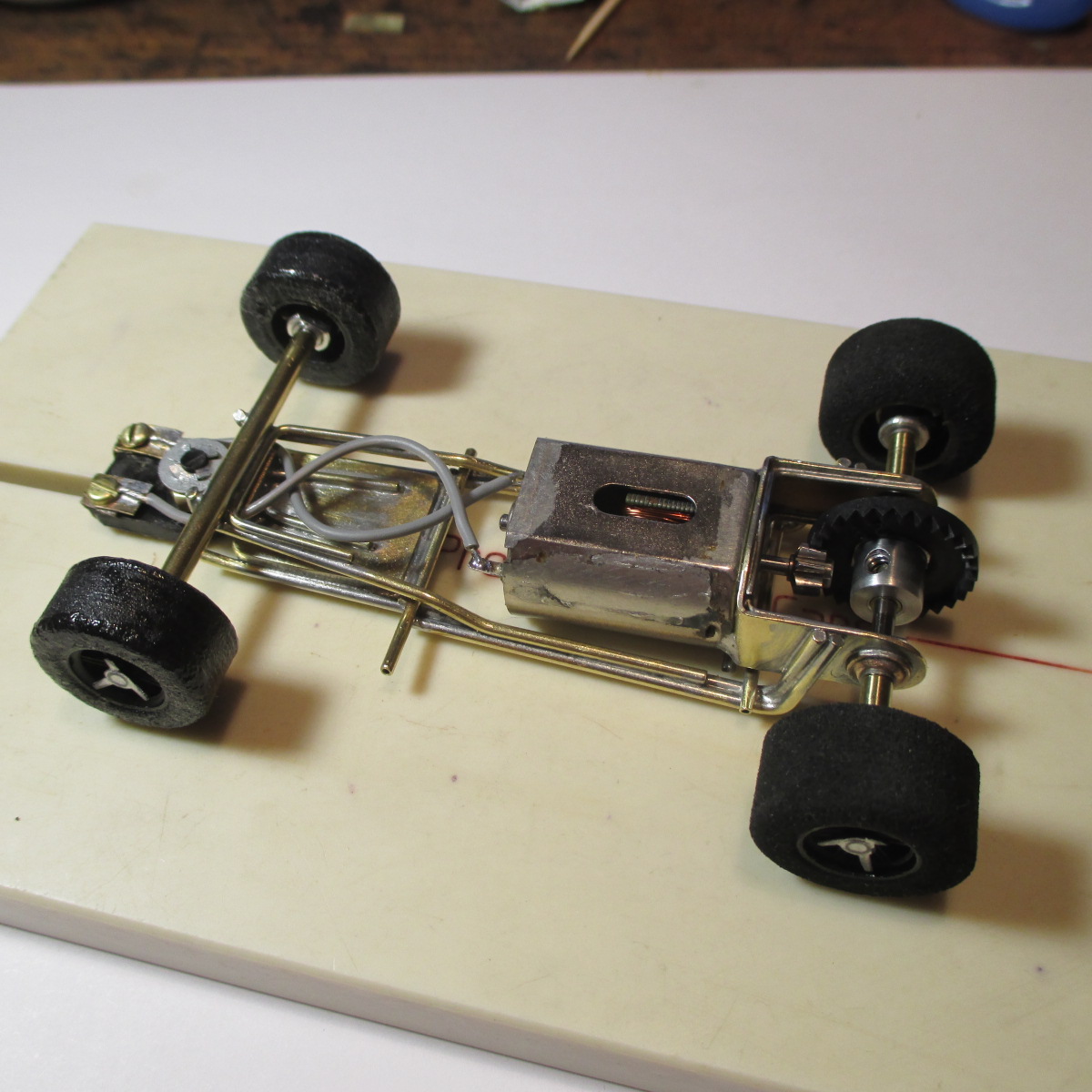

I'm sitting here looking at it, and I respectfully disagree with the brass rod torsion connectors being easy to destroy in a crash.

