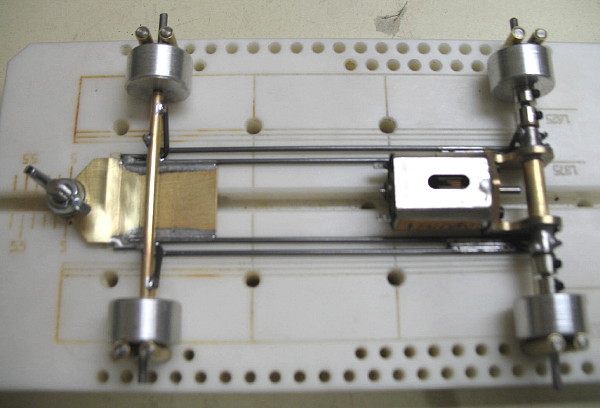

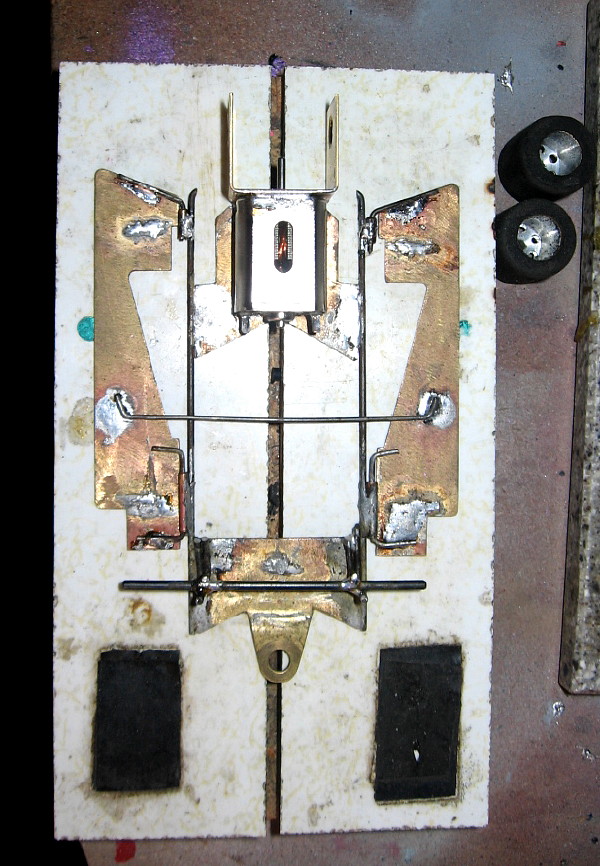

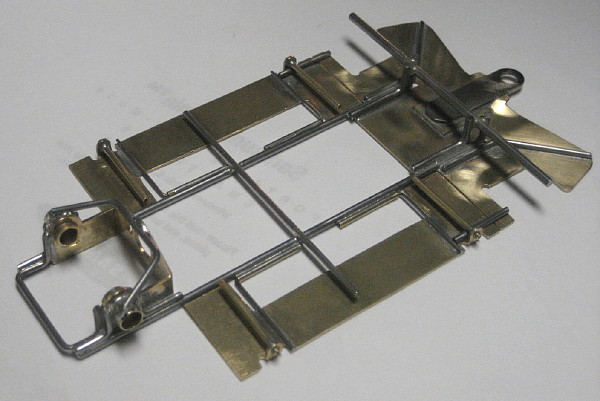

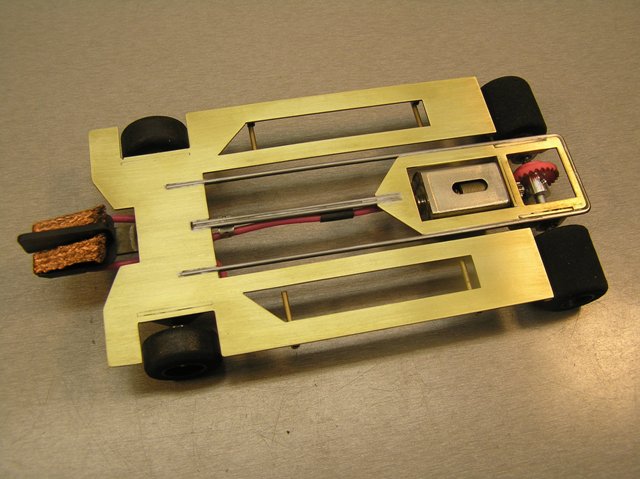

It's been 38 years since I last built a chassis and raced a slot car. My-oh-my what a difference a jig and a good iron makes! (Rick's and Inland Studio Professional, respectively)

