Not much has changed for me - still soldering late at night, but now I suck up excess solder with "Soder-Wick"

Nowadays I have things I didn't in 1966 - patience, lots of tools, access to parts, and helpful friends worldwide at the click of a few buttons.

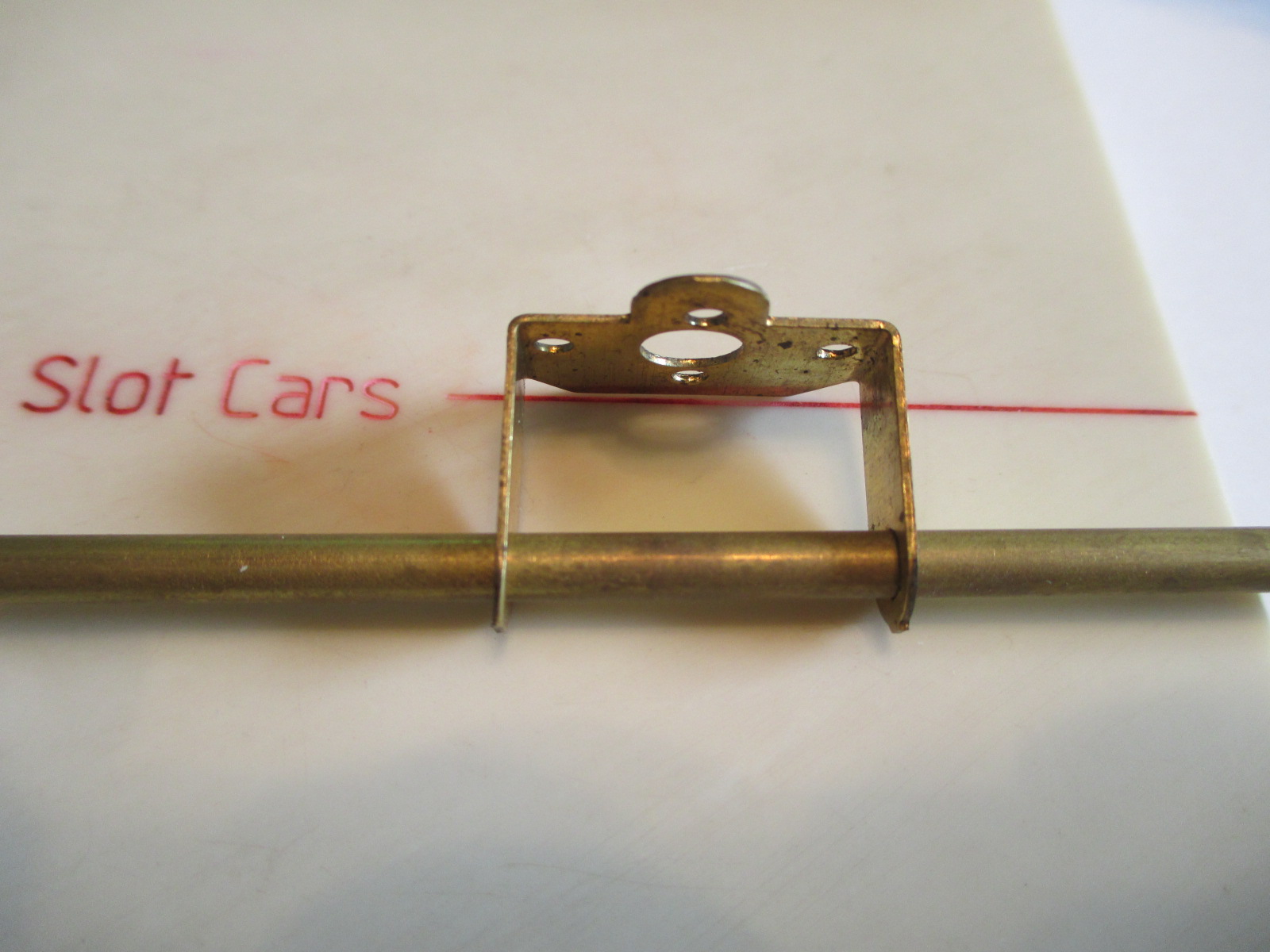

Haven't found a Castleton bracket yet that was even close to being true like a Russkit. This one was no exception.

Bad bends, misaligned holes, arch above upper hole needs complete reshaping, etc. so it took a couple hours to get it right.