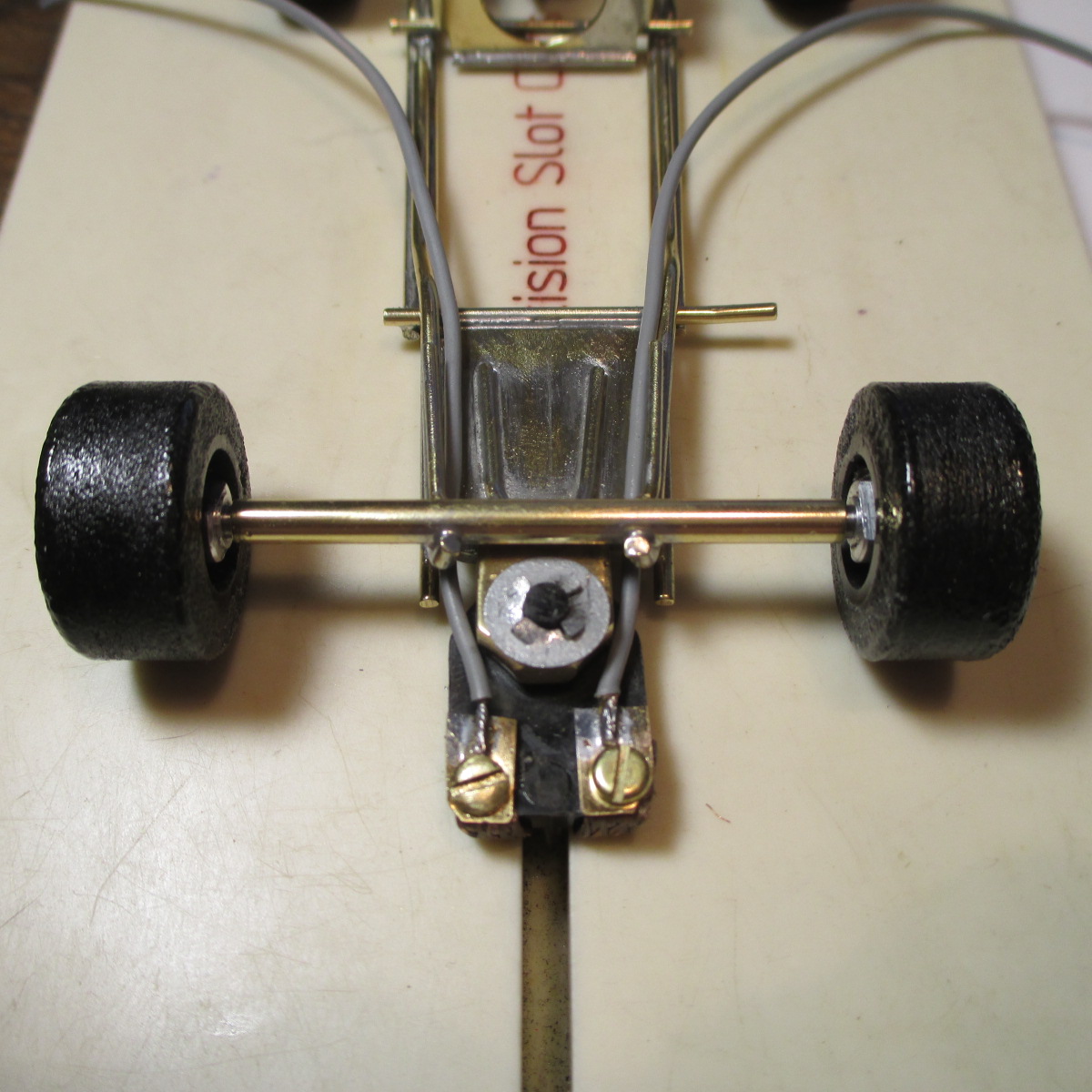

-it's a very small chassis, so the pieces you refer to are <2.5", meaning, not a lot of leverage

