Gizmo is dc-65x's generic name for a whole bunch of different tools. They're all related to a thing-a-ma-jig. ![]()

Ferrari 330 P4 comes back to life

#26

Posted 18 December 2016 - 06:19 PM

- Samiam likes this

I intend to live forever! So far, so good.

#27

Posted 18 December 2016 - 06:53 PM

Some small details are done:

-orange donuts are glued and curing

-Gold Cup flag shaft has thin wall tube secured

-flag tube is cut to size, polished, and elevated above the block .088"

-Wildcat endbell holes tapped 2-56 (I just love saying it - Wildcat ![]() )

)

-iso hinge wire holes drilled in bracket sides

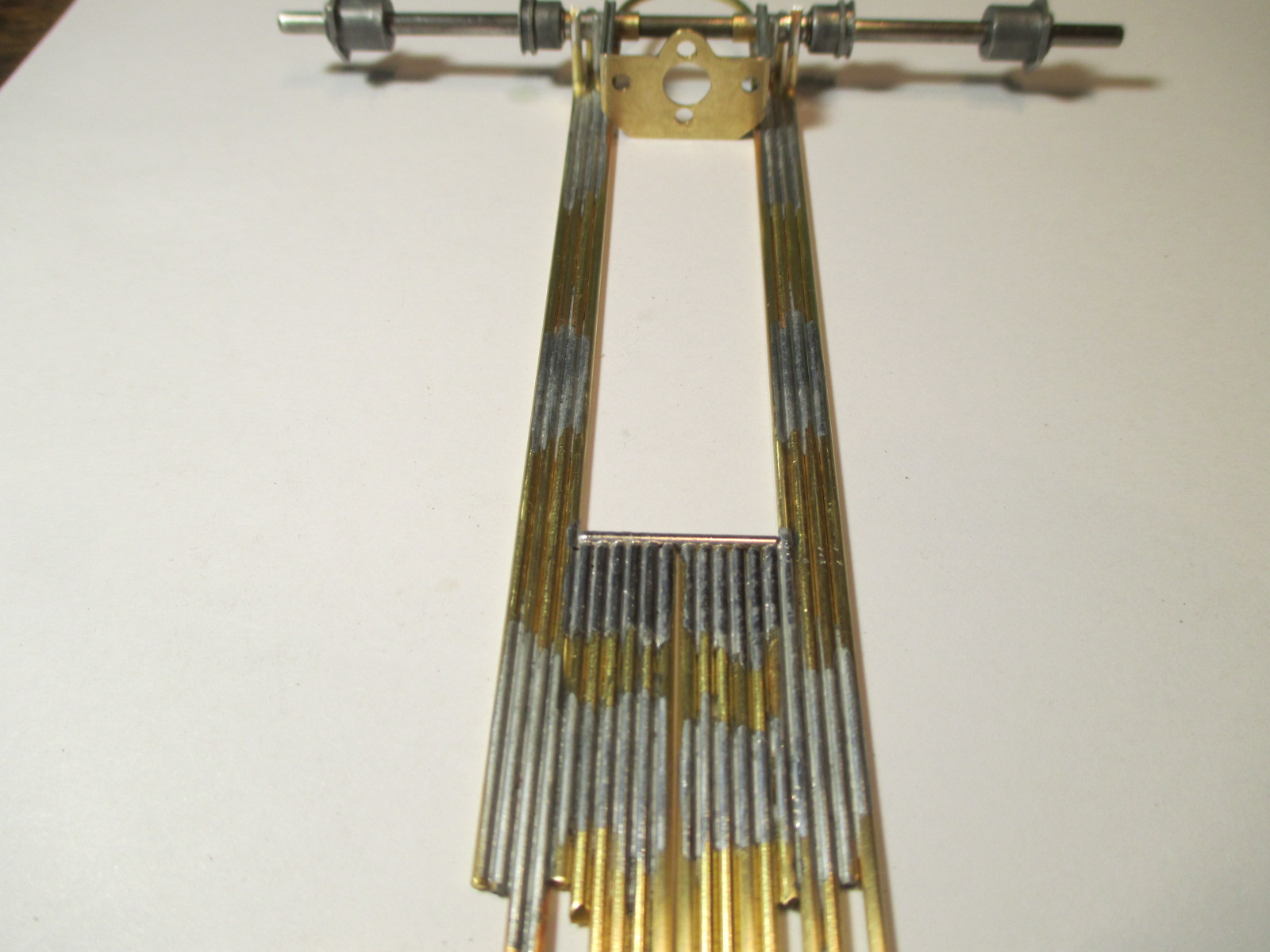

Jigged up with first rails tacked. Forward crosspiece is just temporary to secure the rails for now

- Jencar17 and C. J. Bupgoo like this

Paul Wolcott

#28

Posted 18 December 2016 - 10:31 PM

IMHO the only good Castleton bracket is one Pablo or some other craftsman has spent hours working over!

