Scratchbuilt chassis gallery

#476

Posted 11 August 2010 - 11:07 AM

I have had those issues in the past while building Samson F1 copies, but that was because I had just tack it where the pan stops were. I have actually had less problems soldering the complete rails instead of tack soldering.

#477

Posted 11 August 2010 - 12:17 PM

I try to get the iron touching only the steel and let the steel heat the brass. That way, the steel gets hotter than the brass and the differential expansion is reduced. Lots of flux helps, and of course you need to apply the solder to the hot parts, not carry it to the joint on the iron.

Even with this technique, it is difficult to keep everything flat and straight. I generally start at one end and make sure the other end is not constrained so the things can expand without restraint. Or if I have to solder both ends of a rail first, then I don't try to solder brass and steel together over the whole length of a rail, I just tack-solder them where I need them to be joined.

#478

Posted 11 August 2010 - 02:13 PM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#479

Posted 11 August 2010 - 03:14 PM

Steube breaks this "rule" a lot in his retro video. Dennis, would you care to elaborate why the "solder on the tip" transfer is bad ? Of course I value your opinion !!!you need to apply the solder to the hot parts, not carry it to the joint on the iron.

Paul Wolcott

#480

Posted 11 August 2010 - 04:12 PM

Steube breaks this "rule" a lot in his retro video. Dennis, would you care to elaborate why the "solder on the tip" transfer is bad ? Of course I value your opinion !!!

Pablo, apart from the fact that that is what soldering training courses teach as the correct technique, there are IMO (and please note, this is just my opinion) a number of reasons which apply to us:

1. Applying the solder to the joint instead of the iron gives better control of how much solder is in the joint. Everyone is always asking about how to remove excess solder, the trick is not to put it there in the first place!

2. If the solder has a flux core and that flux is useful to you (like a rosin flux core when soldering brass to brass), then applying the solder to the iron will boil off the flux before it gets to the workpiece.

3. As stated above, if you want to differentially heat two parts being soldered together, you need to have a clean iron, otherwise you will transfer all the solder to one side of the joint, or the solder on the iron will heat up both parts at the same rate.

4. It takes an iron with more heat capacity to carry the solder to the workpiece and still get a decent joint. Granted, heating the parts up first requires a good jig so nothing moves around, but in the long run you will get a better joint.

The only use for applying solder to the iron first should be to provide a small amount that will improve the thermal contact between the iron and the workpiece to heat it up faster.

There are always exceptions of course - like the need to "tack" a joint, especially somewhere that is difficult to reach. We all do it, and

#481

Posted 11 August 2010 - 04:22 PM

So, you won't arrest me if I break the rules every now and then ?

Appreciate the insight, Dennis. I always try and improve.

Sometimes I wish I had a smaller tip for this 455.......