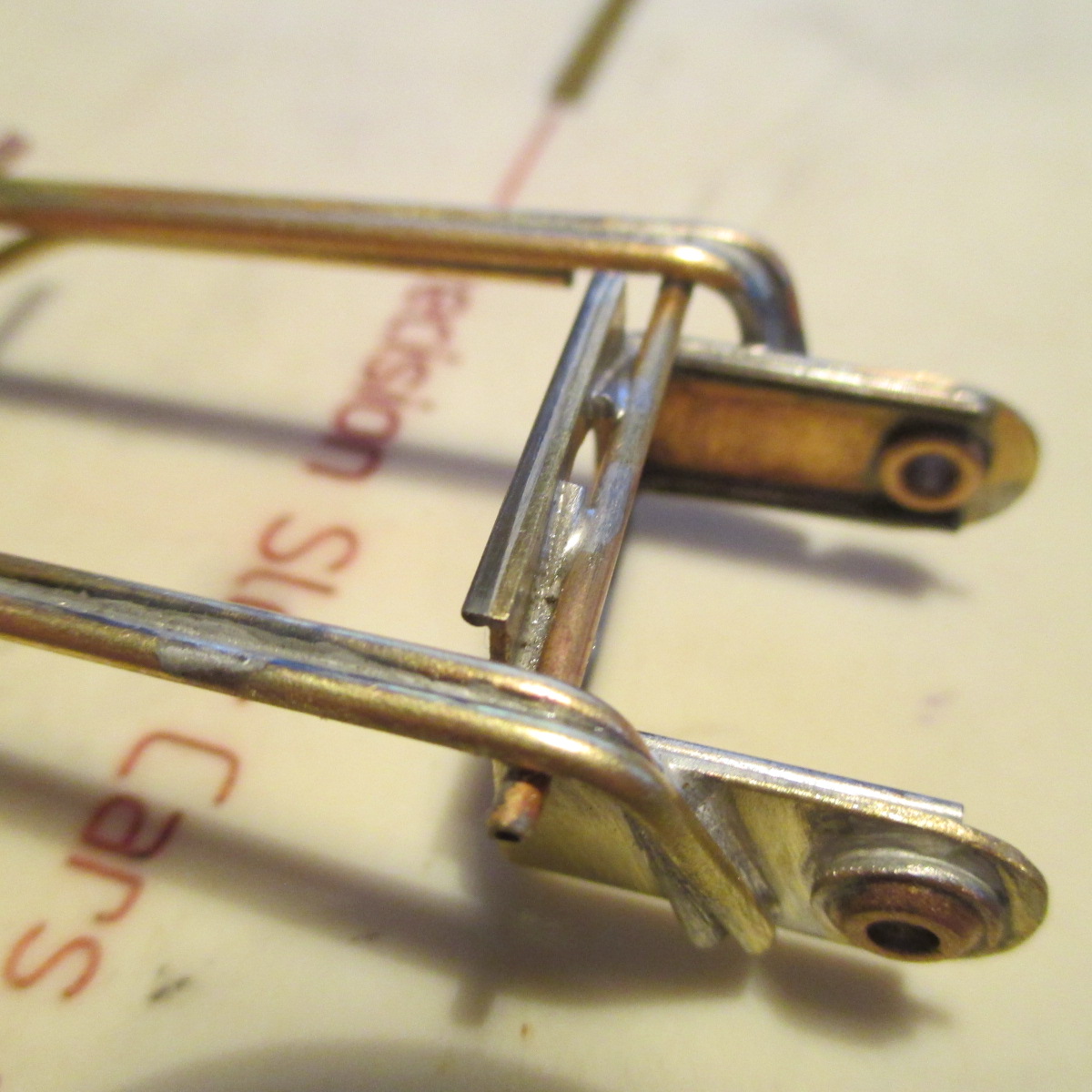

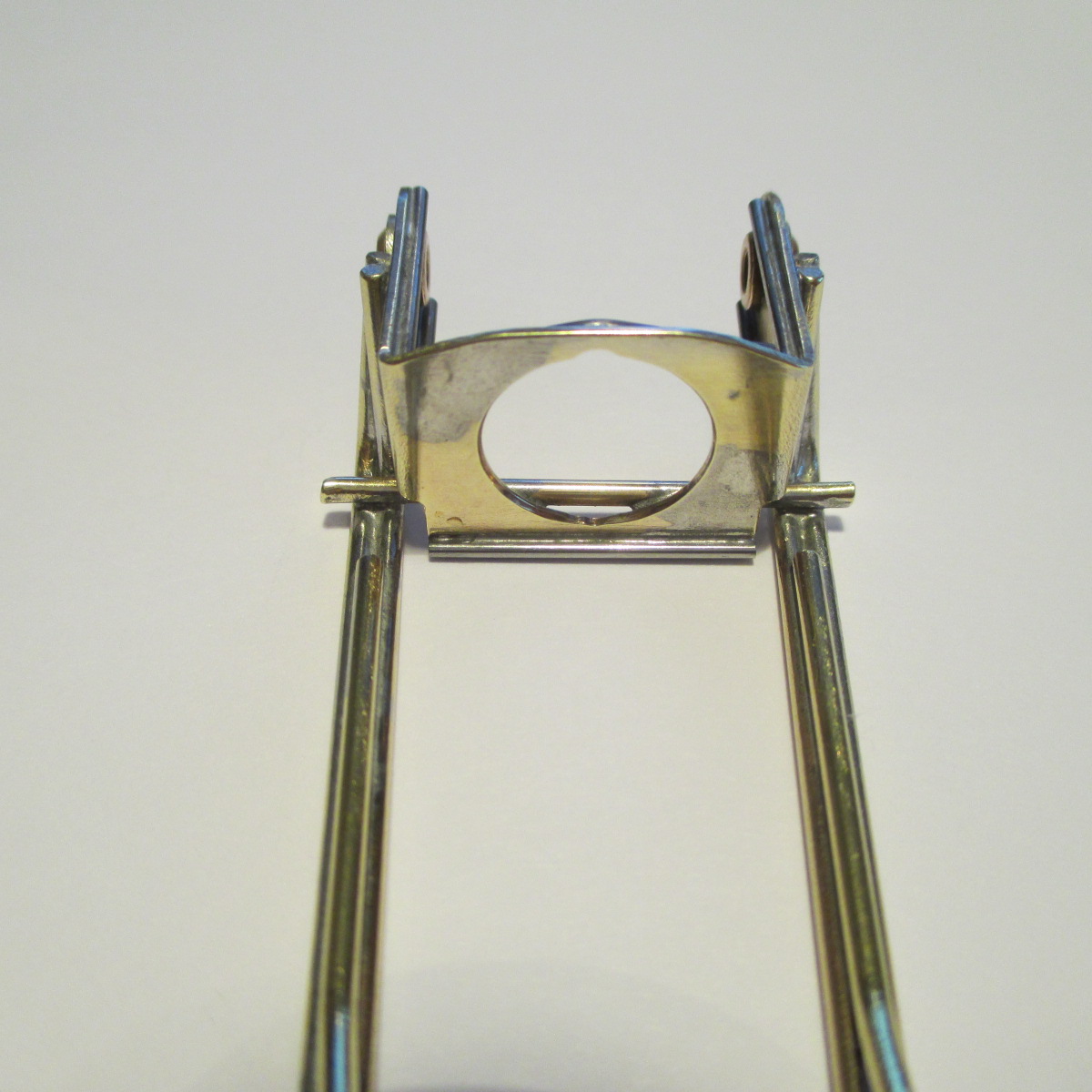

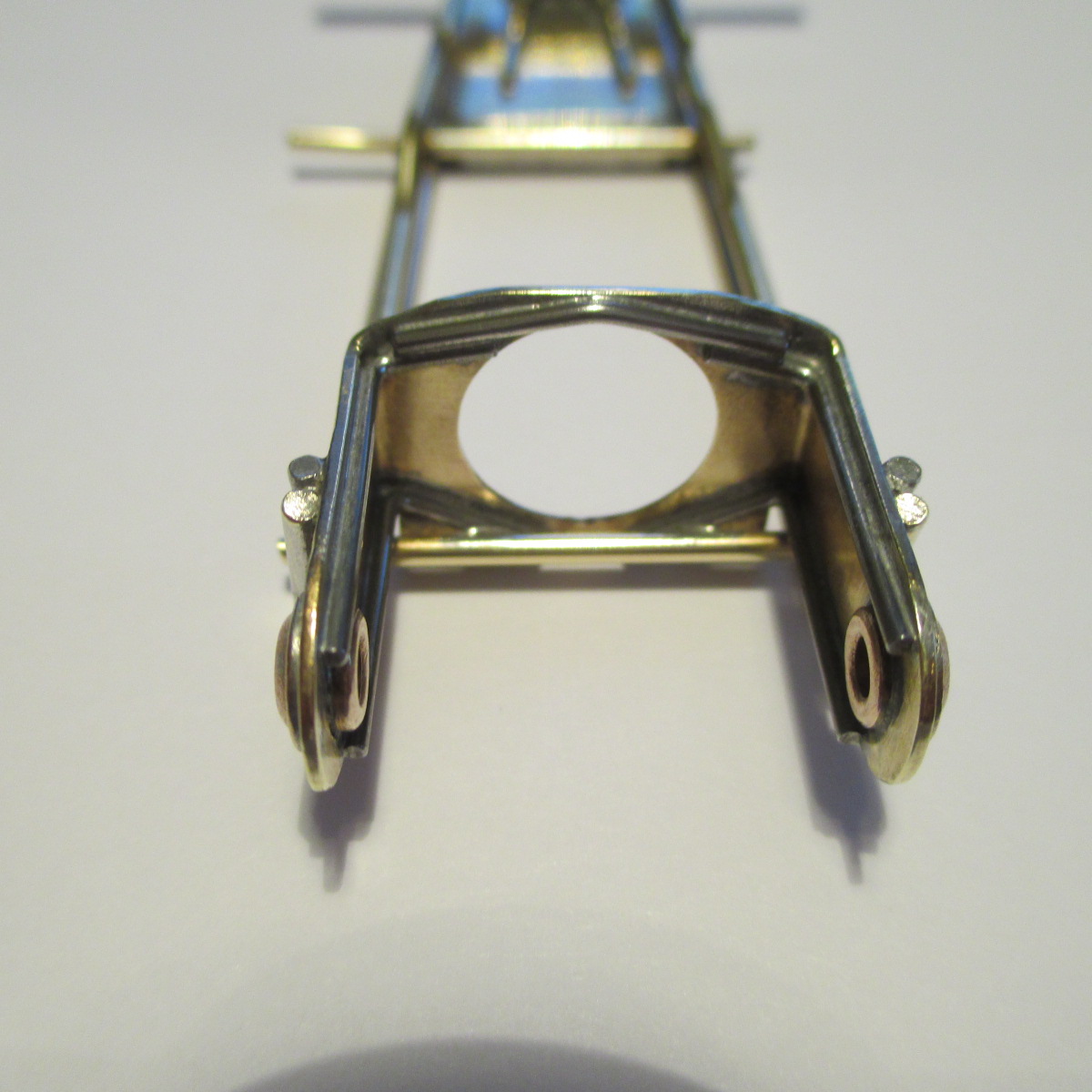

-the forward portion is reinforced with .047 about 3/4" long

-the rear portions are nested in double main rails and soldered solid for 1/2"

-in order for the front axle tubes to be "bent skyward" in a crash, either the tube would have to rip free of the nest (which ain't gonna happen - look at the way it's nested and triangulated) - or BOTH torsion rods would have to bend right at the EB - AND the very thick body would have to rip free of the pin tube mounts, or break them, to allow it - and it can only go downwards about 1/16" because the top of the Dynamic gizmo prevents it

-we are not talking high speed wing car crashes here folks - the motor will be a 13uo. I doubt even a highly modified one would cause a crash like that

-if you've ever soldered wire to brass along a length of more than about 5/8", it will curl the rails like a potato chip

-in high school shop, remember that putting a bend in metals strengthens it? My bends are at the only non-reinforced areas - right at the EB

-all cars are thoroughly track tested before departing The Wolcott Ranch, and I will make an extra effort with your comments in mind to use the strongest test motor I can fit in there - if it fails during a crash you will have proved me wrong

-for a 1966 "look" I chose brass

Don, Alan is welcome to give his answer about SS here, and I'll tell you what I have found in a PM.