Otherwise they are junk.

Now I understand why a kid with a Weller gun, a couple of files, and a hand drill had so many problems getting a chassis to handle in 1967.

- Half Fast, Samiam and Mach9 like this

#29

Posted 19 December 2016 - 04:40 PM

I get your point, Bob, and agree only partially. The pros back then didn't have many special precision tools but managed to make them handle.

The trick is knowing where poor tolerances will and won't hurt performance.

Example; I doubt having an inline motor cocked to one side a little would make any noticeable difference.

Mike Steube, in his retro building video, points out some of his best retro handlers had flaws, therefore didn't insist everything be exact.

Of course there are things that HAVE to be perfect - low CG, strong solder joints, amount and location of flex, etc.

Things like a downward tilted flag or parts binding are just a couple examples of instant handling killers.

I think that's what my old and gray buddy refers to.

I spend lots of time getting these things perfect because I have the time and I enjoy it.

By the time one of my cars gets tested, I pretty much know it's going to handle - the benefit of precision.

Back in the day, the pros could build one in a matter of hours.

Even today with all my special tools, if you told me I had a night to build one, I couldn't.

It would take a lot more than a six pack of Pepsi and a pizza for sure ![]()

Enough talk - where did I put those doggone .062 axle keepers ? ![]()

![]()

- C. J. Bupgoo likes this

Paul Wolcott

#30

Posted 19 December 2016 - 08:42 PM

The pros back then had the Russkit jig. ![]()

![]()

- Joe Mig likes this

I intend to live forever! So far, so good.

#33

Posted 21 December 2016 - 03:09 PM

Originally I planned to round off the front corners but decided against it.

The "square" front end kind of grew on me, so it stays. Love it or hate it ![]()

Sleeved Gold Cup flag with two Koford spacers ready. I'll start with one.

Attention to detail - I didn't just assume both spacers would fall free over the sleeve to sit flat on the flag deck - I checked it - normal procedure

- Jencar17 likes this

Paul Wolcott

#38

Posted 23 December 2016 - 03:41 PM

Pablo. a clean looking chassis design so far! I want to watch how you attach pans or outriggers. (Hint) Pans could be made of brass rods too. ![]()

- Samiam likes this

I intend to live forever! So far, so good.

#40

Posted 23 December 2016 - 09:45 PM

That one looks like it could have been built by a drunken sailor. ![]()

![]()

I intend to live forever! So far, so good.

#41

Posted 23 December 2016 - 10:19 PM

Beauty is in the eye of the beholder, Bill ![]()

This Ferrari chassis needs to make the (curled) body skirts behave and I'll do the best I can.