Sorry for drift

Paul Wolcott

#482

Posted 11 August 2010 - 09:51 PM

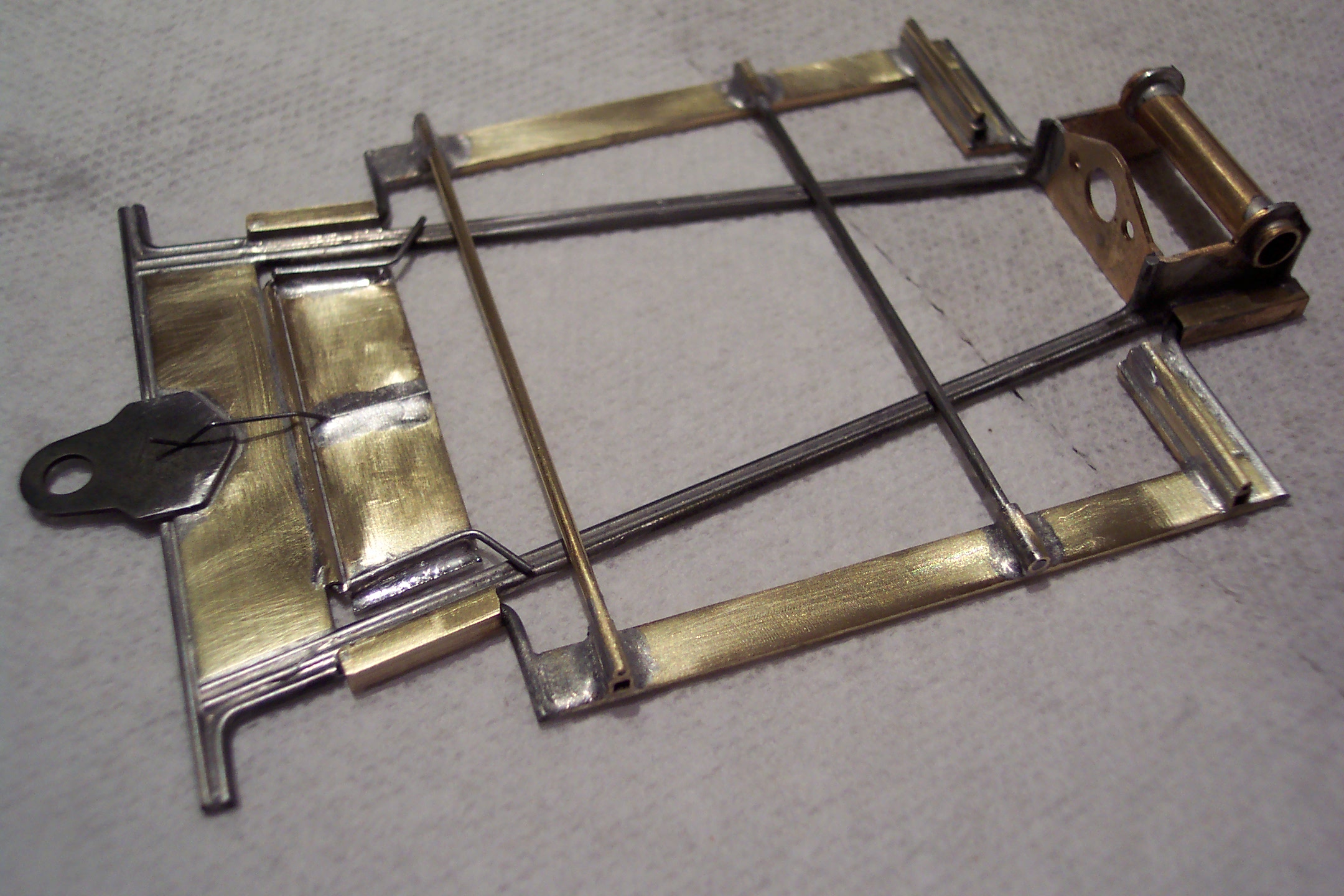

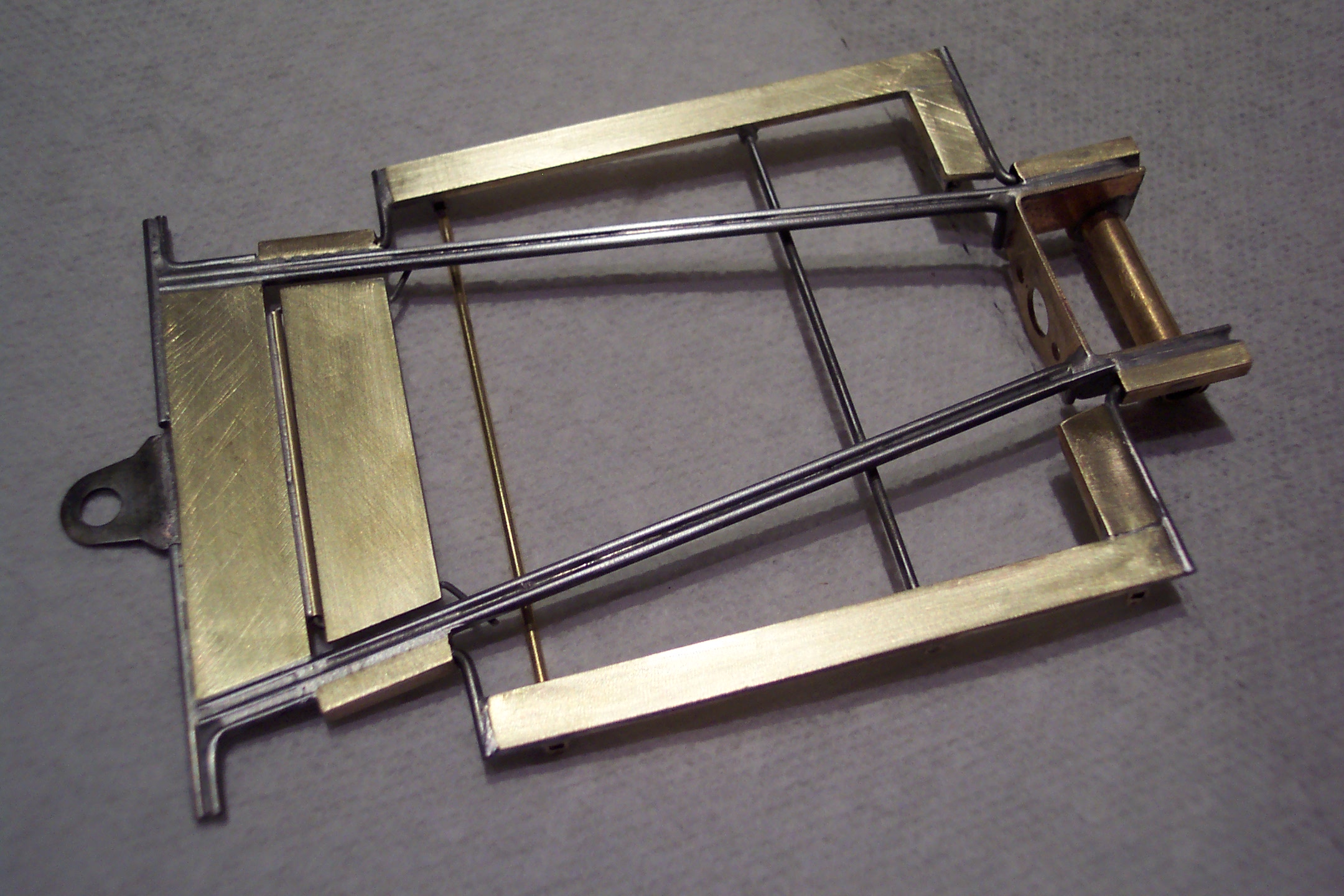

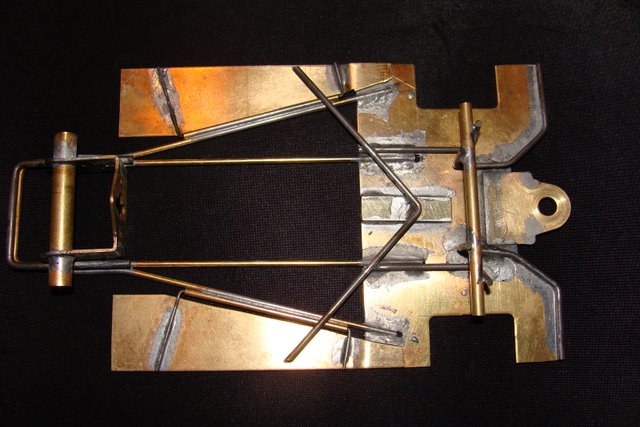

It has a 4.00 wheelbase and a 5.00 GL. The mainrails are double .062, .064 nose piece and side pans, and .032 flapper. The bracket is from JK. The total weight should be around 109 grams.

#483

Posted 11 August 2010 - 10:26 PM

-Richie

Obsessed is the word the lazy use to describe the dedicated.

- Richie Austin

#484

Posted 12 August 2010 - 12:34 AM

Ken Bryan

#485

Posted 12 August 2010 - 06:50 AM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#486

Posted 12 August 2010 - 07:04 AM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#487