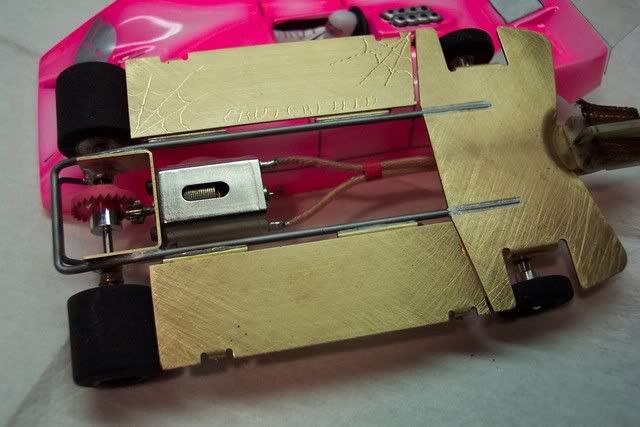

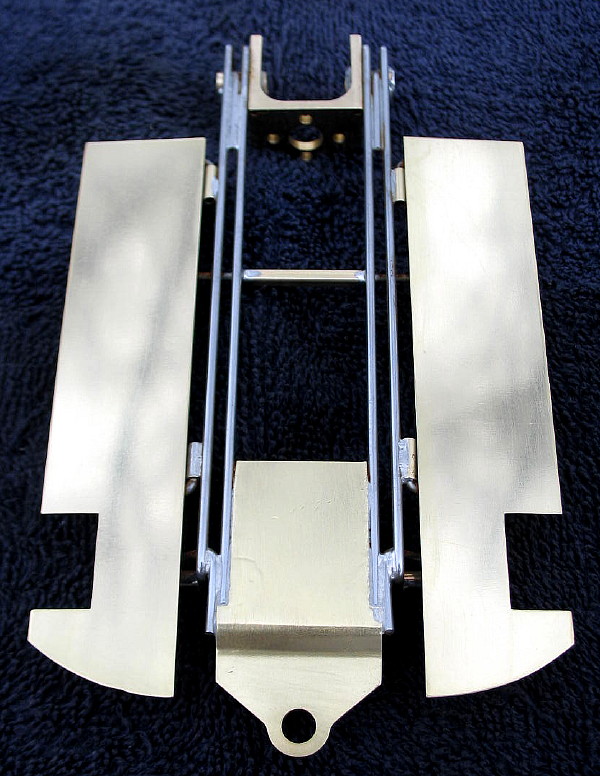

Here is my first attempt at a IRRA/Retro East chassis which I hope to race as a GT Coupe at this weekend's R4, unless it's junk...in which case it will be back to my trusty Skunkworks.

Thanks to Mike McMasters for telling me about Retro Slots last June, Rick Bennardo for his chassis building parts and equipment (especially his jig) and, most of all, to Jersey John Molnar who has freely offered tips, advice, and constant encouragement.