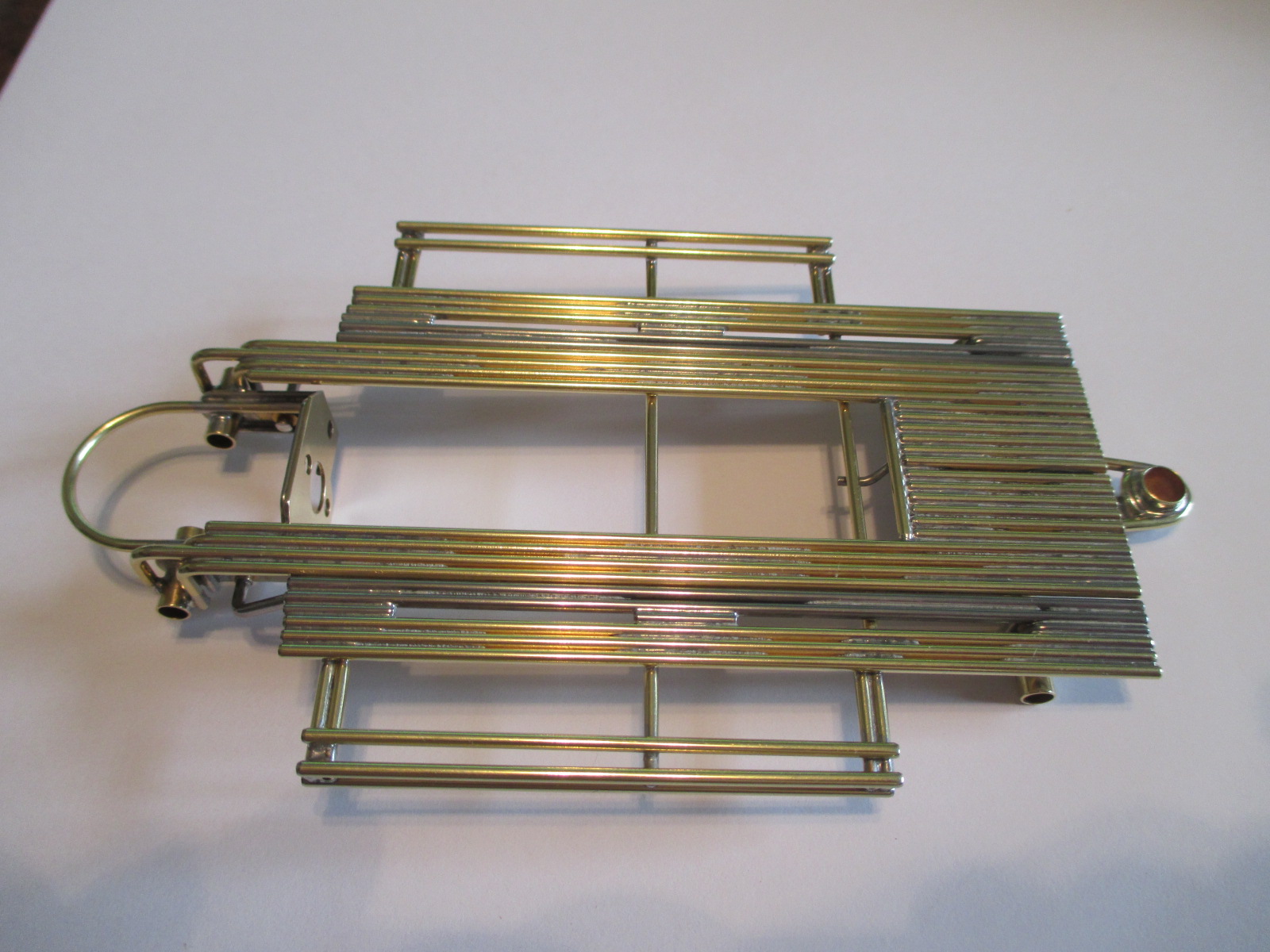

I transitioned the Iso piano wire rails to brass rod with .047" spacers. From here on it will be all brass......

- Jencar17, havlicek, Samiam and 2 others like this

Paul Wolcott

#42

Posted 24 December 2016 - 08:16 AM

Schweet! Last time I saw that much brass, it was in High School band! ![]()

-john

#43

Posted 24 December 2016 - 09:03 AM

Should look nice with the yellow Wildcat, eh John ? ![]()

Paul Wolcott

#44

Posted 24 December 2016 - 03:55 PM

My method of dealing with the curled body skirts:

Upper and lower .063" outrigger type rod pieces with mounting tubes sandwiched between.

Upper rod is slightly inward of the lower rod and mounting tubes are slightly indented.

Nothing but rounded surfaces will touch the body

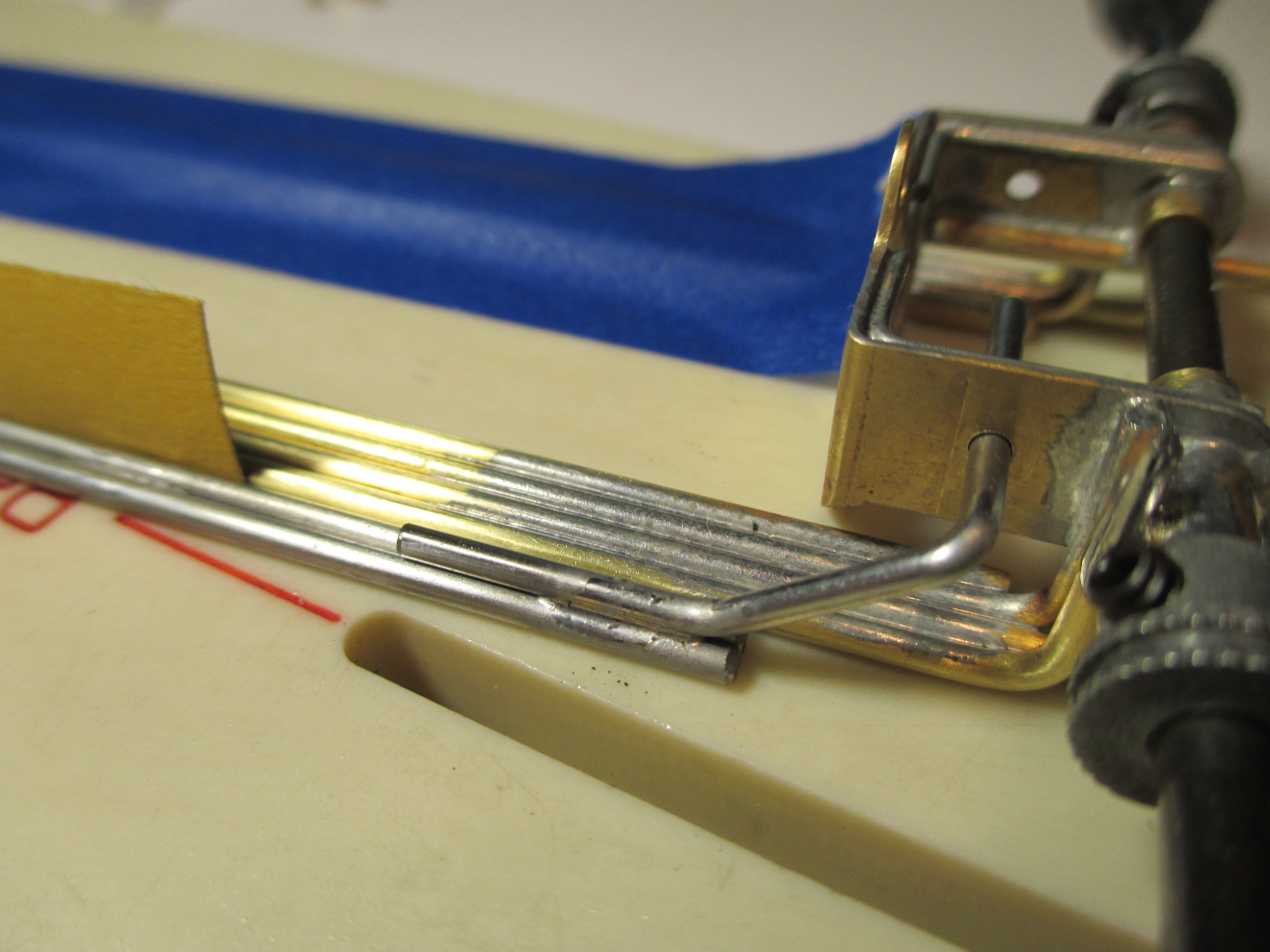

Iso stop - it only takes a hair of movement to make the design work it's magic - I used a sliver of 400 grit sandpaper when I tacked the gizmo on

Time to put a chassis in the tumbler and a ham in the oven for Christmas ![]()

Merry Christmas everyone ![]()

- Jencar17, miko, Bud Greene and 2 others like this

Paul Wolcott

#45

Posted 24 December 2016 - 05:01 PM

.........and a ham in the oven for Christmas

Merry Christmas Pablo and you and your "little buddies" take it easy on that ham! ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#46

Posted 24 December 2016 - 06:12 PM

WOW!

That is one classic looking chassis. Love the " All rod...Nuthin' but rod " theme. Nice. ![]()

Merry Christmas

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#47

Posted 24 December 2016 - 08:05 PM

Merry Christmas Pablo.

Great looking sled.

- gc4895 likes this

#48

Posted 24 December 2016 - 08:52 PM

A+++

I intend to live forever! So far, so good.

#50

Posted 25 December 2016 - 11:06 AM

Your building skills and that Mississippi water in your tumbler sure make for a pretty chassis!

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...