OK then... here you go... my first chassis in over 20 years!!

Took a while to get all the 'bits' you always remember you need... after you come home and get into building!! LOL!

Also... I must admit it has taken me a while to think about these cars and some designs... as realistically... apart from waaay back when I was much, much younger... ahem... cough, cough, wheeeeze...

I have mainly raced 'wing cars'... and was, as I guess were many here also, a 'gooaAddict'... LOL!

So it has been an interesting process... helped in some ways by my 1/32 scale experience perhaps... and NOT hindered by the progressively un-square 'false start'... (now pulled apart and never to be shown!!... LOL!)

I have always been interested in the idea of static and/or floating/isolating weight and general isolation, etc., in chassis and had my mind heading in those directions when I saw a couple of Steube chassis that were doing the same thing and also (apart from many, many Other), was also strangely intrigued by TonyP's 'Aero' chassis. Especially, as I had already started to head in that direction.

Hope you don't mind, Tony??, LOL!!

...No 'venturis' one this on... YET!! LOL!!

But I guess is also a progression of a similar idea.

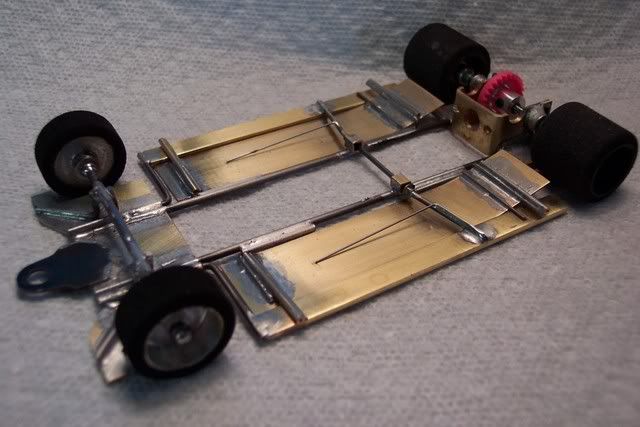

So this is built for the

FLAT Track shown Here; in the

Aussie Retro thread it has some Tight corners,..but is Deceptively Fast with a couple of Tricky bits! and if you get it right, is both Challenging and satisfying, (or Frustrating,..lol), to drive,

It's funny though,..isn't it,..there is something about the 'Balance' and 'Feel' of a car when you are building it,..they often just feel right!,..

So far,..I am happy with how this build has been going,..I have kind of let the 'Car' lead Me!,..

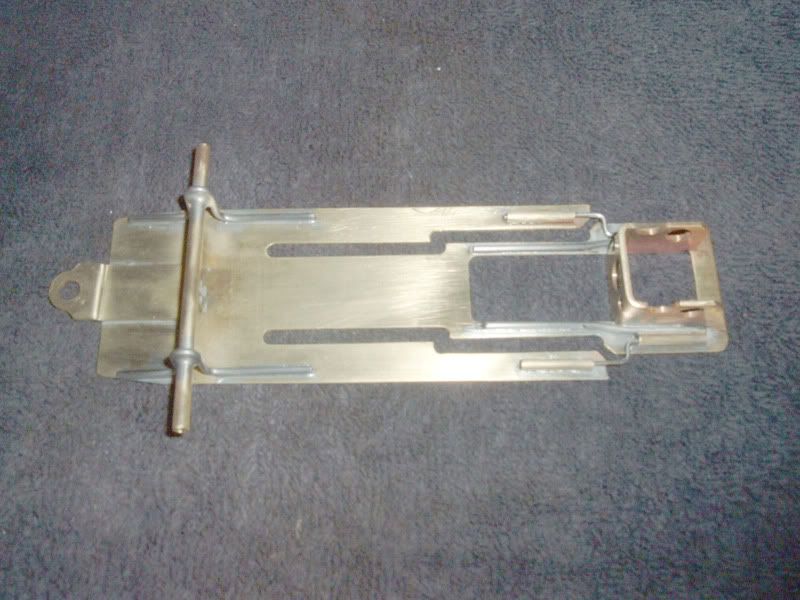

It's Not Yet completed,..but I was trying to make something I could 'Cut' or 'Add' to easily and was thinking of a 'Heavier than Flyweight' chassis, for Stability in the Race,..Not TQ'ing !!!,..rofl