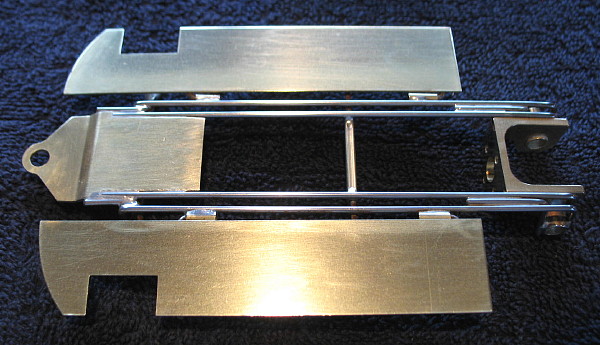

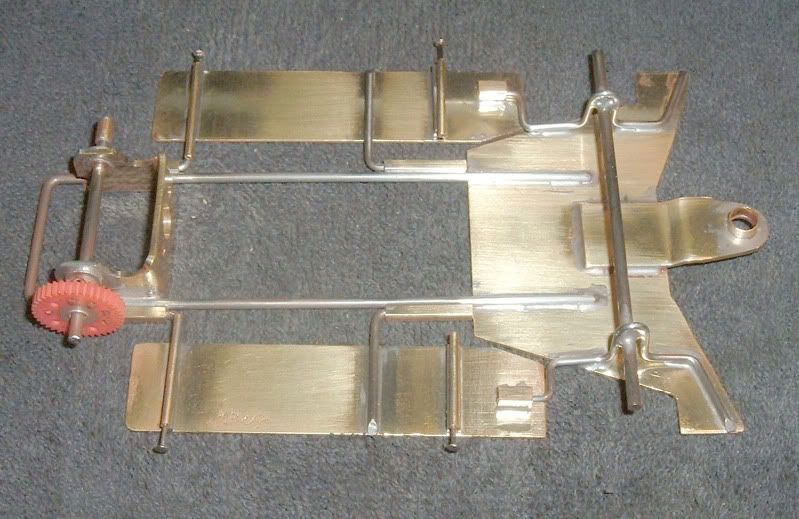

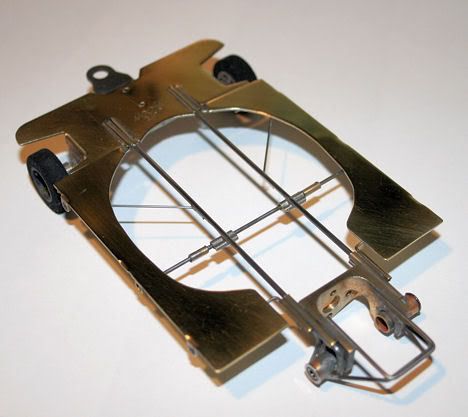

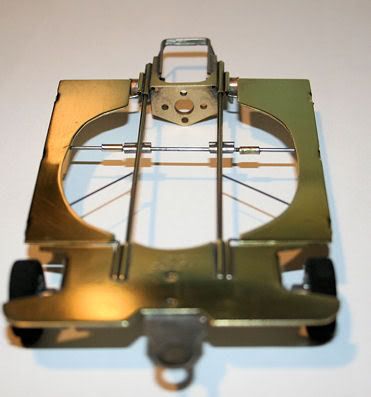

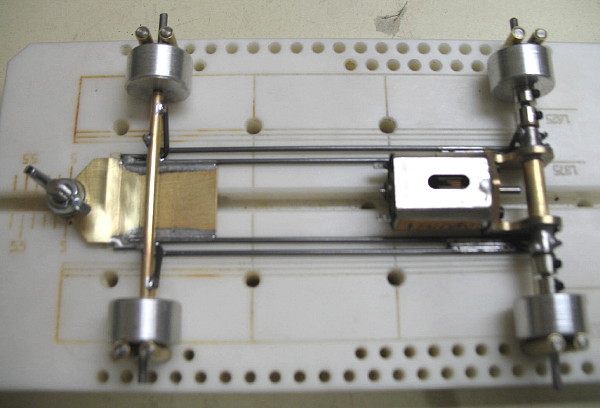

Motor bracket: BWA, uncut

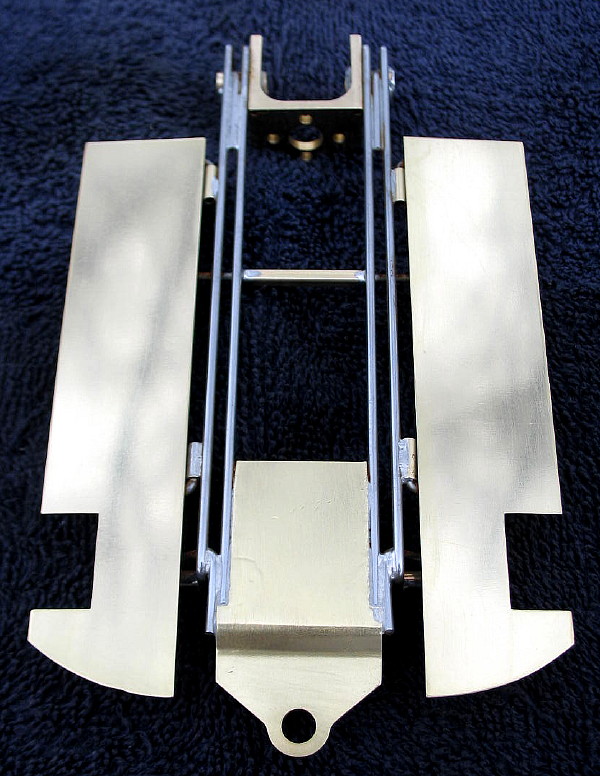

All rails, axle supports and pan hinges are .062 piano wire

Guide tongue: R-Geo, .040 pre-formed

Inside main rail separation: .830

Tongue narrowed to .830 to accommodate inside main rails and shortened to 1.8"

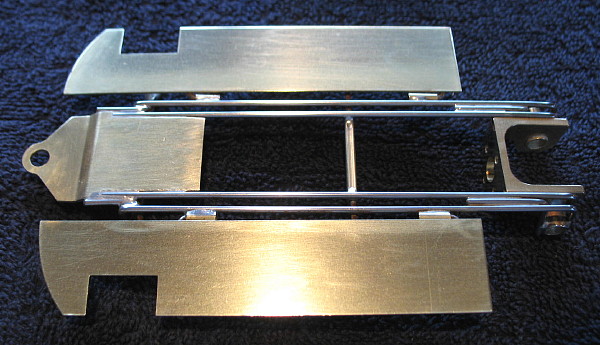

Pans: Modified R-Geo, .026 x .867 wide

Pan stop: .055 wire in 3/32 square tube

4" wheelbase

15/16" guide lead

58.8 grams

Tumbled (obviously)

If I had it to do over (which I do!), I'd make the hinges out of smaller wire and would reinforce the forward part of the pans to prevent droop.