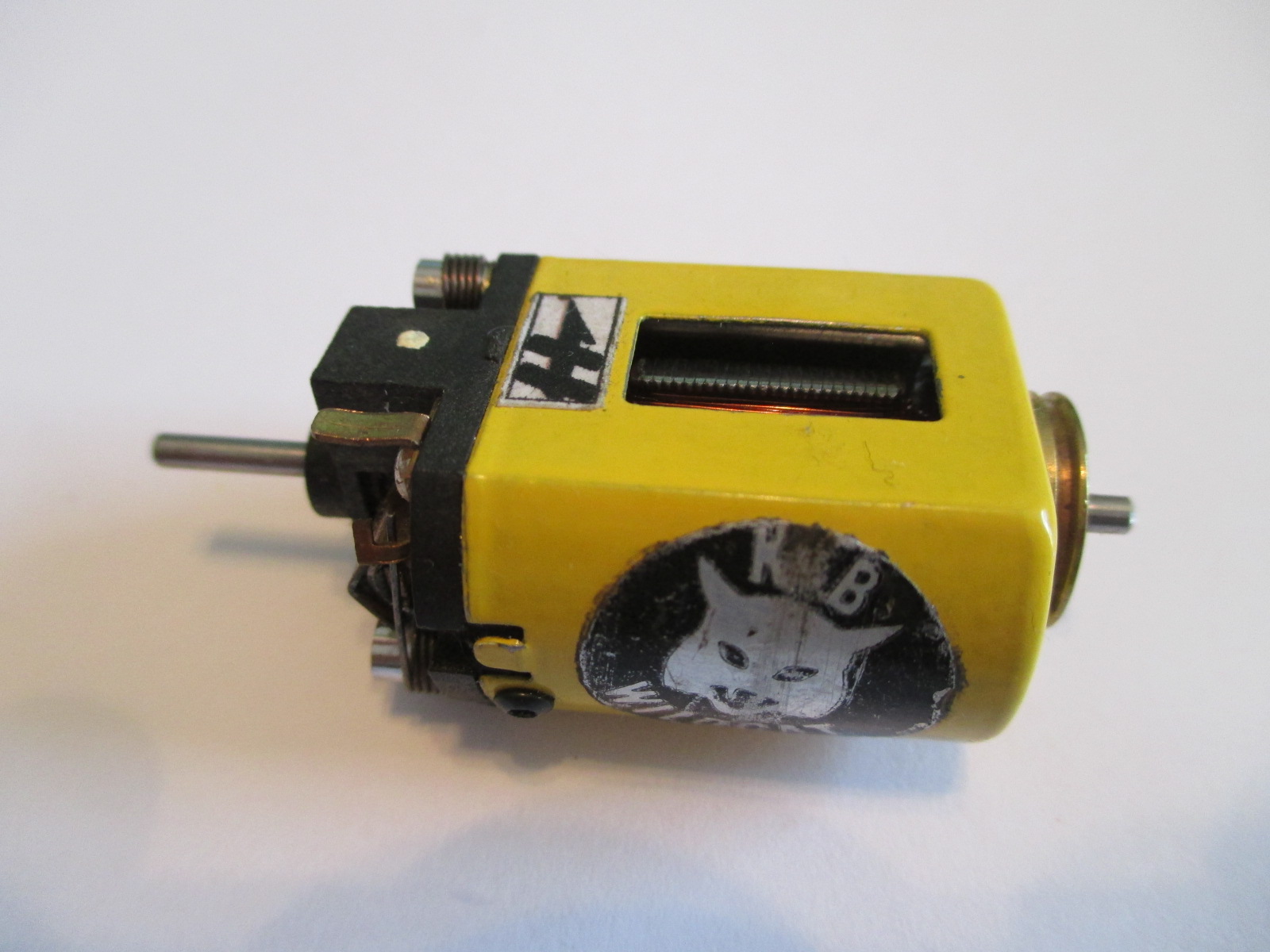

The (trued) bracket, when attached to the Wildcat and sitting face vertical at ground zero, will result in the motor being level and elevated just a hair.

Now all I have to do is jig the height for .062" clearance using .875 wheels, make the face sit square with bottom edge on the block, and tack the tubes.

No bushings or bearings - just tubing - and my centering methods will be done differently this time.

I just used a long piece and didn't centering anything perfectly - yet - gonna use my dc-65x gizmo for all four cuts