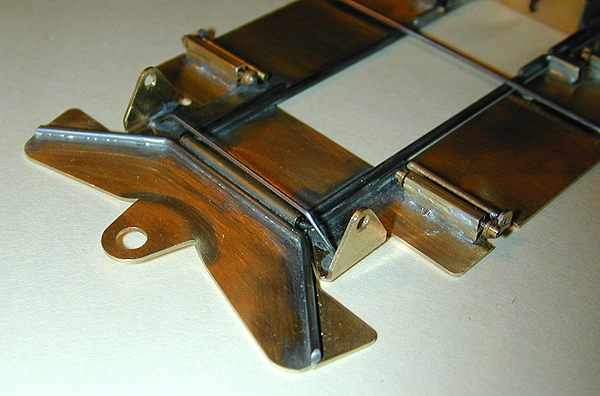

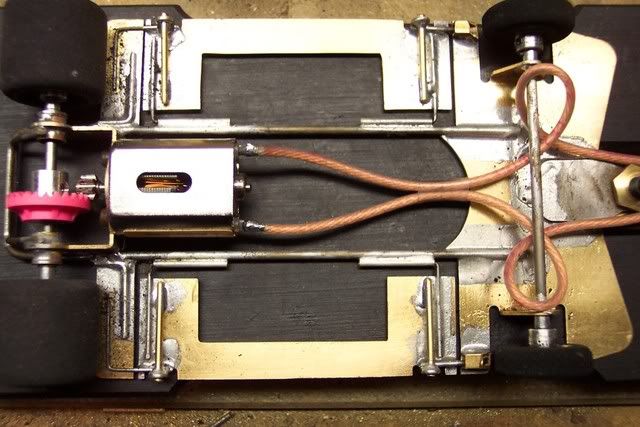

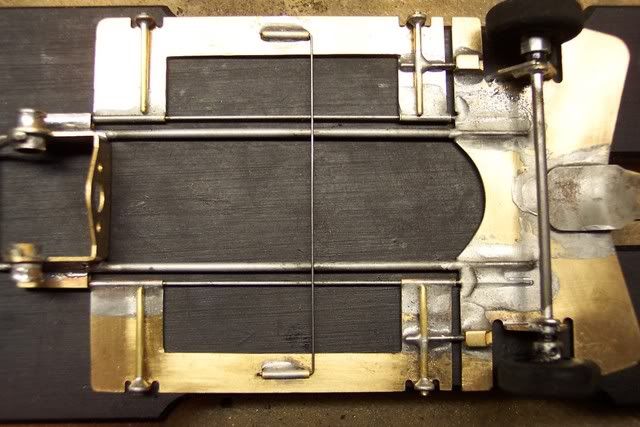

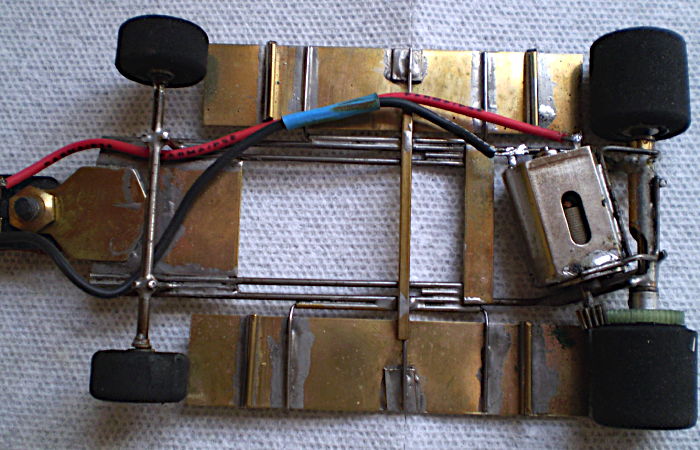

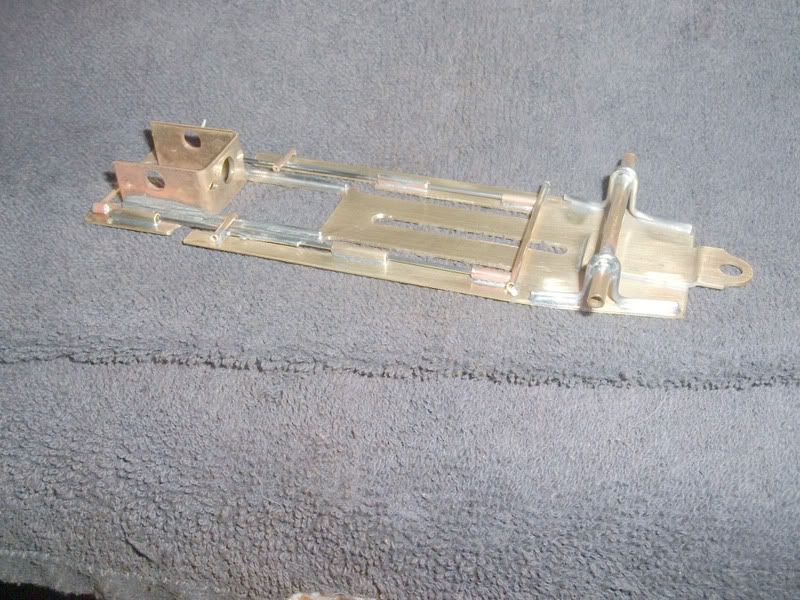

Like Tony's car, I had also started out with a very similar idea at the front and for pans, but was intending to hinge them at the Rear, but at the Moment, have them temporarily attached to an .047 'Spring' (in Effect), located straight through the Motor box. The 'Notched' Rear Pans are Solidly Mounted to the Chassis.

It uses one of those 'Chintsy' motor brackets, but it isn't really doing much apart from locating the Motor and giving me a 'Distance' locatorl for the rear axle tubes.

The Main Rails ar .063 &.055, with .063 Brass rod 'bits' added and possibly to Be added.

As stated above,..I had been thinking of Leaving some weight Low and Hinging the Body,..so at this stage, I have Yet to add the Various Body 'Mounts'/Pseudo Pan Hinges.

Although for this First race,..we are trying to Keep it simple,..(In fact Only Hinges for Pans etc,..No Plumbers),..I couldn't Help but try something Just that little bit 'out of the Ordinary' !!,..

As at this stage I am unsure how or what will proive to be the Best method for mounting the body,..I am intending to Try both Rattle type mounts as well as and in Combo with Hinged/hinges.

Will post any Future Further positive developments,..hope you like it,..comments, criticisms, suggestions etc all welcome,.,.

So Here is My 'Aussie Retro' chassis,..from a Distant,..but very 'Kindred' Slottie Spirit !!,..

:D