Posted 22 August 2010 - 02:32 PM

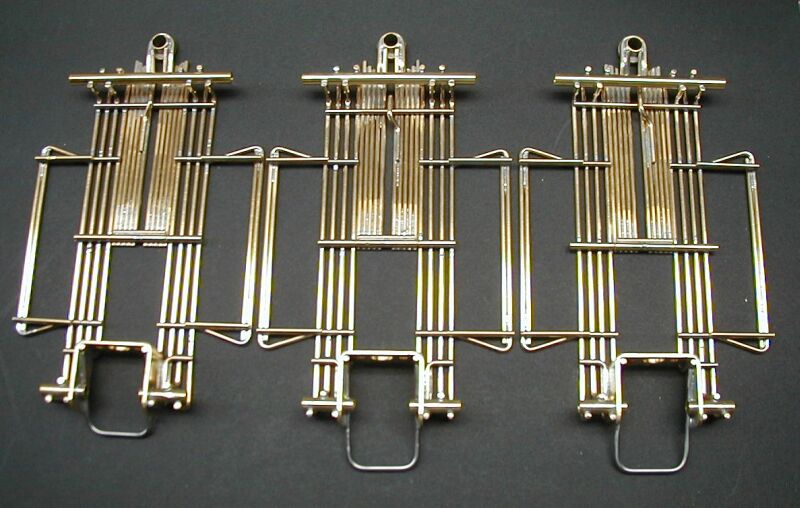

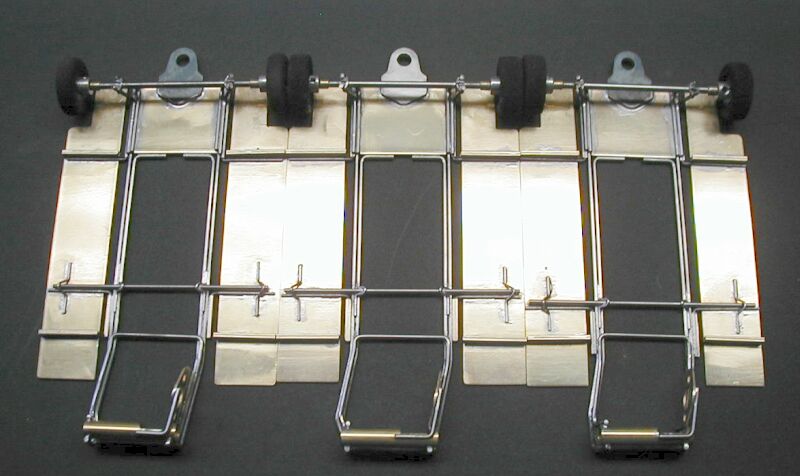

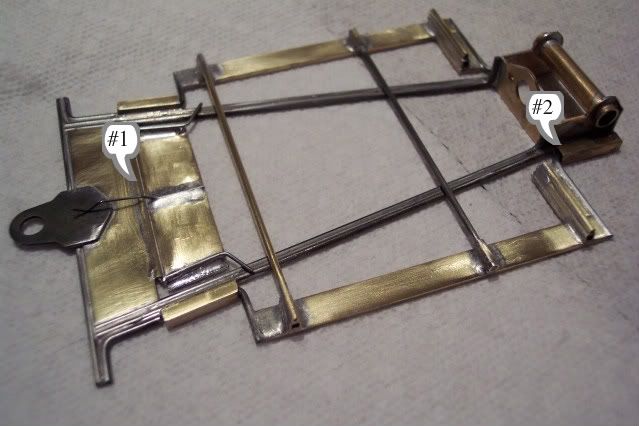

Retro Pro is the first two pics, my typical light weight design with an O/S Honda body, CORT guide tongue and CORT horse power.

In the next two pics is a D3 Retro Coupe using an M&M style nose piece, CORT guide tongue, original M&M pans and a True Scale Lola T70 body..

11/27/57-8/12/22

Requiescat in Pace

#489

Posted 22 August 2010 - 10:31 PM

Nice build Josh.

Out of curosity, I noticed what appears to be hinge points in horizontal and vertical positions. Am I correct?

I'm just curious. . .

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

#490

Posted 22 August 2010 - 10:39 PM

Nice build Josh.

Out of curosity, I noticed what appears to be hinge points in horizontal and vertical positions. Am I correct?

I'm just curious. . .

Thanks John.

The sidepans are not hinged. They are connected by the front pintube and the bite bar. The pans just float in the square tubing in the front and back. The only hinge on the chassis is in the front on the flapper.

Josh

#491

Posted 22 August 2010 - 10:43 PM

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

#492

Posted 22 August 2010 - 11:23 PM

#493

#494

Posted 23 August 2010 - 01:30 PM

#495

Posted 23 August 2010 - 01:42 PM

You've been busy? As always nice builds

Thanks!

Yes, busy - serial #203 is on the jig right now (I started numbering in 2004 when I got back into scratchbuilding)

#496

Posted 23 August 2010 - 02:23 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#497

Posted 23 August 2010 - 02:29 PM

Did you make the JD brackets? Very nice, all of them....

Thanks!

I make all my own inline brackets, as I like to use .040 material, and then I can play with the distance between the axle and the motor. Right now all my brackets are 9/16" between the motor mounting face and the axle centerline.

The anglewinders have the new Chicagoland bracket, which is a nice piece too.

#498

Posted 23 August 2010 - 02:31 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#499

Posted 23 August 2010 - 02:35 PM

Did you find .040 brass strip or cutting it out of pieces of plate?

I buy offcuts of .040 at Industrial Metal Supply, then take it down to Warmack's shop and he cuts it into 1/2" strips for me.

What would we do without Bryan?

#500

Posted 23 August 2010 - 02:40 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace