 😎

#31

Posted 05 December 2016 - 11:16 AM

Clips look ugly, soooooooooooooooooo! ![]()

I intend to live forever! So far, so good.

#32

Posted 05 December 2016 - 12:08 PM

What happens to those chassis skins when you solder motors in & out of a chassis? Years ago we made chassis skins using 3M colored plastic tape, but we never skinned the motorbox.

Shouldn't be an issue. They are made from a material designed to hold up to high temps. Personally I haven't had any problems yet.

The chassis skin and car look great as usual, Pablo.

Thanks for spending the time adding nice pictures and informative text.

- Pablo likes this

Ralph Thorne

ralph@ralphthorneracing.com

RTR Facebook page

#33

Posted 05 December 2016 - 02:28 PM

I can tell you the skins hold up on a chassis dragging on the chassis ears as well... very impressive product.

- Pablo and Guy Spaulding like this

#34

Posted 05 December 2016 - 02:42 PM

Let's see you paint a body to match LOL.

- Pablo likes this

#36

Posted 05 December 2016 - 07:10 PM

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#37

Posted 05 December 2016 - 08:06 PM

Funny looking wheel openings.

Those openings are for his clip holes, or else he's planning to run scale moped wheels and tires.

That's way too much paint to qualify as a parking lot job. You just spray a cloud of paint in the air, then wave a clear body through the cloud twice. All Californians know how to do it.

I intend to live forever! So far, so good.

#38

Posted 05 December 2016 - 08:28 PM

Red will love the color - looks like I'll need to send Mr. Valentine some HP... LOL.

- bluecars likes this

Charlie McCullough

Charlie's Speed Shop

Kelly Racing Wanna Be

#39

Posted 05 December 2016 - 10:28 PM

9/18/51-8/30/24

Requiescat in Pace

#40

Posted 06 December 2016 - 07:51 AM

Do they have separate categories for roller concours and body concours? You might need that, Pablo.

- Dave Person and Eddie Fleming like this

Tim Homola

JK Products

#41

Posted 06 December 2016 - 09:46 AM

That's way too much paint to qualify as a parking lot job.

![]() Concur, but I will say:

Concur, but I will say:

1. it's lacquer and all joking aside I want it to last at least three races.

2. the photo makes it look a lot denser than it actually is - in fact it is on the verge of not passing tech if there was a 'must be opaque" rule.

There is no official concours judging at The Dungeon, Tim, but photos are always taken of all the cars in all three classes.

Bud Greene, John Clow, and Bobby Page always show up with concours quality cars.

I have to say, during lane changes Bobby's cars on his pit caddy actually look like a real NASCAR pit.

For you "horsepower" freaks out there, just keep in mind I'm a "buy a motor, put it in the car" guy. No cherrypicking going on.

I do enjoy walking around during lunch within eavesdrop range of Red Valantine, muttering under my breath the words:

"Dyno... last night on the dyno... Bud's dyno... 110K RPM... real amp sucker... Norwegian squid bearing lube." ![]()

- MSwiss, Tim Neja, boxerdog and 1 other like this

Paul Wolcott

#42

Posted 06 December 2016 - 11:44 AM

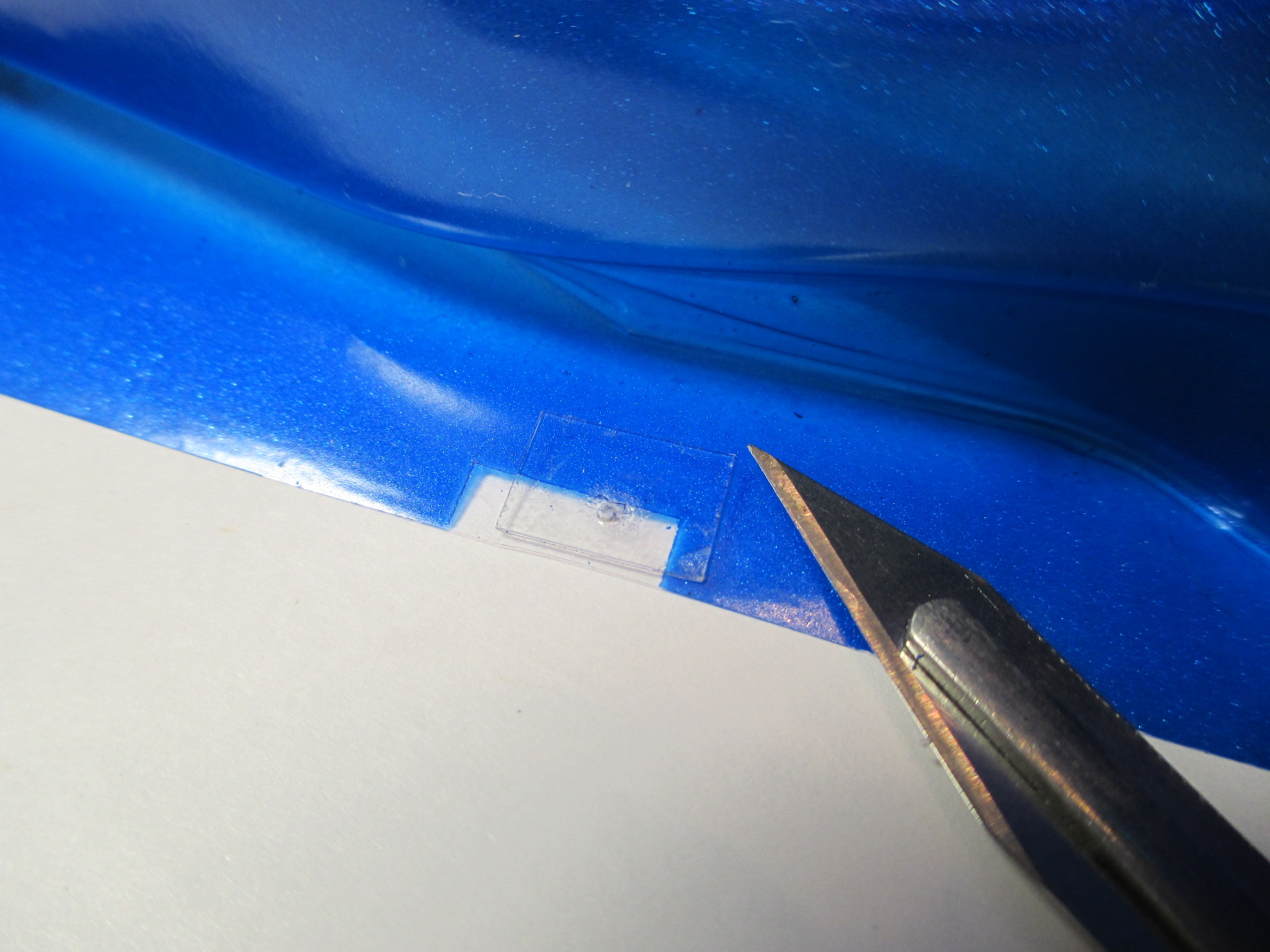

Are those body clips bent to be race ready? Do you have a specific procedure you go through to make them "Pablo style" race ready.

I haven't always understood your method on how to bend the clips. Do you install the long leg in the front and then tape over the rear leg?

I have a new C43 that I'm going to use the clips instead of pin tubing. I'm a proponent of pin tubes on just about everything and have used them since the early '90s but I thought for this chassis and one other one I have I'll give the clips a try.

#43

Posted 06 December 2016 - 11:45 AM

Thanks for all the tips, Pablo, and for taking the time to post about them with pictures for us less adept folks!!

Merry Christmas to all you slot heads!!

#44

Posted 06 December 2016 - 04:55 PM

I did post my method a while back, page #1, post 14, and page #2, post 62, here:

New Kurtis proxy car built by Pablo

After I punch the holes first time, I mount the body on the clips and note if there are any needing to go higher/lower or right/left.

Then I place squares of bulletproofing on the insides over the holes. Punch the final holes with the desired corrections.

Paul Wolcott

#45

Posted 07 December 2016 - 02:31 PM

Slice it off with a sharp blade (I use a scalpel), otherwise your body won't move freely.

Clips are secured with tape. This also reinforces the bottom of the body skirt, precluding fouling.

Normally for a race car I use filament tape but this time I wanted to show off my sexy blue clips.

Transparent tape works fine.

Cheater Wells and Jay Guard taught me this stuff years ago and it still works.

- Jencar17 likes this

Paul Wolcott

#47

Posted 07 December 2016 - 04:16 PM

As an addendum, I'd like to say the rear upright brace probably isn't needed, as this chassis material is quite strong.

But I had one sitting here just collecting dust so I used it. No doubt in my mind it was simply overkill.

I chose not to double the tongue - due to the same reason - strong steel, and I didn't consider it necessary. ![]()

- MSwiss and JK Products like this

Paul Wolcott

#48

Posted 07 December 2016 - 04:31 PM

As an addendum, I'd like to say the rear upright brace probably isn't needed.

Maybe, maybe not.

I think most racers underestimate the forces involved in the motor bracker/rear axle assembly, especially with inlines but also with anglewinders. And even more so with fast cars on highly-banked tracks.

One way to check whether an upright brace is warranted is to take your thumb and forefinger and squeeze as hard as you can to try to force the uprights toward each other. If you feel any movement at all, install a brace.

Here's a snippet from the T-Flex Tome giving another method for checking whether an upright brace is worth installing.

"On banked tracks, running fast C-can motors, a rear upright brace is necessary to keep the rear axle from binding in the banks; the rear of the chassis will flex under the loads it sees. You can usually see this yourself on an unbraced chassis: space the motor from the axle with a piece of paper when soldering it in place, and then take a black magic marker and color the axle for about 1/4 inch at the point where the can is nearest the axle. After racing a while, you will usually see that the can has been touching the axle, as evidenced by a silver stripe rubbed into the black marking."

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#49

Posted 07 December 2016 - 05:45 PM

Did it anyway just to show off.

Paul Wolcott

#50

Posted 08 December 2016 - 11:10 AM

This step-by-step set-up guide deserves a place beside Greg's Turbo-Flex magnum opus! ![]()

Cheers.

- Cheater likes this

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

This topic is locked

This topic is locked